Floating drying device for agricultural cereal seeds

A drying device and grain technology, applied in the direction of drying gas arrangement, dry solid material, dry cargo handling, etc., can solve the problems of excessive drying methods, different drying degrees, too dry or too wet seeds, etc., to achieve consistent drying degree and heat Uniform, easy drying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

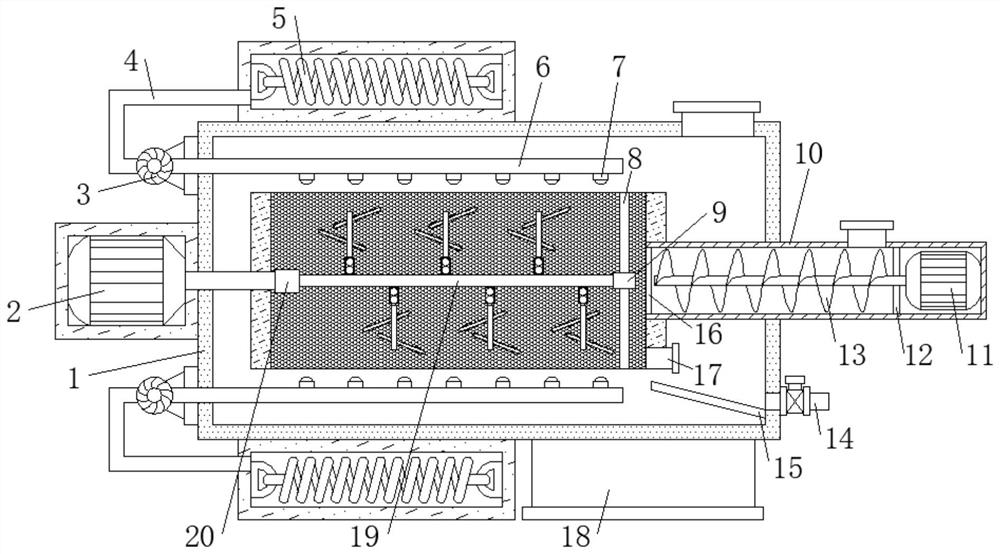

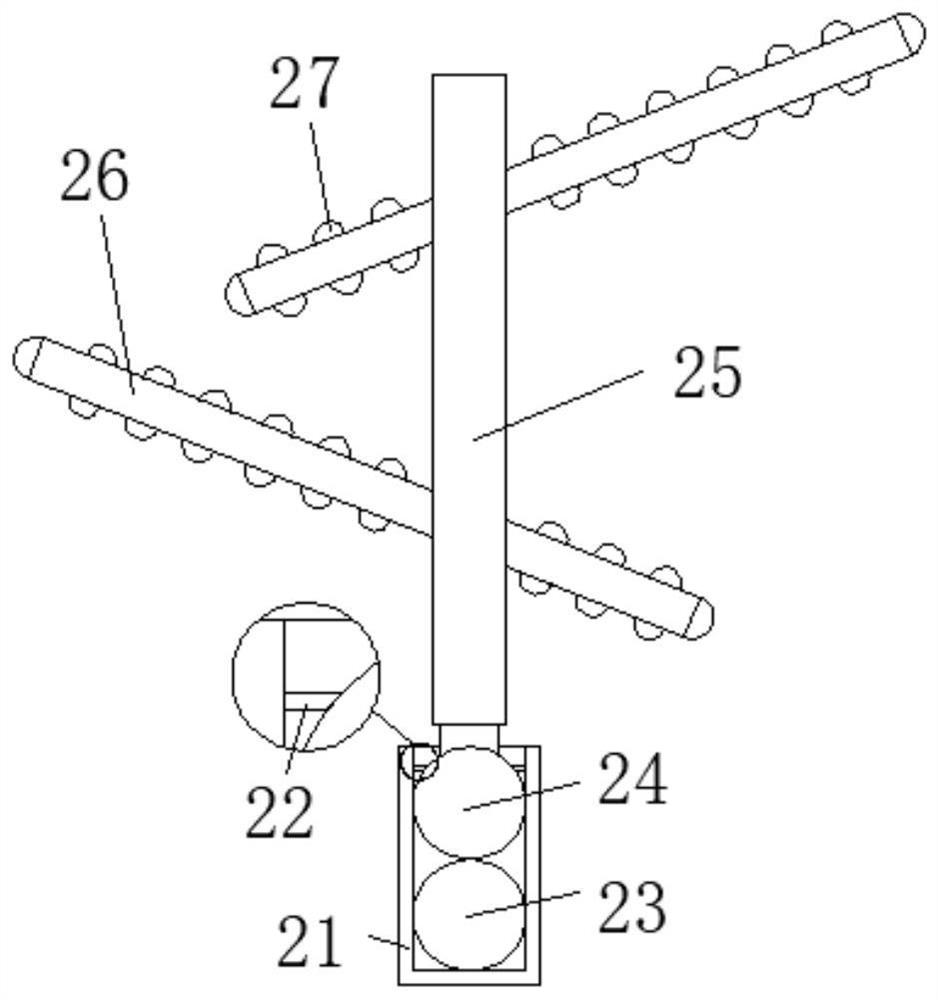

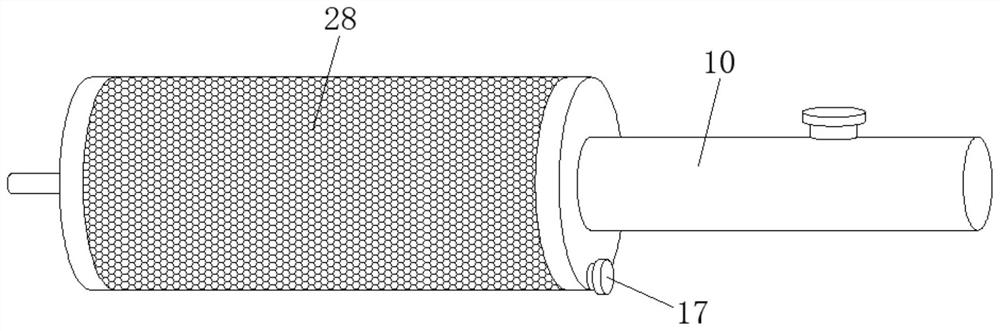

[0025] refer to Figure 1-3 , a floating drying device for agricultural grain seeds, comprising a box body 1, a feeding mechanism is arranged on one side of the outer wall of the box body 1, one end of the feeding mechanism is located inside the box body 1, and the side of the box body 1 away from the feeding mechanism The motor box is fixed on the outer wall by bolts, and the servo motor 2 is fixed on the inner wall of one side of the motor box by bolts. One end of the output shaft of the servo motor 2 is located inside the box body 1, and one end of the output shaft of the servo motor 2 is sleeved with a mesh cylinder. 28. The feeding mechanism is rotated and plugged on one side of the outer wall of the net cylinder 28, and one end of the output shaft of the servo motor 2 is sleeved with a sleeve 20. The inner wall of the circumference of the sleeve 20 is engraved with a threaded groove, and the inner wall of the threaded groove is screwed. There is a connecting shaft 19, an...

Embodiment 2

[0031] refer to Figure 4, a floating drying device for agricultural grain seeds. Compared with Embodiment 1, this embodiment has a temperature sensor 29 fixed on one side of the inner wall of the top of the box body 1 by bolts, and an alarm light is fixed on the outer wall of the top of the box body 1 by bolts. 30. The signal output end of the temperature sensor 29 is connected to the signal input end of the warning light 30 through a signal line.

[0032] When in use, when the temperature sensor 29 is provided with a critical temperature, the alarm lamp 30 will be triggered to give an alarm after the device is heated to a certain degree, thereby reminding the staff to control the temperature during drying.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com