Centrifugal pump performance curve sample acquisition method and its application in machine learning

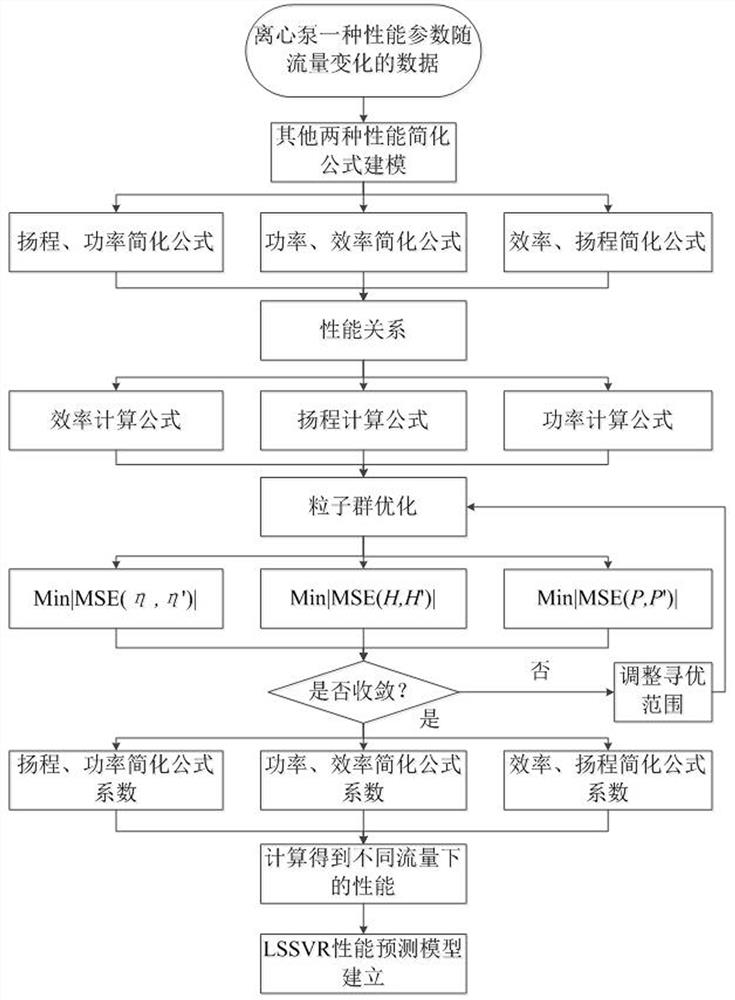

An acquisition method and centrifugal pump technology, applied in nuclear methods, special data processing applications, instruments, etc., can solve problems such as short calculation time and large calculation amount of performance prediction model, achieve short calculation time, reduce performance test cost, and speed up The effect of the design process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

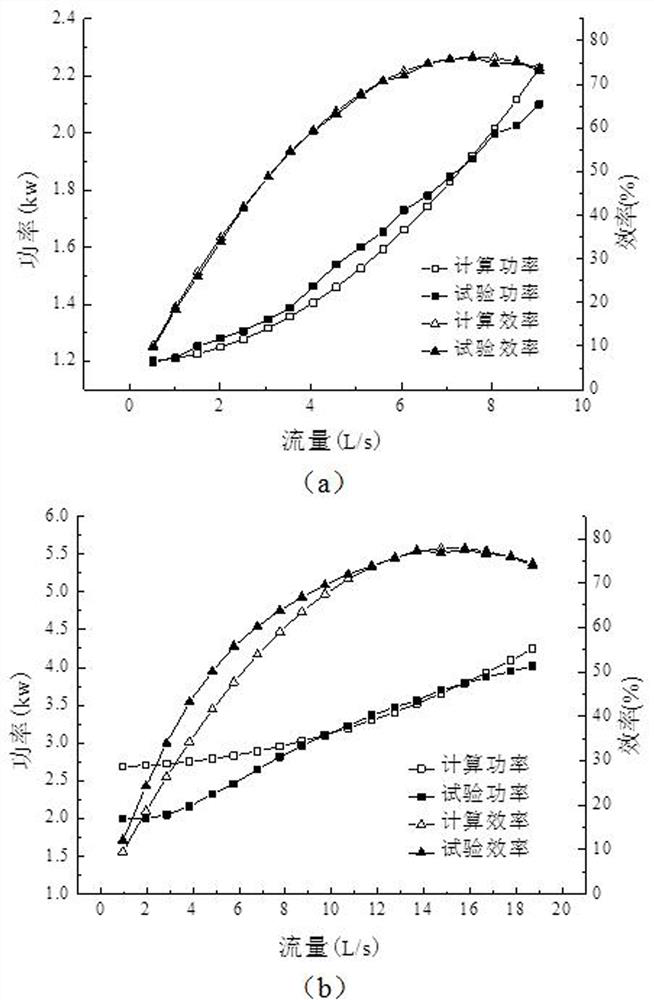

[0079] Step 1: Data acquisition of head performance curve.

[0080] Collect 10 sets of lift curves of single-stage single-suction clean water centrifugal pumps with different specific speeds, and each lift curve takes the performance of 14 to 20 working conditions.

[0081] Step 2: Power and efficiency curve formula modeling.

[0082] According to the relationship between the power and efficiency performance curves and the flow rate, the formulas of the power and efficiency performance curves are modeled. The specific modeling formulas are:

[0083]

[0084]

[0085] in Q for the flow, Q N is the rated flow, P , n , H represent power, efficiency and head, respectively, k 1 , b is the coefficient of the power formula. k 2 , c is the coefficient of the efficiency formula.

[0086] Step 3: Based on the calculation formula between the three performance parameters and the simplified formula of power and efficiency in Step 2, calculate the calculated value of the...

Embodiment 2

[0107] Step 1: Obtain power performance curve data.

[0108] Collect 10 sets of power curves of single-stage single-suction clean water centrifugal pumps with different specific speeds, and each power curve takes the performance of 14 to 20 working conditions.

[0109] Step 2: Formula modeling of lift and efficiency curves.

[0110] According to the relationship between the head and the efficiency performance curve with the flow rate, the formula of the head and efficiency performance curve is modeled. The specific modeling formula is:

[0111]

[0112]

[0113] in Q for the flow, Q N is the rated flow, H , n represent head and efficiency, respectively, k 3 , d is the coefficient of the lift formula. k 2 , c is the coefficient of the efficiency formula.

[0114] Step 3: Based on the calculation formula between the three performance parameters and the simplified formula of the lift and efficiency in Step 2, calculate the calculated value of the change of powe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com