Patents

Literature

49results about How to "Realize the function of limit fixation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

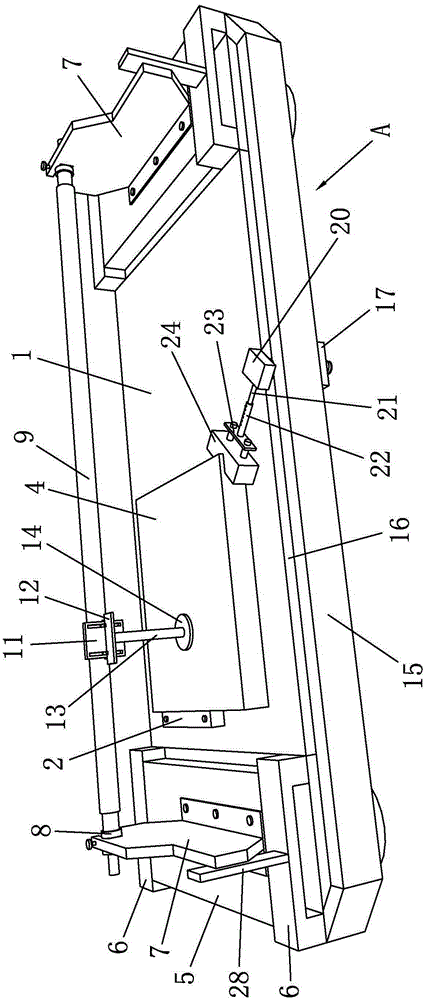

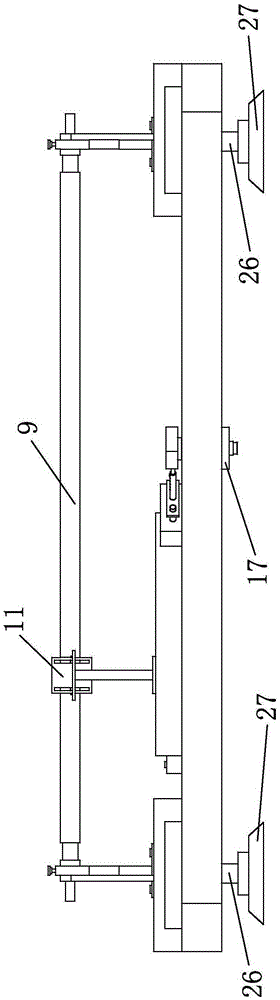

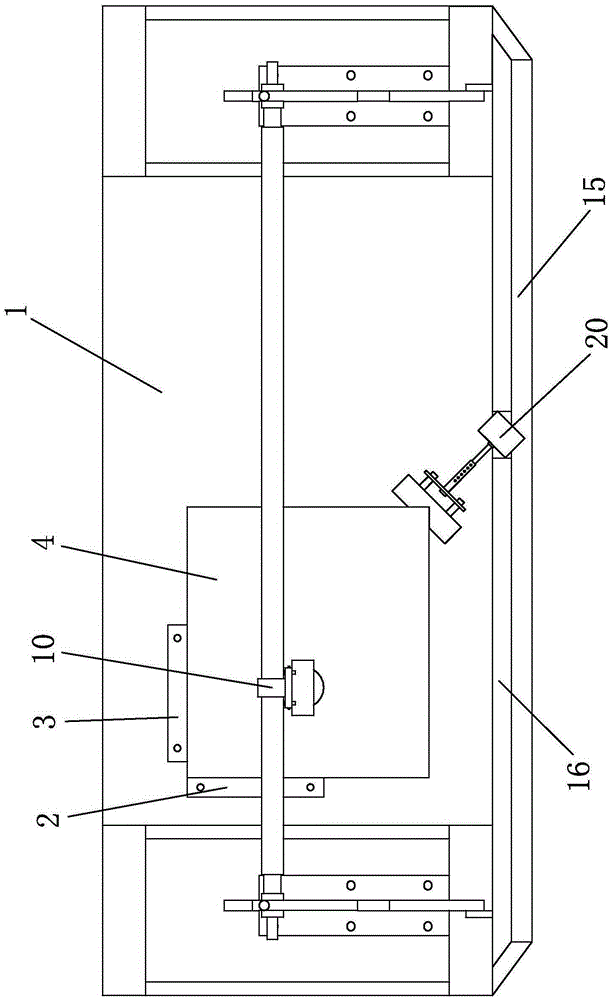

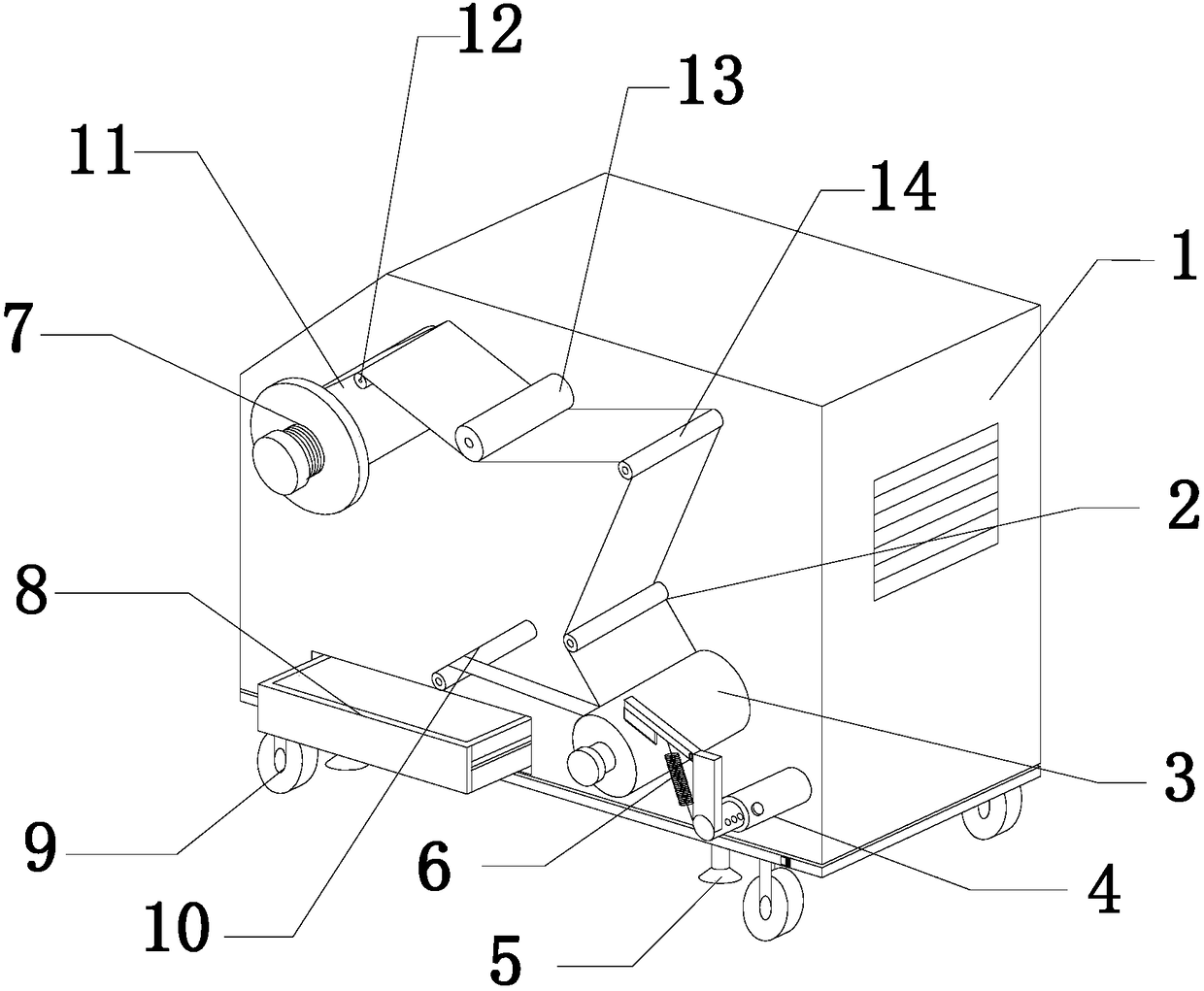

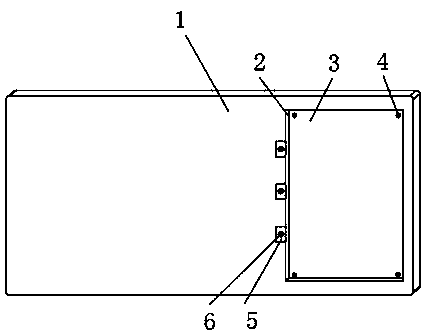

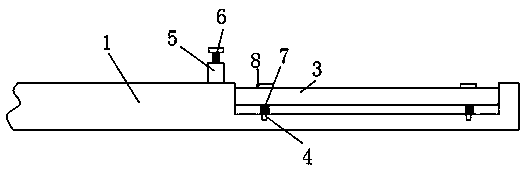

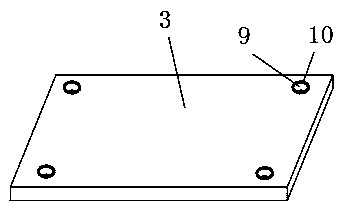

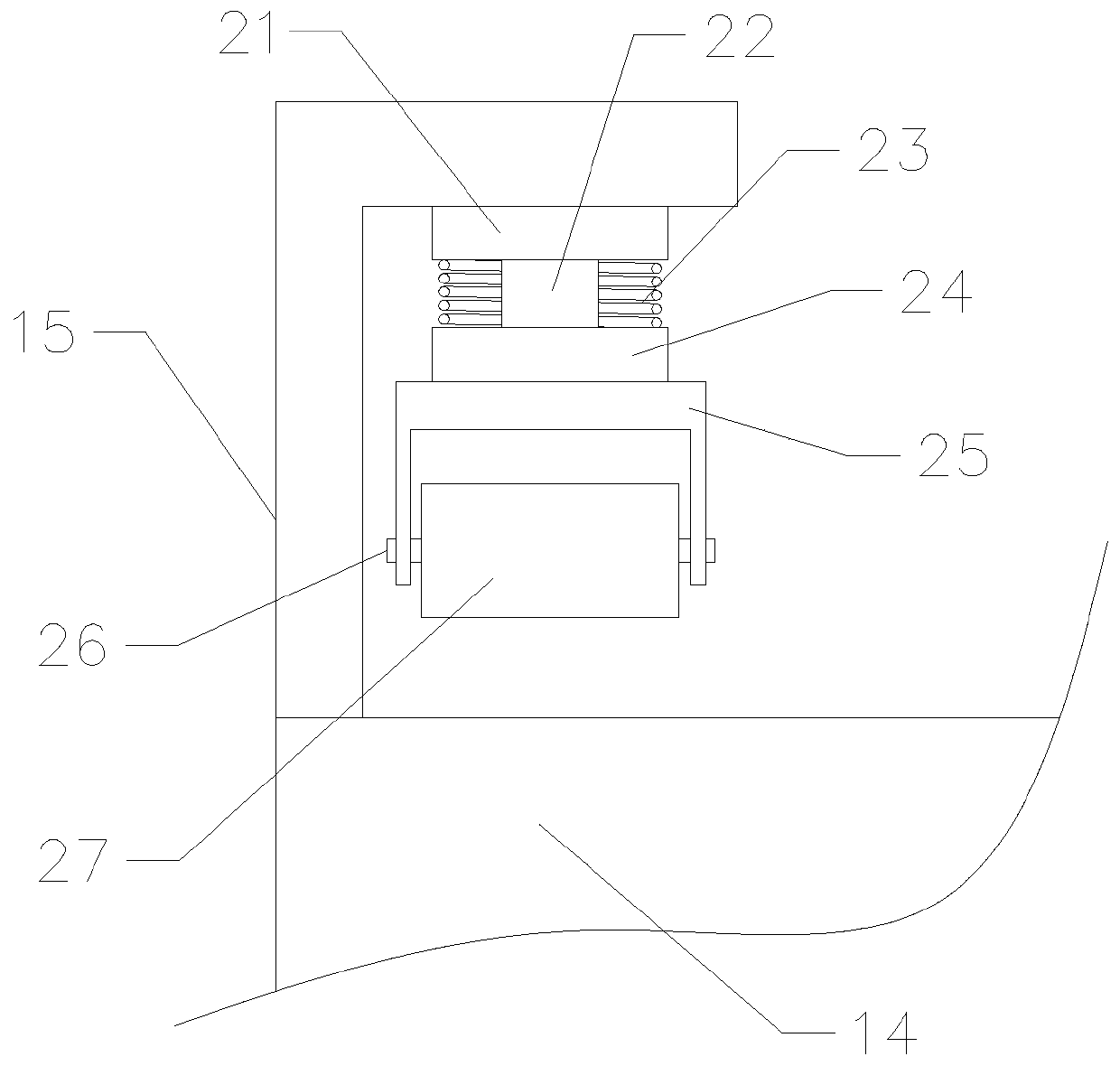

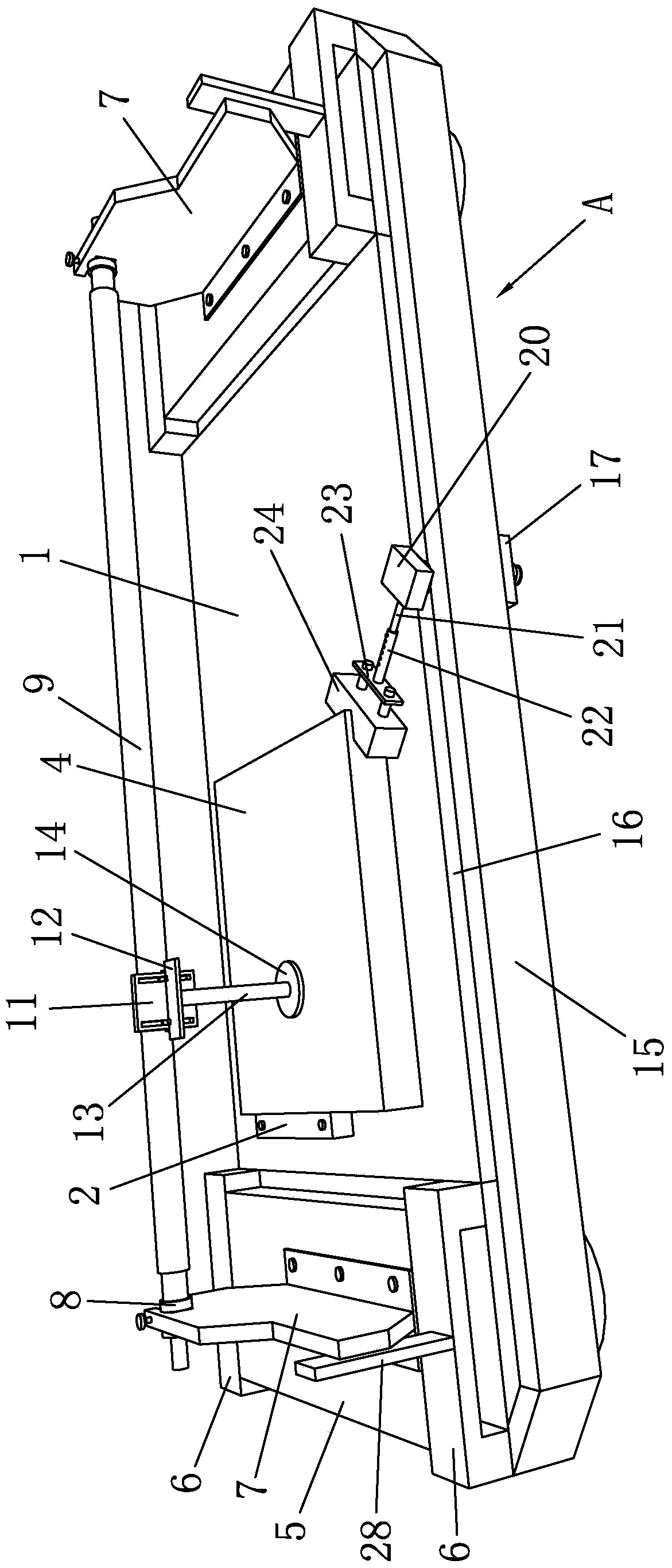

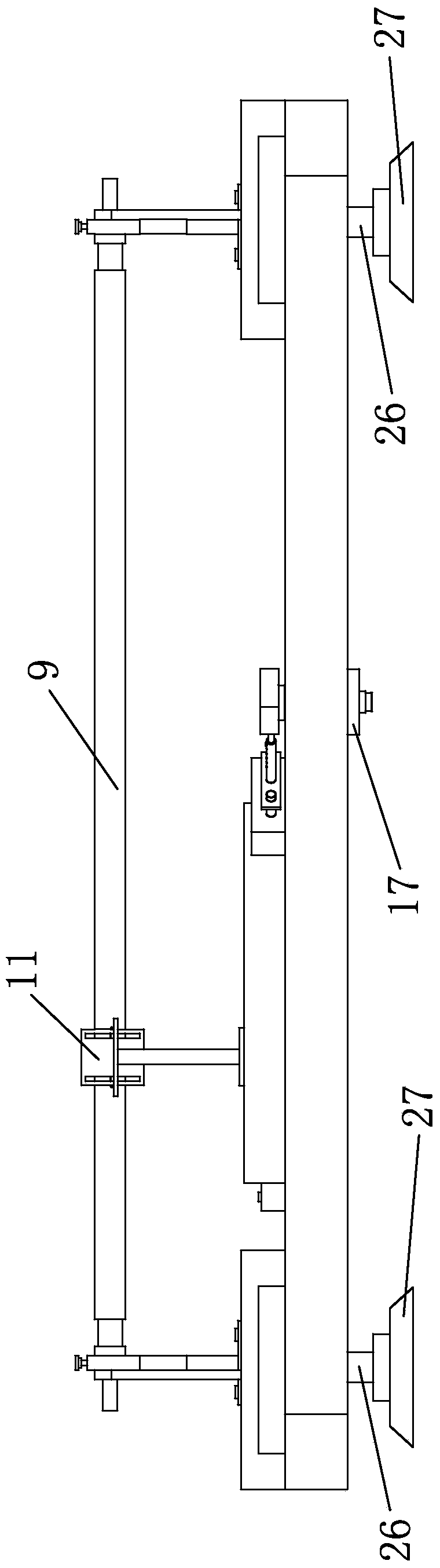

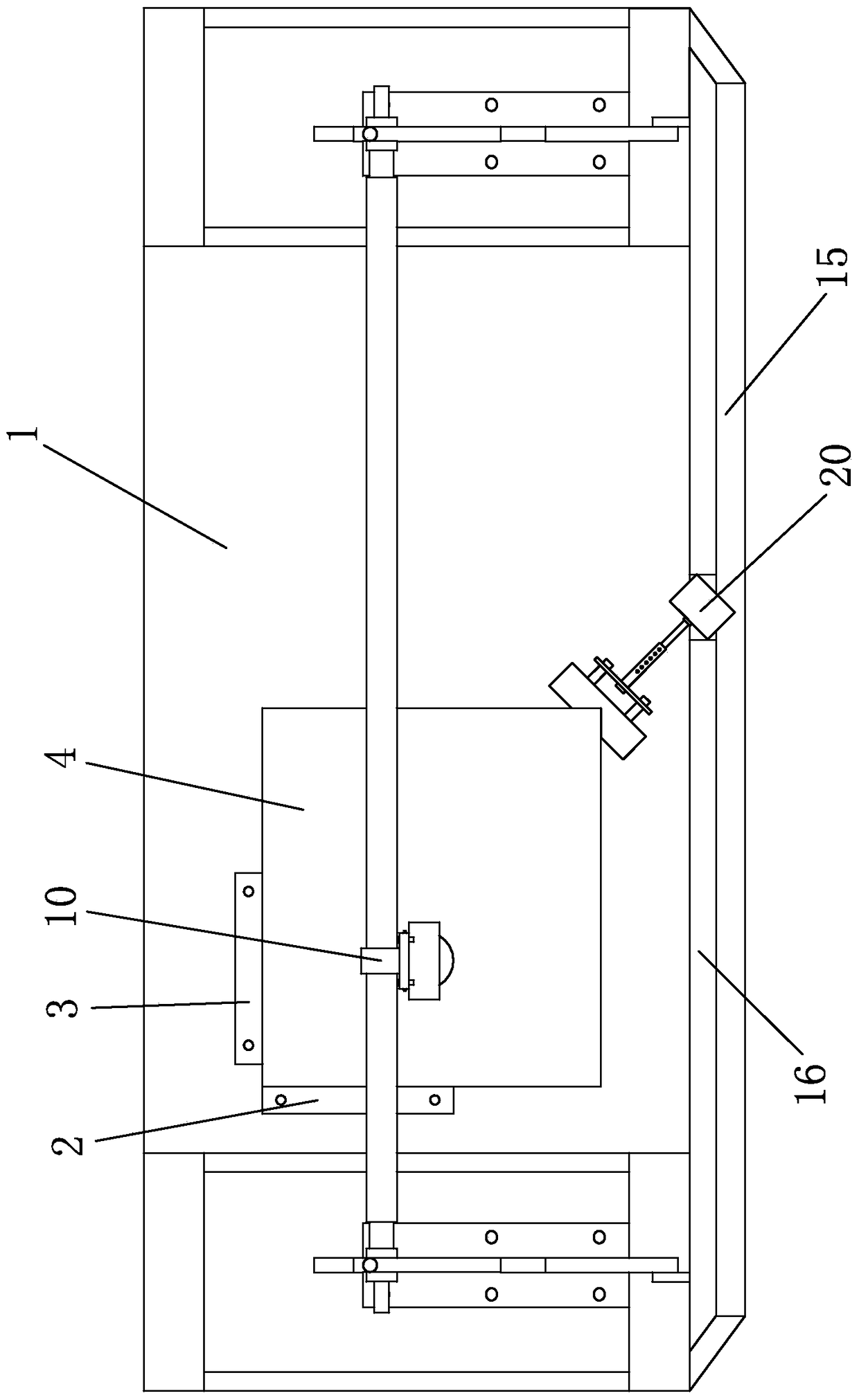

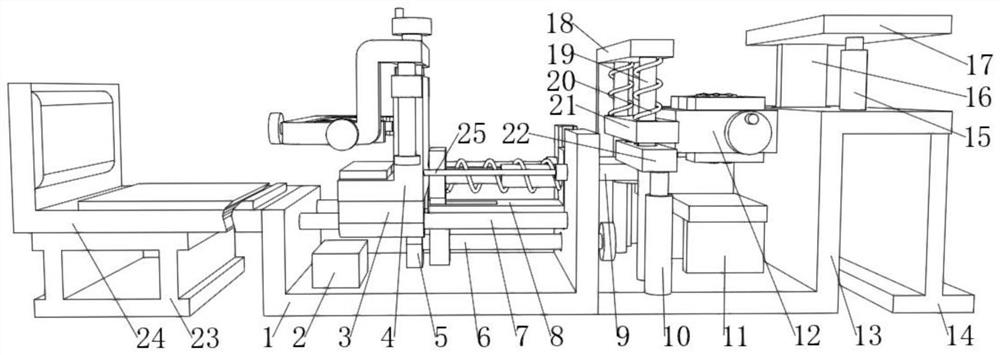

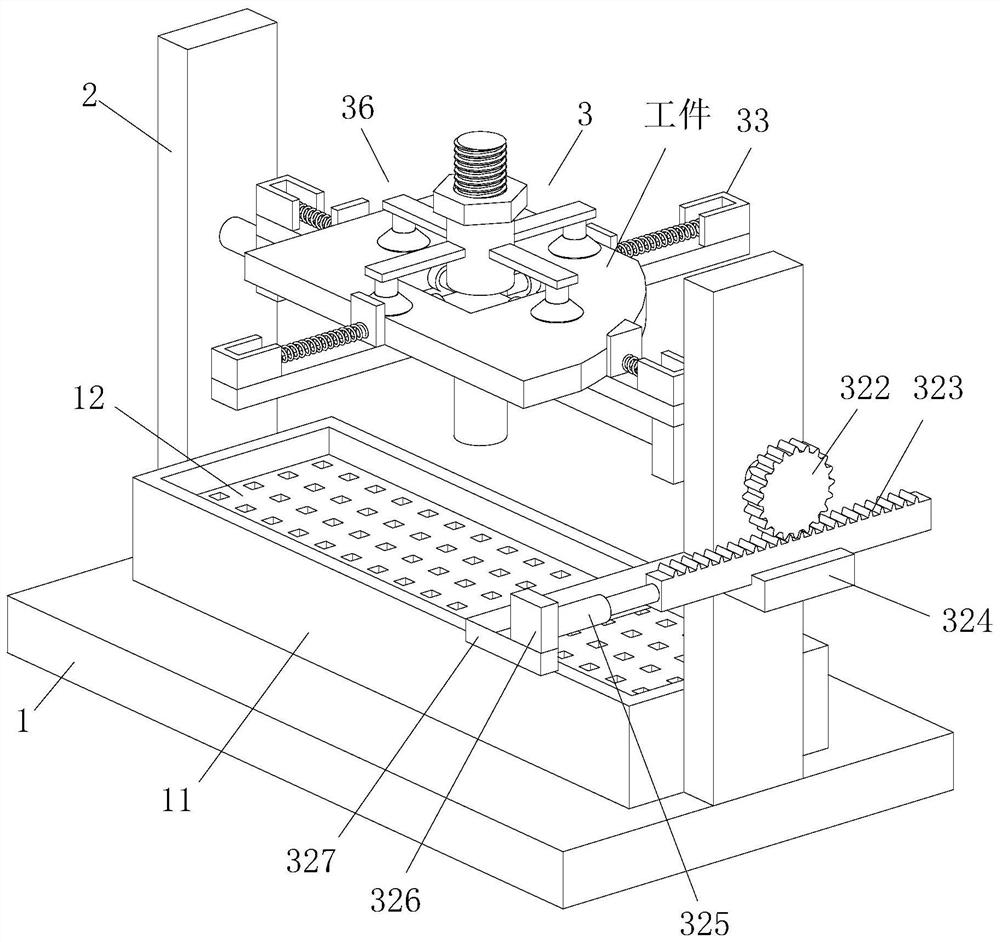

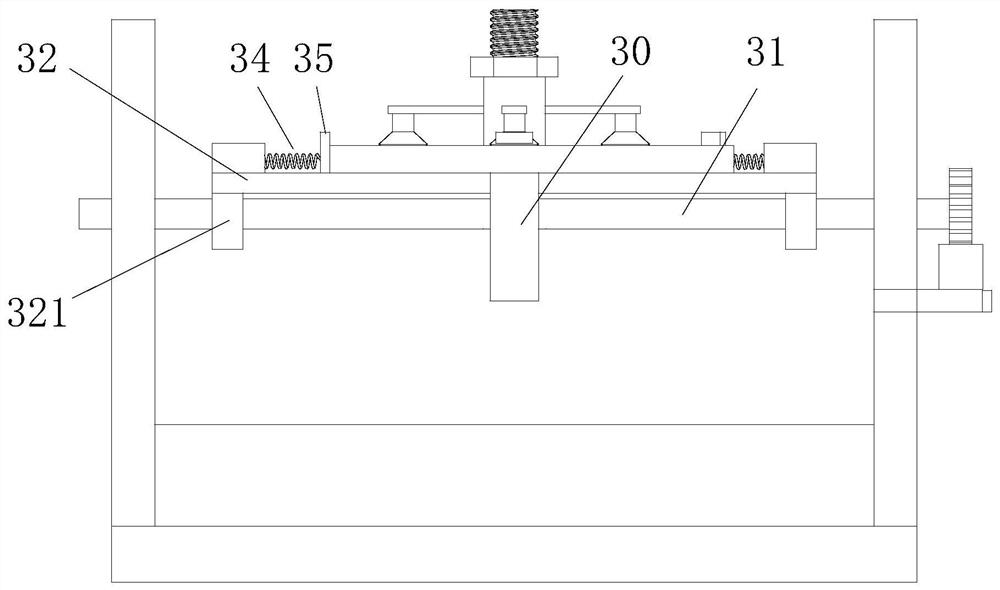

Location-fixation mechanism for wood plate drilling

ActiveCN105415451AReduce structural damageRealize the function of limit fixationDrilling machinesSlide plateDrill hole

