Regeneration method of casting wet type mixed old sand

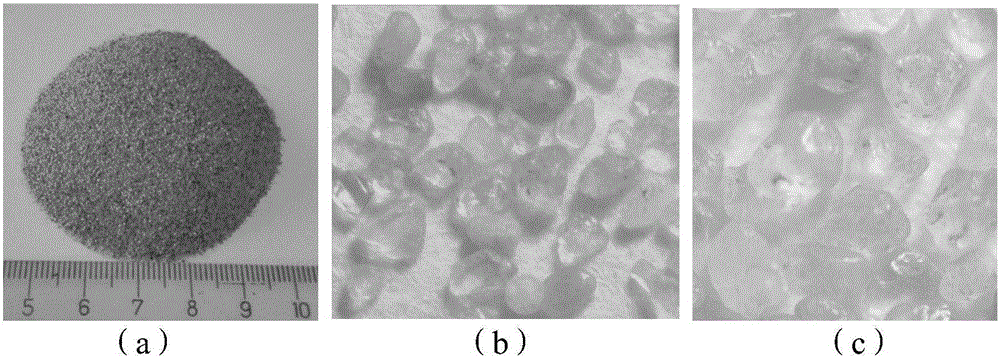

A used sand and wet mold technology is applied in the field of casting wet mold mixed used sand regeneration. The particle shape is round and the effect of reducing the amount of sand hair

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

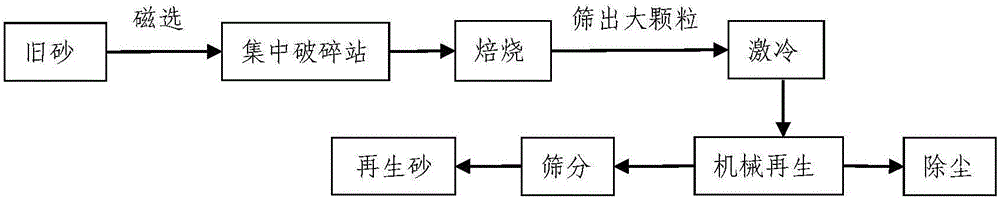

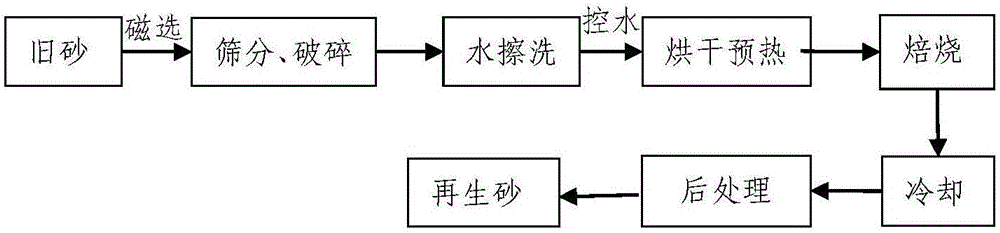

Method used

Image

Examples

Embodiment 1

[0052] A method for regenerating old sand mixed with casting green molds, comprising the following steps:

[0053] 1) Magnetic separation, screening, and crushing of the foundry wet mixed old sand: After magnetic impurities are selected from the old sand through magnetic separation, sand blocks larger than 5 mesh are screened out through a screening machine, and the sand blocks are crushed with a crusher. Filter through a 12-mesh sand net, and sand blocks larger than 12 mesh return to the crusher;

[0054] 2) The old sand pretreated in step 1) is firstly cleaned and deslimed by a spiral sand washing machine, and then enters a 6-barrel series scrubbing machine for water scrubbing. The mass ratio of sand and water in scrubbing is 1:5. Put the sand on the hardened ground to control water, and the mud content of the sand after scrubbing is <0.3%;

[0055] 3) Use a drying drum to dry and preheat the non-agglomerated sand after water scrubbing and water control. The drying temperat...

Embodiment 2

[0059] A method for regenerating old sand mixed with casting green molds, comprising the following steps:

[0060] 1) Magnetic separation, screening, and crushing of the foundry wet mixed old sand: the old sand is magnetically separated to select magnetic impurities, and then the sand blocks larger than 5 mesh are screened out through a screening machine, and the sand blocks are crushed by a crusher. After crushing, the sand blocks are passed 12-mesh sand mesh filter, sand larger than 12 mesh returns to the crusher;

[0061] 2) The old sand pretreated in step 1) is firstly cleaned and deslimed by a spiral sand washing machine, and then enters a 6-barrel series scrubbing machine for water scrubbing. The mass ratio of sand and water in scrubbing is 1:3. Put the sand on the hardened ground to control water, and the mud content of the sand after scrubbing is <0.5%;

[0062] 3) Use a drying drum to dry and preheat the non-agglomerated sand after water scrubbing and water control. ...

Embodiment 3

[0066] A method for regenerating old sand mixed with casting green molds, comprising the following steps:

[0067] 1) Magnetic separation, screening, and crushing of the foundry wet mixed old sand: the old sand is magnetically separated to select magnetic impurities, and then the sand blocks larger than 5 mesh are screened out through a screening machine, and the sand blocks are crushed by a crusher. After crushing, the sand blocks are passed 12-mesh sand mesh filter, sand larger than 12 mesh returns to the crusher;

[0068] 2) The old sand pretreated in step 1) is firstly cleaned and deslimed by a spiral sand washing machine, and then enters a 3-barrel series scrubbing machine for water scrubbing. The mass ratio of sand and water in scrubbing is 1:1. Put the sand on the hardened ground to control water, and the mud content of the sand after scrubbing is <0.5%;

[0069] 3) Use a drying drum to dry and preheat the non-agglomerated sand after scrubbing with water and control th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com