Automatic descaling method and device and system

A technology of automatic descaling and descaling agent, applied in washing devices, steam generation methods, boiler cleaning devices, etc., can solve problems such as serious scaling of equipment and inability to descale

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

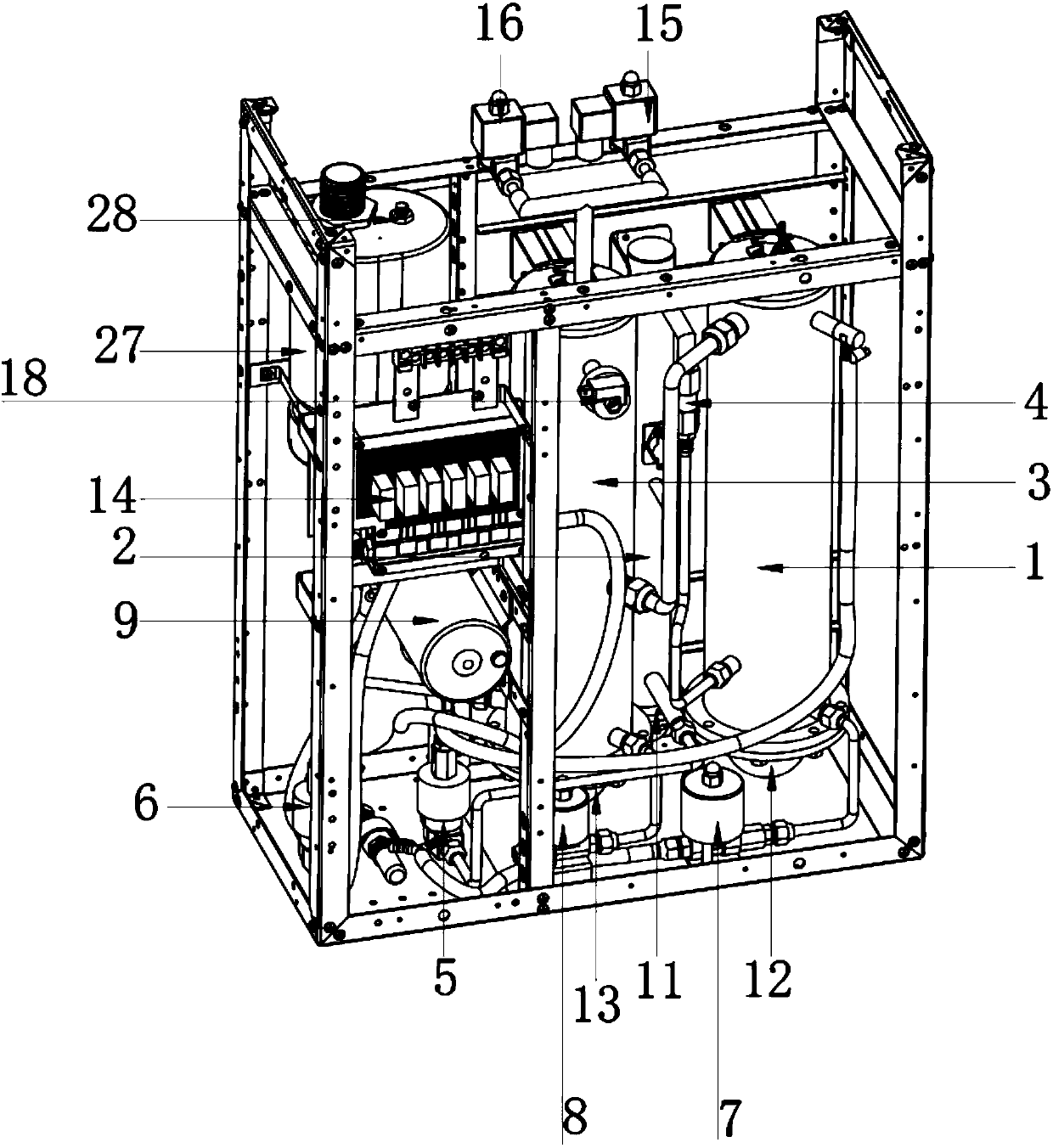

[0049] The embodiments of the present invention will be further described in detail below in conjunction with the drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the embodiments of the present invention, rather than to limit the embodiments of the present invention. In addition, it should be noted that, for the convenience of description, the drawings only show some but not all structures related to the embodiments of the present invention.

