Loading device and method for reliability test of rolling linear guide rail and ball screw system

A technology of ball screw and linear guide rail, which is applied in the field of machine tool reliability testing, can solve the problems of product reliability reduction, increase of machine tool failure rate, large manpower, material resources and financial resources, etc., and achieve the effect of reducing test cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

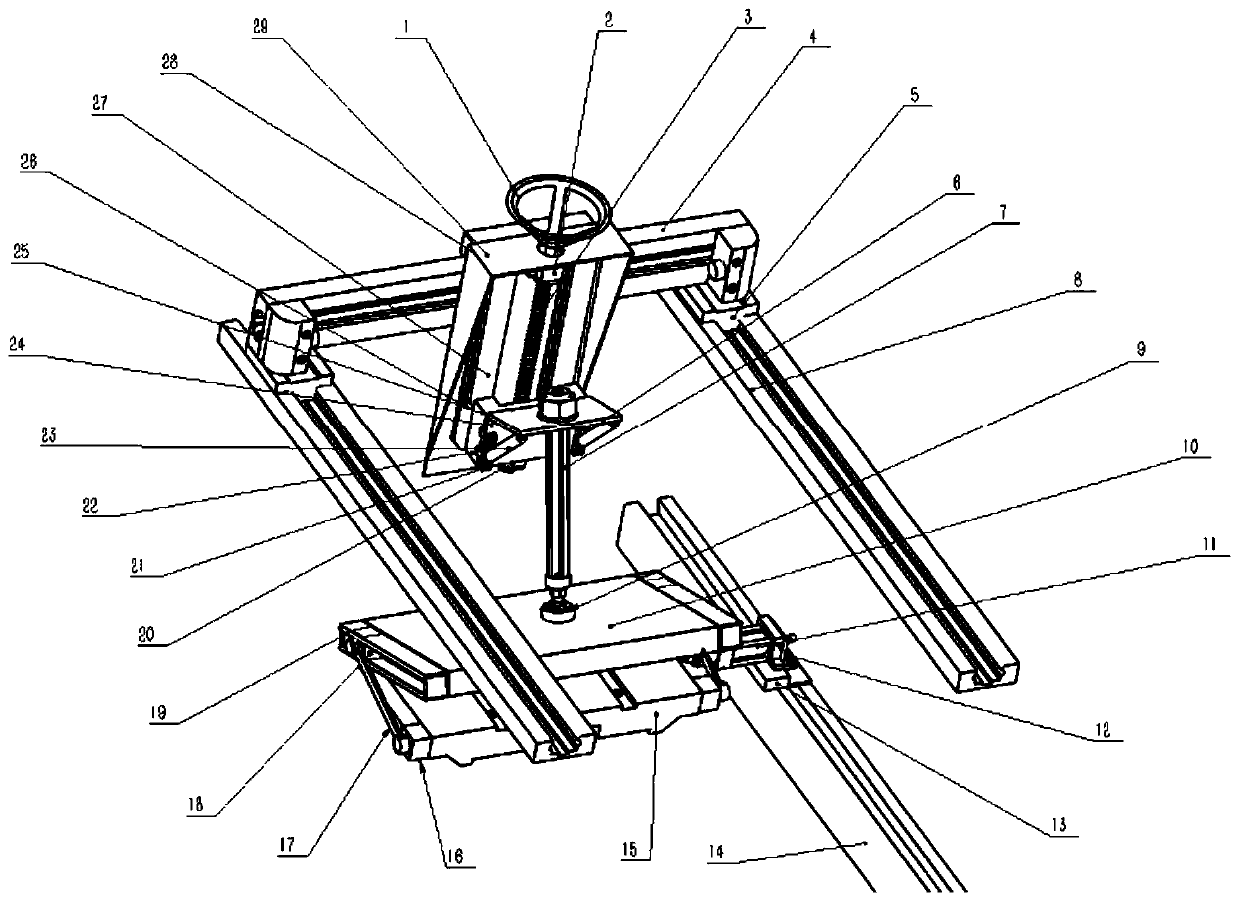

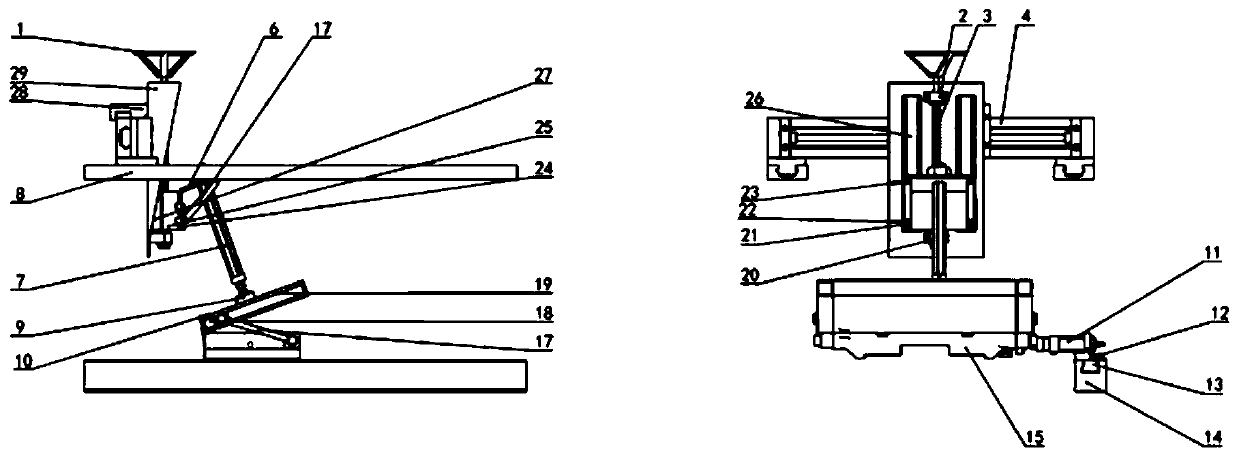

[0027] Attached below figure 1 And attached figure 2 The present invention is described in further detail with specific examples.

[0028] Rolling linear guide and ball screw system reliability test loading device, including: X-direction load loading assembly, Y-direction and Z-direction load loading assembly;

[0029] The X-direction load loading assembly includes: a hydraulic cylinder 11, a Y guide rail 2 (14 in the figure), a Y guide rail 2 slider 13, the hydraulic cylinder 11 is connected to the side end of the loaded platform base 15, and the bottom surface of the hydraulic cylinder 11 is It is connected with the slider 13 of the Y-guided rail 2, and the slider 13 of the Y-guided rail 2 is connected with the Y-guided rail 14;

[0030] The Y-direction and Z-direction load loading components include: a load applying mechanism, a force loading platform;

[0031]The load applying mechanism includes a handwheel 1, a housing 29, an X guide rail 4, an X guide rail slider 28,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com