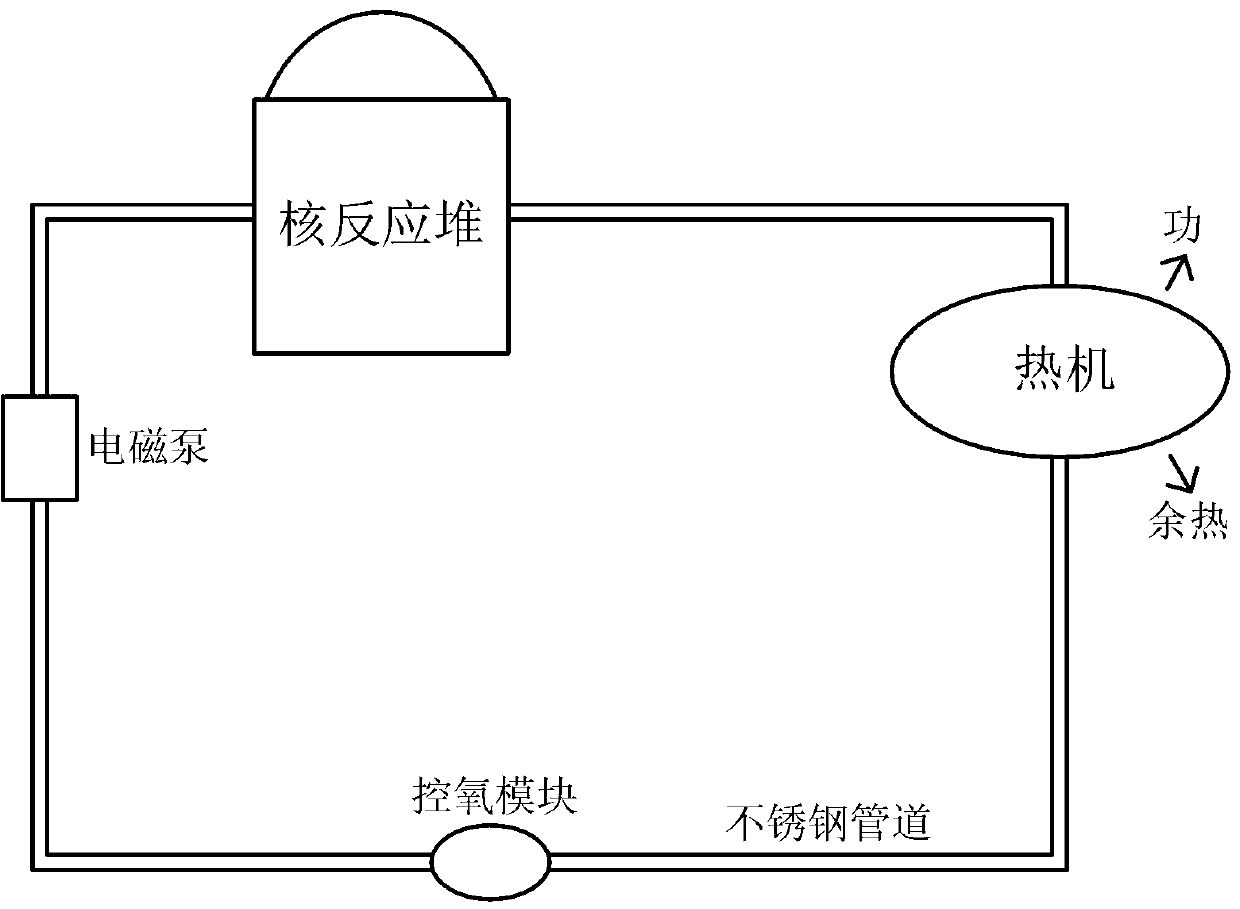

Nuclear reactor oxygen control type liquid metal used under 200-300 DEG C and compatibility process thereof

A liquid metal and nuclear reactor technology, applied in the field of alloys, can solve the problems of liquid metal heat transfer materials such as corrosion and dissolution, and achieve the effects of ensuring the stability of physical and chemical properties, eliminating corrosion, and fast dissolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

