Ultralight aluminum-lithium alloy and preparation method and application thereof

A technology of aluminum-lithium alloy and metal liquid, which is applied in the field of ultra-light aluminum-lithium alloy and its preparation, can solve problems such as oxidation burning loss, achieve the effects of reducing oxidation burning loss, solving layered segregation, and improving strong plasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

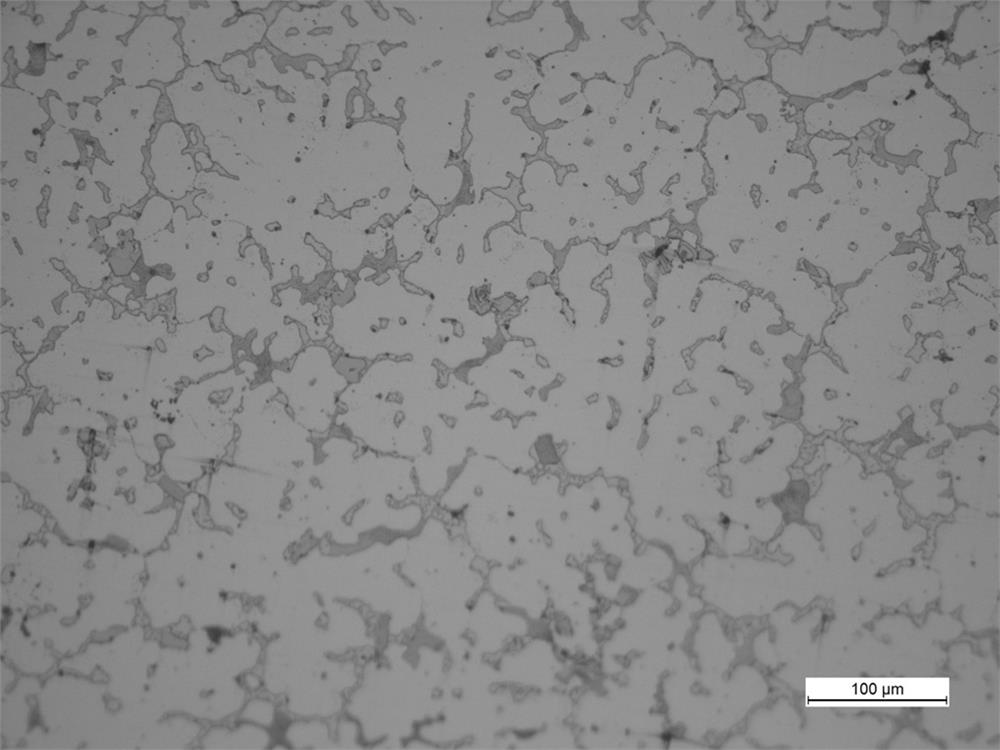

Image

Examples

Embodiment 1

[0036] An ultra-light aluminum-lithium alloy consisting of the following components in mass percentage: Li: 5%, Mg: 4.5%, Mn: 0.6%, Ti: 0.1%, Sb: 0.05%, Be: 0.01%, Sc: 0.2 %, the balance is Al.

[0037] The preparation method of the ultra-light aluminum-lithium alloy, the specific steps are as follows:

[0038] (1) Dosing according to the mass percentage of each component in the alloy; put the prepared raw materials into a vacuum induction melting furnace to preheat to 100°C, and after vacuuming until the vacuum degree reaches 10Pa, pass high-purity argon into the furnace The pressure reaches 300Pa, the temperature is raised to 730°C, and the molten metal is obtained by electromagnetic stirring under an argon atmosphere;

[0039](2) Refining the molten metal obtained in step (1) under an argon atmosphere at 730°C for 15 minutes, keeping mechanical stirring during refining; and then standing at 730°C for 10 minutes, casting the molten metal into a cylindrical water-cooled copp...

Embodiment 2

[0047] An ultra-light aluminum-lithium alloy composed of the following components in mass percentage: Li: 4.5%, Mg: 4%, Mn: 0.6%, Ti: 0.1%, Sb: 0.05%, Be: 0.01%, Sc: 0.2 %, Zr: 0.1%, and the balance is Al.

[0048] The preparation method of the ultra-light aluminum-lithium alloy, the specific steps are as follows:

[0049] (1) Dosing according to the mass percentage of each component in the alloy; put the prepared raw materials into a vacuum induction melting furnace to preheat to 100°C, and after vacuuming until the vacuum degree reaches 10Pa, pass high-purity argon into the furnace The pressure reaches 300Pa, the temperature is raised to 750°C, and the molten metal is obtained by electromagnetic stirring under an argon atmosphere;

[0050] (2) Refining the molten metal obtained in step (1) under an argon atmosphere at 750°C for 15 minutes, keeping mechanical stirring during refining; and then standing at 750°C for 10 minutes, casting the molten metal into a cylindrical wate...

Embodiment 3

[0057] An ultra-light aluminum-lithium alloy composed of the following components in mass percentage: Li: 3.2%, Mg: 4%, Mn: 0.6%, Ti: 0.1%, Sb: 0.05%, Be: 0.01%, Sc: 0.2 %, Zr: 0.1%, and the balance is Al.

[0058] The preparation method of the ultra-light aluminum-lithium alloy, the specific steps are as follows:

[0059] (1) Dosing according to the mass percentage of each component in the alloy; put the prepared raw materials into a vacuum induction melting furnace to preheat to 100°C, and after vacuuming until the vacuum degree reaches 10Pa, pass high-purity argon into the furnace The pressure reaches 300Pa, the temperature is raised to 740°C, and the molten metal is obtained by electromagnetic stirring under an argon atmosphere;

[0060] (2) Refining the molten metal obtained in step (1) under an argon atmosphere at 770°C for 15 minutes, maintaining mechanical stirring during refining; and then standing at 770°C for 10 minutes, casting the molten metal into a cylindrical ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com