Production plan management optimization method based on longitudinal federated learning industrial software docking

A technology of production planning and optimization method, which is applied in the field of machine learning and industrial Internet, can solve problems such as production planning lag, non-compliance, and inability to complete collaborative production of people, machines, and objects, so as to achieve good production planning management optimization and solve hysteresis sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Next, the technical solutions in the embodiments of the present invention will be described in connection with the drawings of the embodiments of the present invention, and it is understood that the described embodiments are merely the embodiments of the present invention, not all of the embodiments. Based on the embodiments in the present invention, all other embodiments obtained without creative labor are not made in the premise of creative labor.

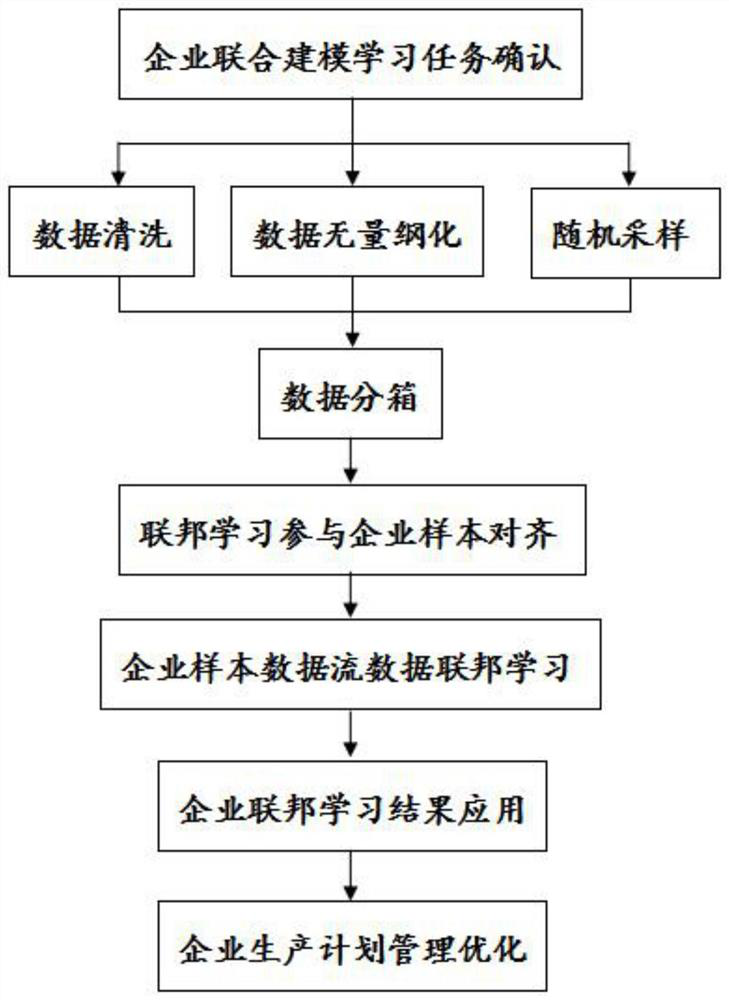

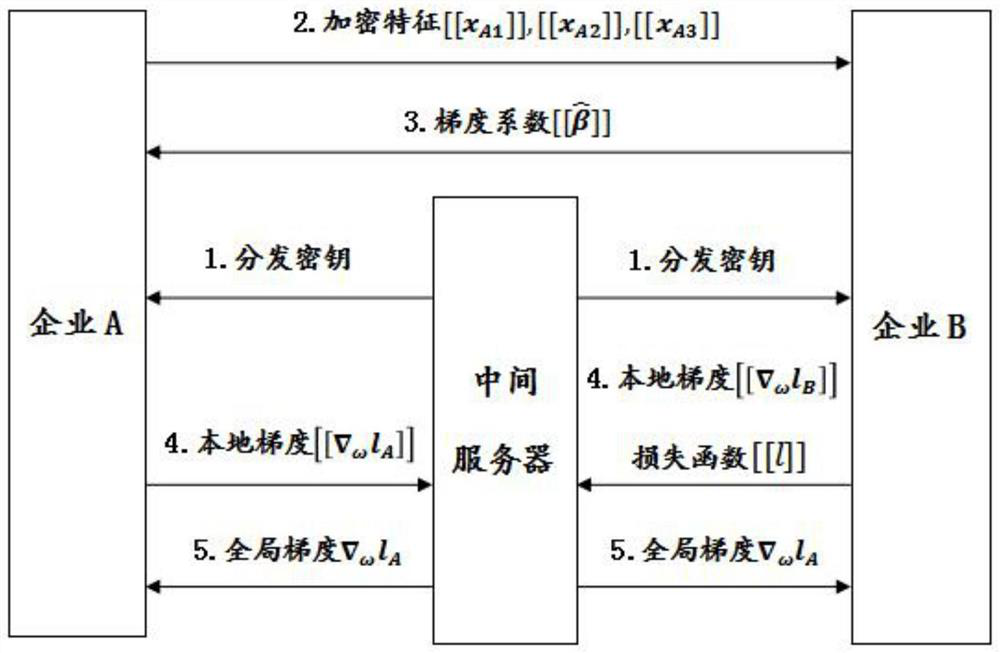

[0035] See figure 1 , figure 2 This embodiment provides a production plan management optimization method based on longitudinal federal learning industrial software, including the following steps:

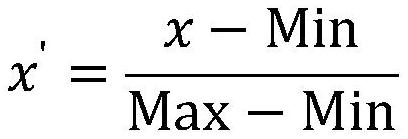

[0036] Step 1: Will go to the middle and lower reaches of industrial enterprises or different vertical sectors of the company as the participants of the industrial Internet portrait federal learning, and the participants in the industrial Internet are in the participants of the federal learning, with the raw materials, product flows...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com