Pressure control recovery equipment and process for glyphosate hydrolysis tail gases produced by alkyl ester method

A recovery equipment, glyphosate technology, applied in the field of new equipment for solvent recovery of glyphosate produced by the alkyl ester method, can solve the problems of high dependence on graphite condenser, poor intrinsic safety, poor operation stability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

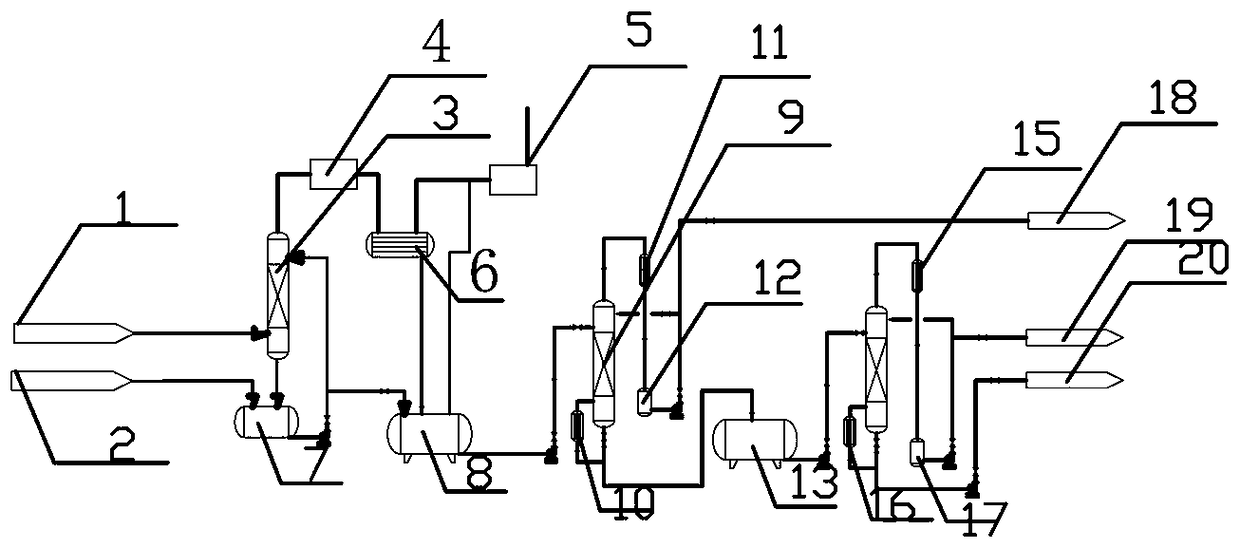

[0038] A pressure-controlled recovery device for glyphosate hydrolysis tail gas produced by an alkyl ester method, comprising a dilute methanol solution collection tank 8, a methylal rectification tower 9, a methanol aqueous solution intermediate tank 13, and a methanol rectification tower 14,

[0039] The glyphosate hydrolysis tail gas pretreatment system produced by the alkyl ester method is connected with the dilute methanol solution collection tank 8,

[0040]The dilute methanol solution collection tank 8 is connected to the upper part of the methylal rectification tower 9 through pipelines, and the top of the methylal rectification tower 9 is connected to the reflux tank 12 of the methylal rectification tower through the condenser one 11, and the methylal rectification tower The reflux tank 12 is connected to the methylal finished product tank 18, and the bottom of the methylal rectifying tower 9 is provided with a reboiler;

[0041] The bottom of the methylal rectifying ...

Embodiment 2

[0057] A pressure-controlled recovery process for glyphosate hydrolysis tail gas produced by an alkyl ester method, comprising the steps of:

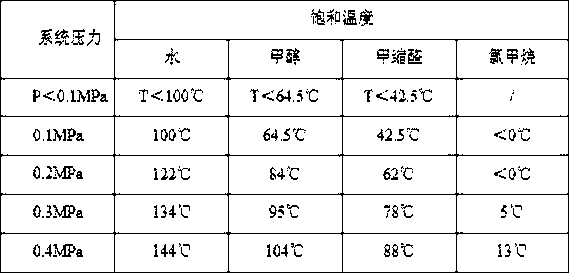

[0058] Neutralization and pressure control step: the mixture of hydrogen chloride, methyl chloride, methanol, methylal, and water vapor from the glyphosate hydrolysis station enters the tail gas neutralization tower together with liquid caustic soda to neutralize to a pH of 7-11, and removes the tail gas The acidic components in the gas will then enter the tail gas condenser for condensation and separation after pressure control, the condensate will go to the dilute methanol solution collection tank, and the non-condensable gas will go to the methyl chloride recovery device.

[0059] The pressure of the exhaust gas condenser, dilute methanol solution collection tank and its pressure balance pipe is controlled by 1# and 2# compressors at 0.1-0.4MPa, denoted as P. The specific boundaries of the system are 1# compressor outlet, 2# compress...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com