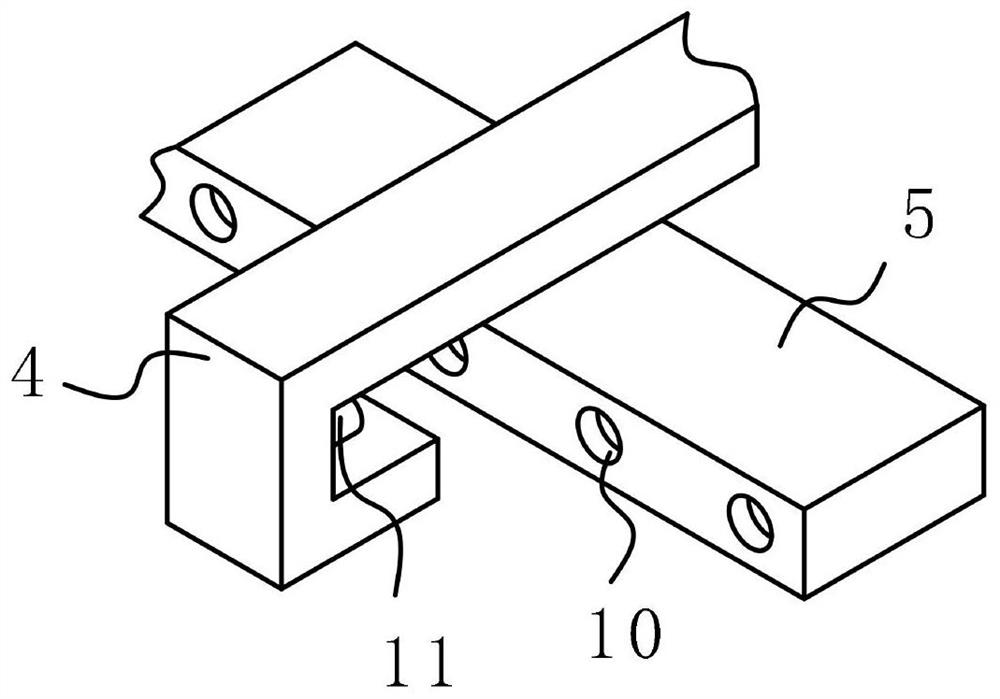

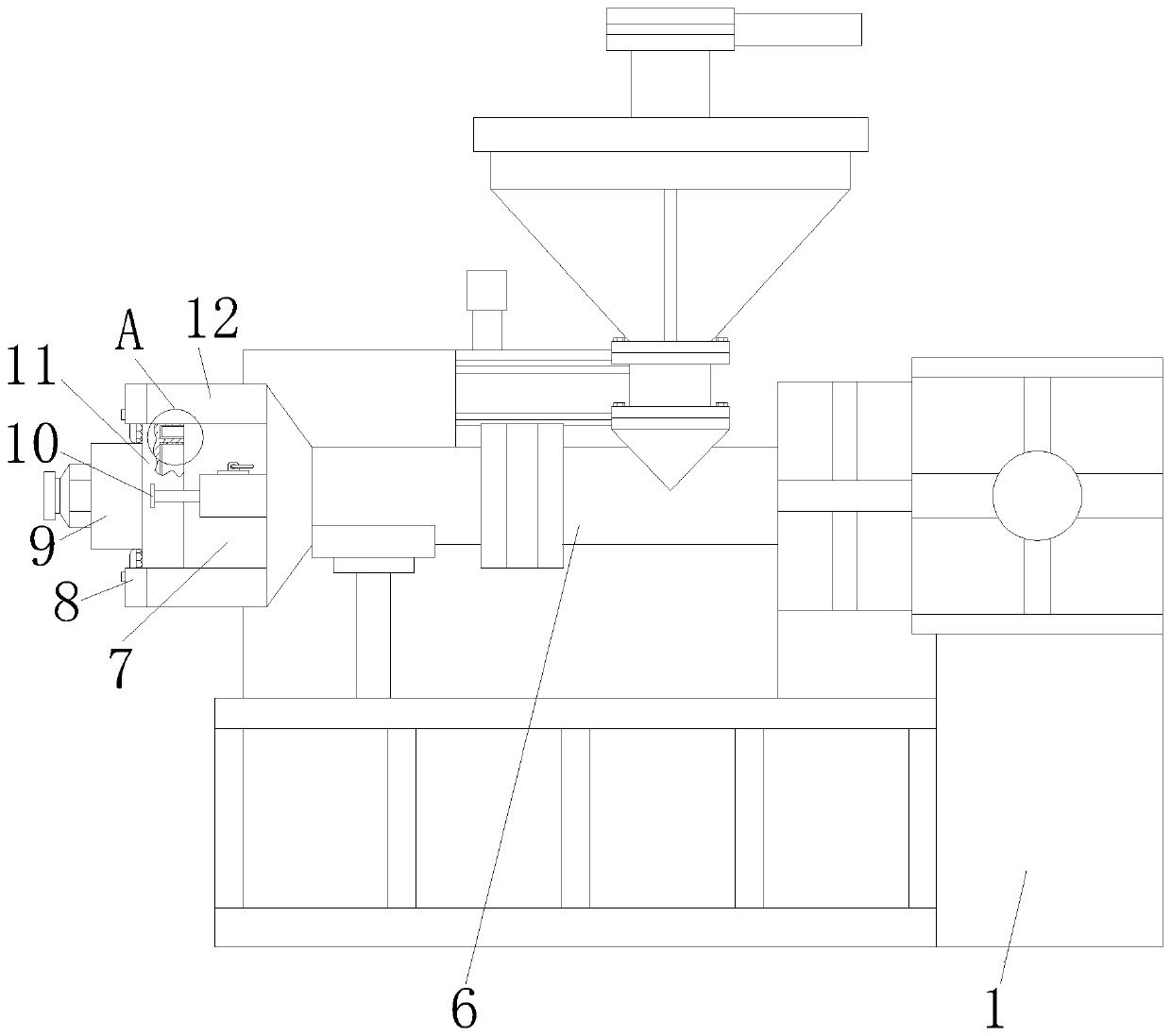

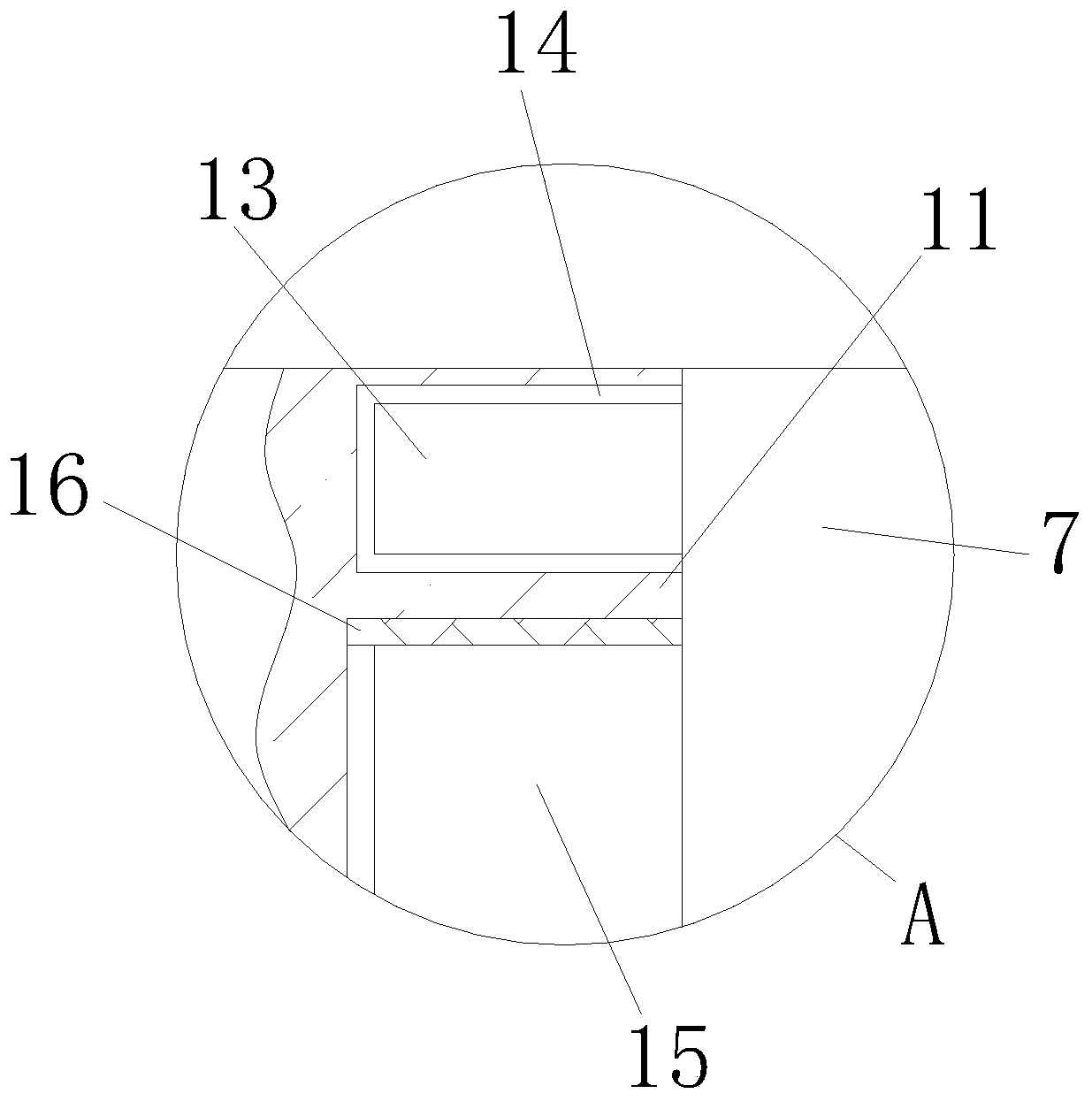

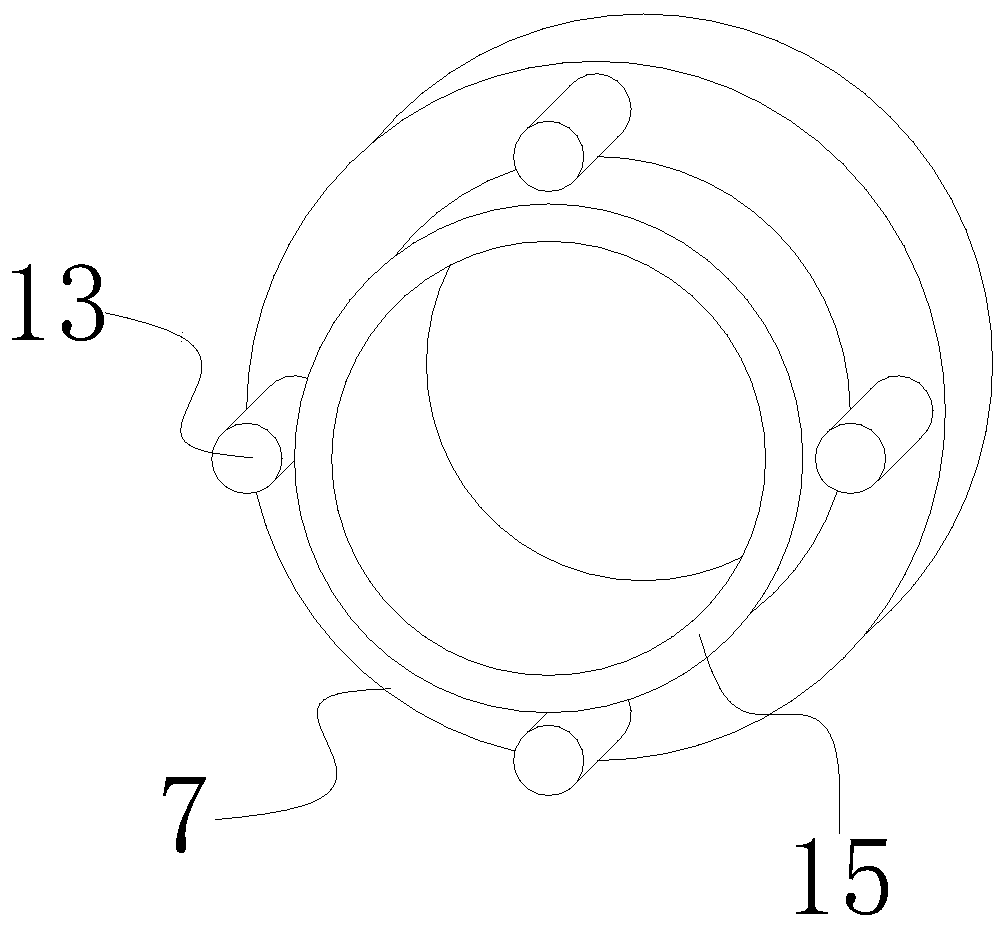

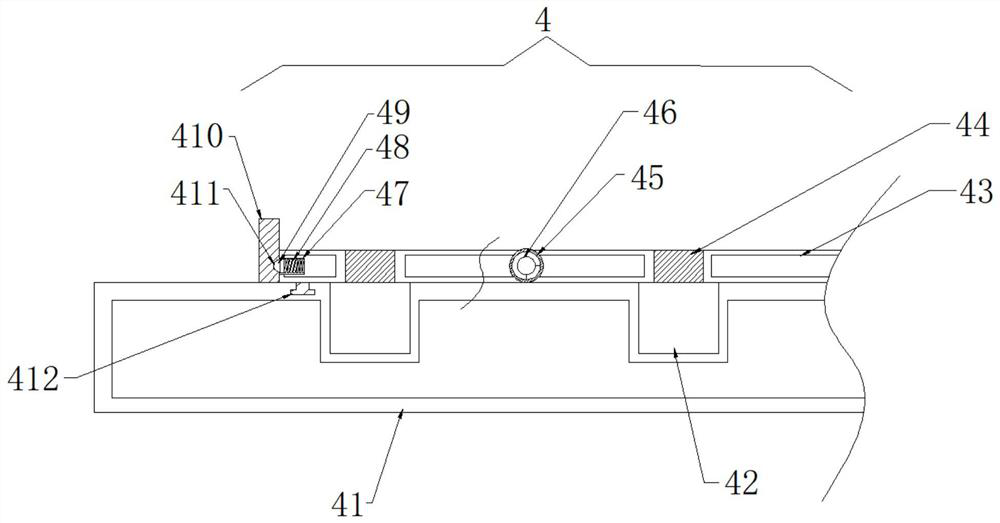

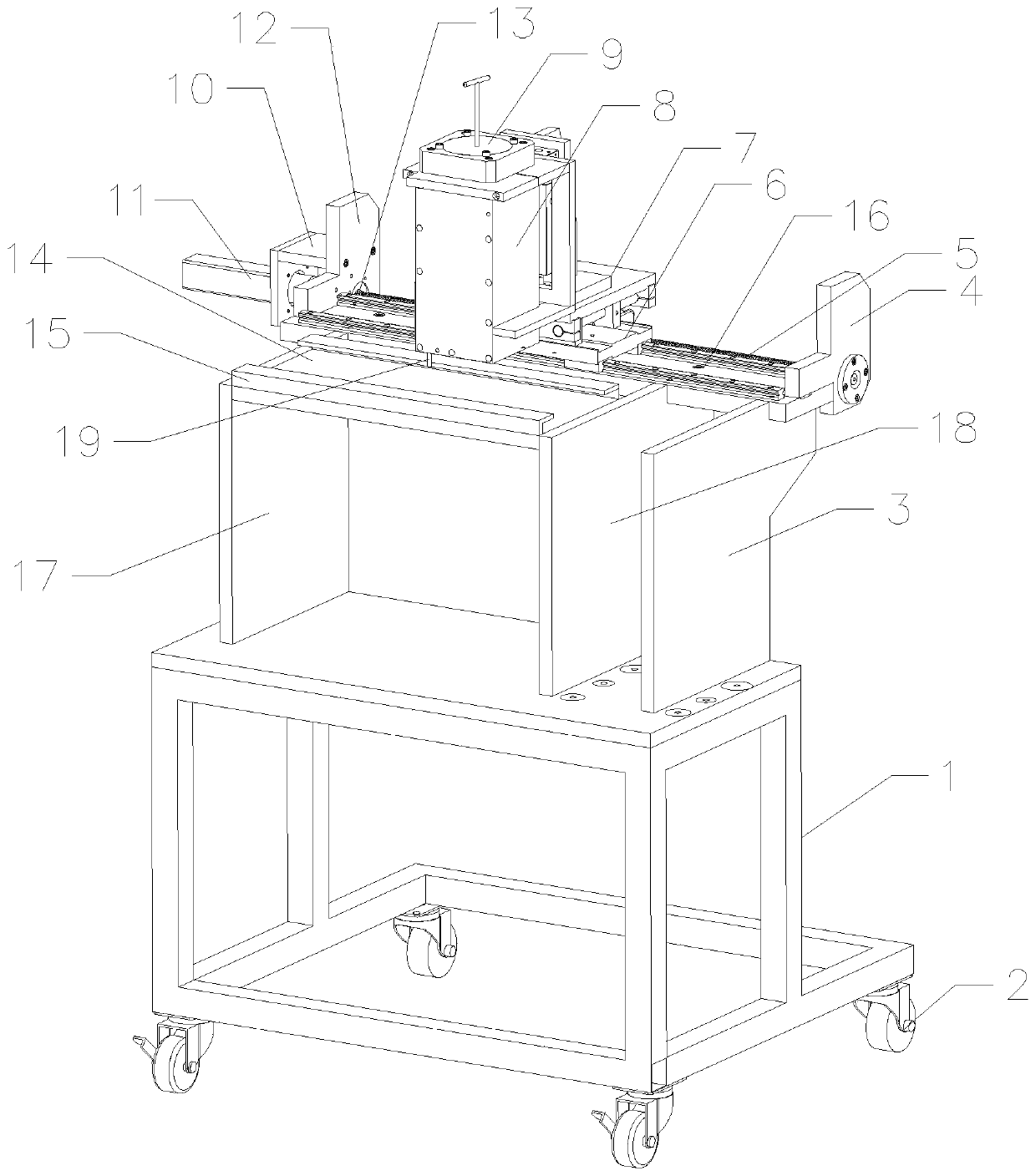

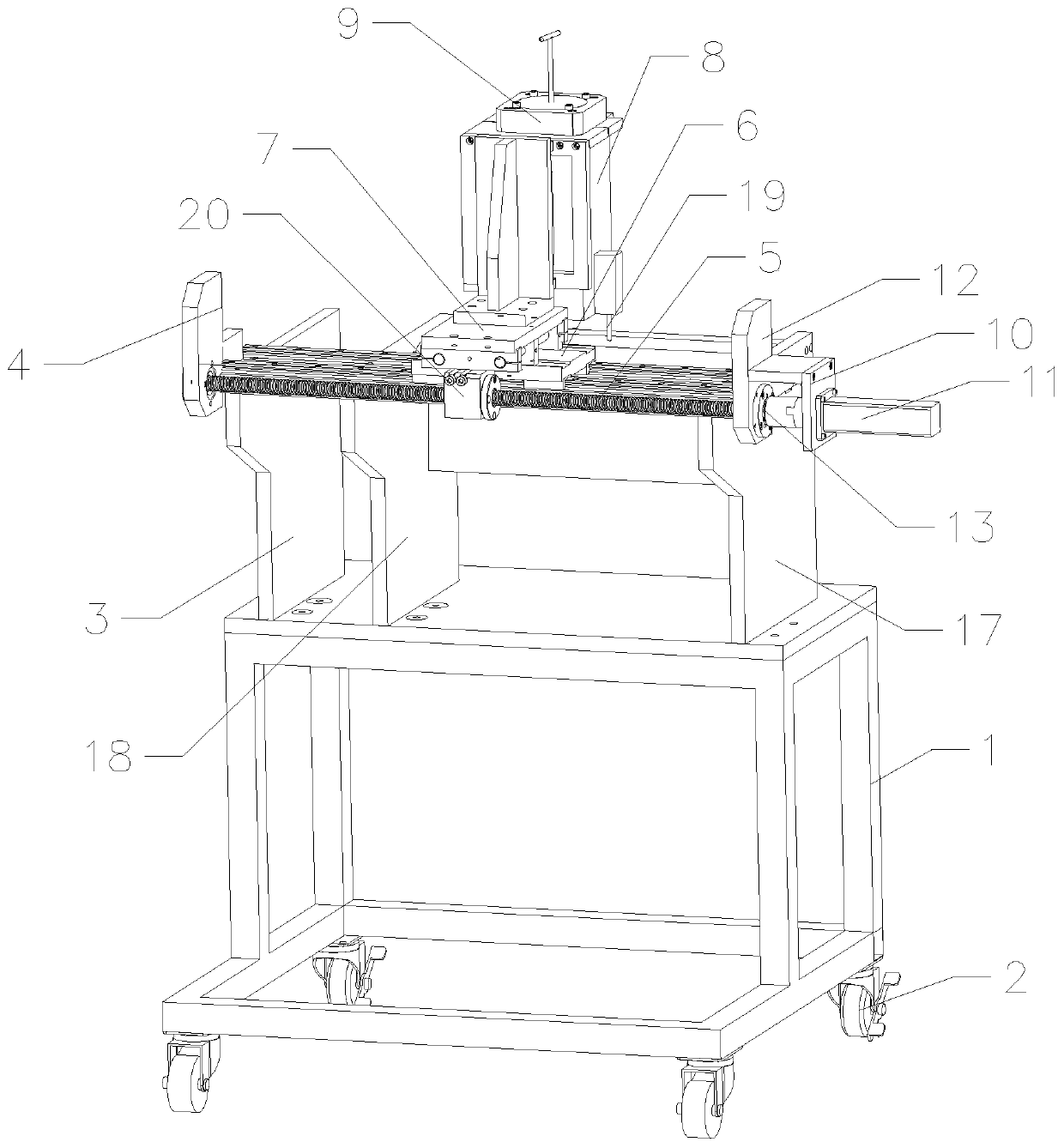

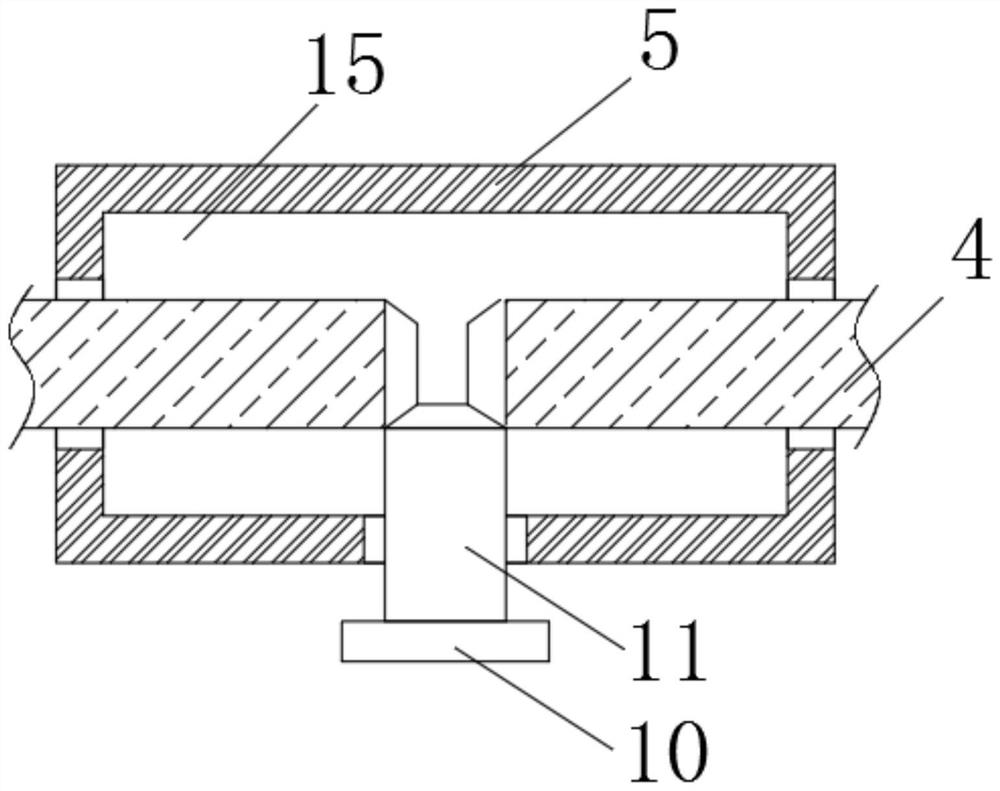

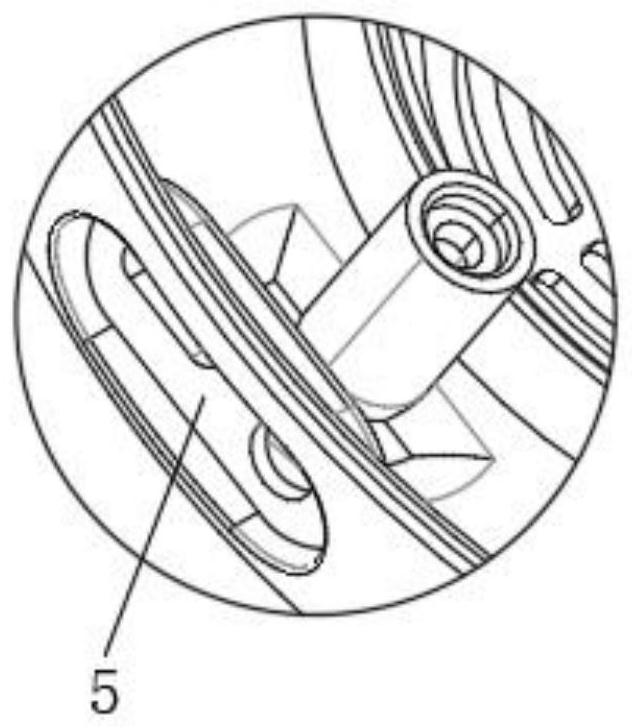

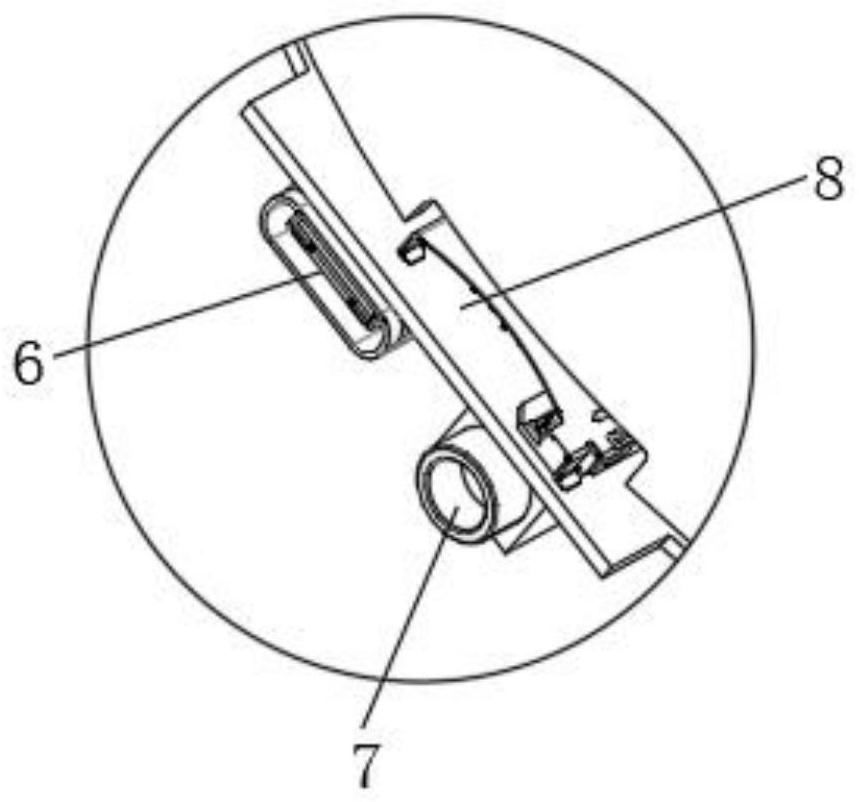

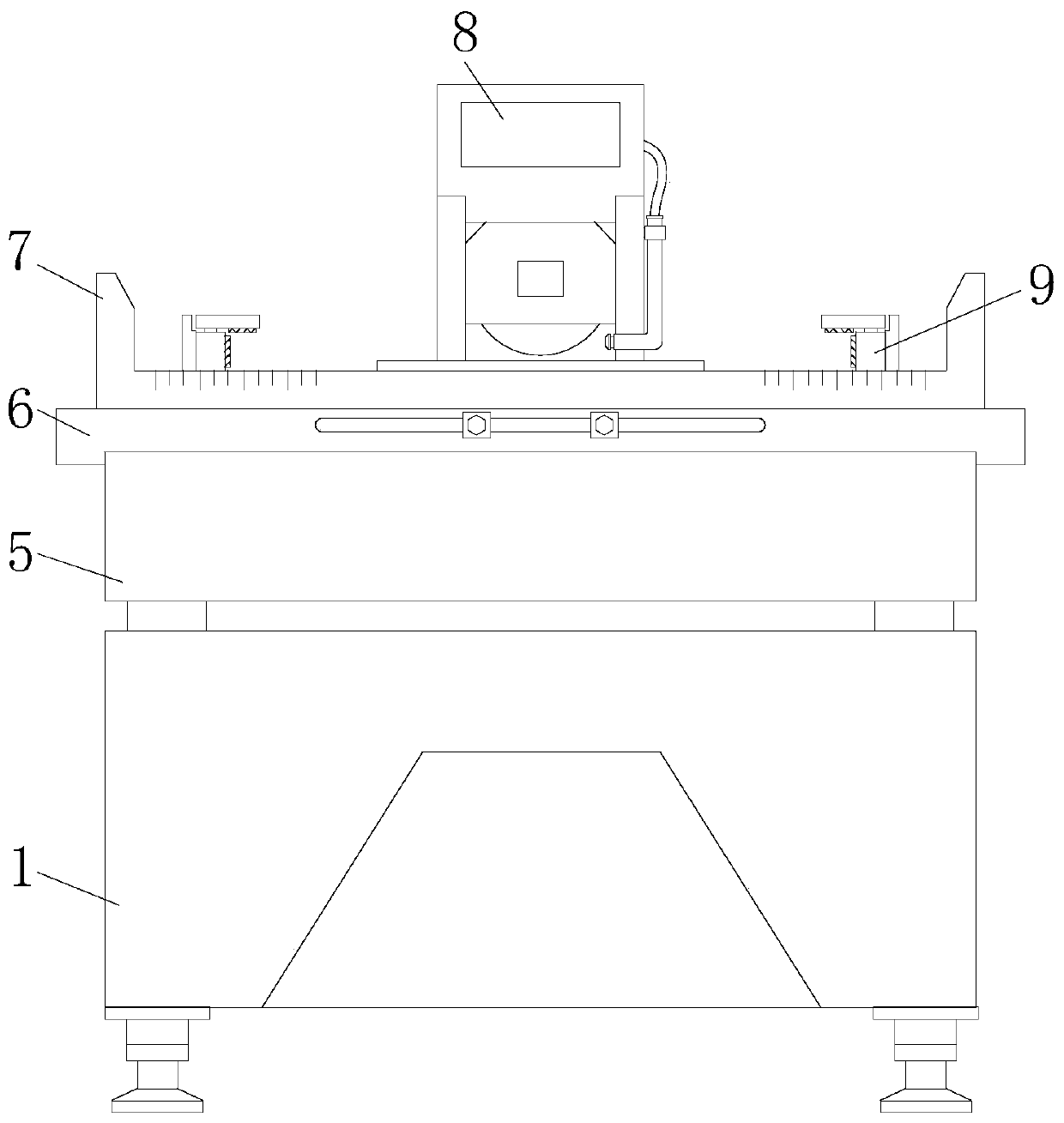

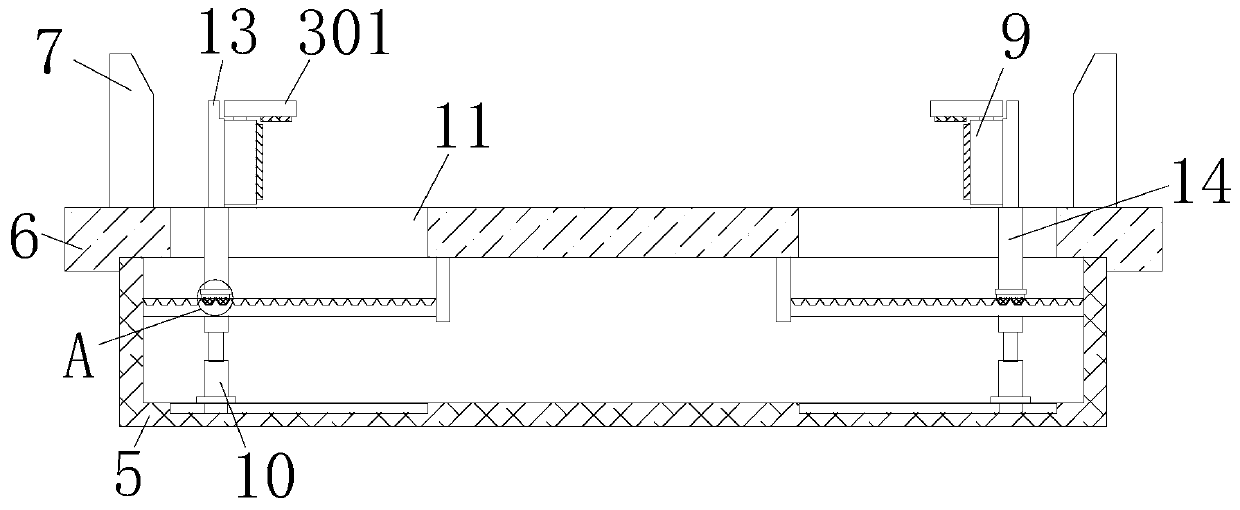

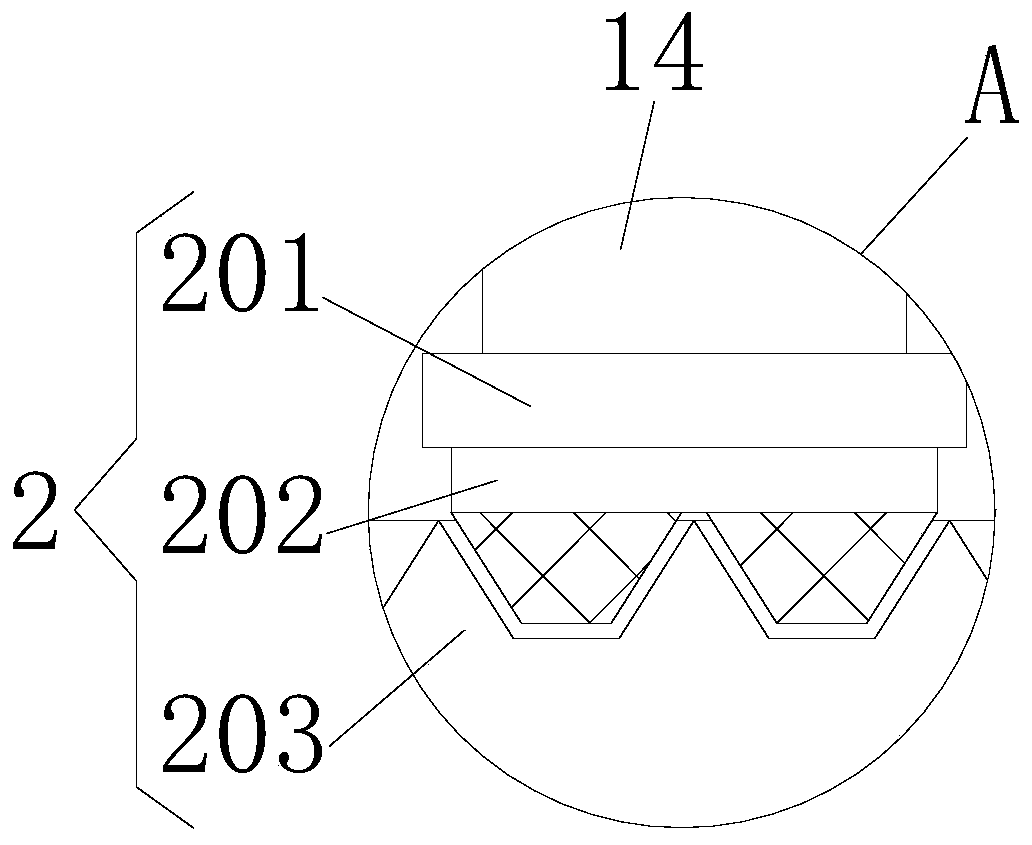

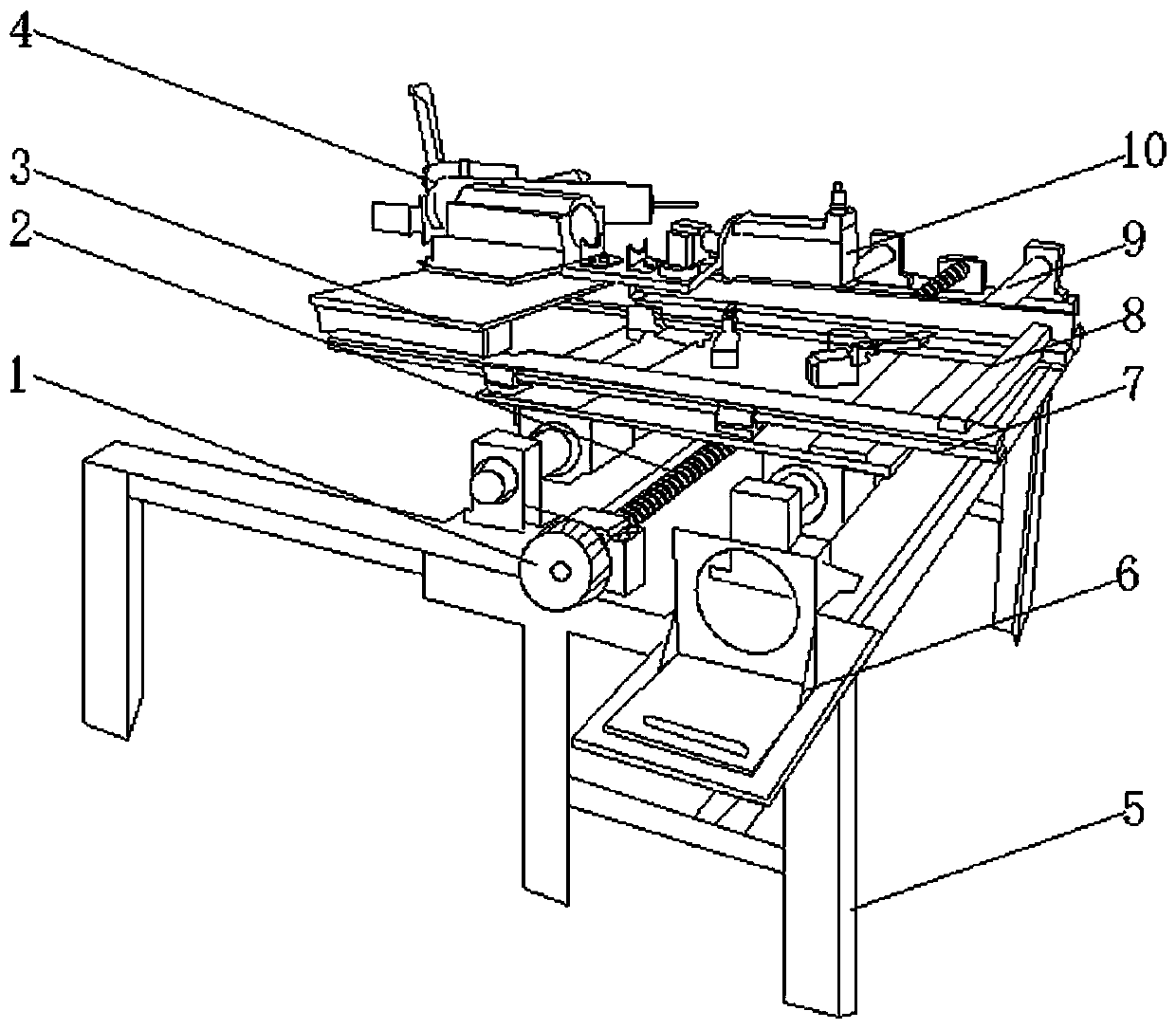

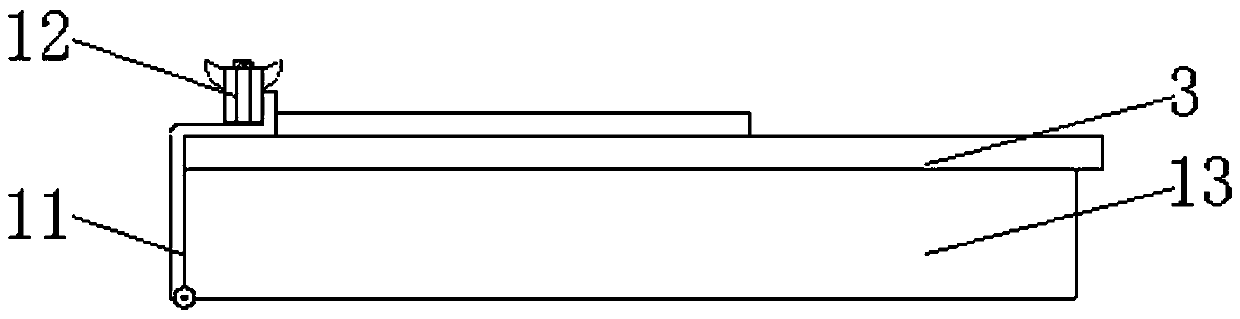

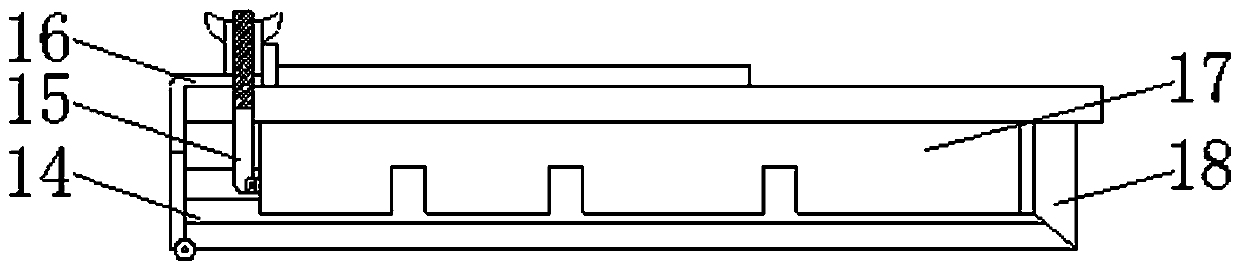

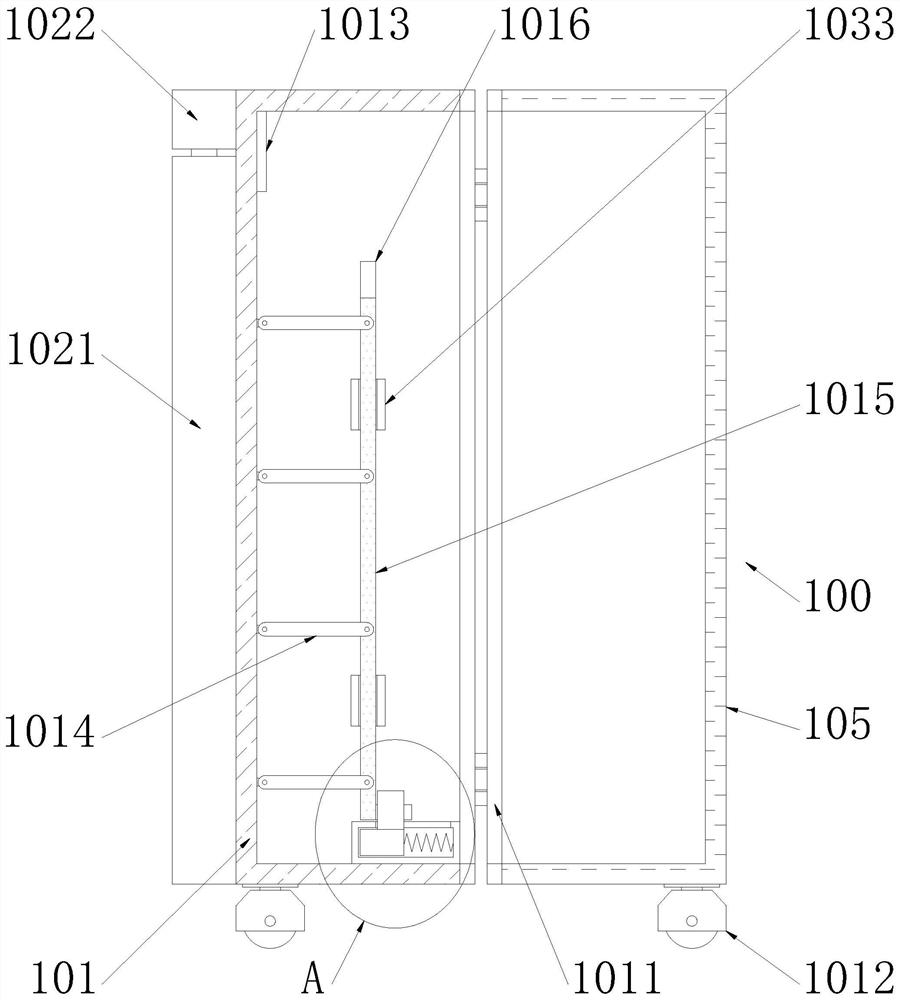

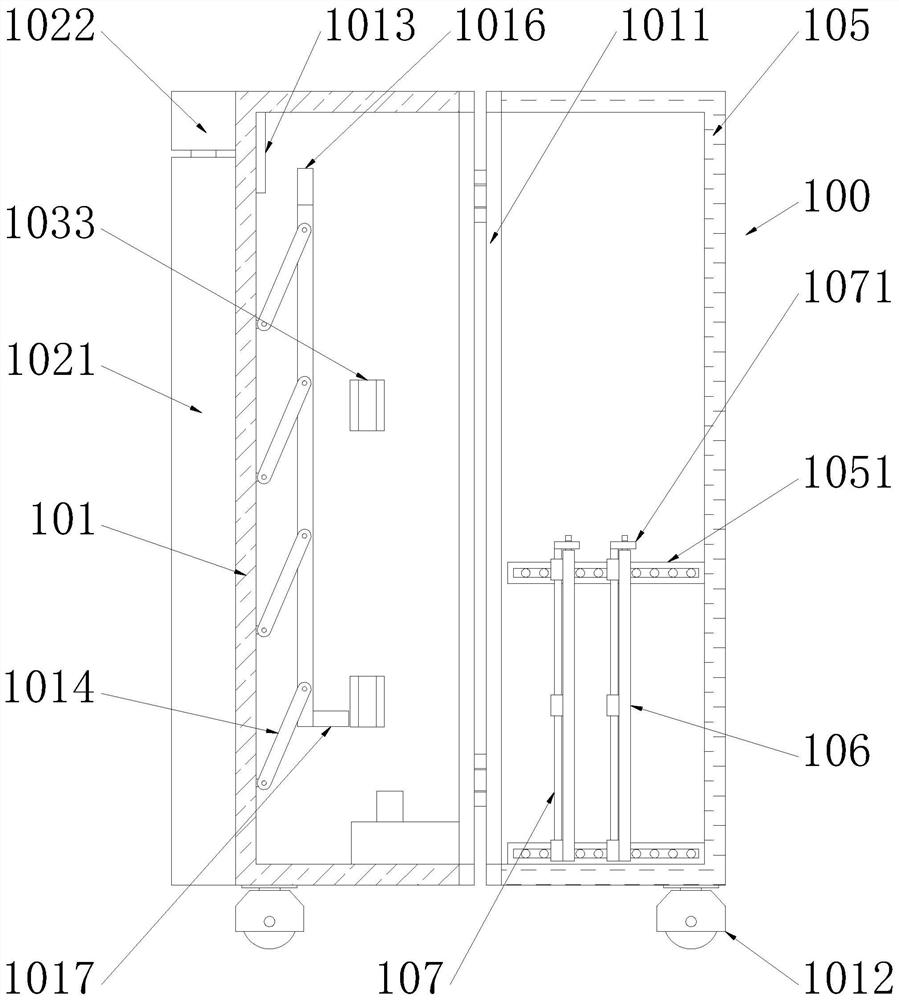

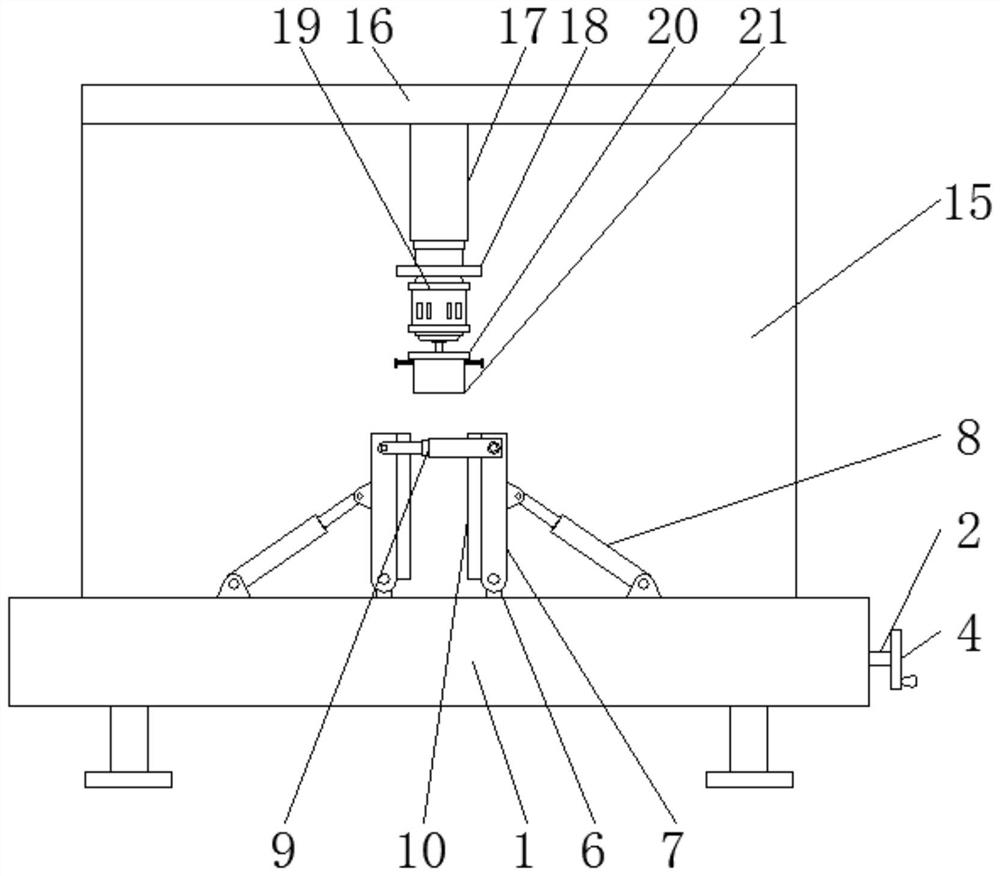

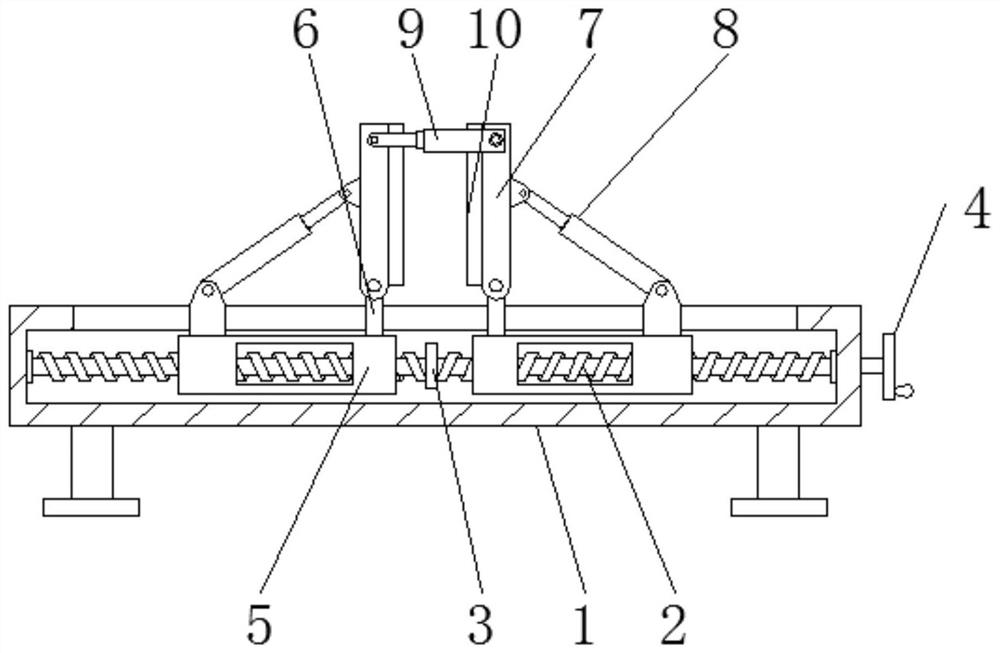

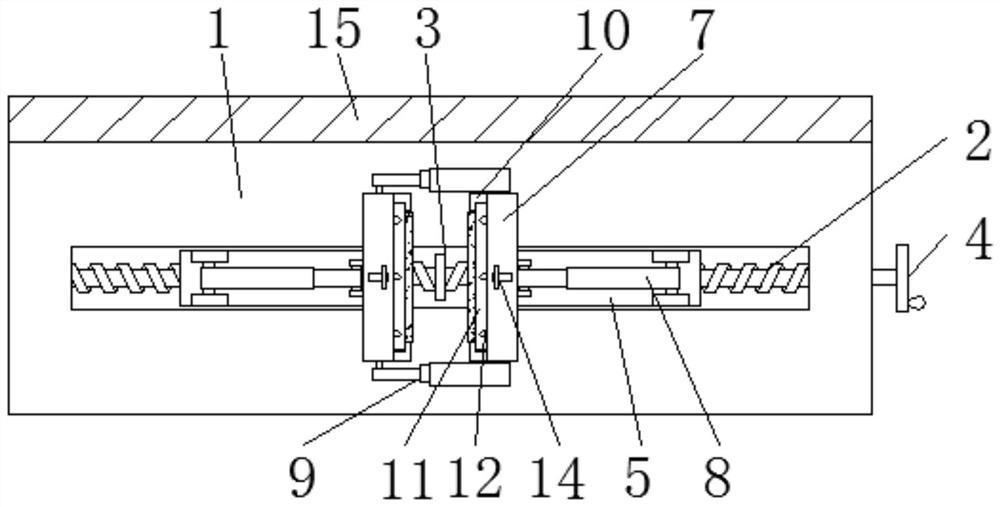

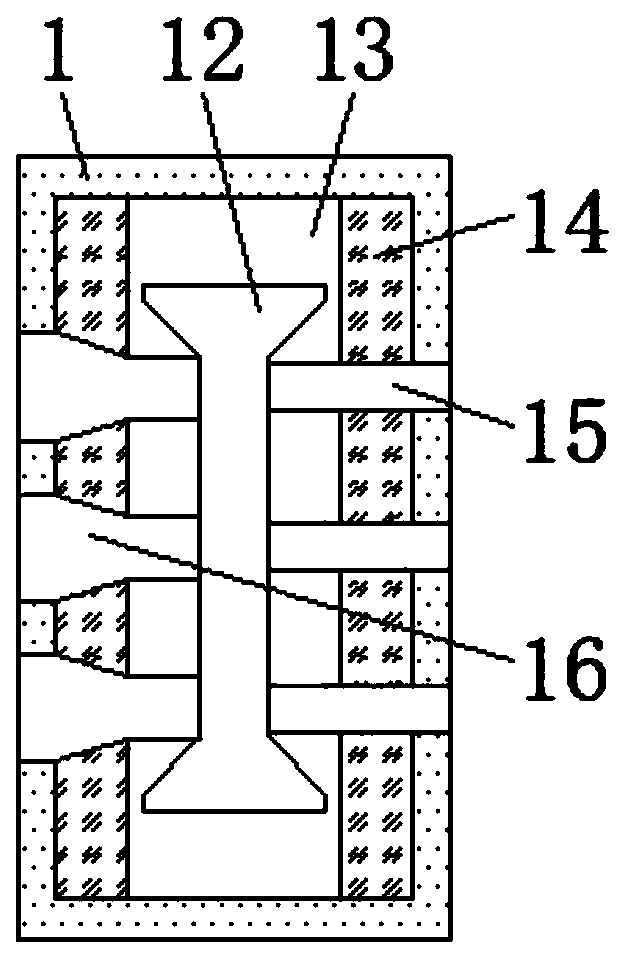

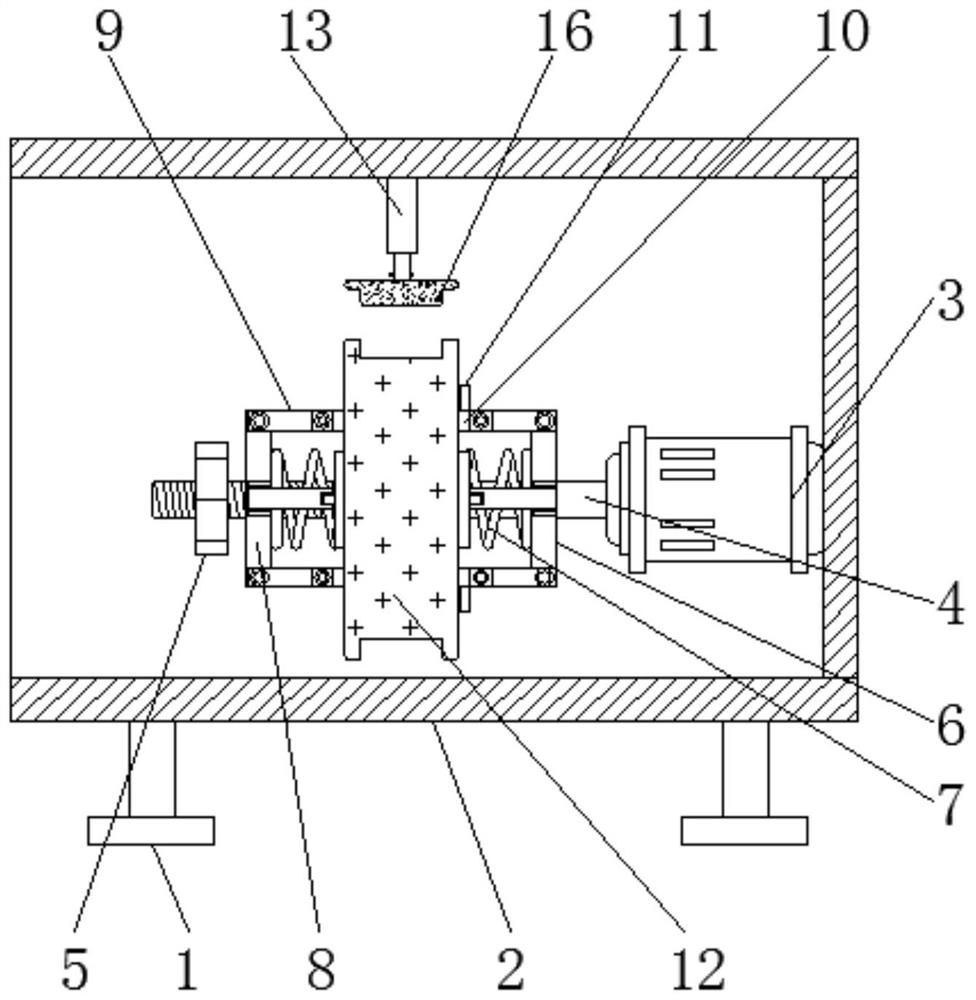

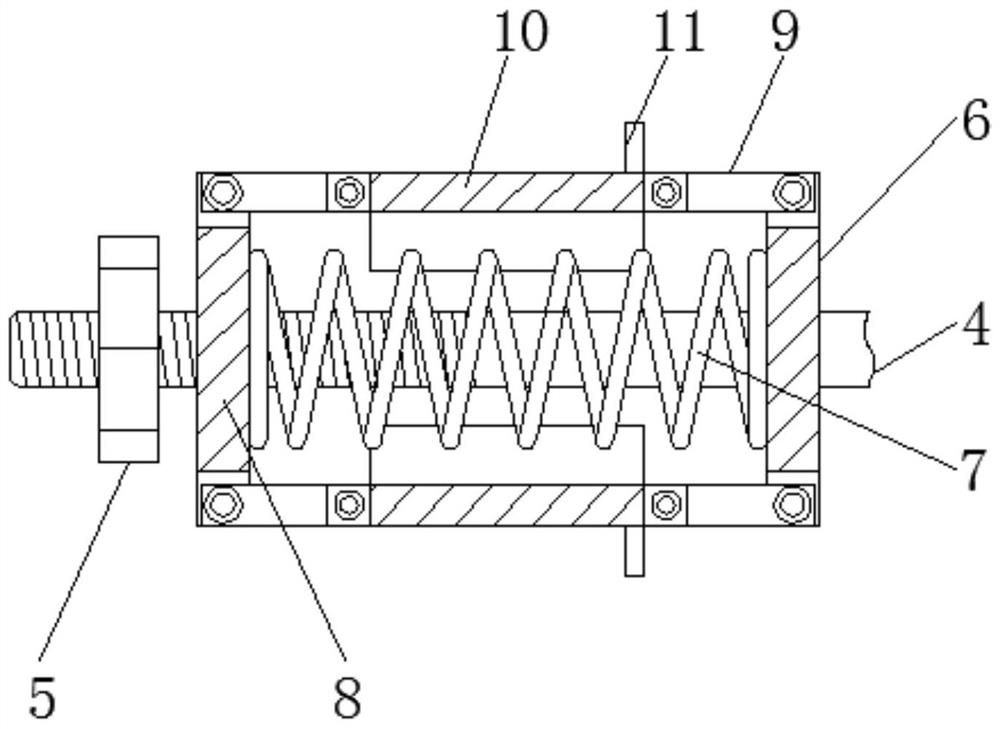

