Smelting furnace

A smelting furnace and furnace cover technology, applied in the field of smelting furnaces, can solve problems affecting the smelting purity and achieve the effect of avoiding scratches

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

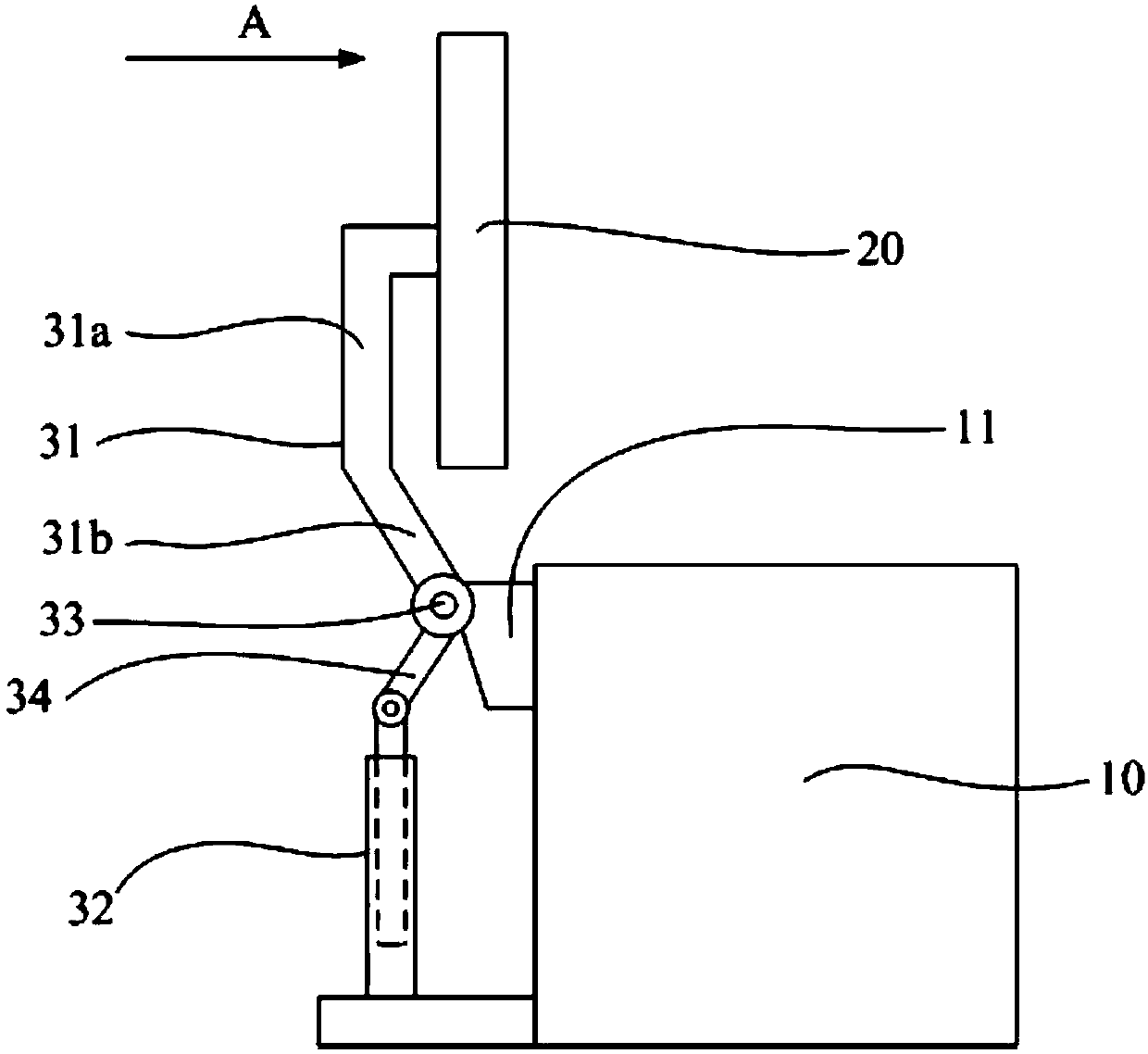

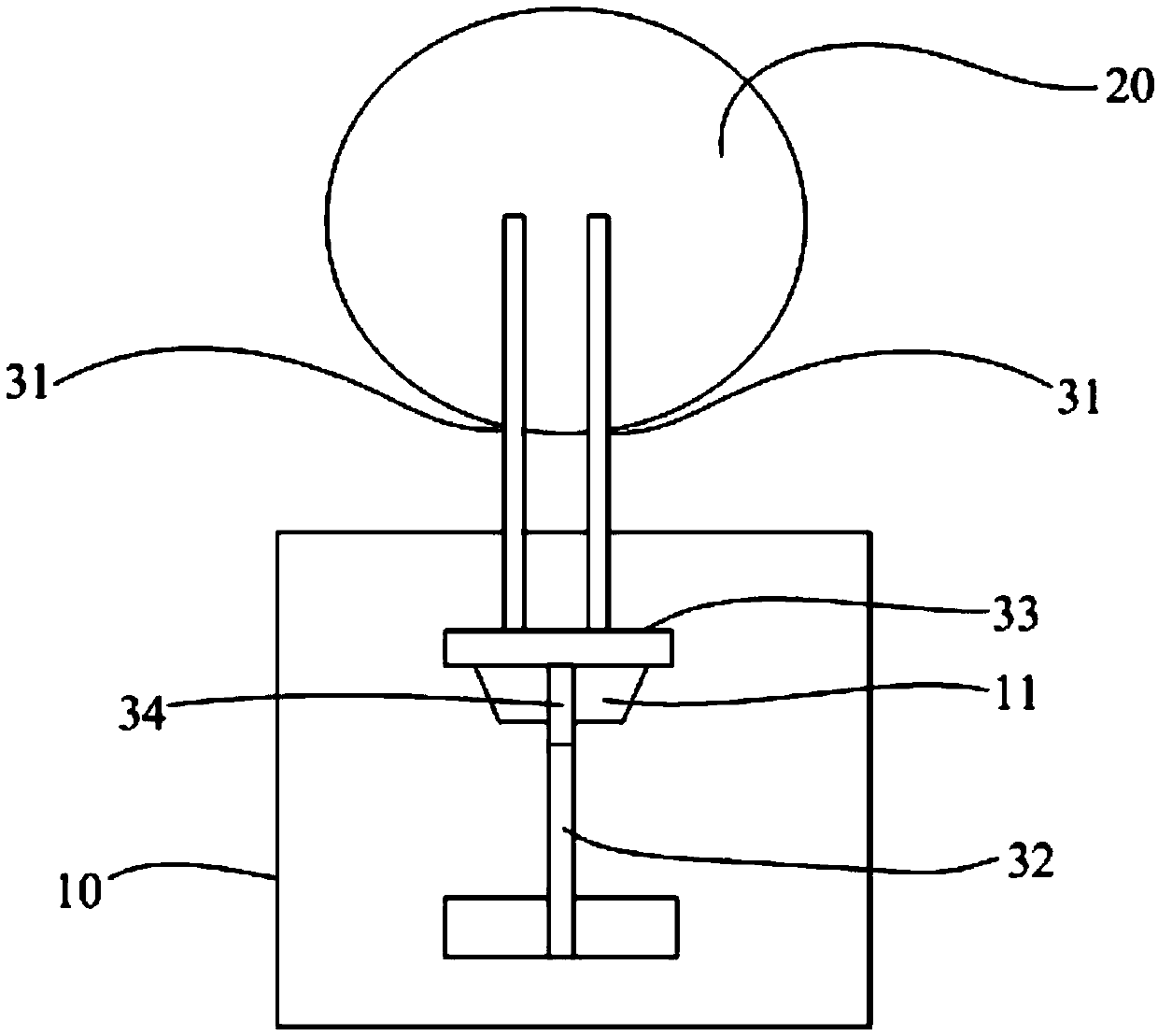

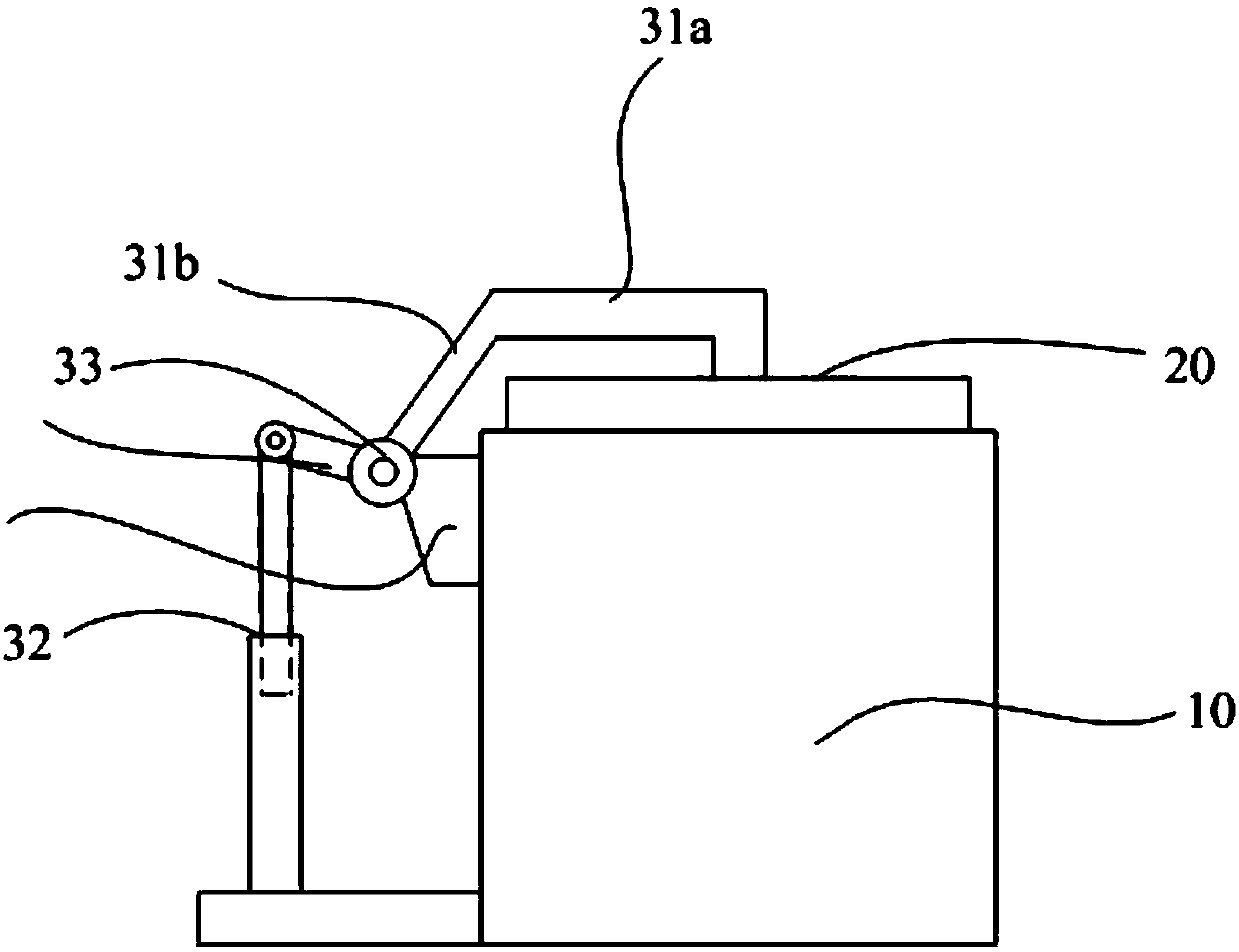

[0020] It can be seen from the background art that during the opening and closing process of the furnace cover of the melting furnace in the prior art, impurities on the main body of the melting furnace will be brought into the melting furnace.

[0021] The analysis found that the furnace cover of the existing smelting furnace is directly fixed on the main body of the smelting furnace. During the opening and closing process, it is always in contact with the main body of the melting furnace, which will cause scratches during the sliding opening and closing process, and will bring impurities on the surface of the furnace body into the melting furnace, thereby affecting the purity of smelting. In order to solve the above problems, the present invention provides a smelting furnace, comprising a smelting furnace main body, a furnace cover, and a hydraulic transmission mechanism, the furnace cover is used to close the opening on the smelting furnace main body, the hydraulic transmiss...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com