Electrical machine with an auxiliary movable self-directing stator

A stator and rotor technology, applied in the direction of synchronous machines, electrical components, electromechanical devices, etc., can solve problems such as reduced efficiency, limited operating range, rotor deformation, etc., to achieve the effect of reducing loss and avoiding hysteresis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0073] The invention is applicable to all types of electrical machines operating in generator or motor mode. For example, DC motor, induction motor, etc. While the invention is applicable to various types of electric motors and generators, the drawings consider brushed DC motors and induction motors in order to explain the same concepts for all electric motors. The drawings do not cover / exhaust all possible configurations.

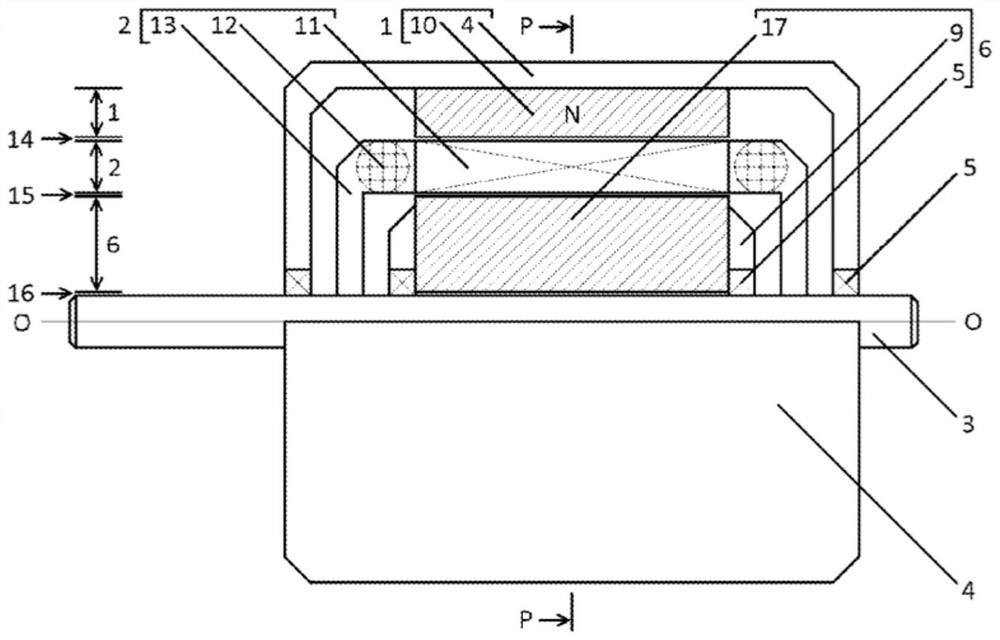

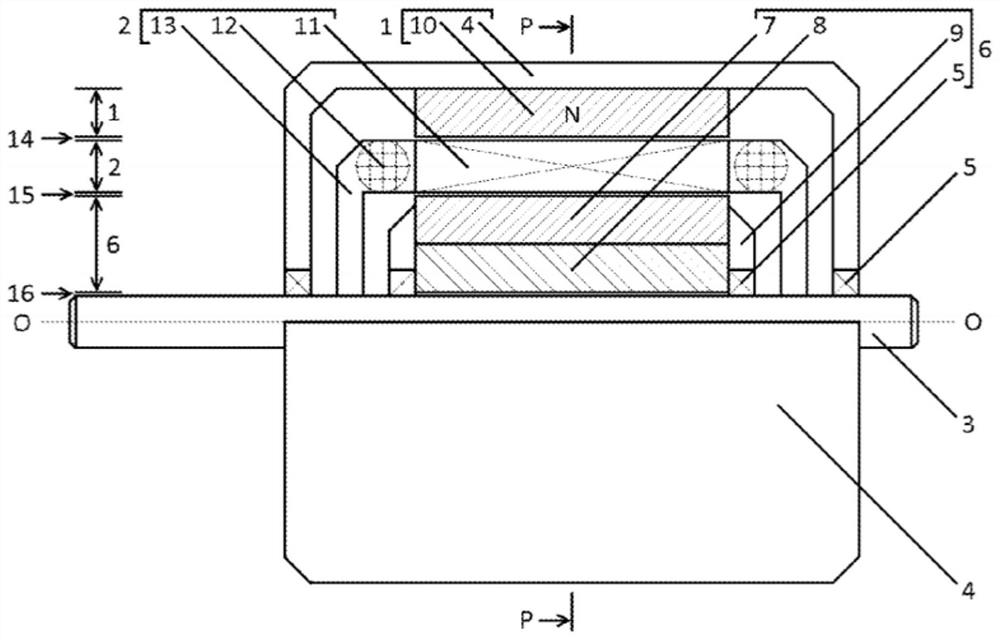

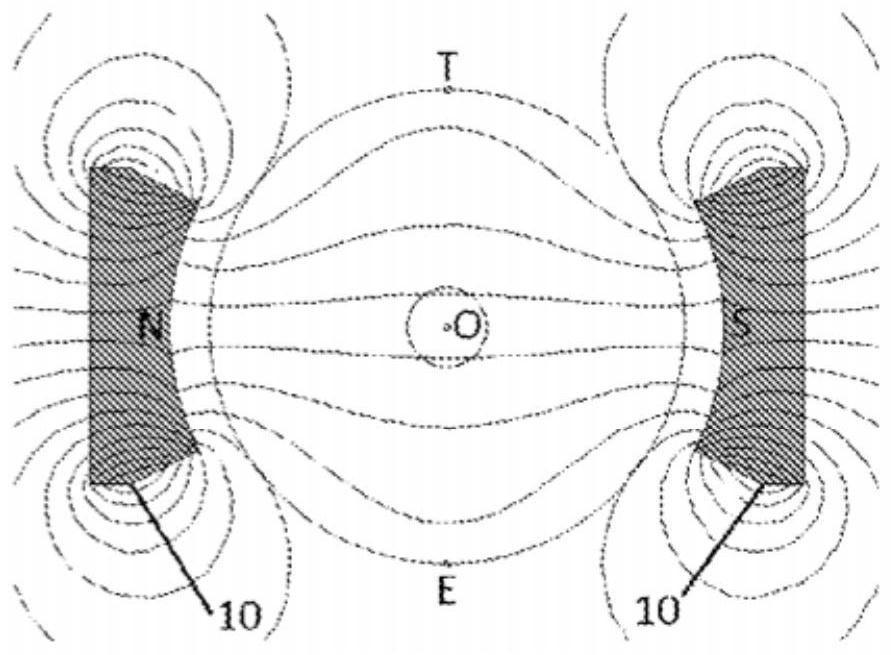

[0074] figure 1 and figure 2 A simplified longitudinal top view of a brushed DC motor is shown. Only the stator and rotor designs are shown. The commutators are not shown in the figures as they are not directly relevant to the invention. Permanent magnets 10 securing the stator 1 are attached to the motor housing 4 (fasteners not shown). Bearing 5 allows free rotation of shaft 3 about the O-O axis. The hollow rotor 2 is attached to the shaft 3 by fasteners 13 and rotates together with the shaft 3 . A movable stator 6 is provided inside the rotor 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com