Process of recovering and utilizing pollutant waste acid liquid

A low-concentration, acid recovery technology, applied in chemical instruments and methods, water/sewage treatment, water/sewage multi-stage treatment, etc., can solve the problems of iron powder consumption, invention method limitations, and large waste of manpower, so as to save waste water The effect of processing fees

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

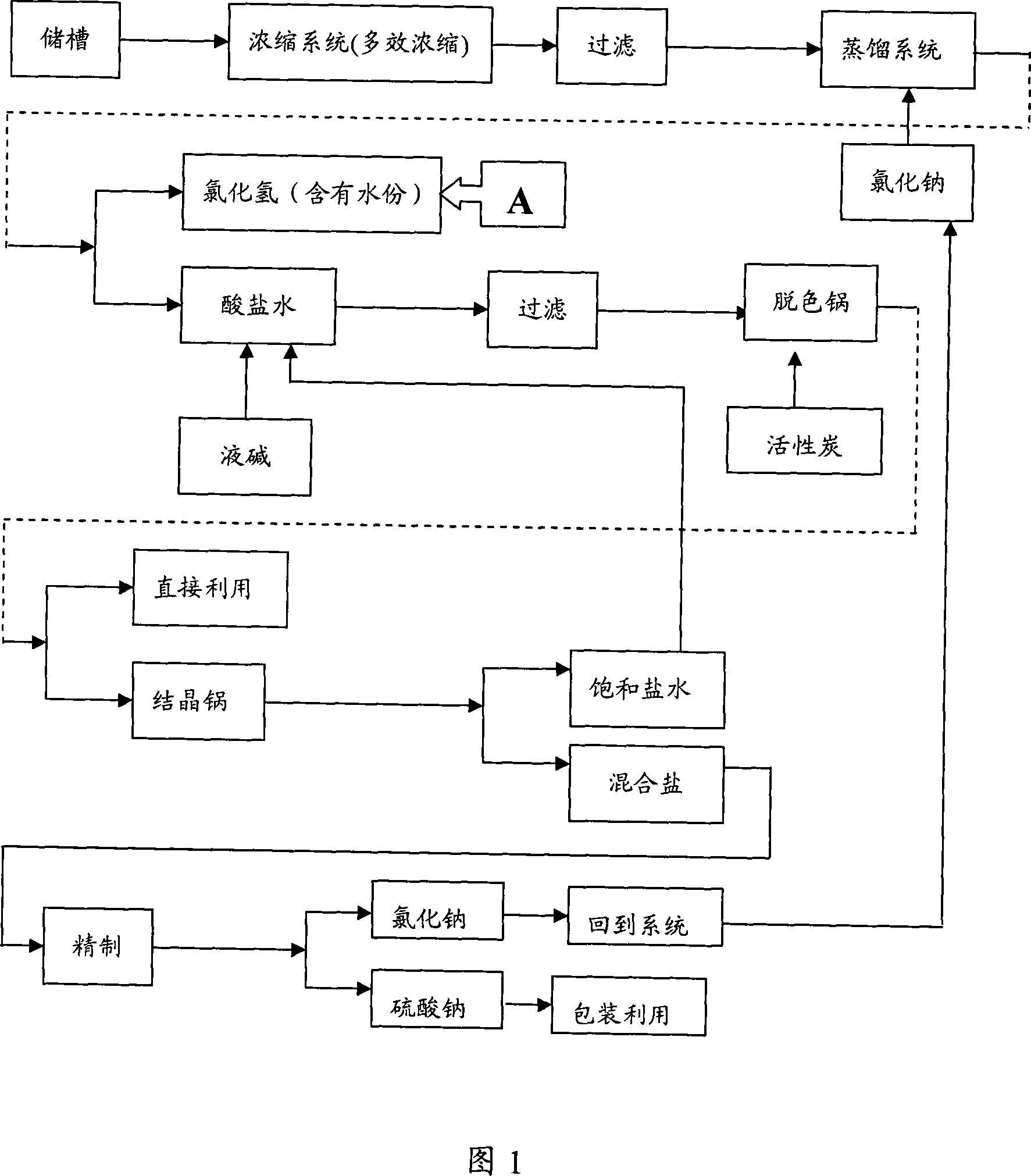

[0023] See Figure 1. After mixing all kinds of wastewater mother liquors evenly, measure the acidity. It is required to have a sulfuric acid acidity greater than 5%. The higher the better, otherwise it will lead to difficulties in recovery. 3 In a large tank, batch homogenization is carried out, and then the mixed mother liquor water is pumped into the concentration system for concentration. It is also best to carry out decolorization and filtration before concentration, so as to remove some impurities and avoid blockage of pipelines and evaporators in the concentration system. Concentrate until the acidity is about 30-75%. At this time, a large amount of impurities will be precipitated, and the precipitated impurities will be removed by filtration after cooling down slightly.

[0024] Put the concentrated and impurity-removed wastewater into the distillation pot, add the prepared sodium chloride, the molar ratio of sodium chloride to sulfuric acid is 0.70-1.50, then close the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com