A kind of industrial software grasping robot and grasping method

An industrial and robotic technology, applied in manipulators, manufacturing tools, program-controlled manipulators, etc., can solve the problems of easy failure, difficult fingers, and complex joints of dozens of mechanical fingers, achieving the effect of strong practicability and cost reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

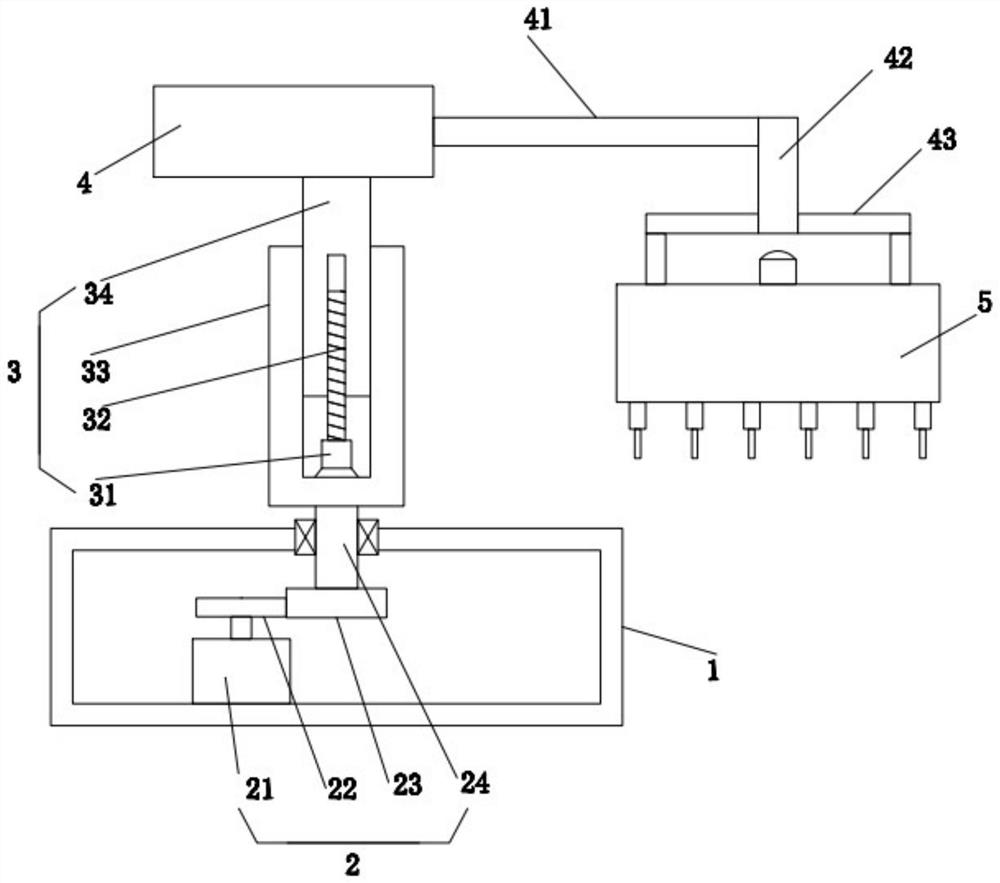

[0034] see Figure 1-7 , in an embodiment of the present invention, an industrial software grabbing robot includes a base 1, a lift assembly 3 is provided above the base 1 for adjusting the grab height, and the bottom of the lift assembly 3 is connected to adjust the grab circumference. The steering assembly 2 to the position, the output end of the lifting assembly 3 is provided with a horizontal hydraulic cylinder 4 for realizing grabbing horizontal position movement, the output end of the horizontal hydraulic cylinder 4 is provided with a horizontal telescopic rod 41, and the horizontal telescopic The end of the rod 41 is provided with a vertical suspension rod 42, and the lower end of the suspension rod 42 is connected to the software grabbing assembly 5 through a connecting frame 43;

