Firearm laser calibrator, method for demarcating firearm laser calibrator, method for calibrating firearm and method for determining target point of bore axis

A technology of calibrator and laser, which is applied in the field of calibrating guns and determining the target point of the bore axis, calibration, and laser calibrator for firearms. It can solve the problems of inability to determine the extension line of the bore axis, low calibration accuracy, and unchanged operation. Achieve the effects of improving the combat effectiveness of the troops, the calibration process is fast and accurate, and the operation and use are convenient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

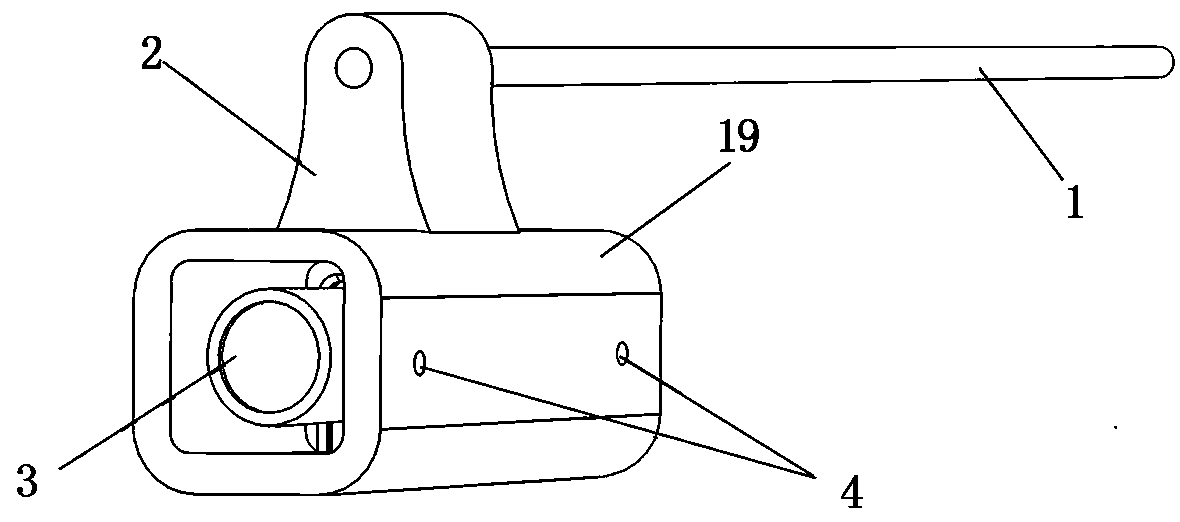

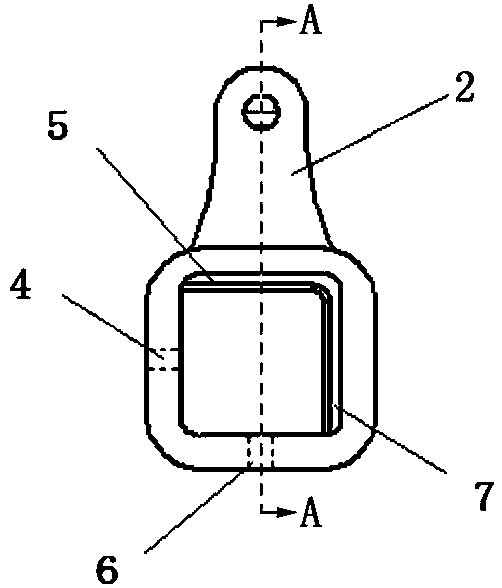

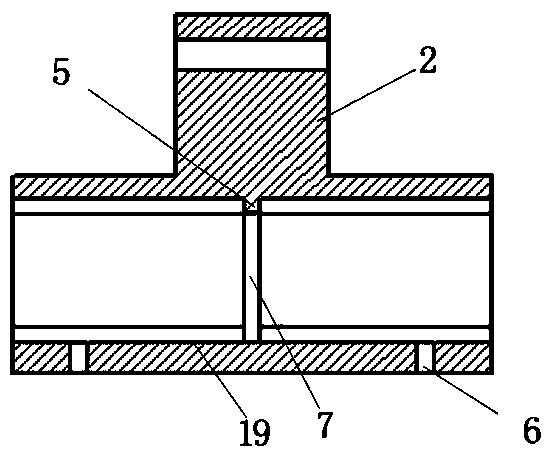

[0064] The structure of the gun laser aligner in this embodiment is as follows figure 1 As shown, it includes a plunger 1, a laser fixing frame and a laser generator 3.

[0065] The plunger 1 is rod-shaped as a whole, preferably a straight-handled round rod body, and its diameter is slightly smaller than the inner diameter of the male side of the inner spiral of the barrel of the firearm to be calibrated, so that the plunger can be smoothly inserted into the barrel from the muzzle and can Free rotation. The laser fixing frame is composed of a positioning cylinder 19 and a plunger positioning member 2 arranged on the upper side of the positioning cylinder 19. The front end of the plunger 1 is fixedly connected to the plunger positioning member 2. The positioning cylinder 19 is used to fix the laser generator 3, and the laser generator 3 is arranged in the positioning cylinder 19 of the laser fixing frame for emitting positioning laser light to the front target. The cross-section ...

Embodiment 2

[0069] Combine Figure 7 This embodiment provides a specific method for determining the target point of the 95-type rifle barrel axis extension line on the target, including the following steps:

[0070] ① Set up a stand with a longitudinal jack 22, the inner diameter of the longitudinal jack 22 is the same as the inner diameter of the male side of the inner spiral line of the barrel of the firearm to be tested, and the length between the front and rear ports of the longitudinal jack 22 is greater than that of the firearm Half the length of the plunger 1 in the laser collimator;

[0071] ②Set the target 20 in front of 100 meters from the front end of the bracket, and make a marking point 21 on the target 20, and adjust the bracket so that the axis of the longitudinal jack 22 on the bracket points to the marking point;

[0072] ③ Insert the plunger 1 of the laser aligner of the firearm into the longitudinal jack 22 of the bracket;

[0073] ④Turn on the laser generator 3, adjust the las...

Embodiment 3

[0078] Combine Figure 7 This embodiment provides a method for calibrating a laser calibrator for firearms, which includes the following steps:

[0079] ① Set up a bracket with a longitudinal jack 22. The inner diameter of the longitudinal jack 22 is the same as the inner diameter of the male side of the inner thread of the barrel of the firearm to be calibrated, and the length between the front and rear ports of the longitudinal jack 22 is greater than that of the firearm Half the length of the plunger 1 in the laser collimator;

[0080] ②Set the target 20 in front of 100 meters from the front end of the bracket, and make a mark 21 on the target 20, adjust the bracket so that the axis of the longitudinal jack 22 on the bracket is aligned with the mark 21;

[0081] ③ Insert the plunger 1 of the laser aligner of the firearm into the longitudinal jack 22 of the bracket;

[0082] ④Turn on the laser generator 3 and adjust the laser generator 3 on the laser aligner of the gun to make the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com