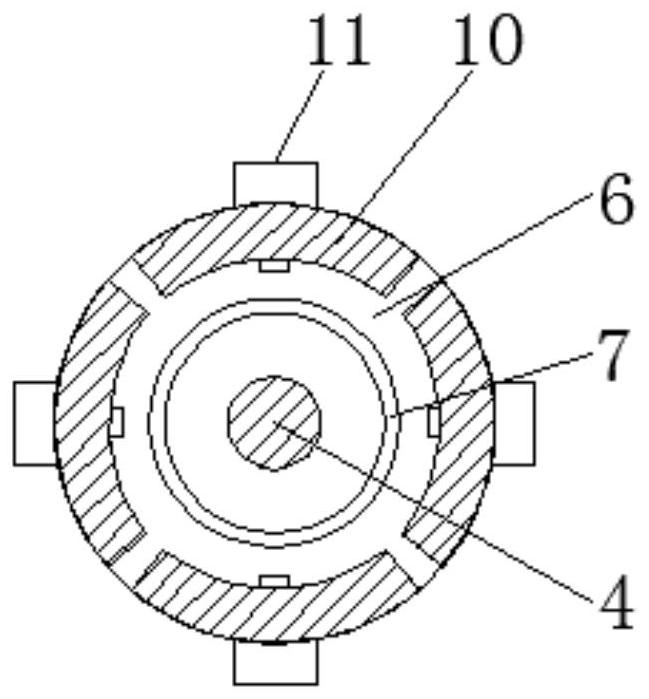

The invention discloses a location-fixation mechanism for wood plate drilling. The location-fixation mechanism for wood plate drilling comprises a workbench, wherein a fixed base is arranged on the workbench; a support table is fixedly connected to the fixed base; a support rod is fixedly connected to the support table; an adjustment panel is slidably connected to the support rod; a first slide plate is slidably connected to the adjustment panel; a fixed shaft is arranged at the bottom of the first slide plate; a press block is arranged at one end of the fixed shaft; a slide support frame is arranged on the workbench; a second slide plate is slidably connected to the slide support frame; a rotary shaft is arranged on the second slide plate; a rotary disc is rotationally connected to the rotary shaft; and a location device is arranged on the rotary disc. According to the invention, a wood plate is accurately located in a drilling area, and bidirectional limit