Aleurone-layer fine dried noodles and preparation technology thereof

A technology of aleurone layer and wheat aleurone layer, which is applied in the field of aleurone layer noodles and its production process, can solve the problems of increased production cost, poor taste of dried noodles, and lack of texture, so as to improve the resistance to pressure, increase the toughness of noodles, prevent The effect of receding gums

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

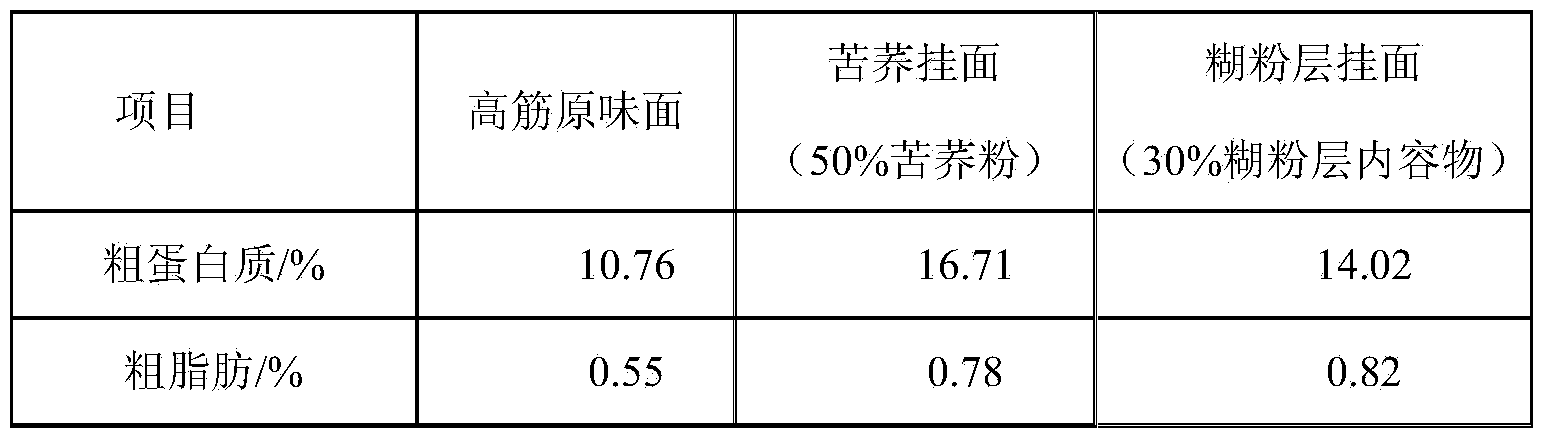

[0060] See attached figure 1 , wherein 1 is the dried noodle that present embodiment makes, and its component is as follows:

[0061] The proportion of flour raw materials is 80% of high-gluten flour and 20% of the content of wheat aleurone layer; wherein, the mass ratio of added auxiliary materials to the flour raw materials is: 1%-1.5% of salt added; 1%-3% of gluten powder %; xanthan gum 0.2%-0.4%; vitamin C20-50PPM; water addition 20%-35%.

[0062] attached by figure 1 It can be seen that the dried noodles made with this formula are slightly brown, and at the same time, the dried noodles are smooth and chewy after cooking, and the taste fully meets the edible requirements.

Embodiment 2

[0064] See attached figure 1 , wherein 2 is the dried noodle that present embodiment makes, and its component is as follows:

[0065] The proportion of flour raw materials is 70% of high-gluten flour and 30% of the content of wheat aleurone layer; wherein, the mass ratio of added auxiliary materials to the flour raw materials is: 1%-1.5% of salt added; 1%-3% of gluten powder %; xanthan gum 0.2%-0.4%; vitamin C20-50PPM; water addition 20%-35%.

[0066] attached by figure 1 It can be seen that the vermicelli made with this formula is light brown, the taste of the vermicelli is not rough after cooking, and meets the edible requirements, and because the proportion of the content of the aleurone layer is increased, it can provide more abundant nutrients such as dietary fiber substance.

