Inner taper angle magnetic liquid damping vibration absorber

A technology of magnetic liquid and shock absorber, applied in the direction of shock absorber, shock absorber, spring/shock absorber, etc., can solve the problems of scratching, difficult flow of magnetic liquid, inability to be applied, etc., to avoid scratching. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

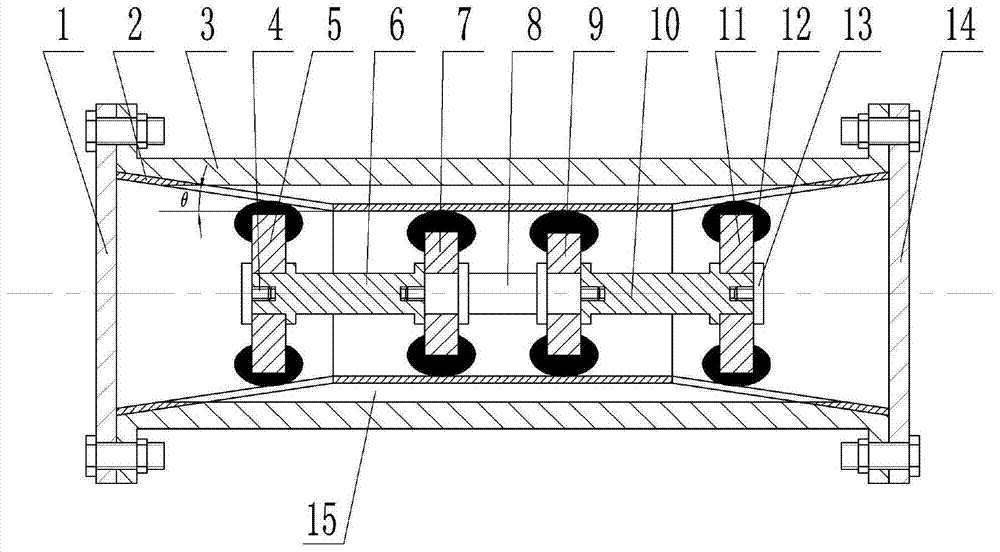

[0030] The present invention will be further described with accompanying drawing as specific embodiment:

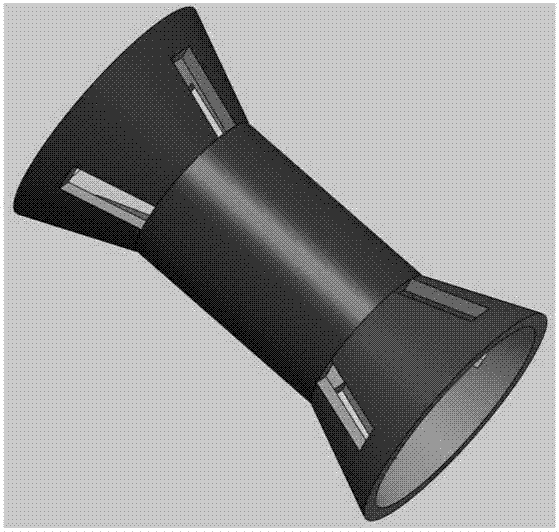

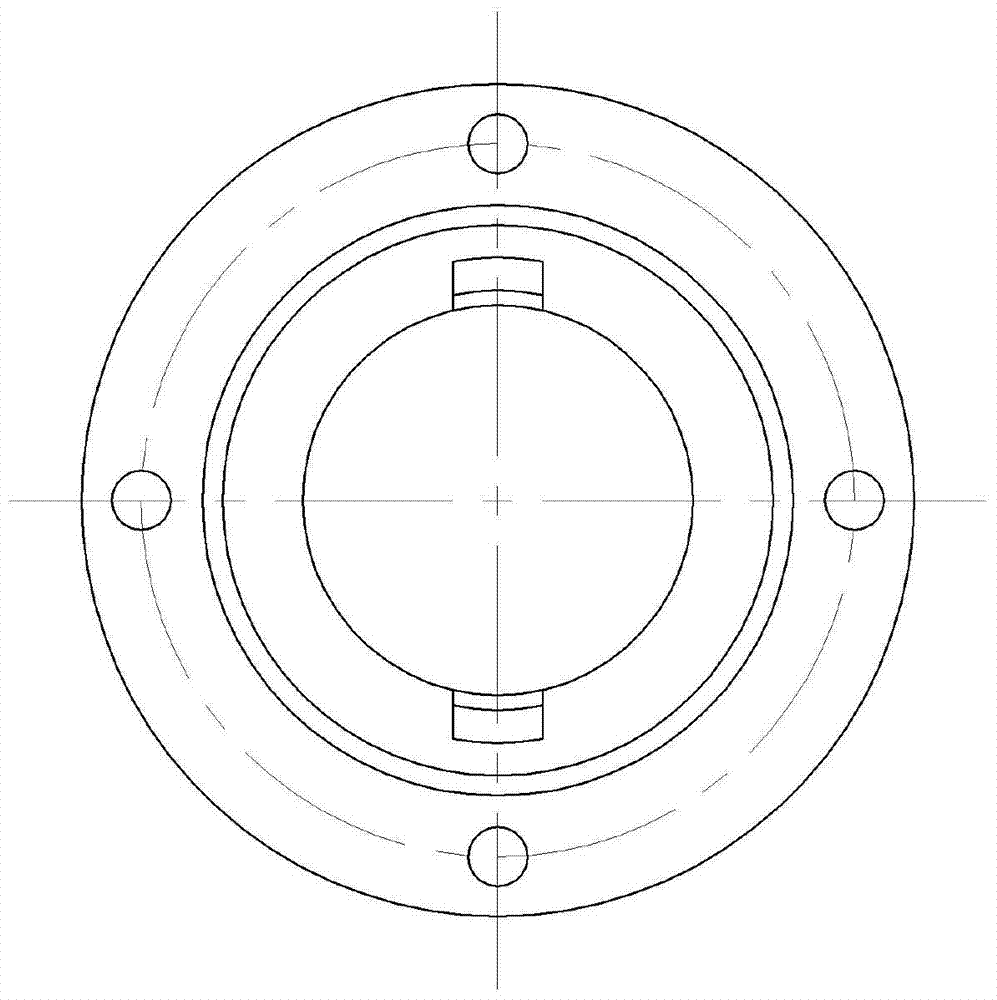

[0031] An inner cone angle magnetic liquid damping shock absorber with an elastic pad, such as figure 1 , the damping device includes: a left end cover 1, an elastic pad 2, a housing 3, a left thread retaining ring 4, a left positioning permanent magnet 5, a left positioning rod 6, a first energy-dissipating permanent magnet 7, a connecting rod 8, a second Energy-consuming permanent magnet 9, right positioning rod 10, right positioning permanent magnet 11, magnetic liquid 12, right screw retaining ring 13, right end cap 14, ventilation groove 15.

[0032] Connections between the parts making up the device:

[0033] First, the elastic pad 2 is fixedly connected with the housing 1 to form a housing with an elastic pad, and the connection method is the bonding method; The permanent magnet 7, the connecting rod 8, the second energy-dissipating permanent magnet 9 and the rig...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com