Drying method and equipment capable of realizing concentrated dehumidification, vertical alternate air-blowing and hot air recycling

A technology of drying equipment and hot air, applied in lighting and heating equipment, drying, drying machines, etc., can solve the problems of inconsistent drying, waste of heat and energy, and high drying cost, and achieve improved drying efficiency and consistent drying degree , good drying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

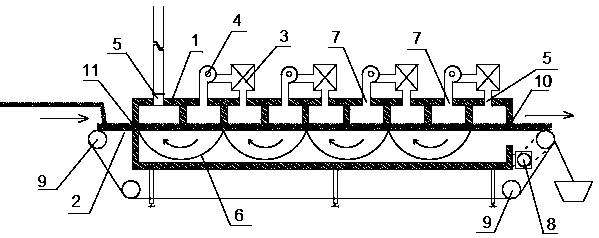

[0023] Example 1 Concentrated dehumidification, alternate up and down blowing, hot air recovery and reuse drying method

[0024] The present invention provides a drying method of centralized dehumidification, alternating blowing up and down, and all the hot air is recycled and reused. The dry hot air passes through the last chamber at the 10 outlets to heat and dry the product, and then passes through the adjacent chamber in the opposite direction. The same heating and drying process is carried out in each chamber, and finally the first chamber at the feed port 11 is discharged outside the workshop to realize centralized dehumidification and all hot air can be recycled and reused.

[0025] Specifically, the dry air is heated from the last drying chamber at the discharge port 10 of the drying equipment to the set temperature through the heat exchanger 3 and then sucked in by the centrifugal fan 4 and blows down through the object to be dried for heating and drying. Dry. After ...

Embodiment 2

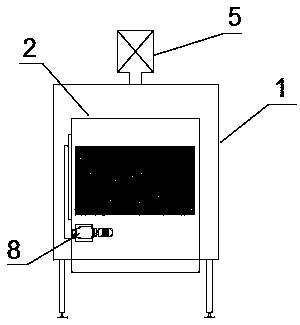

[0026] Example 2 Concentrated dehumidification, alternate up and down blowing, hot air recovery and reuse drying equipment

[0027] Such as Figure 1-2 As shown, the present invention provides a drying equipment for centralized dehumidification, alternate blowing up and down, and hot air recovery and reuse, which includes a shell 1, and a plurality of sequentially adjacent chambers are arranged inside the shell 1, and the chambers The number of is singular.

[0028] The outer top of the casing 1 is provided with a heat exchanger 3 and a fan 4 , and the heat exchanger 3 and the fan 4 are sequentially arranged at intervals on the top of the casing 1 and correspond to different chambers respectively.

[0029] The top of the odd-numbered chambers is provided with a moisture outlet 5 , and the top of the even-numbered chambers is provided with a drying air inlet 7 .

[0030] One side of the housing 1 is provided with a feed port 11, and the other side of the housing 1 is provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com