Thermal barrier coating layer resisting CMAS erosion and preparation method

A technology of thermal barrier coating and bonding layer, which is applied in the direction of coating, metal material coating process, liquid chemical plating, etc., can solve problems such as failure and CMAS corrosion, and achieve compact structure, high interface matching degree, phase good stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

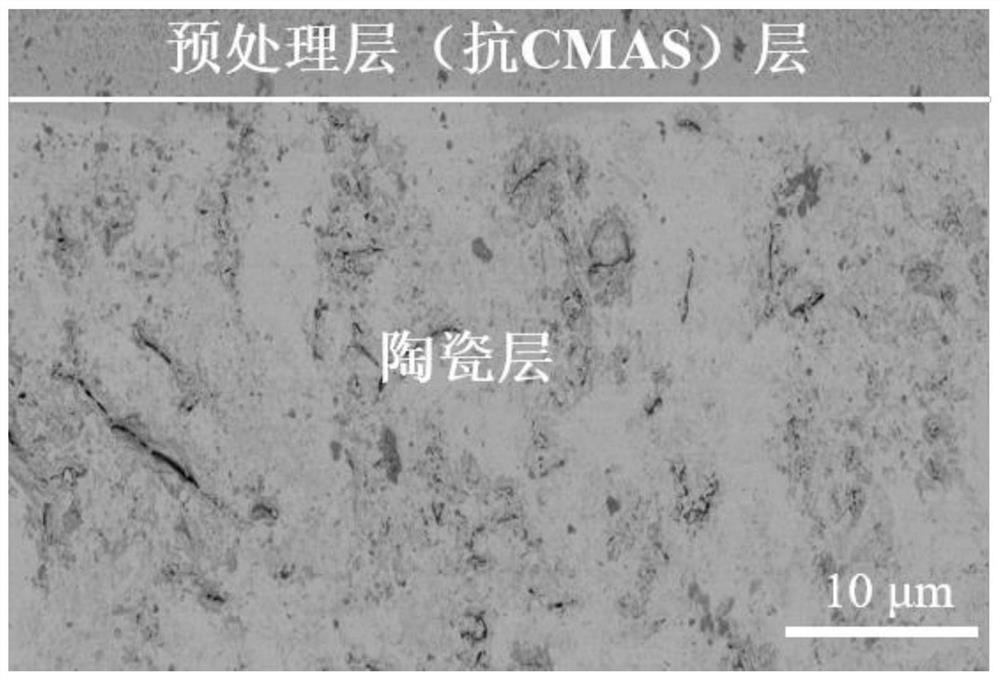

Embodiment 1

[0036] (1) Grinding with 100-mesh, 500-mesh, and 1000-mesh sandpaper on the surface of 5 samples of superalloy GH4586 to remove surface scratches, and then polishing to the mirror surface with diamond polishing agent, followed by surface sandblasting to form roughness on the surface degree, and the CoCrAlYTaSi bonding layer was prepared by plasma spraying method, and the spraying process was optimized at the same time (power 40kW, main gas flow rate 50L / min, auxiliary gas flow rate 25L / min, powder feeding rate 2r / min, carrier gas flow rate 7L / min, The spraying distance is 80μm), the spraying time is 30s, and the thickness is controlled to be 80μm. Then, the prepared adhesive layer is subjected to vacuum diffusion heat treatment (900°C) and surface sandblasting to improve the surface roughness.

[0037] (2) Spray Gd on the surface of the sample prepared with the bonding layer by plasma spraying 2 Zr 2 o 7 Ceramic layer, and by optimizing the spraying process parameters (powe...

