Nonlinear autoregressive neural network machine tool thermal error modeling method with external input

A nonlinear autoregressive and neural network technology, applied in the field of thermal error compensation of precision CNC machine tools, can solve the problem of difficult to establish thermal error prediction models, improve prediction accuracy and adaptability, improve modeling accuracy, overcome hysteresis Effects of Features

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

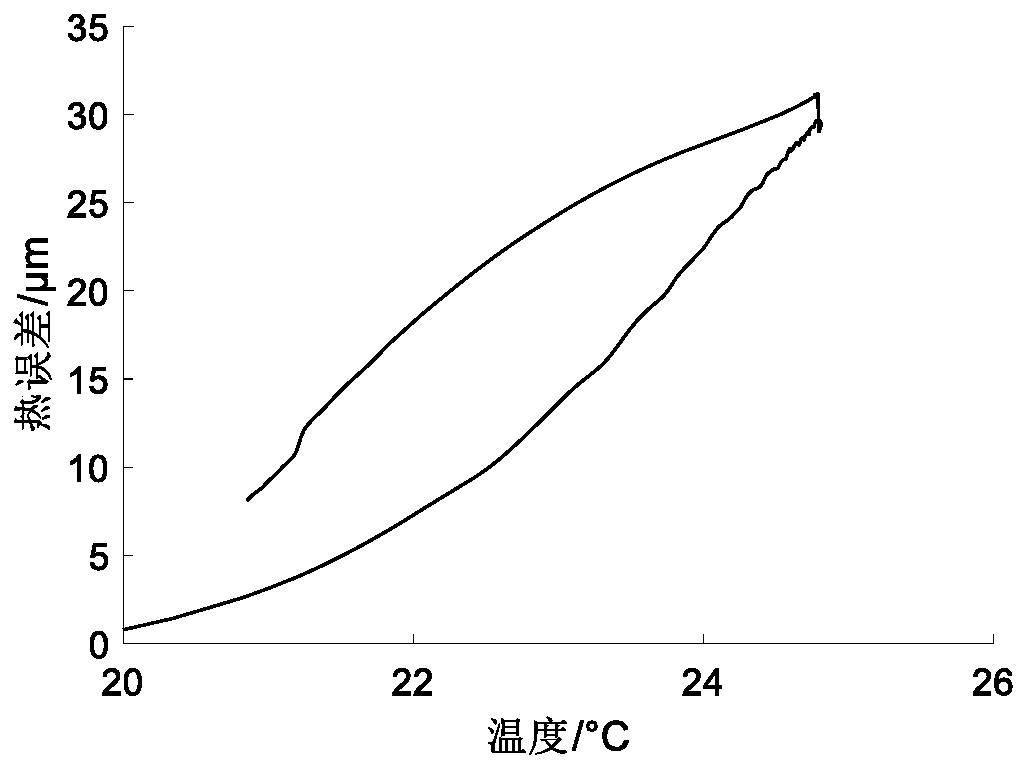

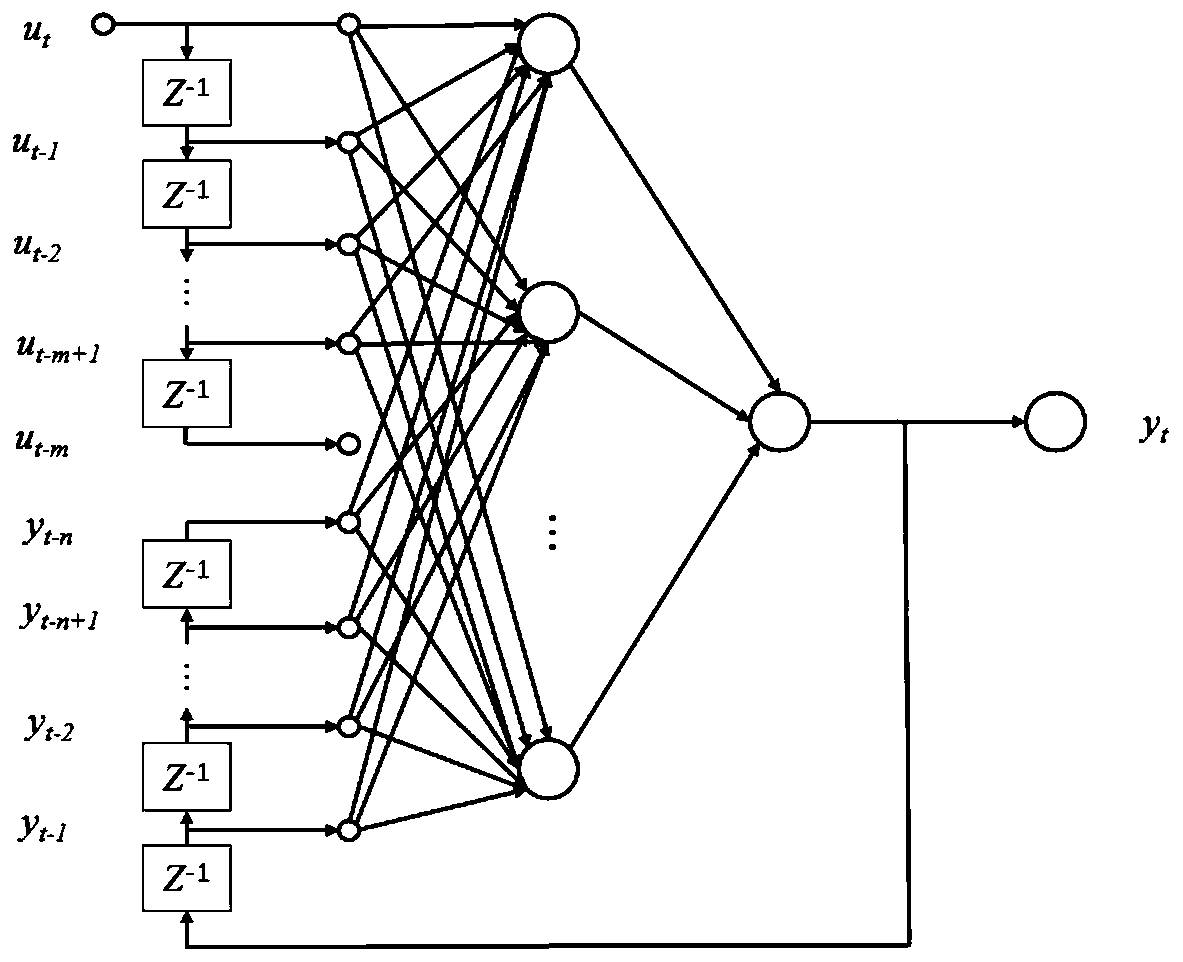

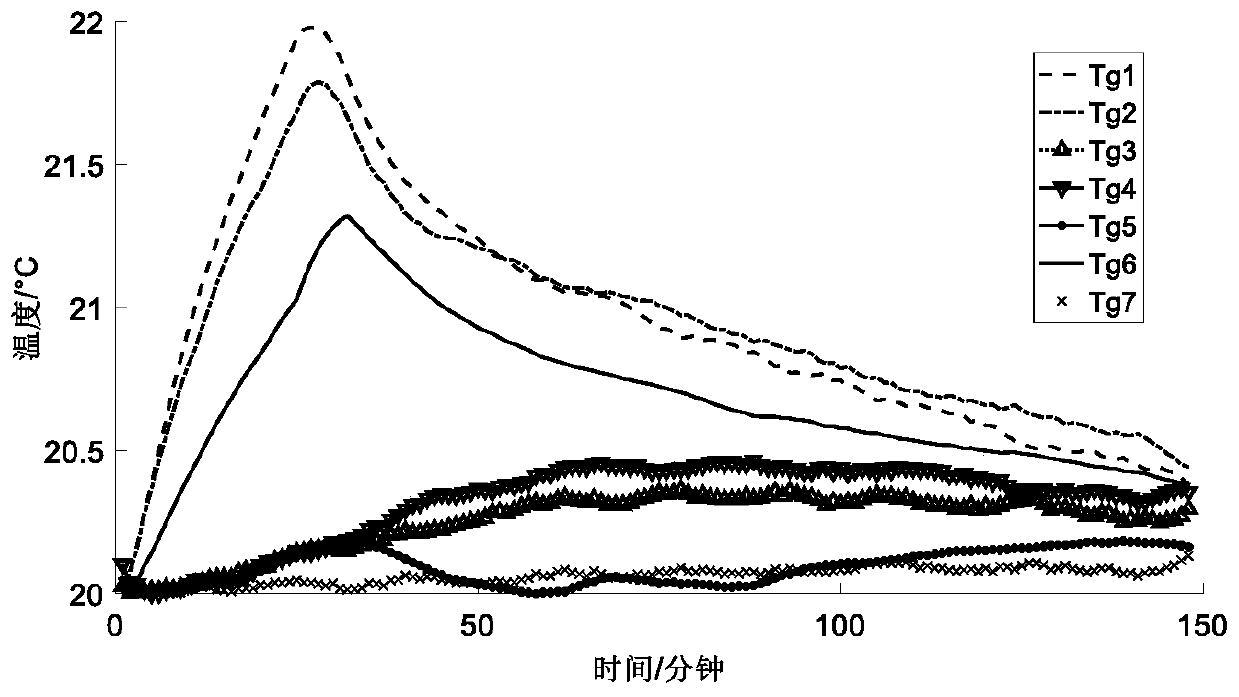

[0050] Embodiment: Carry out modeling test to the axial thermal error of a CNC lathe spindle, the measured modeling temperature curve is as follows image 3 As shown, the thermal error as Figure 4 shown. Follow step 2 to normalize all measurement data; according to step 3, take N=50 when grouping data, calculate the relative information entropy of each temperature point, select temperature measurement point 6 as the modeling input point, temperature measurement point 6 hysteresis curves with thermal errors such as Figure 5 As shown; in step 3, the input and output delay of the NARX model is selected to be 2 orders, the hidden layer is 10 layers, and the training algorithm is Levengerg-Marquardt, and then the model is trained. After getting the model use Figure 5 , 6 The data is tested, and the results are as follows Figure 7 As shown, the maximum error between the model prediction data and the measured data is about 1.5 microns, which can meet the requirements of prac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com