High shearing force three-layered polyolefin anti-corrosive thermal insulation steel pipe and manufacturing process thereof

A technology with high shear force and manufacturing process, which is applied in pipeline anticorrosion/rust protection, heat preservation, and pipeline protection through heat insulation, etc. It can solve the problems that it is difficult to ensure the shear strength and high crystallinity of foam and anticorrosion layer, and achieve Enhance adhesive performance, improve shear strength, and solve industry problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Embodiments of the present invention are further described below in conjunction with accompanying drawings:

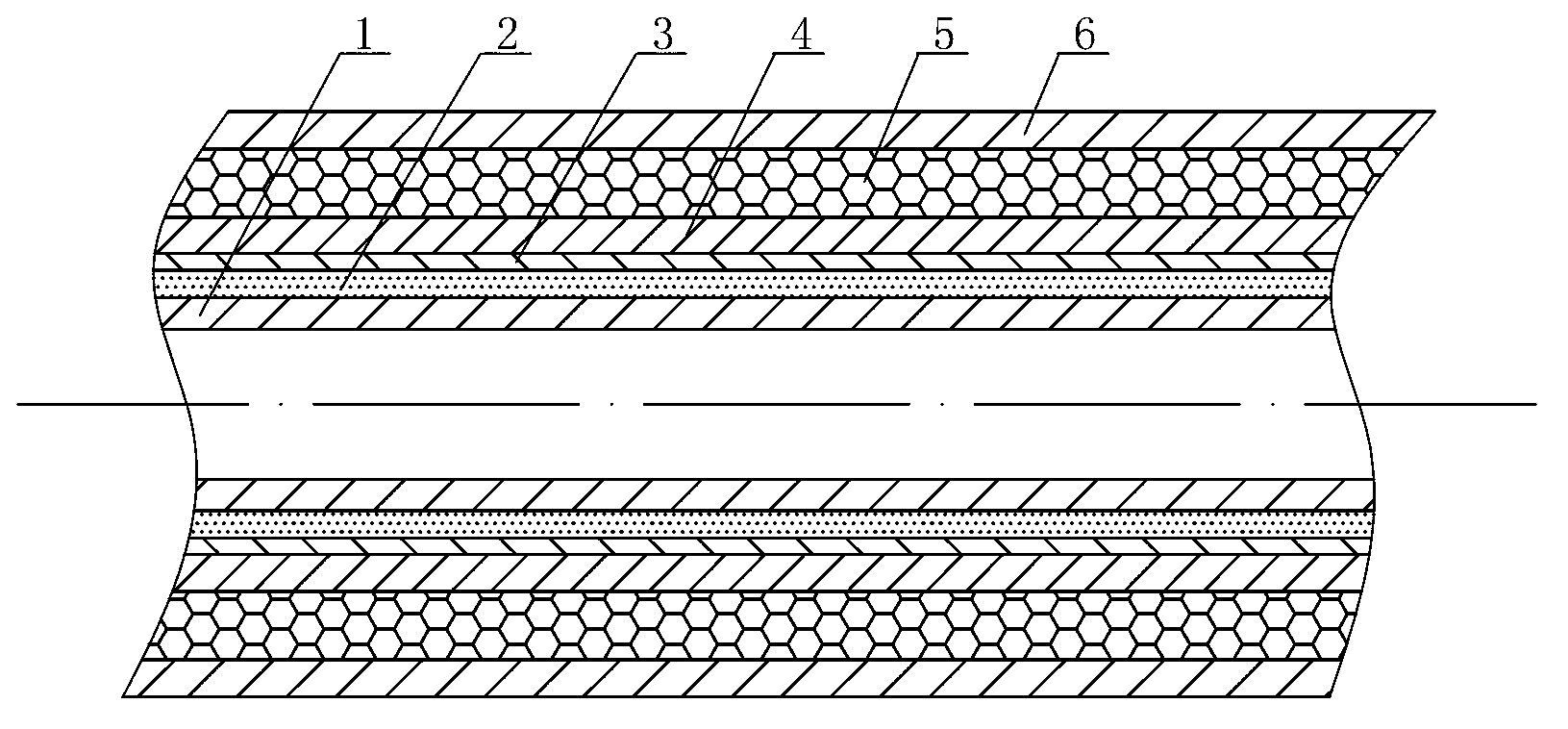

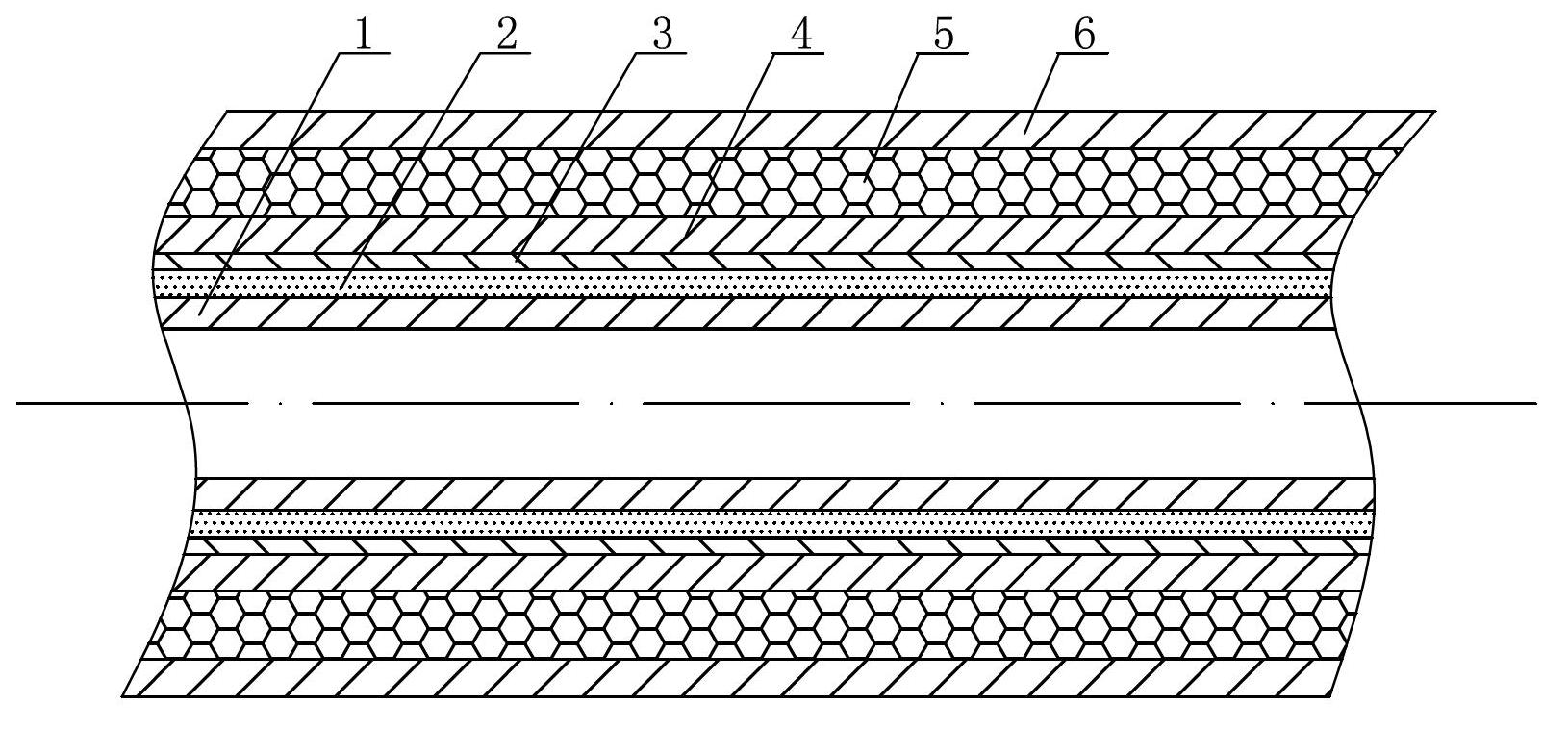

[0028] like figure 1 As shown, the high-shear force three-layer polyolefin anti-corrosion and thermal insulation steel pipe includes three-layer polyolefin anti-corrosion pipe. The anti-corrosion pipe includes steel pipe body 1, epoxy powder layer 2, adhesive bonding layer 3 and polyolefin Layer 4, the anti-corrosion pipe is covered with a polyethylene jacket pipe 6, and a polyurethane foam material layer 5 is arranged between the anti-corrosion pipe and the polyethylene jacket pipe 6.

[0029] There are many types of three-layer polyolefin anti-corrosion pipes (namely: 3LPO anti-corrosion pipes). Now take three-layer polyethylene anti-corrosion pipes (3PE anti-corrosion pipes, that is, the polyolefin layer is a polyethylene layer) as an example to describe the production process of the present invention:

[0030] (1) Prepare 3PE anti-corrosion pipe according t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com