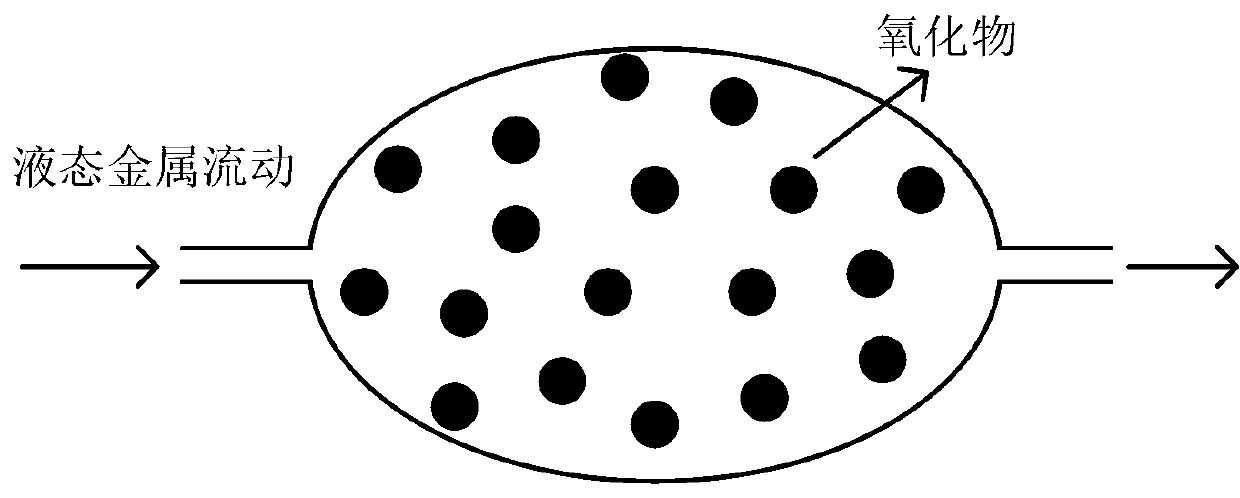

Method used

Image

Examples

Embodiment 1

[0019] A 200-300 degree nuclear reactor oxygen control type liquid metal and its compatibility technology. In terms of weight percentage, the alloy composition is Ag: 0.3wt.%, Sb: 3.2wt.%, Mn: 1.0wt.%, Bi: 12.5wt.%, Cd: 8.0wt.%, Ga: 2.0wt.% , Pb: 20.0wt.%, the balance is tin; the oxide composition to control the oxygen activity is PbO: 12.0wt.%, CuO: 2.5wt.%, Sn 2 o 3 : 1.8wt.%, AgO: 5.0wt.%, ZnO: 10.0wt.%, the balance is Fe 2 o 3 .

[0020]The aforementioned 200-300°C nuclear reactor oxygen-controlling liquid metal and its compatibility process include the following processing and use steps: (a) After the alloy is configured according to the required components, it is put into an induction furnace for melting, And use graphite crucible for smelting under the protection of argon; keep warm at 200 degrees for 10 minutes, use electromagnetic stirring to fully stir the alloy melt evenly, after cooling, remove the scum on the surface of the melted alloy melt and pour it into a...

Embodiment 2

[0023] A 200-300 degree nuclear reactor oxygen control type liquid metal and its compatibility technology. In terms of weight percentage, the alloy composition is Ag: 0.4wt.%, Sb: 4.0wt.%, Mn: 1.8wt.%, Bi: 14.0wt.%, Cd: 11.0wt.%, Ga: 2.5wt.%. , Pb: 26.0wt.%, the balance is tin; the oxide composition to control the oxygen activity is PbO: 12.0wt.%, CuO: 4.0wt.%, Sn 2 o 3 : 3.0wt.%, AgO: 6.5wt.%, ZnO: 15.0wt.%, the balance is Fe 2 o 3 .

[0024] The aforementioned 200-300°C nuclear reactor oxygen-controlling liquid metal and its compatibility process include the following processing and use steps: (a) After the alloy is configured according to the required components, it is put into an induction furnace for melting, A graphite crucible is used for smelting under the protection of argon; after 10 minutes of heat preservation at 300 degrees, the alloy melt is fully stirred evenly by electromagnetic stirring, and after cooling, the scum on the surface of the melted alloy melt i...

Embodiment 3

[0027] A 200-300 degree nuclear reactor oxygen control type liquid metal and its compatibility technology. In terms of weight percentage, the alloy composition is Ag: 0.2wt.%, Sb: 3.8wt.%, Mn: 1.4wt.%, Bi: 12.0wt.%, Cd: 10.0wt.%, Ga: 2.5wt.%. , Pb: 24.0wt.%, the balance is tin; the oxide composition to control the oxygen activity is PbO: 11.0wt.%, CuO: 4.0wt.%, Sn 2 o 3 :2.0wt.%, AgO:6.0wt.%, ZnO:14.0wt.%, the balance is Fe 2 o 3 .

[0028] The aforementioned 200-300°C nuclear reactor oxygen-controlling liquid metal and its compatibility process include the following processing and use steps: (a) After the alloy is configured according to the required components, it is put into an induction furnace for melting, And use graphite crucible for smelting under the protection of argon; keep warm at 200 degrees for 10 minutes, use electromagnetic stirring to fully stir the alloy melt evenly, after cooling, remove the scum on the surface of the melted alloy melt and pour it into a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com