Coupler protective cover achieving machine oil lubrication

A technology of couplings and protective sleeves, which is applied in the direction of couplings, elastic couplings, engine lubrication, etc., can solve the problems of easy damage of couplings, and achieve the effects of avoiding damage, overcoming hysteresis, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

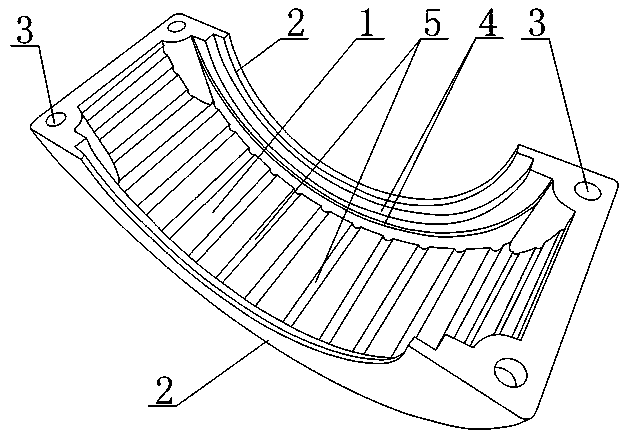

[0019] Such as figure 1 As shown, an oil-lubricated shaft coupling protective sleeve of the present invention includes an axial plate 1 and end panels 2 located at both ends of the axial plate 1, and the axial plate 1 is bent to form a cylindrical half side wall. The two ends of the side wall are respectively equipped with a semi-circular end panel 2, the end panel 2 is connected to the radial direction of the cylinder formed by the axial plate 1, and a through hole 3 is also provided, and the opening of the through hole 3 is located between the end surface of the axial plate 1 and the On the outer side, two sealing rings 4 are arranged on the inside of the two end panels 2, and the two sealing rings 4 and the end panels 2 form three stepped structures, using hard plastic as raw material, using mold injection molding process or mold The stamping forming process forms an integrated structure of the axial plate, the end plate, and the sealing ring at one time; a plurality of oil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com