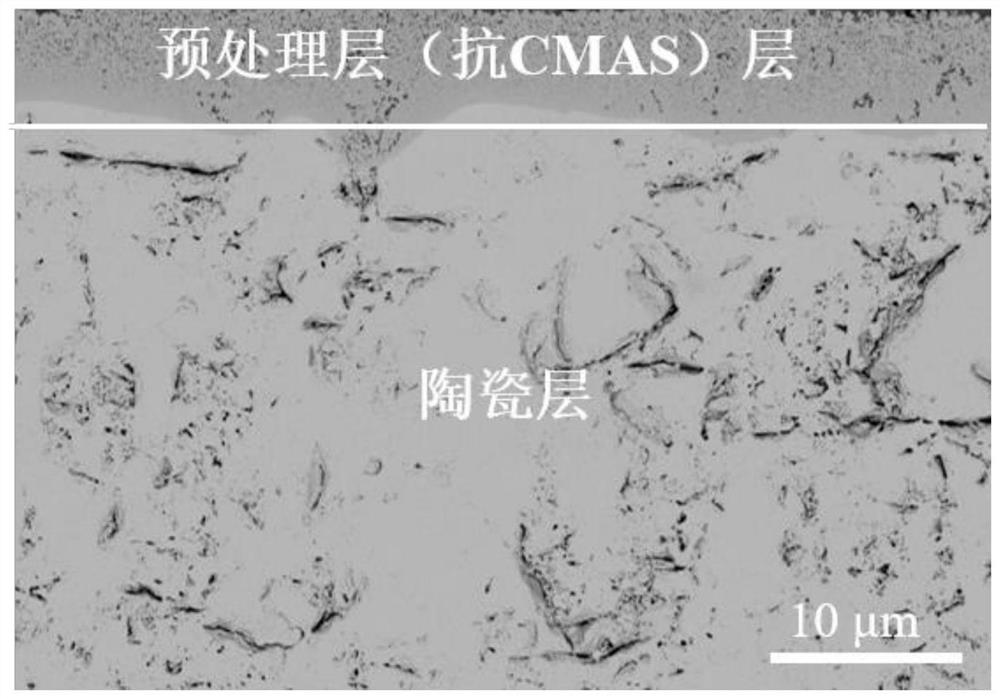

Embodiment 2

[0042] (1) Grinding with 100-mesh, 500-mesh, and 1000-mesh sandpaper on the surface of 5 samples of superalloy GH4586 to remove surface scratches, and then polishing to the mirror surface with diamond polishing agent, followed by surface sandblasting to form roughness on the surface degree, and the CoCrAlYTaSi bonding layer was prepared by plasma spraying method, and the spraying process was optimized at the same time (power 40kW, main gas flow rate 50L / min, auxiliary gas flow rate 25L / min, powder feeding rate 2r / min, carrier gas flow rate 7L / min, The spraying distance is 80μm), the spraying time is 30s, and the thickness is controlled to be 80μm. Then, the prepared adhesive layer is subjected to vacuum diffusion heat treatment (900°C) and surface sandblasting to improve the surface roughness.

[0043] (2) adopt plasma spraying method to spray (La 0.5 Gd 0.5 ) 2 Zr 2 o 7 Ceramic layer, and by optimizing the spraying process parameters (power 60kW, main gas flow 60L / min, au...

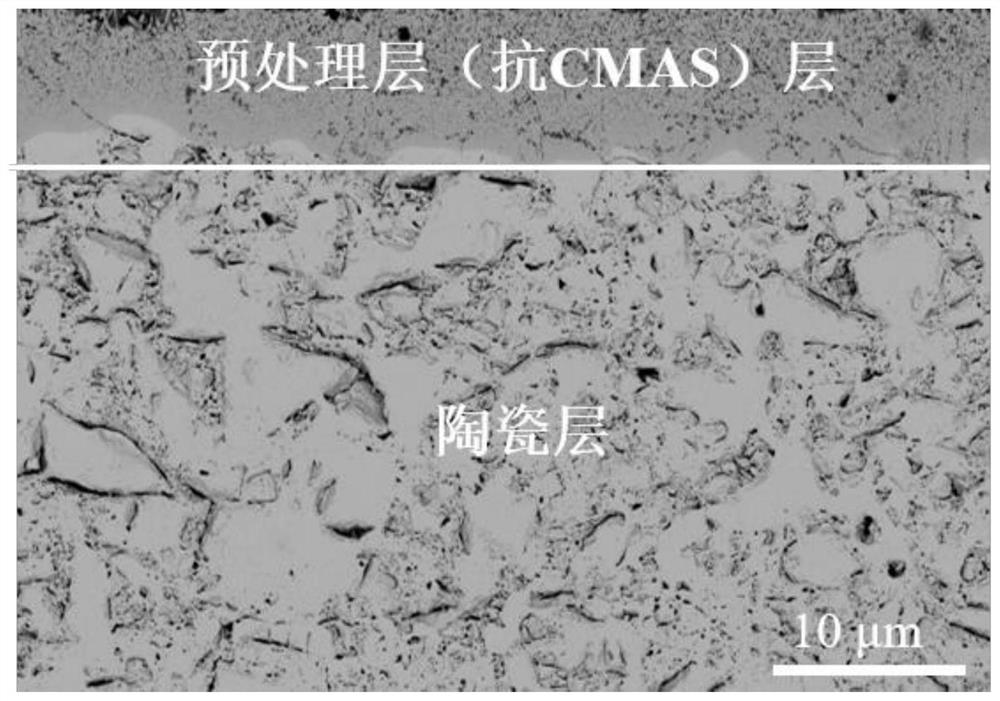

Embodiment 3

[0048] (1) Grinding with 100-mesh, 500-mesh, and 1000-mesh sandpaper on the surface of 5 samples of superalloy GH4586 to remove surface scratches, and then polishing to the mirror surface with diamond polishing agent, followed by surface sandblasting to form roughness on the surface degree, and the CoCrAlYTaSi bonding layer was prepared by plasma spraying method, and the spraying process was optimized at the same time (power 40kW, main gas flow rate 50L / min, auxiliary gas flow rate 25L / min, powder feeding rate 2r / min, carrier gas flow rate 7L / min, The spraying distance is 80μm), the spraying time is 30s, and the thickness is controlled to be 80μm. Then, the prepared adhesive layer is subjected to vacuum diffusion heat treatment (900°C) and surface sandblasting to improve the surface roughness.

[0049] (2) Spray (Gd) on the prepared bonding layer surface by plasma spraying 0.7 Yb 0.3 ) 2 Zr 2 o 7 Ceramic layer, and by optimizing the spraying process parameters (power 60kW,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com