and fixation effects on a horizontal surface and a vertical surface are conducted on the wood plate to avoid a displacement phenomenon of the wood plate during drilling; drilled holes are uniform in shape and size, and thus the drilling quality is improved; and moreover, the position adjustment of 90-degree rotation can be carried out on the wood plate according to the actual needs of operating personnel, and thus the drilling efficiency is increased.

Owner:闼闼盈佳(江苏)工贸有限公司

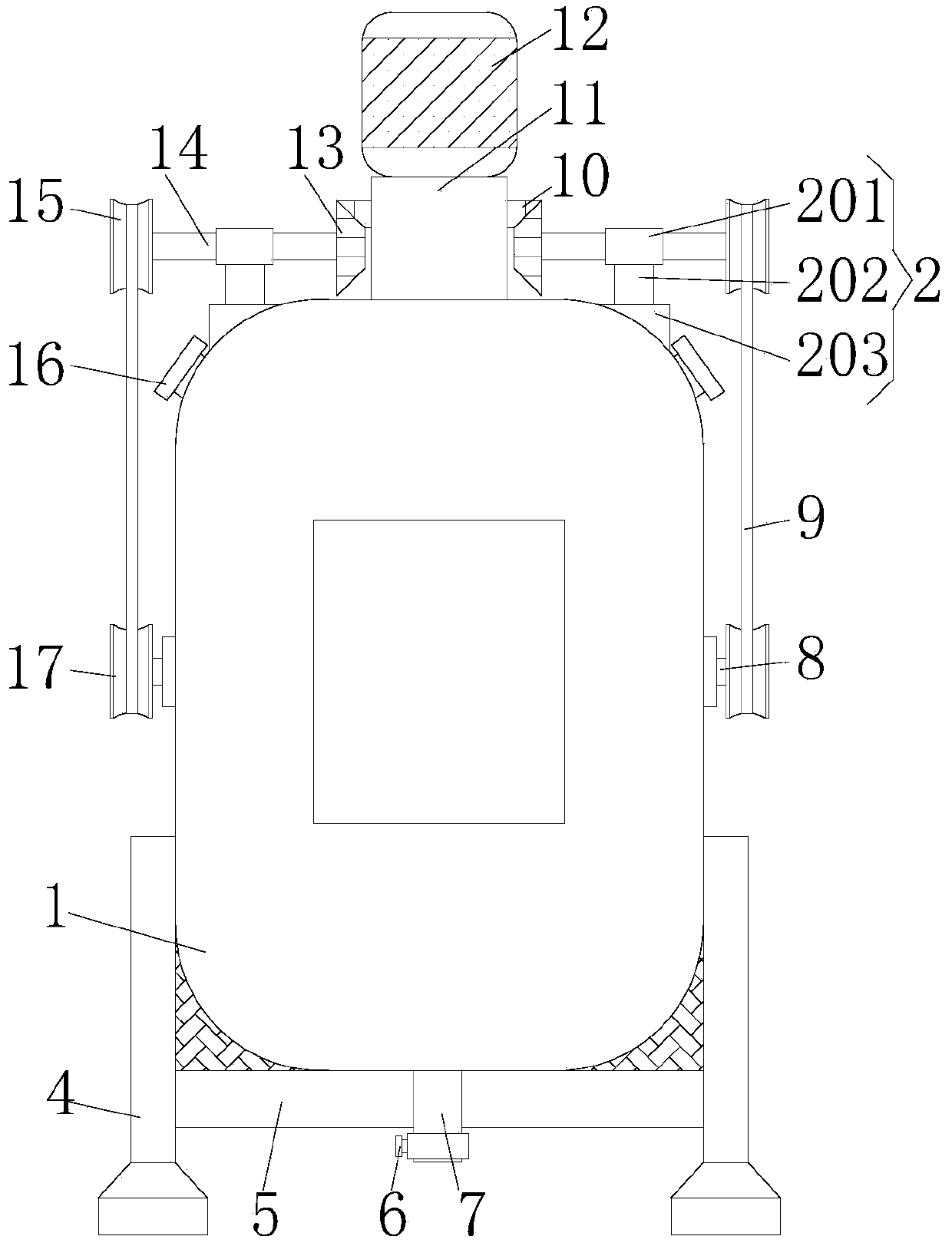

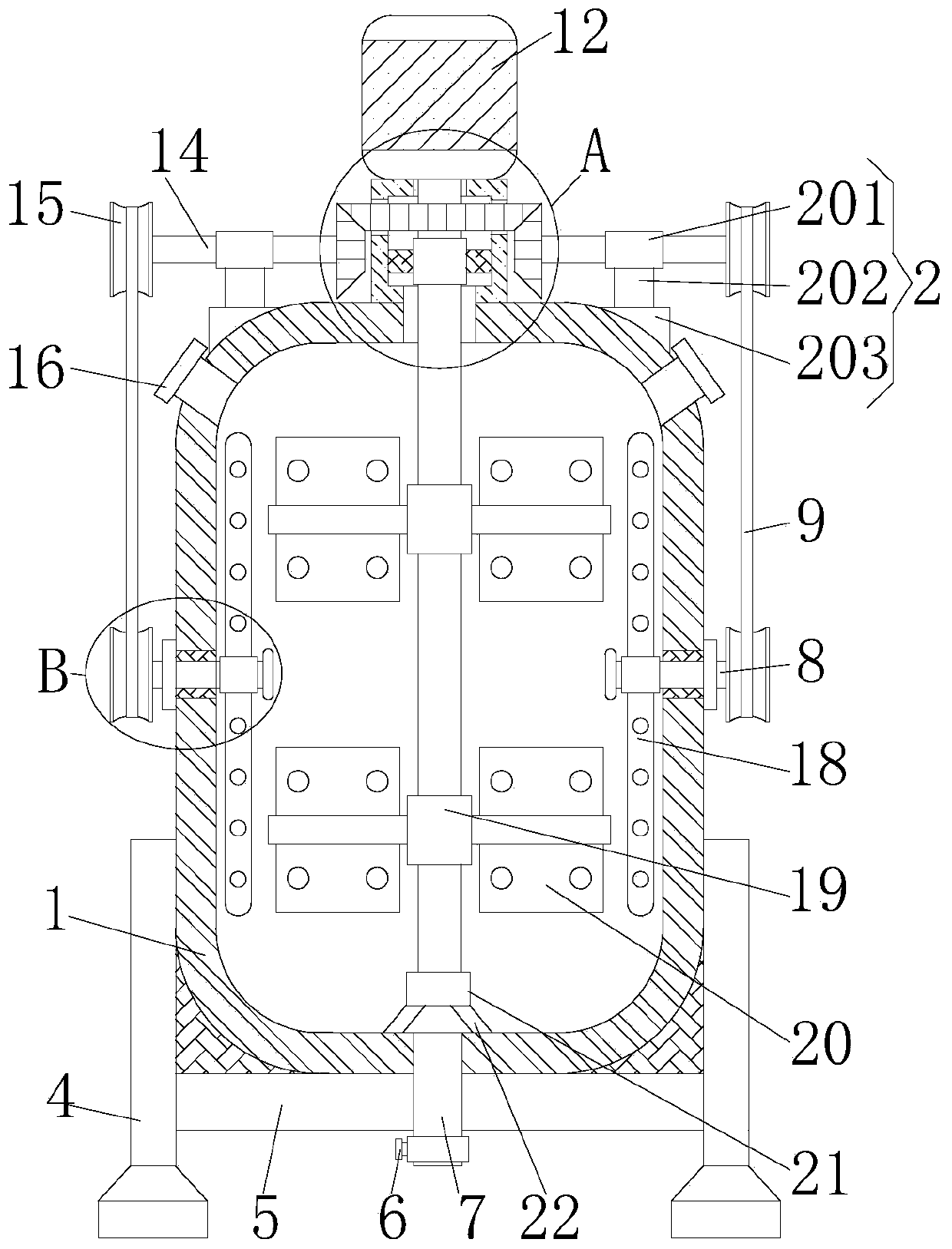

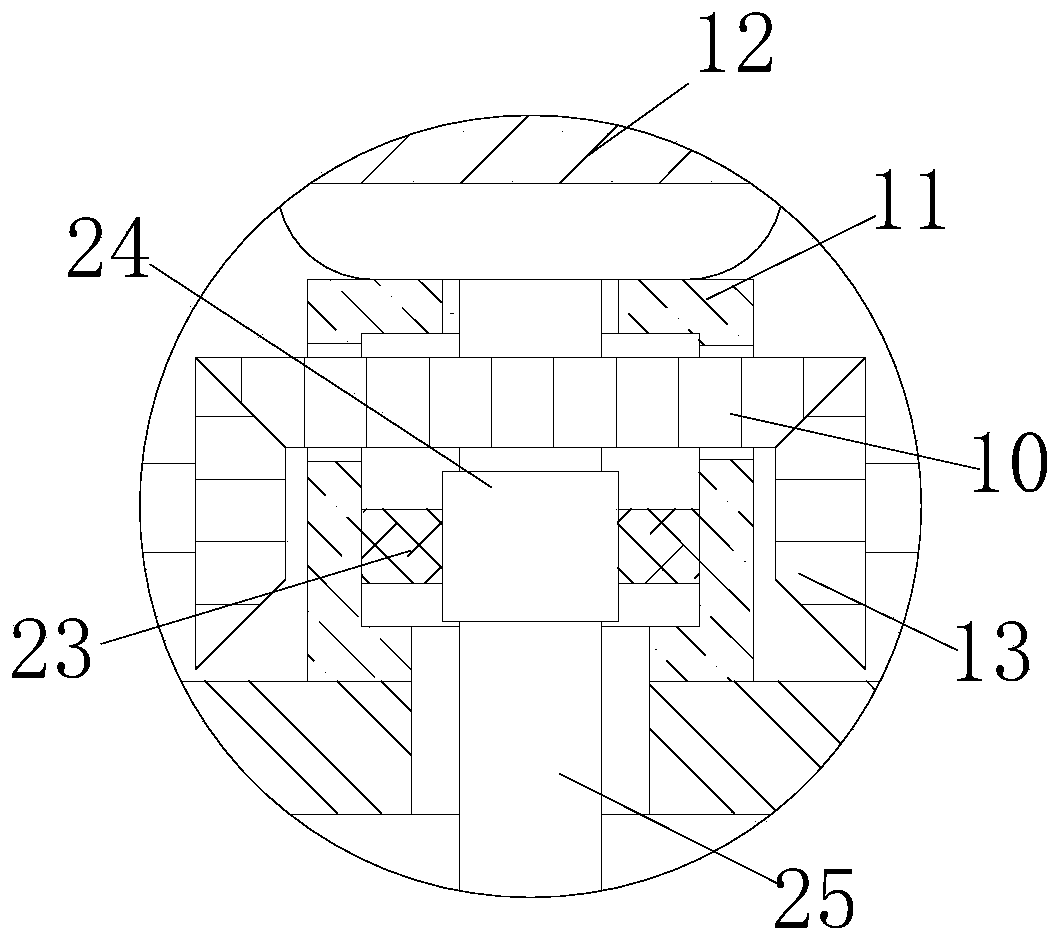

Stirring device for material production

InactiveCN109908782AEasy to useImprove mix qualityRotary stirring mixersMixer accessoriesEngineeringControl valves

The invention discloses a stirring device for material production. The stirring device for the material production comprises a stirring box, wherein a bottom plate is fixedly connected to the bottom of the stirring box, supporting legs are fixedly connected to both sides of the bottom plate, one side, close to the supporting legs, of the stirring box is fixedly connected with the supporting legs,feeding pipes communicate with the both sides of the top of the stirring box, and discharging pipes communicate with the bottom of the stirring box. According to the stirring device, the stirring box,a supporting mechanism, a second rotating sleeve, the supporting legs, the bottom plate, a control valve, the discharging pipes, a rotating shaft, a belt, a first bevel gear, a fixed shell, a motor,a second bevel gear, a movable rod, a transmission wheel, the feeding pipes, a second transmission wheel, a second stirring blade, a first rotating sleeve, a first stirring blade, a second bearing seat, a support rod, a connecting plate, a first bearing seat and a rotating rod are used cooperatively to solve the problem of low material stirring quality caused by uneven stirring and incomplete stirring of the existing stirring device for material production.