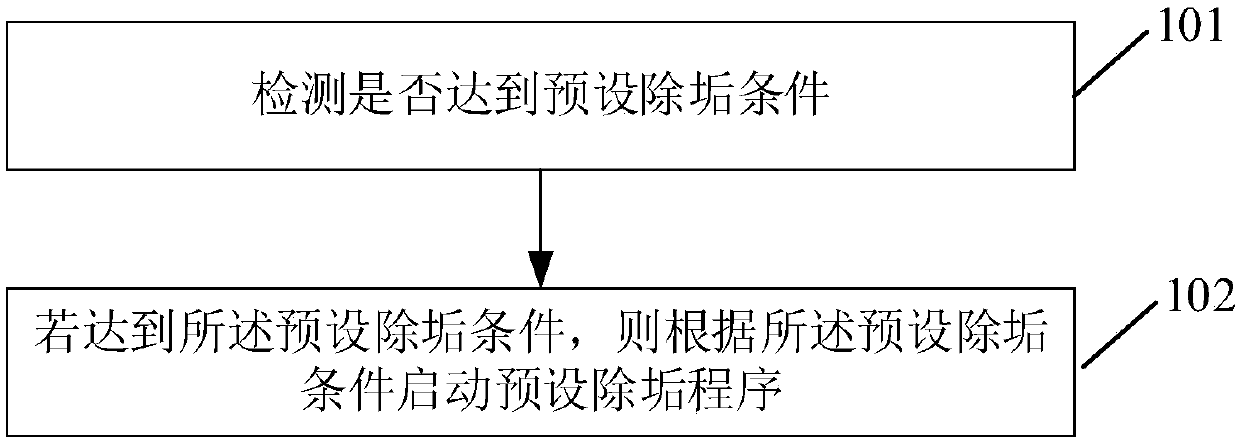

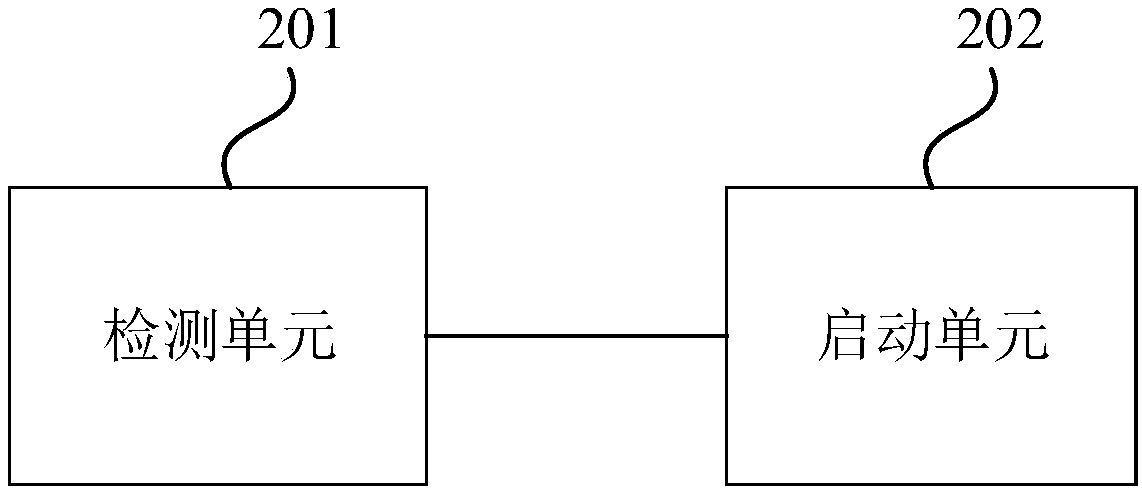

[0050] refer to figure 1 , the methods of intelligent descaling include:

[0051] Step 101: Detect whether the preset descaling conditions are met. The preset descaling conditions include: the cumulative working time of the equipment reaches the preset time threshold, the remaining amount of descaling agent reaches the preset standard, and the OFF / off work button of the equipment is triggered;

[0052] Step 102, if the preset descaling condition is reached, start a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com