Circumfluent cooling dehumidifying barn

A cooling and dehumidification technology for granaries, applied in the field of granaries, can solve problems such as dead angles and incomplete ventilation, and achieve the effects of saving labor, solving dead angles of ventilation, and uniform drying degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

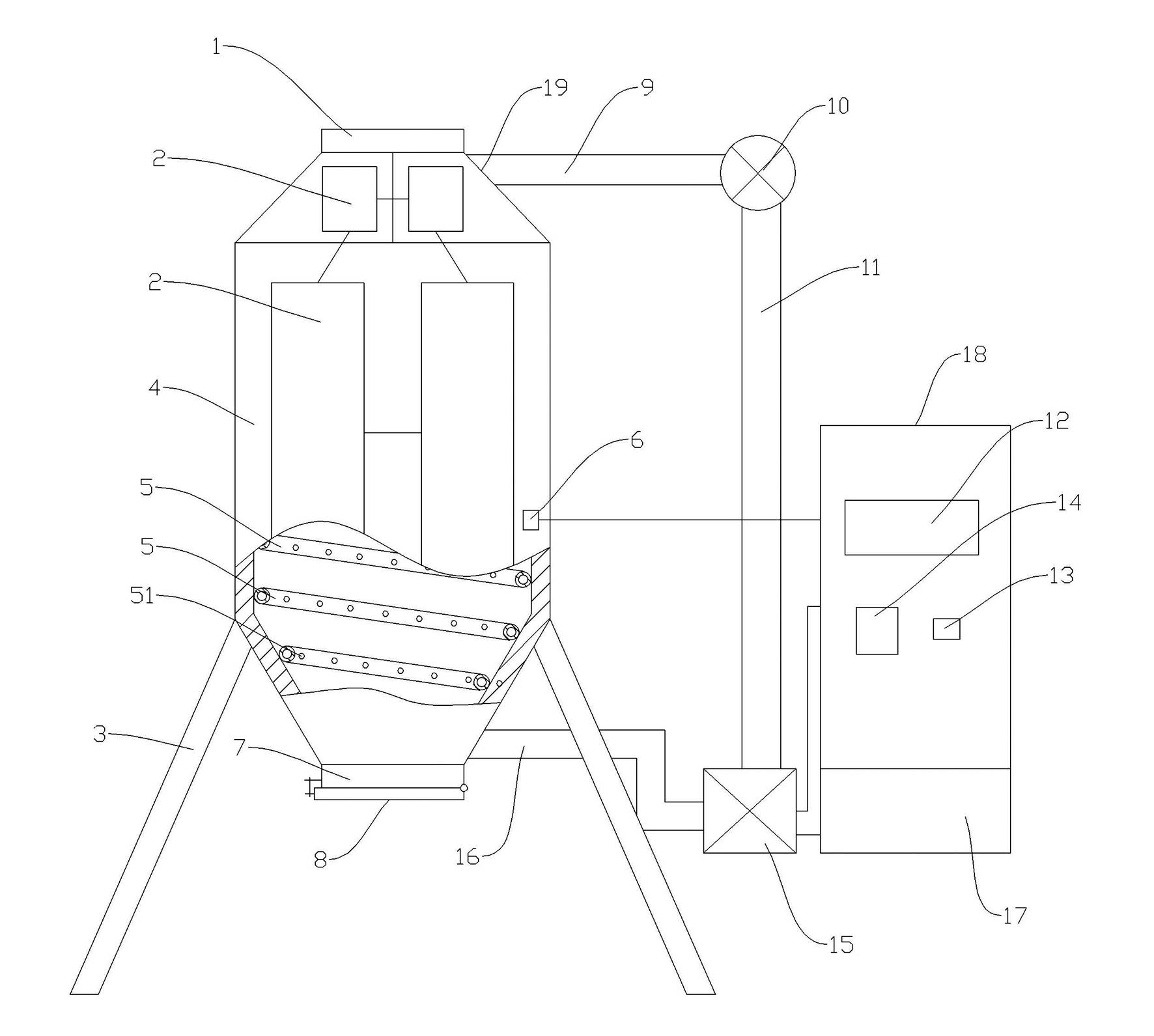

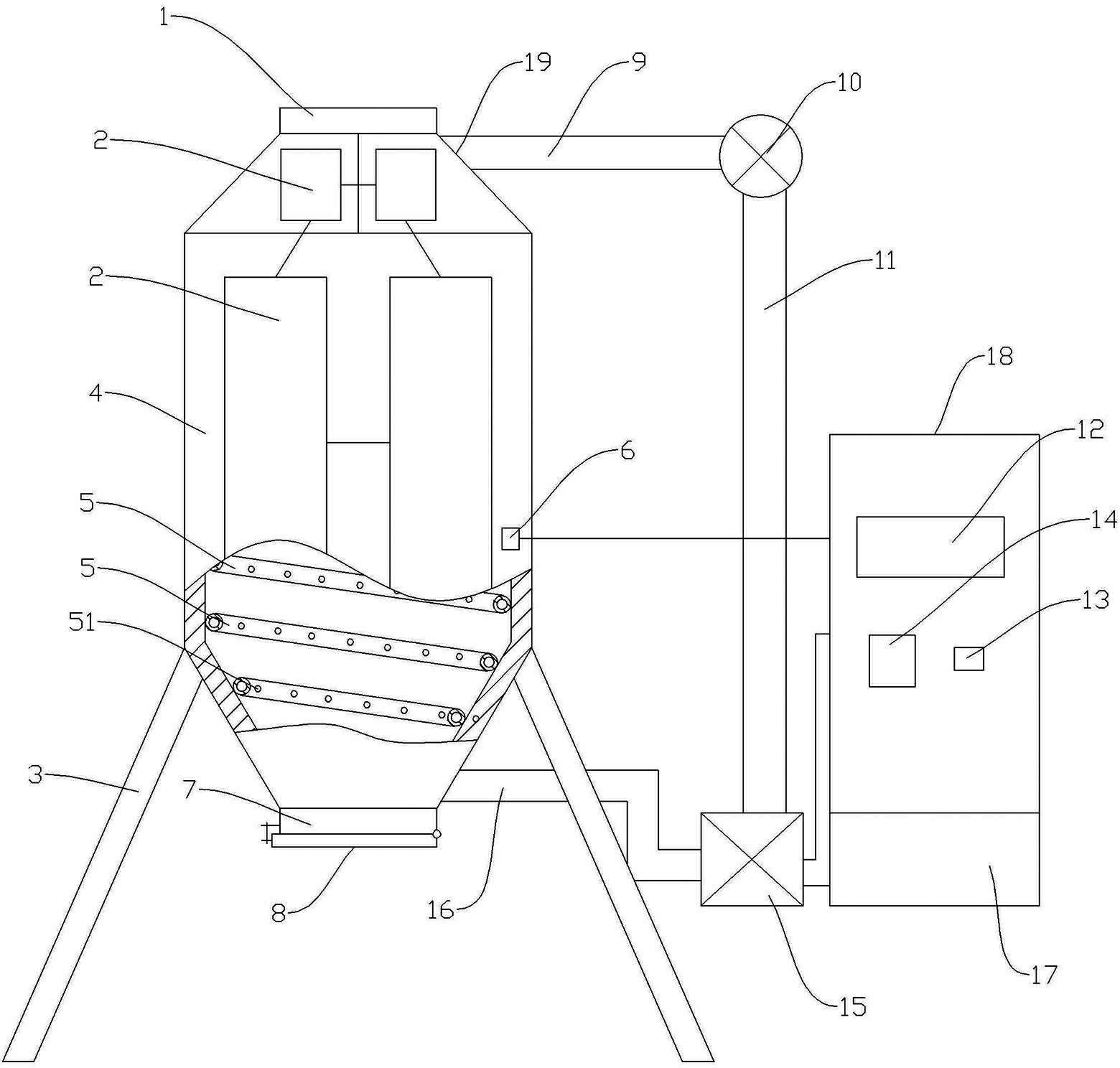

[0014] Such as figure 1 shown. A circulating cooling and dehumidifying granary mainly includes a granary main body, a granary support 3 , a solar panel 2 , and a control cabinet 18 .

[0015] The main body of the granary includes a granary top cover 1 and a silo body 4; the bottom of the silo body is provided with a grain outlet 7 of the silo body, and the grain outlet 7 of the silo body is provided with a grain outlet sealing plate 8; Temperature and humidity probe 6.

[0016] The control cabinet 18 is located outside the warehouse body 4 . The solar panel 2 is fixed on the outer surface of the bin body 4 .

[0017] The inner wall of the bin body 4 is fixed with a spiral ventilation duct 5 spiraling upward around the center line of the bin body. Several through holes 51 are provided on the pipe wall of the spiral ventilation pipe 5 .

[0018] The bottom of the spiral air duct 5 communicates with one end of the air blast duct 16 located outside the warehouse bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com