Owner:JIANSU JINSHAN BEER RAW MATERIAL CO LTD

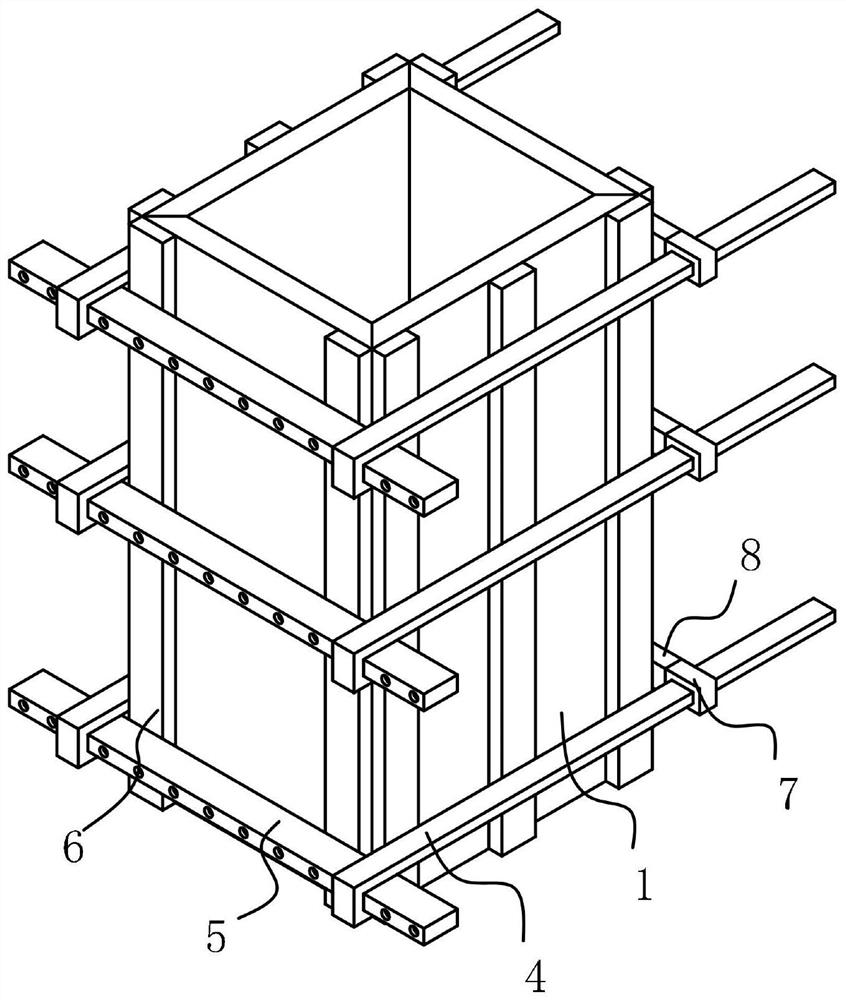

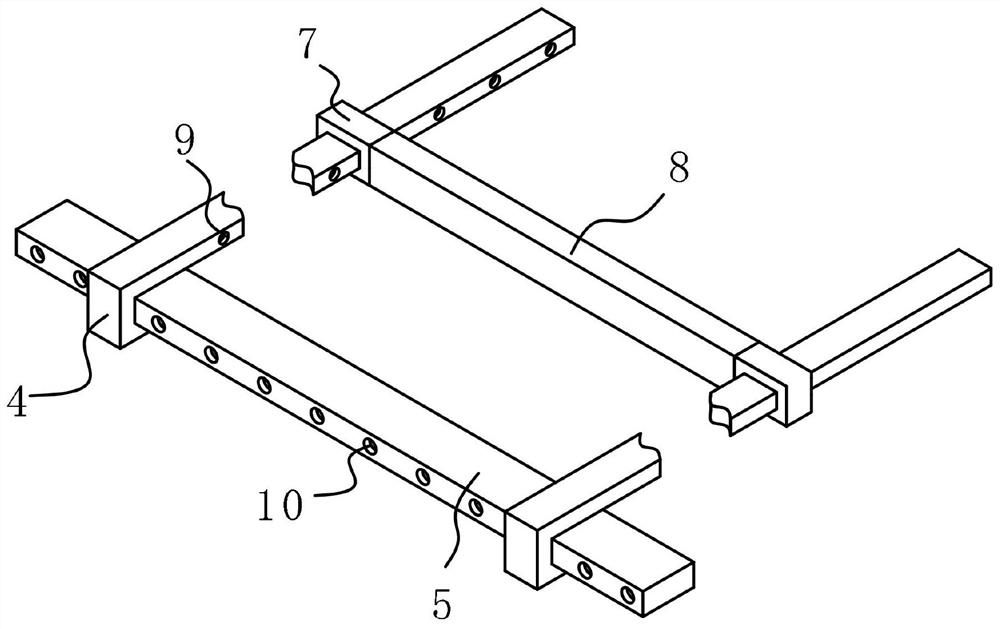

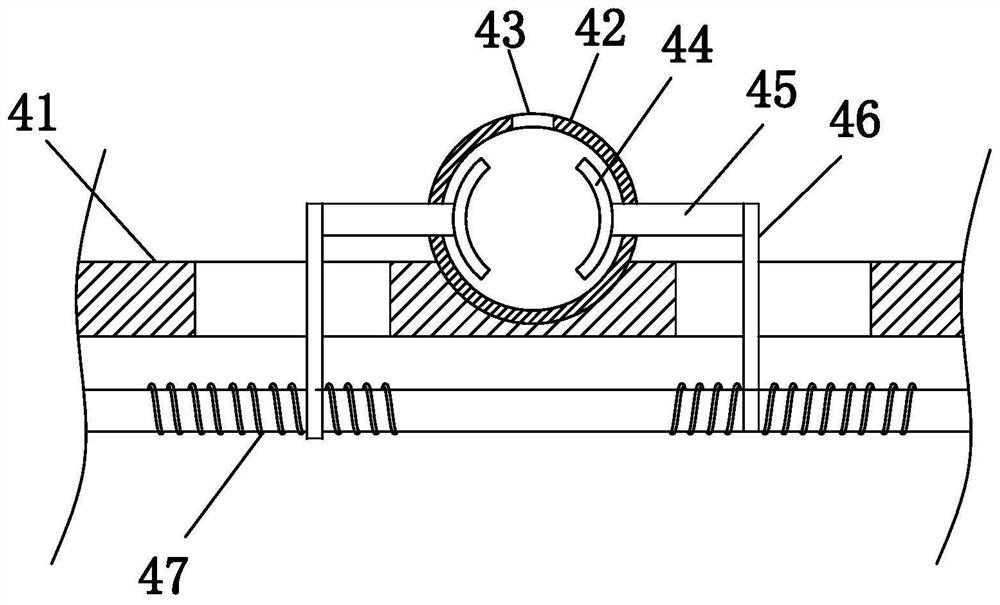

Connecting and locking device of building formwork

InactiveCN111677274ARealize the function of limit fixationPrevent movementForms/shuttering/falseworksArchitectural engineeringLocking plate

The invention discloses a connecting and locking device of a building formwork. The connecting and locking device comprises a formwork body, a base plate is fixedly connected to the surface of the formwork body, a limiting plate used in cooperation with the base plate is movably connected to the left side of the formwork body, the surface of the limiting plate is sleeved with two clamping plates,the surfaces of the clamping plates are sleeved with adjusting sleeves, and a locking plate used in cooperation with the base plate is fixedly connected between the opposite sides of the two adjustingsleeves. According to the device, through cooperative use of the formwork body, a positioning mechanism, a buckling mechanism, the clamping plates, the limiting plate, the base plate, the adjusting sleeves, the locking plate, a positioning groove, a supporting groove, a clamping column, a handle, a sliding button, a movable groove, a clamping groove, a movable hole, a sliding block, a sliding groove and a mounting groove, the problems that when an existing connecting and locking device for the building formwork is spliced and fixed, holes need to be fixed, when a user conducts splicing and fixing, operation is inconvenient, a large amount of installation time is consumed during splicing and fixing, the construction efficiency is affected, and use is inconvenient for the user are solved.

Owner:李平

Extrusion head protection mechanism of extruder for plastic production

The invention discloses an extrusion head protection mechanism of an extruder for plastic production. The extrusion head protection mechanism involves an extruder body, wherein a material conveying pipe is arranged inside the extruder body, a supporting mechanism is fixedly connected with the bottom of the material conveying pipe, the left side of the material conveying pipe fixedly communicates with a connecting pipe, the left side of the connecting pipe communicates with an installing pipe, and the left side of the installing pipe fixedly communicates with an extrusion head body. According to the extrusion head protection mechanism of the extruder for the plastic production, the extruder body, a sliding mechanism, a limiting mechanism, a guiding mechanism, the supporting mechanism, the material conveying pipe, the connecting pipe, a fixing shell, the extrusion head body, a installing block, the installing pipe, a fixing plate, a positioning column, a positioning groove, a discharging pipe, a sealing gasket, a first spring, a sliding groove, a sliding block, a clamping plate, a clamping groove, a clamping block, a shell body, a connecting plate and a limiting groove are arranged and matched in use, so that the problems of inconvenient installation of an existing extrusion head of the extruder for the plastic production and looseness caused by long-time use are solved.

Owner:朱兰英

Rewinding machine for cigarette receiving and packaging paper

PendingCN108382906ARealize the scaling functionSolve the problem of not being able to scaleWebs handlingPulp and paper industryBrake pad

The invention belongs to the field of cigarette equipment and particularly relates to a rewinding machine for cigarette receiving and packaging paper. The rewinding machine comprises a first round rod, a second round rod, electric push rods, first springs, a blade, a second spring, a fixing device, a limiting plate, a sliding groove, first wheels and braking pads. The rear end of the second roundrod is connected with the front end of the first round rod so that the stretching and contacting function of a cutting device can be achieved through the design. The upper ends of the electric push rods are installed in third grooves so that the stabilizing and damping function of the rewinding machine for the cigarette receiving and packaging paper can be achieved through the design. The blade isinstalled at the lower end of a second vertical rod so that the limiting and fixing function can be achieved on the cigarette receiving and packaging paper through the design. The sliding groove is formed in the left end and the right end of a collecting box so that the function of collecting cutting waste paper of the cigarette receiving and packaging paper can be achieved through the design. The first wheels are installed in a lower base, and mute wheels are assembled at the lower end of the lower base. The rewinding machine is novel in structure, good in cutting effect, good in stabilizingand damping performance and strong in limiting and fixing performance.

Owner:江苏众立生包装科技有限公司

Stretchable rotating dairy product sale frame

InactiveCN110215091AEasy to useImprove practicalityShow cabinetsShow shelvesEngineeringMilk products