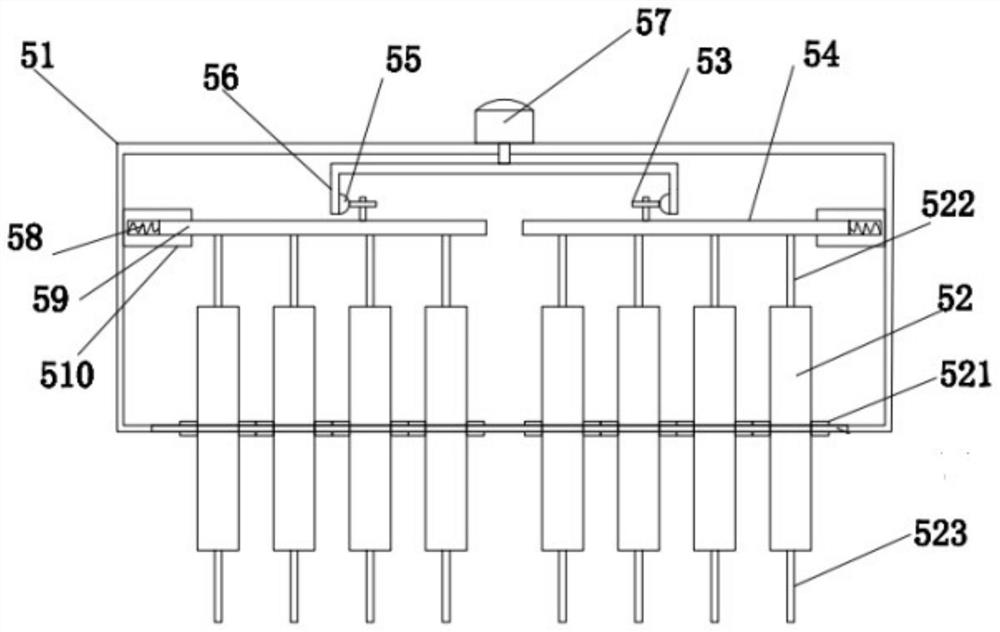

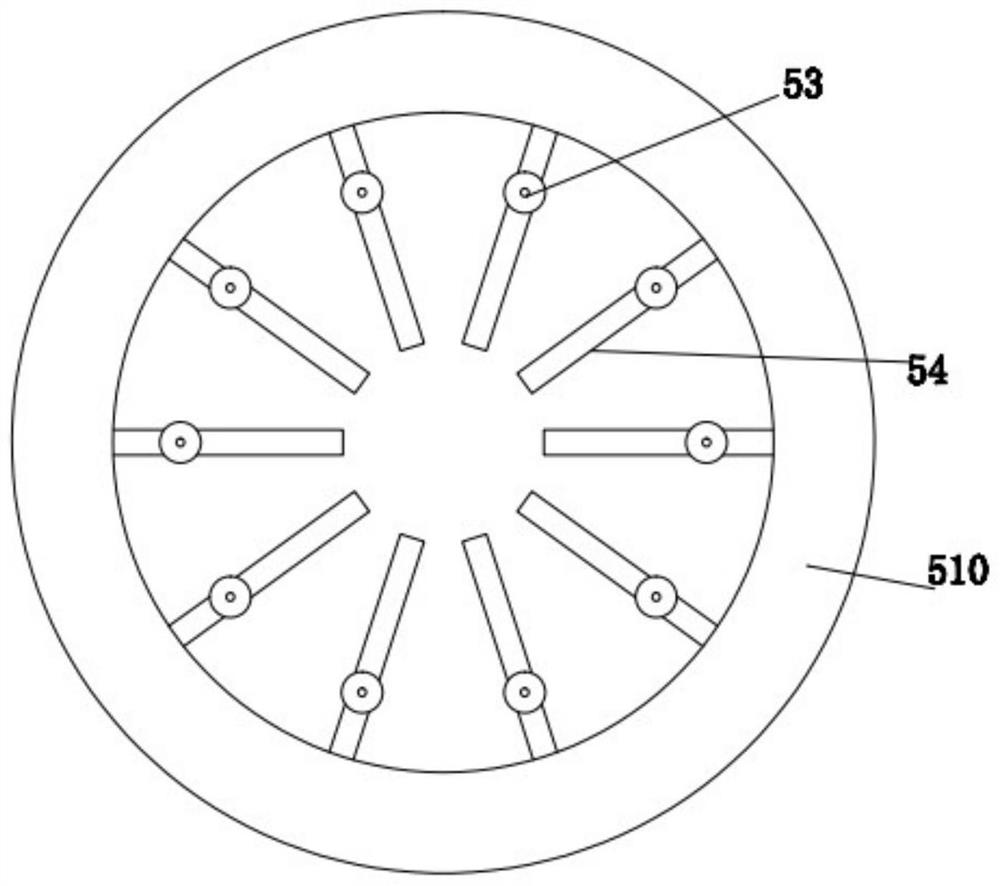

[0035] The software grabbing assembly 5 includes a fixed box 51 in a cylindrical structure, the inner wall of the fixed box 51 is provided with a mounting ring plate 510 coaxially arranged t...

Embodiment 2

[0044] The sliding pallet is provided with a pulley for resisting the wall of the fixed box, and the setting of the pulley converts sliding friction into rolling friction, which is convenient for the later reset of the fixing sleeve.

Embodiment 3

[0046] In order to reduce the friction loss between the upper telescopic rod 522 and the driving slide, the top of each of the upper telescopic rods is an arc-shaped top, and the arc-shaped top helps the upper telescopic rod to slide on the lower end surface of the driving slide.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com