Embodiment 3

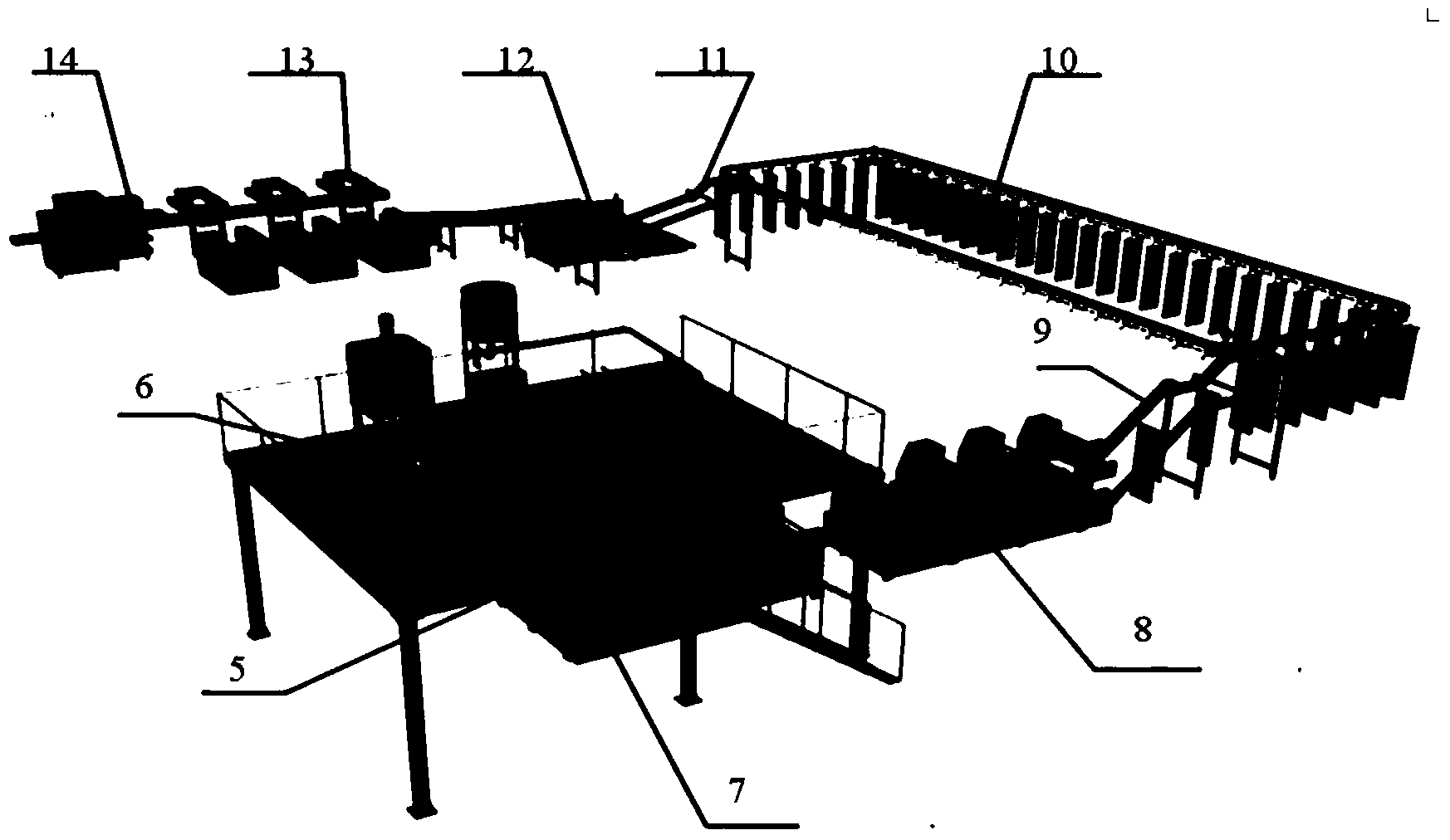

[0068] Below, refer to figure 2 The production process of the aleurone noodles of the present invention will be described. First, the content of the wheat aleurone layer, high-gluten flour, gluten powder, xanthan gum, and vitamin C mixture are sent into the dough mixer 6 by the feeder 5 and mixed to make the aleurone layer flour, and the mixing time is 20 2) After mixing, add salt solution and knead the dough, and ripen; wherein the time for kneading and kneading the dough is 30 minutes; 3) After the kneading, the dough is sent to the compound press 7 and the continuous press 8, and the dough is rolled into a predetermined specification ; Wherein the forming process of the noodle band is as follows: first rolled into a 3.5mm thick noodle band, then through multiple calendering, finally pressed into a 1.0mm thick noodle band. 4) After the noodle band is formed, it is cut into strips and cut off at the end of the continuous press 8; 5) After the dried noodles are formed, it is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com