Owner:灵璧县童师傅食品有限公司

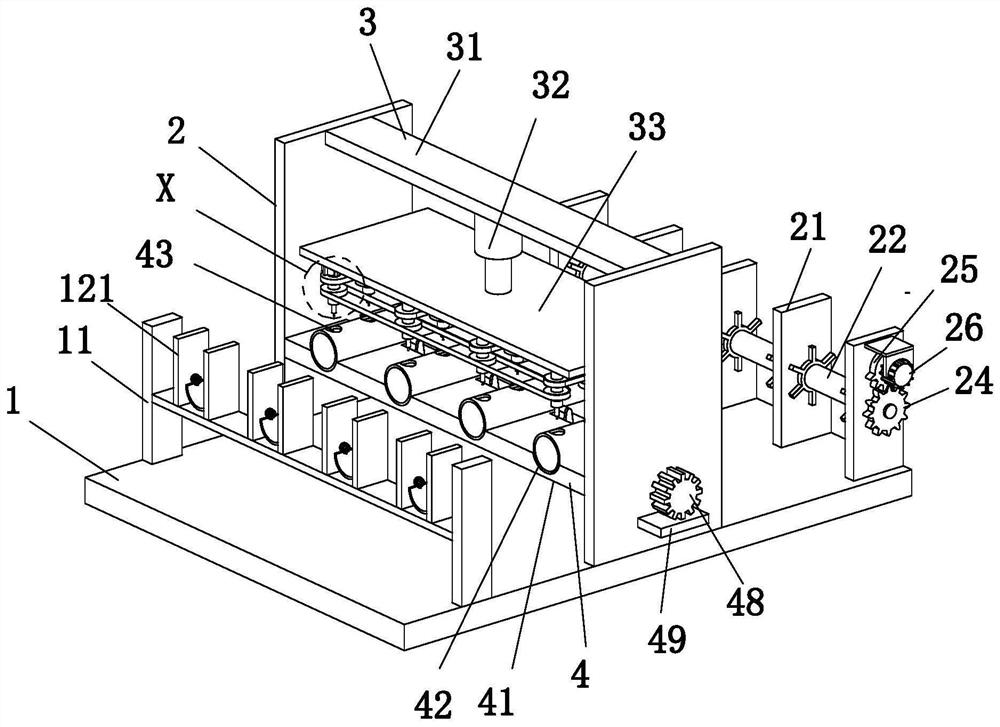

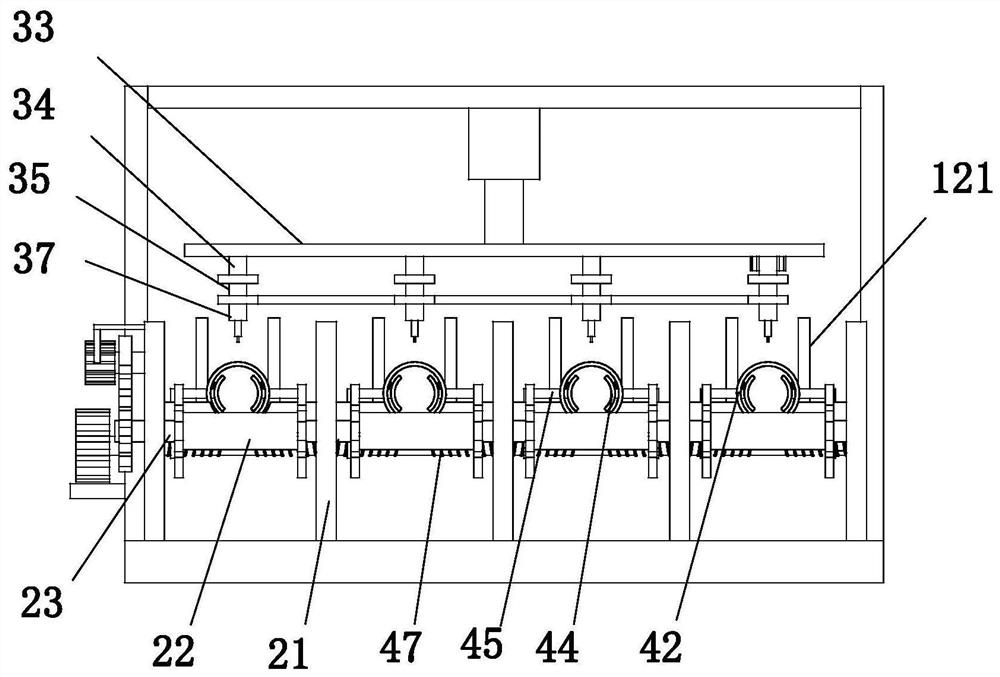

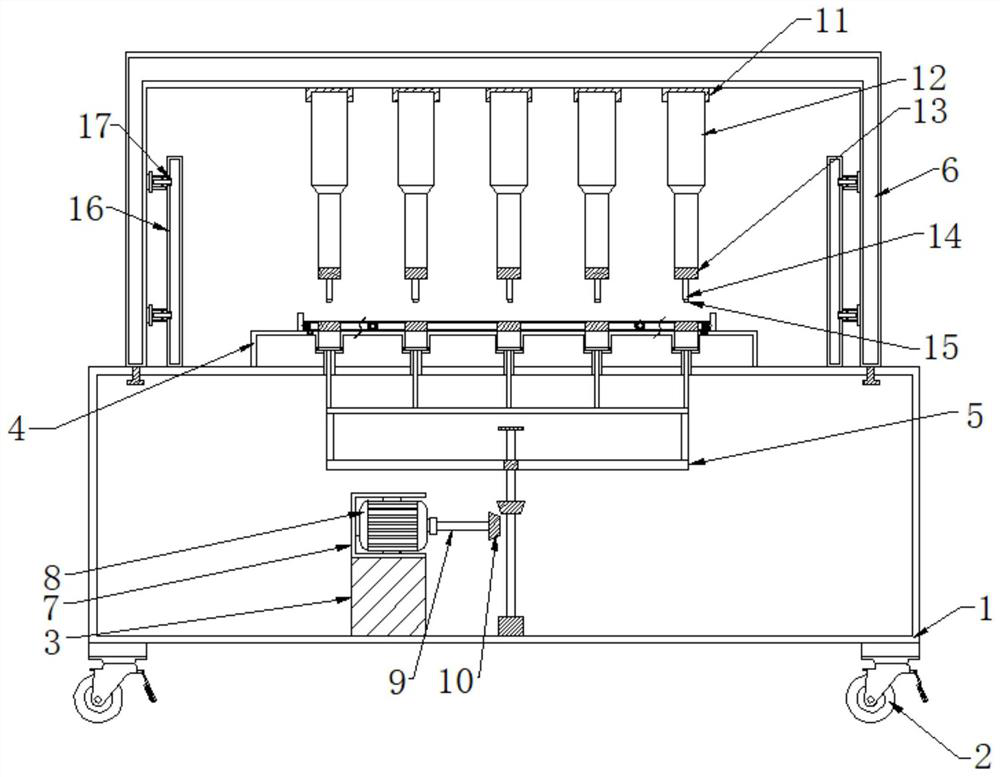

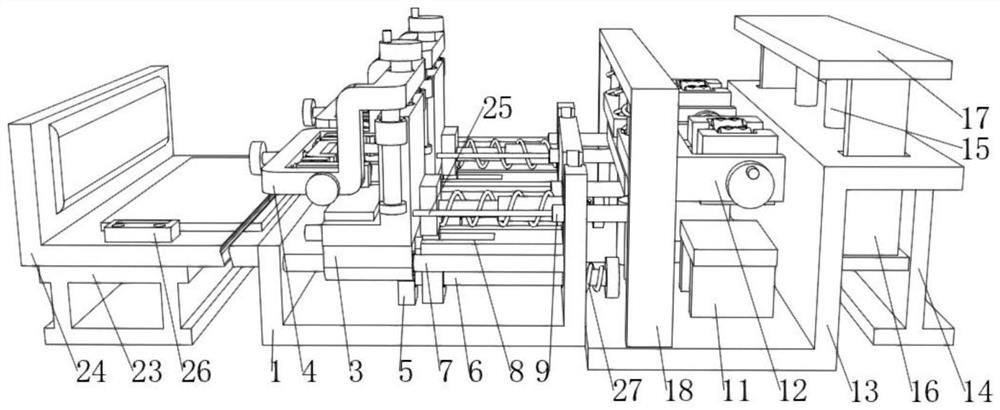

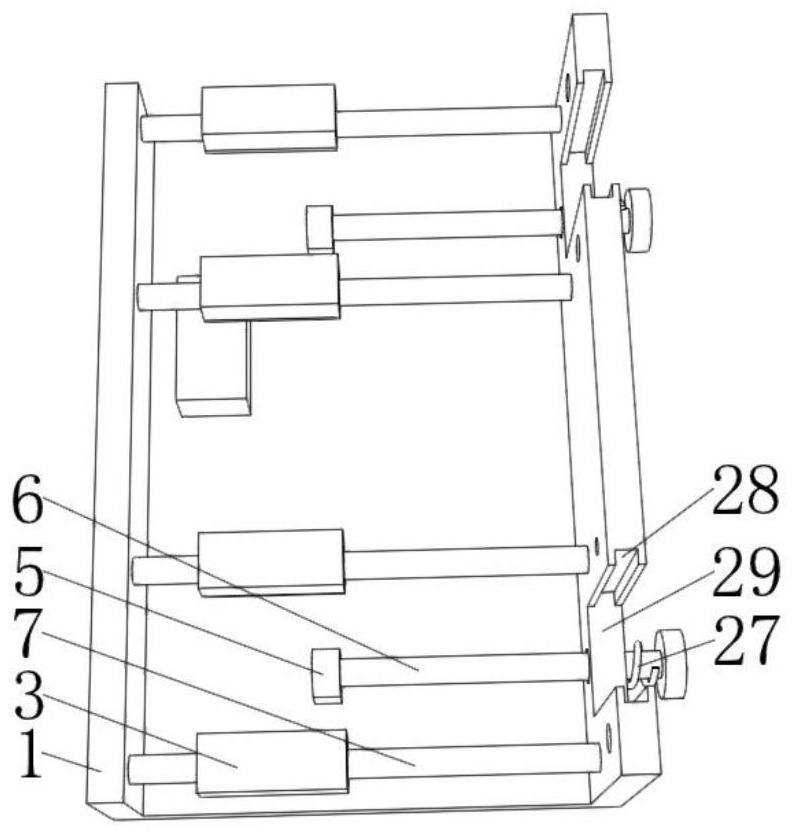

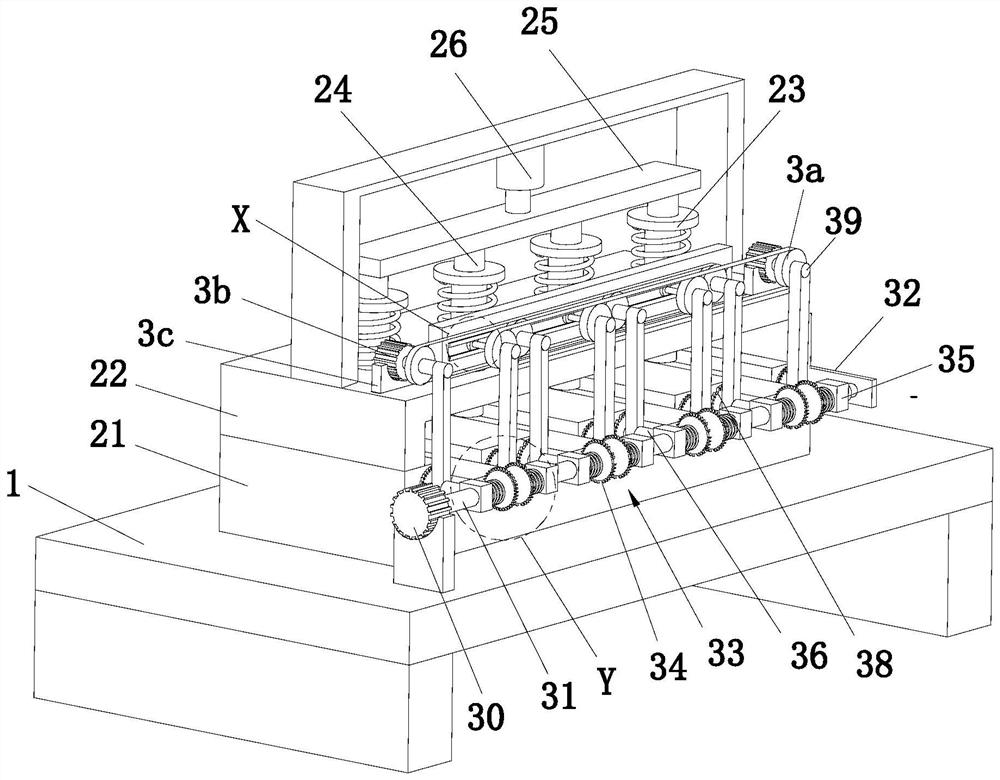

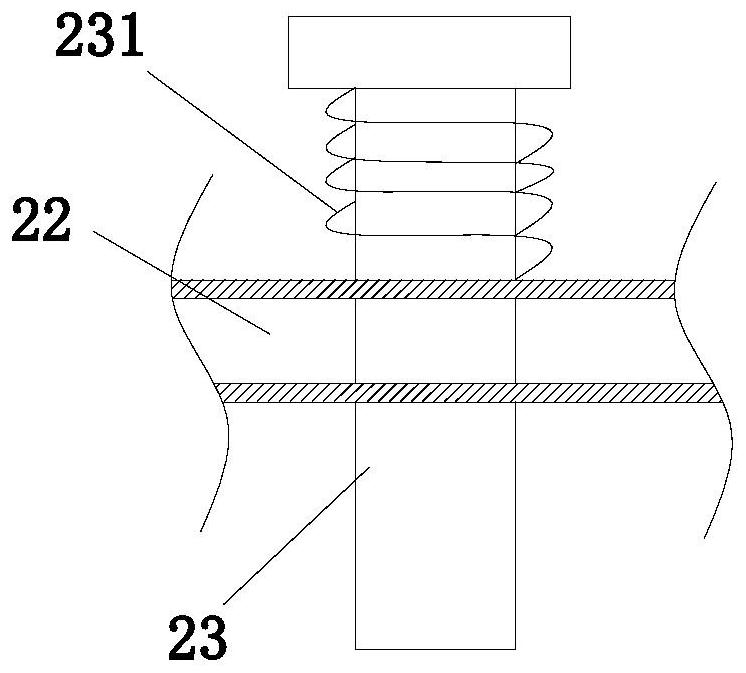

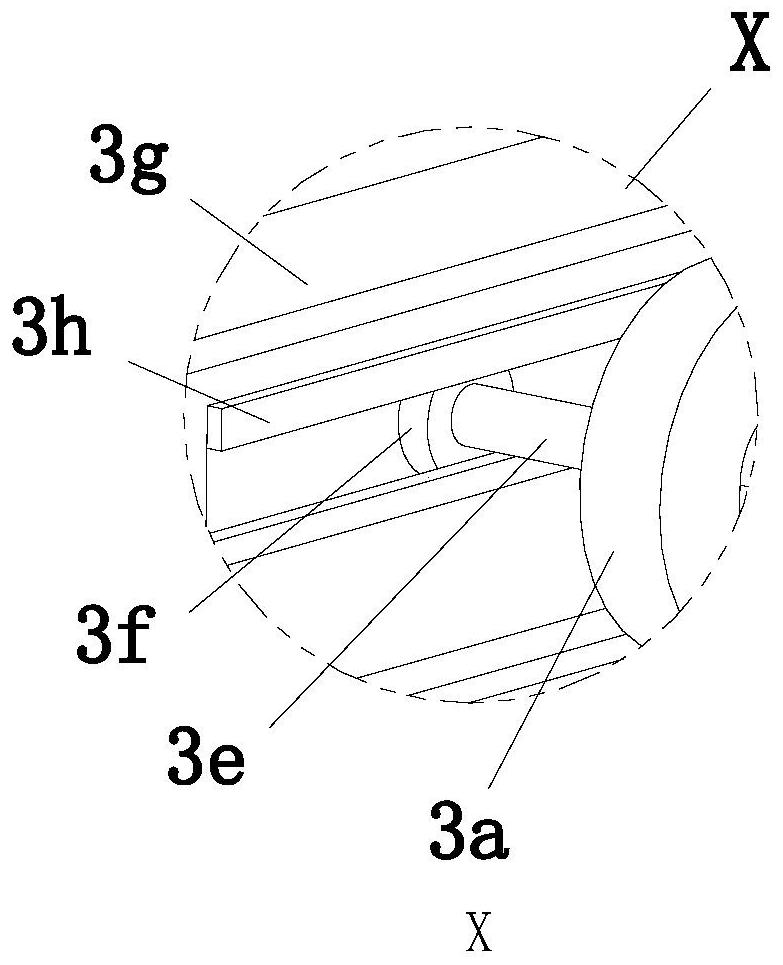

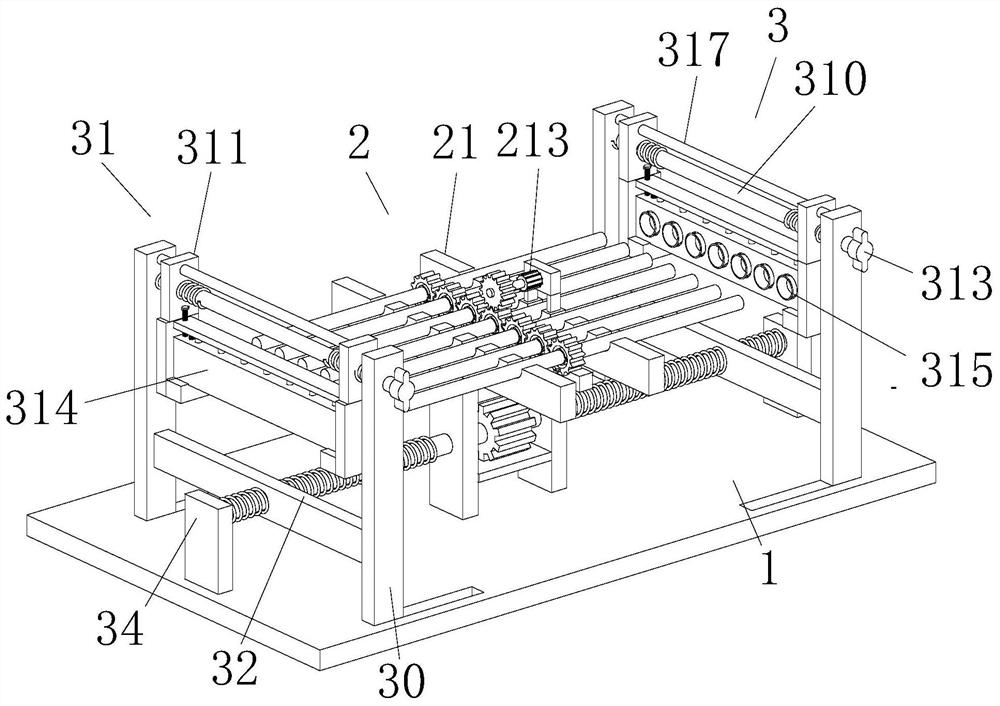

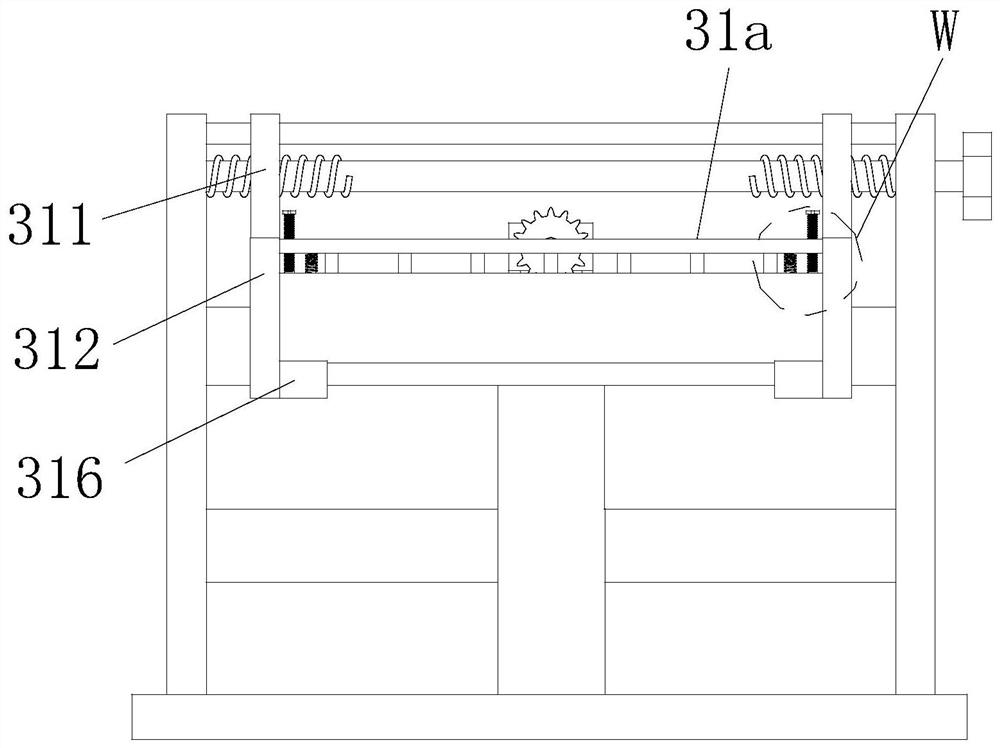

Batch tapping device for corrugated pipe

ActiveCN112317802AAchieve the effect of batch openingHigh porosityFeeding apparatusPositioning apparatusBilateral symmetryMechanics

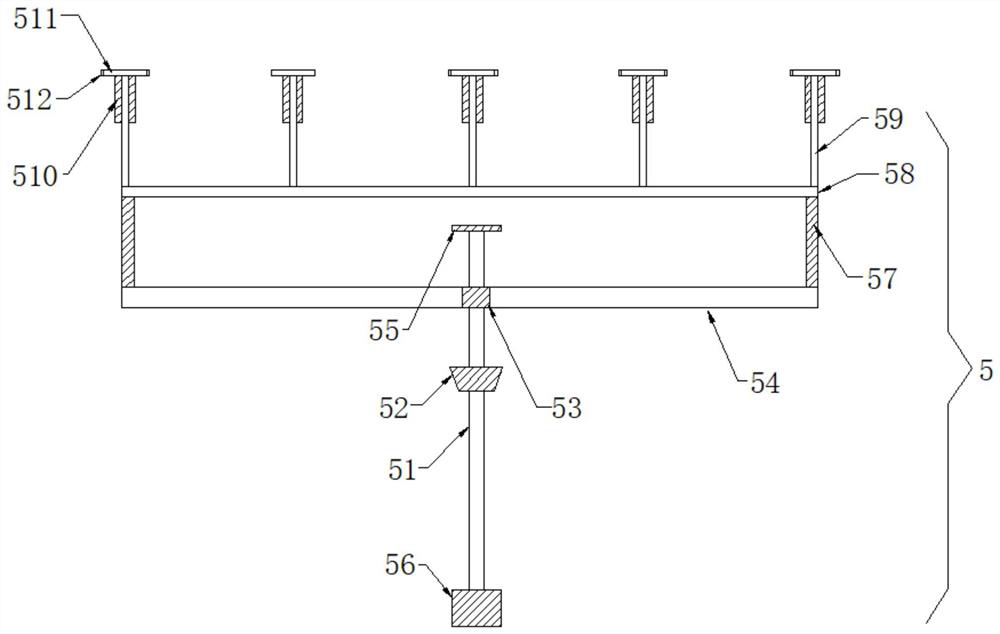

The invention relates to a batch tapping device for a corrugated pipe. The batch tapping device comprises a bottom plate, fixing plates, a tapping mechanism and a fixing mechanism, wherein the fixingplates are installed on the upper end face of the bottom plate and are of a bilateral symmetry arrangement structure, and the tapping mechanism and the fixing mechanism are sequentially arranged fromtop to bottom between the left fixing plate and the right fixing plate which are directly opposite. According to the batch tapping device for the corrugated pipe, the design concept that multiple groups of drill bits conduct tapping at the same time is adopted for batch tapping of the corrugated pipe, the tapping mechanism arranged on the device can achieve the function of synchronous working of all the drill bits, then the effect of batch tapping of the corrugated pipe can be achieved, meanwhile, the corrugated pipe can be limited and fixed through the fixing mechanism, and therefore, the tapping effect is enhanced.

