Ceramic impeller fixing device, ceramic impeller, and manufacturing method and detachment method for ceramic impeller

A technology for fixing devices and impellers, which is applied in the direction of manufacturing tools, ceramic molding machines, and parts of pumping devices for elastic fluids, etc. Problems such as poor metal bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The ceramic impeller provided by the present invention will be described in detail below in conjunction with the accompanying drawings. The accompanying drawings and embodiments cannot be understood as limiting the present invention.

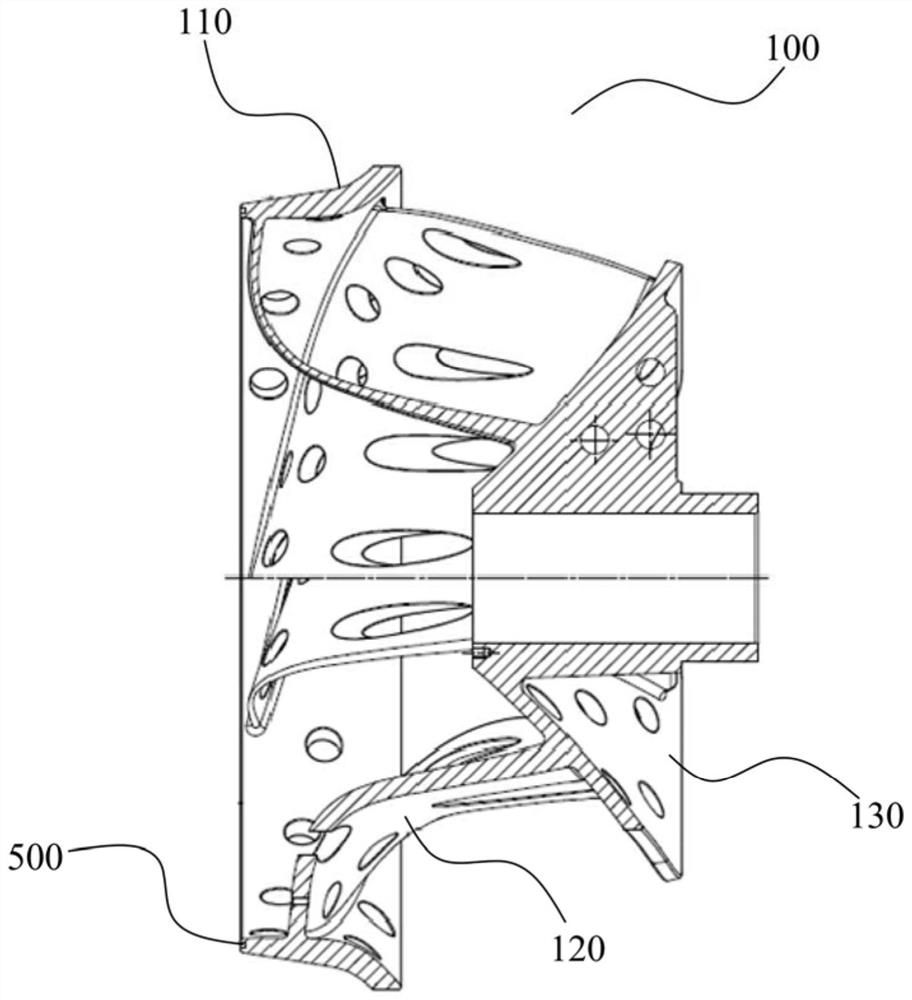

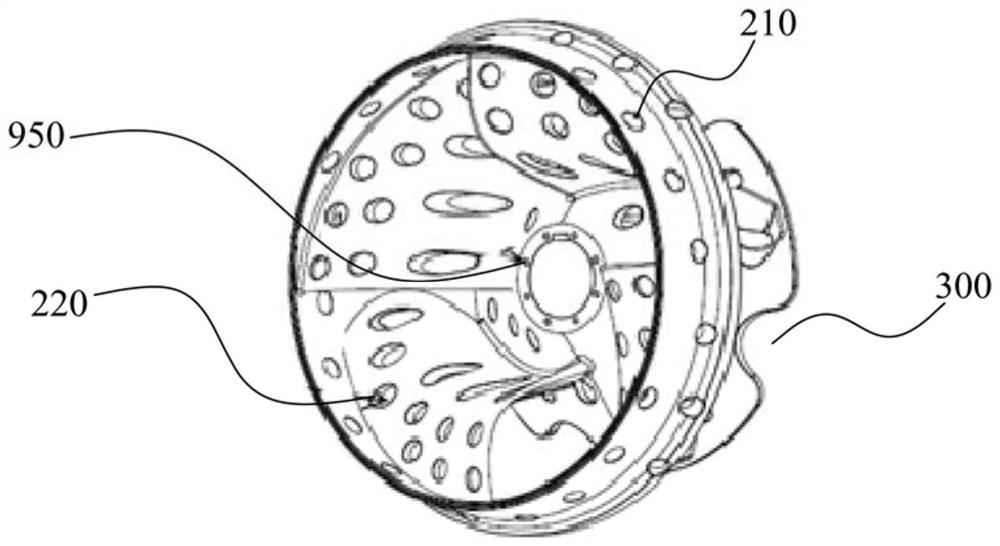

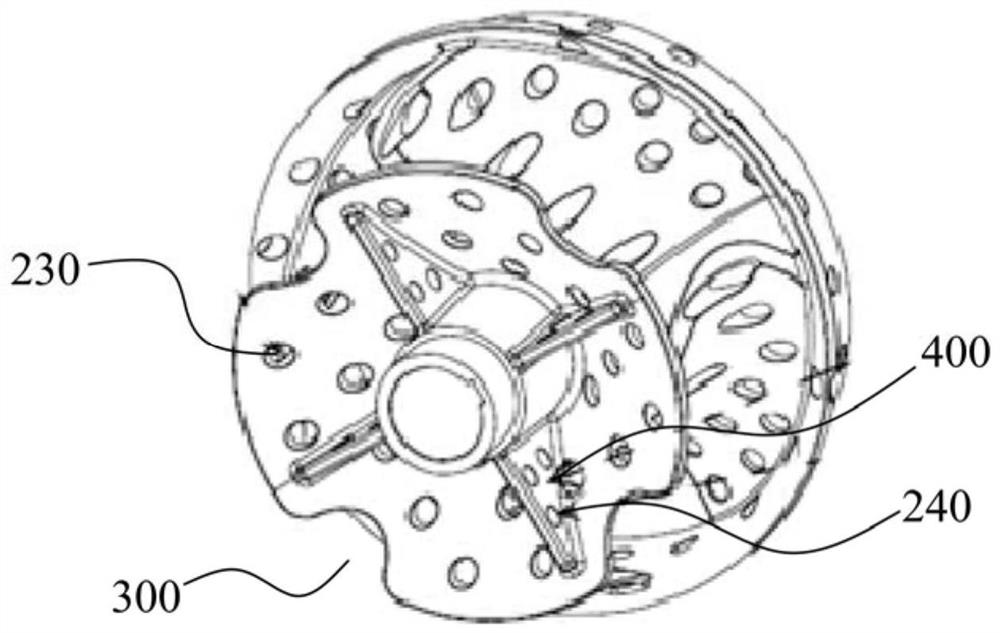

[0034] figure 1 Illustrates the metal skeleton of the ceramic impeller provided by the present invention, such as figure 1 As shown, the metal frame 100 in the ceramic impeller provided by the present invention includes a front cover 110, a rear cover 130, and blades 120 arranged between the front cover 110 and the rear cover 130.

[0035] The ceramic layer is formed on the metal skeleton 100 by vacuum casting to form the ceramic impeller of the present invention.

[0036] Wherein, a groove 500 is provided on the end side of the front cover 110 of the metal skeleton 100 to hold the ceramic layer cast on the metal skeleton. The grooves are usually arranged on the end faces of the front and rear cover plates so that the ceramic layer A metal skele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com