Owner:YANCHENG JIACHENG PLASTIC

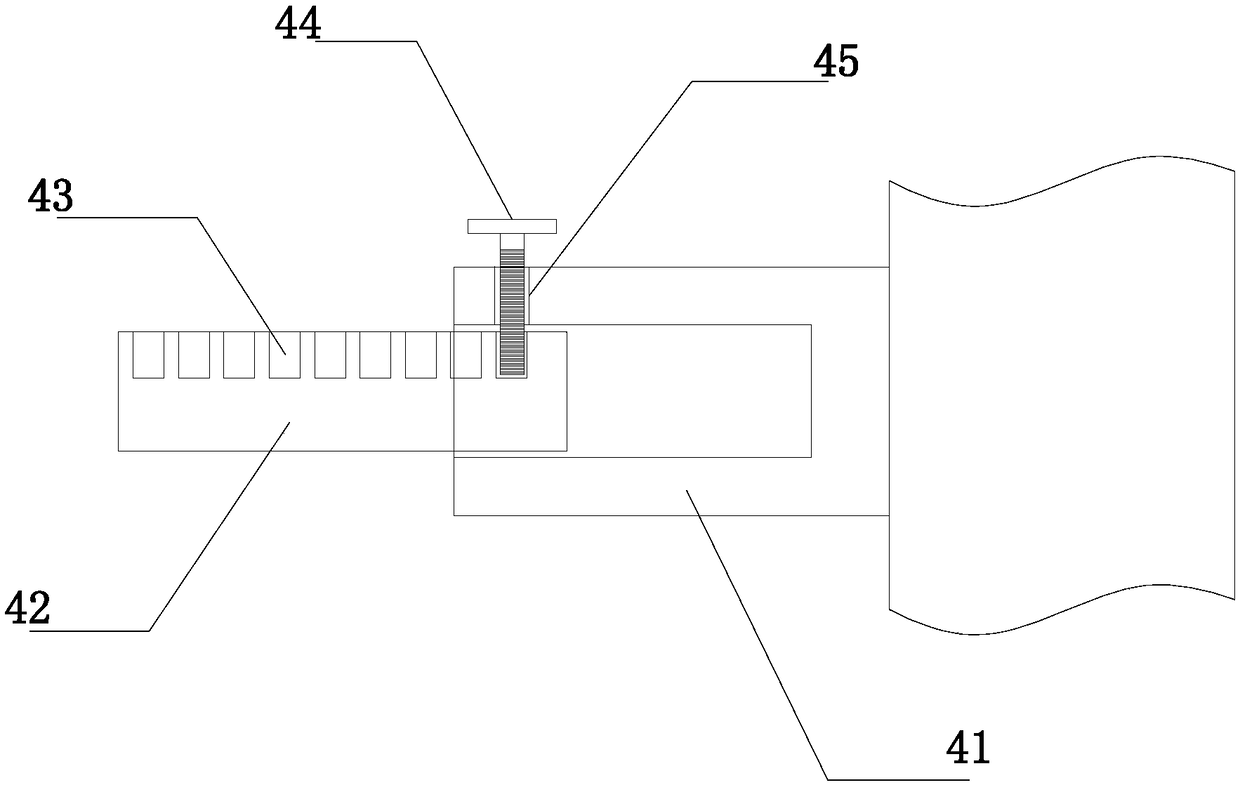

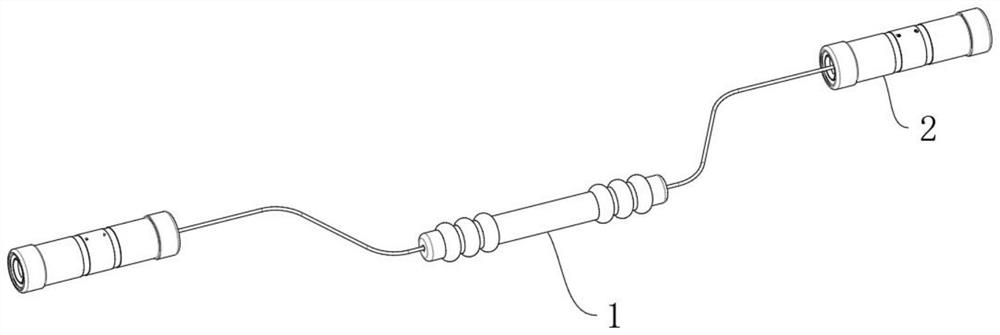

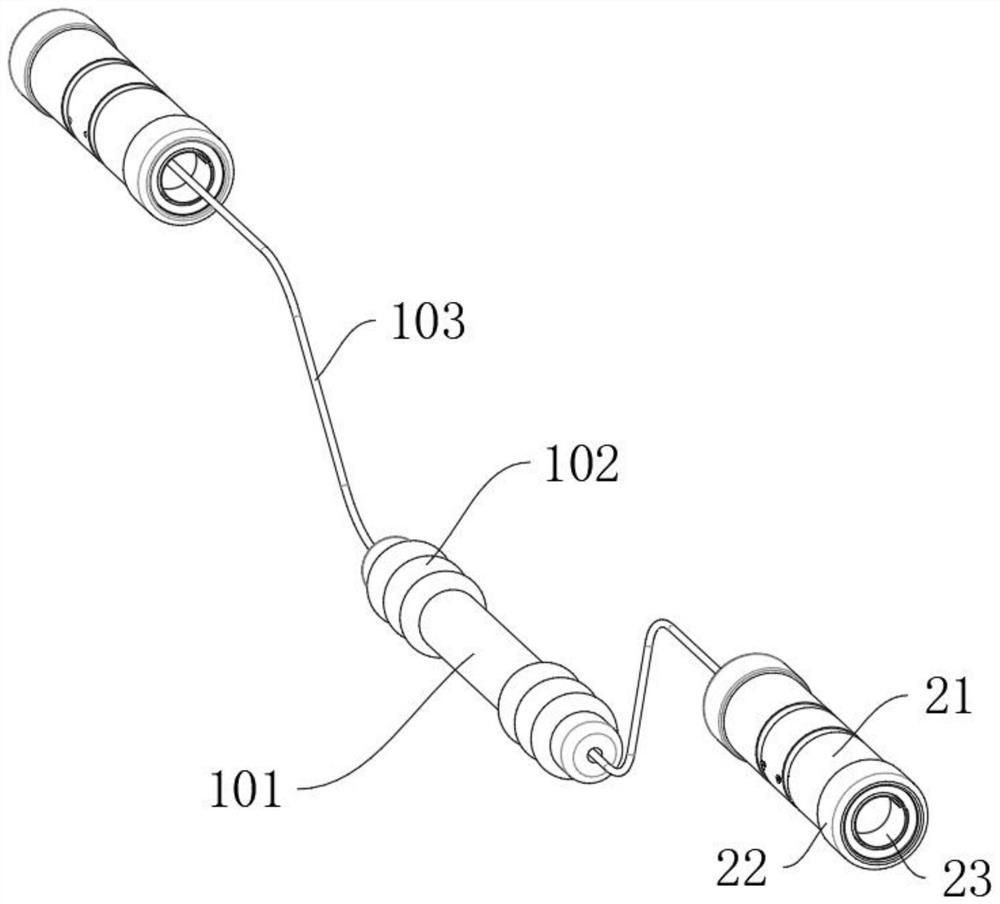

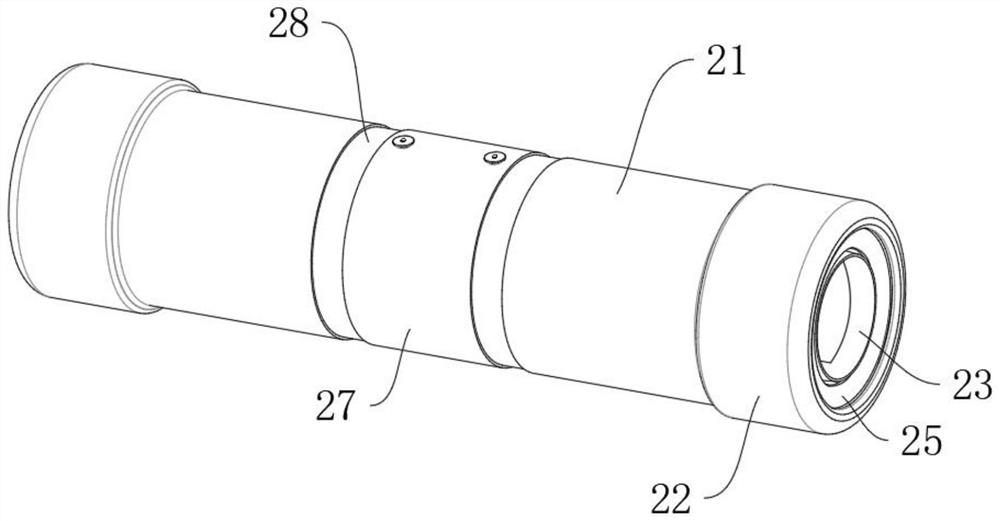

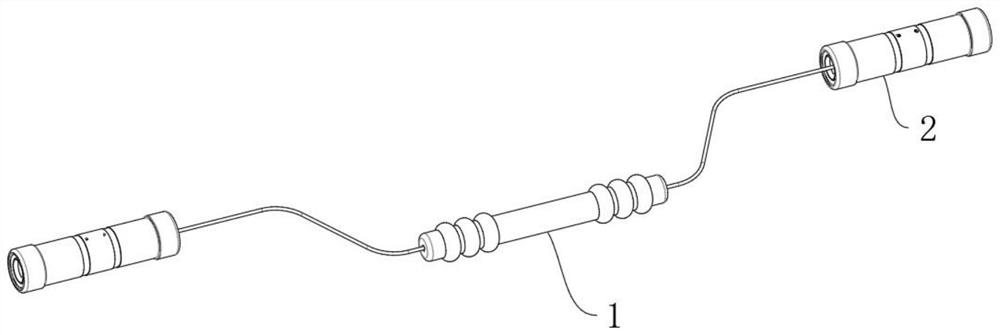

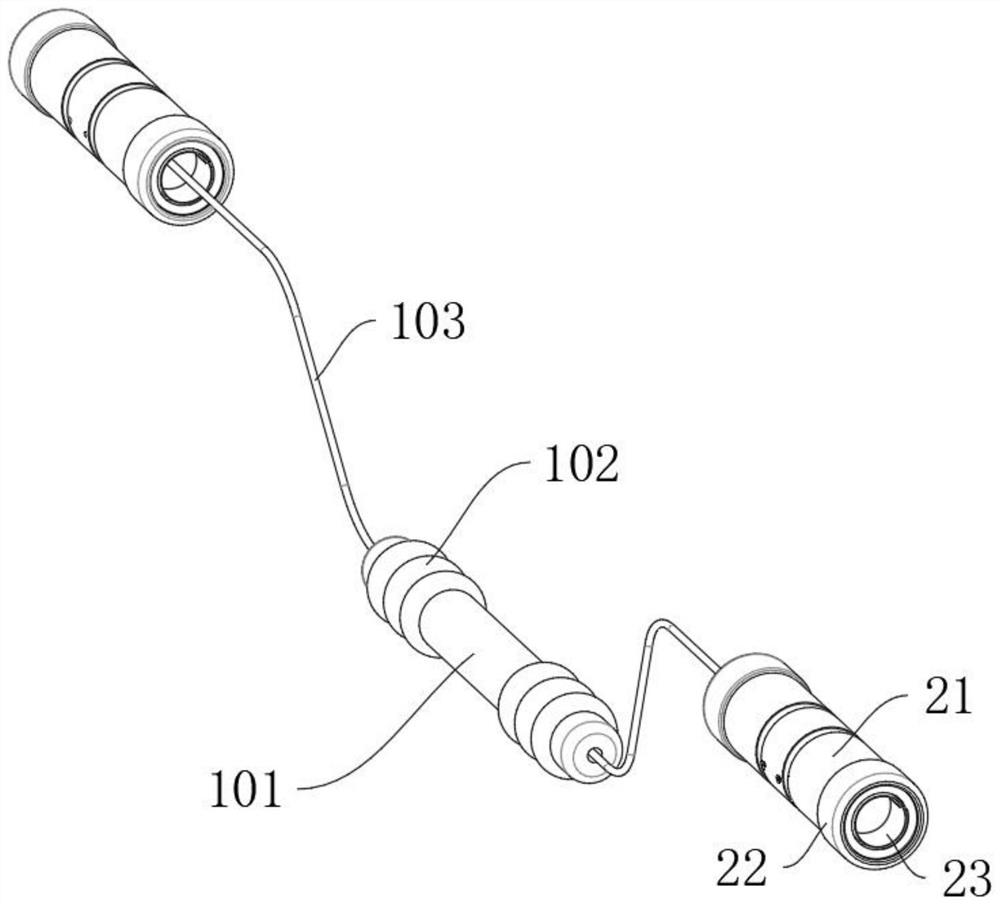

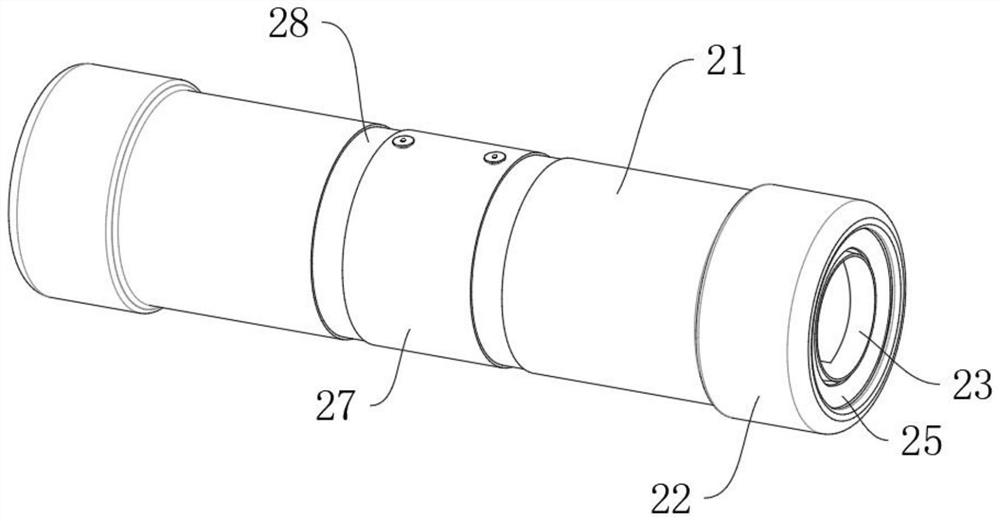

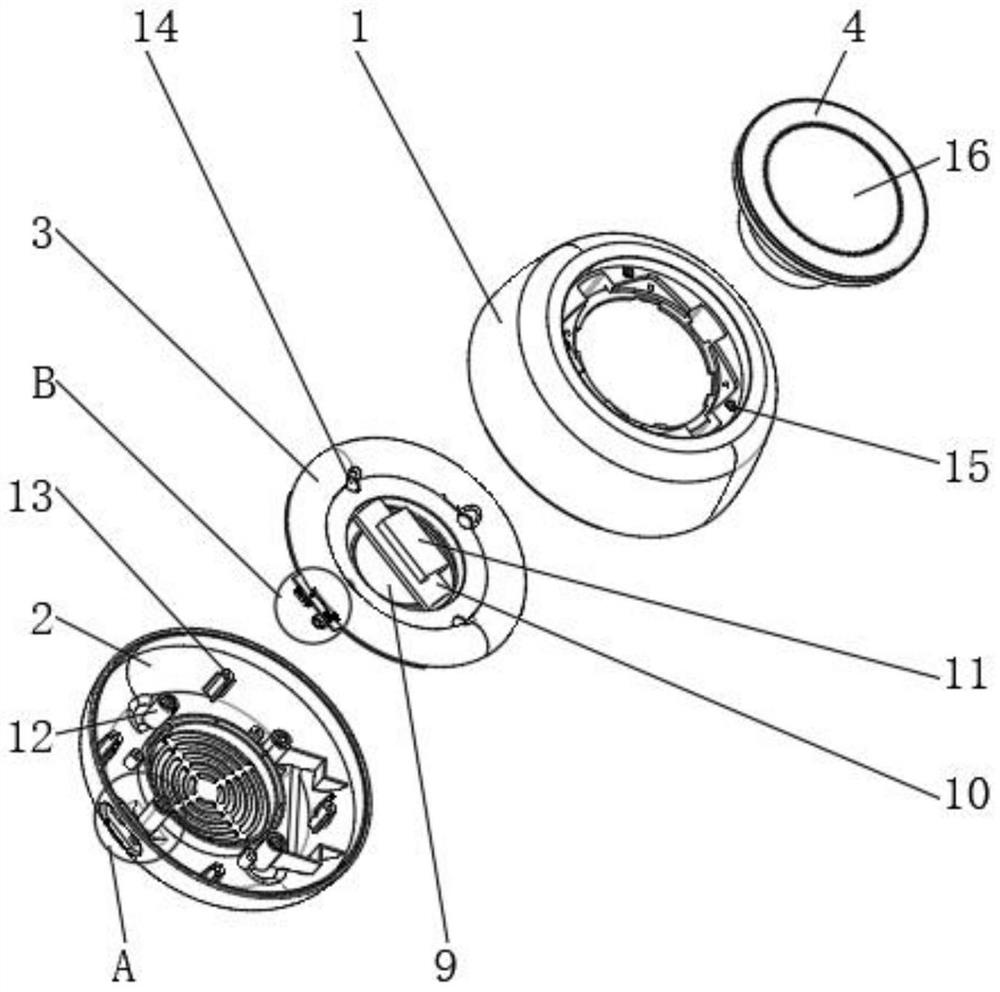

Semi-precision plastic package resistor

ActiveCN113851288AImprove convenienceComponents in auxiliary protection circuitResistor terminals/electrodesResistor mounting/supportingEngineeringElectrical connection

The invention discloses a semi-precision plastic package resistor, and particularly relates to the field of resistors, the semi-precision plastic package resistor comprises a resistor mechanism used for adjusting the current blocking effect in a circuit, and the two ends of the resistor mechanism are electrically connected with conductor connecting mechanisms used for assisting in connecting all levels of elements. A reset mechanism serving as a transmission power source is installed in the conductor connecting mechanism. When a torsion spring connection section is disconnected from a fusing block, the reset type ruler spring section drives the central positioning sleeve to rotate, and the outer ring sleeve is pushed to move towards the end part of the conductor connection mechanism by utilizing the meshing of a corresponding external thread groove and a guide sheet type internal thread tooth groove. Therefore, a conductor type cantilever and an elastic arc sheet conductor are pushed to bind a rod-shaped wire outside the conductor connecting mechanism, and the problem that small circuit board elements are difficult to weld uniformly for electrical connection is relatively solved.

Owner:蚌埠市爱瑞特电子有限责任公司

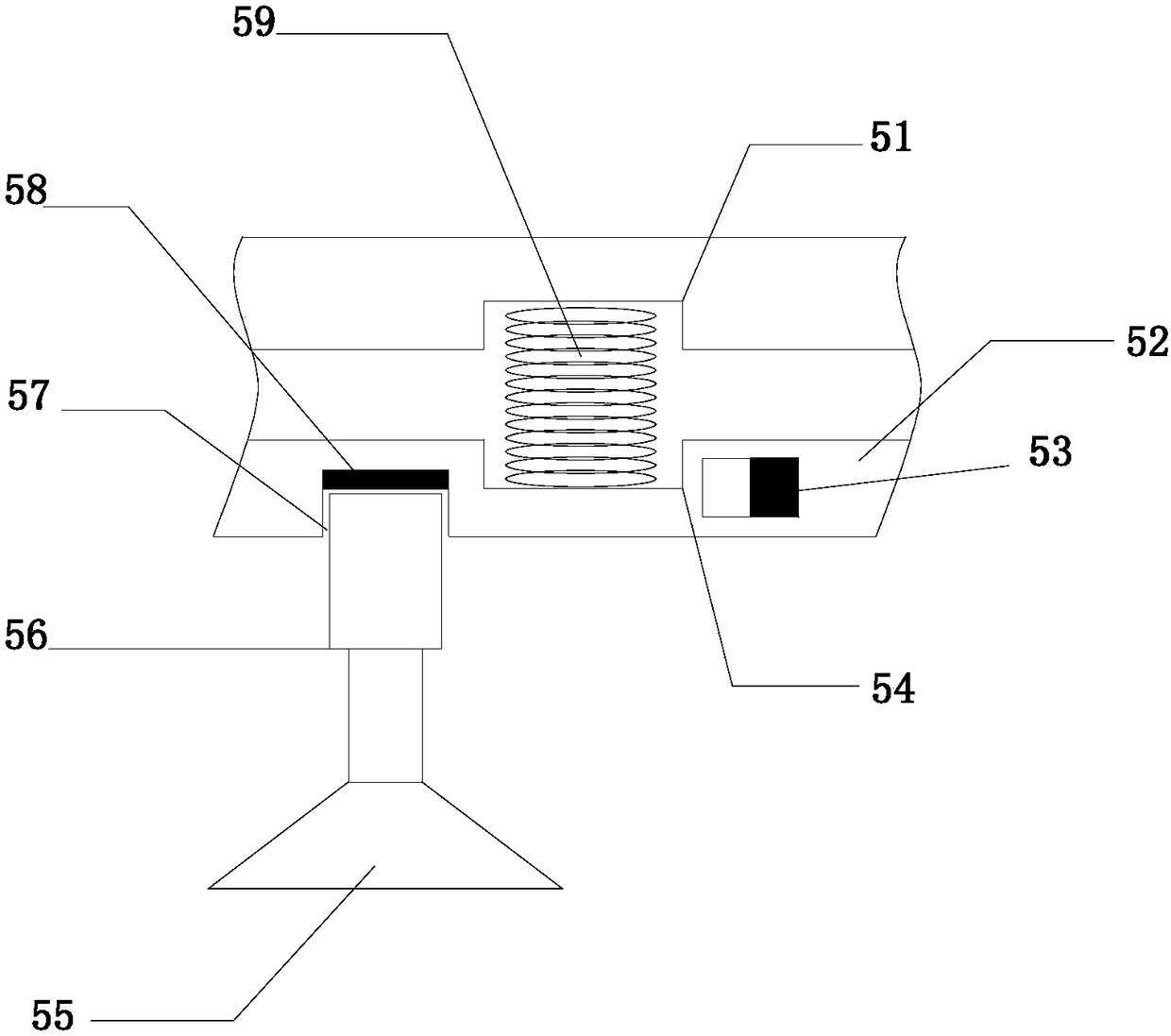

Independent operation mobile phone with high shock absorption structure stability

PendingCN110505326AImprove stabilityRealize the function of limit fixationTelephone set constructionsStructural stabilityEngineering

The invention discloses an independent operation mobile phone with high shock absorption structure stability. The independent operation mobile phone comprises a mobile phone substrate, a mobile phonemainboard and a positioning rod, a groove is formed in one end of the mobile phone substrate along the length direction; a mobile phone main board is arranged in the groove, a positioning rod is inserted into the mobile phone main board, the bottom end of the positioning rod is in threaded connection with the bottom of the groove, a damping spring sleeves the positioning rod and is located below the mobile phone main board, and the top end of the positioning rod is located above the mobile phone main board and is in threaded connection with a limiting nut. In the present invention, the head groove is formed in the mobile phone substrate, the positioning rod is inserted into the mobile phone mainboard, then the positioning rod is connected to the bottom of the groove in a threaded mode, sothat limiting and fixing of the mobile phone mainboard are completed, the portion, located below the mobile phone mainboard, of the positioning rod is further sleeved with the damping spring, and vibration of the mobile phone mainboard can be reduced through elastic stretching and retracting of the damping spring.

Owner:郑州联创电子有限公司

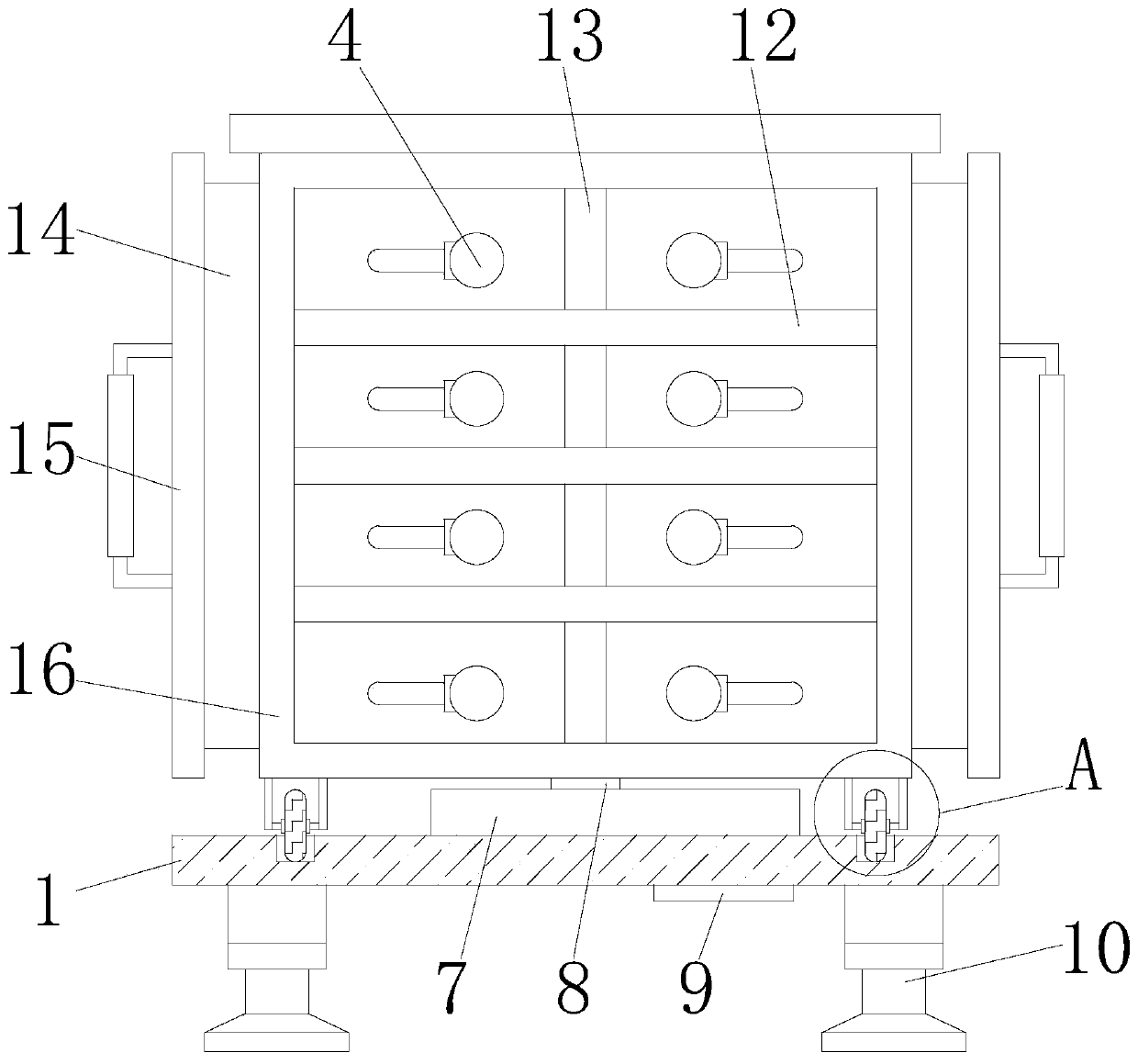

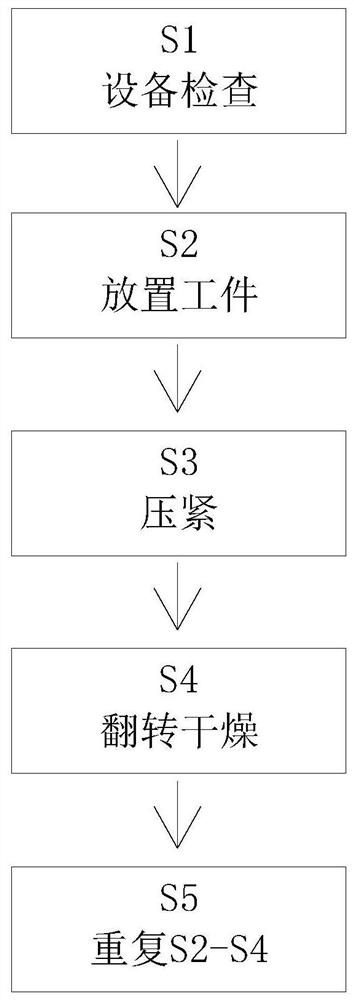

Auxiliary jig for chip production and using method

InactiveCN112051498ARealize the function of limit fixationPrecise stopElectronic circuit testingMeasurement instrument housingElectro hydraulicEngineering

The invention discloses an auxiliary jig for chip production in the technical field of auxiliary jigs for chip production, which comprises a workbench, universal wheels are arranged at four corners ofthe bottom of the workbench, a fixed block is arranged at the bottom of an inner cavity of the workbench, a motor base is arranged at the top of the fixed block, and a gear motor is arranged in the inner cavity of the motor base. The right side of the gear motor is connected with a transverse rotating shaft, the right side of the transverse rotating shaft is connected with a driving bevel gear, the right side of the driving bevel gear is provided with an ejection component, the top of the workbench is provided with a movable frame, the bottom of an inner cavity of the movable frame is provided with multiple sets of fixing bases, and electric hydraulic rods are arranged in inner cavities of the fixing bases. A bottom connecting base is arranged at the bottom of each electric hydraulic rod,a pressing rod is arranged at the bottom of the bottom connecting base, a jig component is arranged in the center of the top of the workbench, and the testing jig can achieve automatic pressing testing on a chip, is high in testing efficiency and facilitates material taking of the tested chip.

Owner:浙江酷趣智能科技有限公司

Gluing device for luggage production

ActiveCN110841843AQuality assuranceAchieve ejectionSpraying apparatusPretreated surfacesElectric machineryEngineering

The invention discloses a gluing device for luggage production, and relates to the technical field of dental comprehensive treatment machines. The gluing device for luggage production aims to solve the problem that the gluing efficiency of luggage production is low. The gluing device for luggage production specifically comprises a support, wherein a guide rail is arranged between a fourth mountingplate and a fifth mounting plate; a bearing plate is connected between a third mounting plate and a second mounting plate; the bearing plate is parallel to the guide rail; a sliding block capable ofsliding along the guide rail is arranged on the guide rail; a material box is arranged on the sliding block; a spray head is arranged on the material box; a booster pump for extruding glue from the spray head is arranged at the upper end of the material box; a linear motor mounting frame is arranged on one side of the fifth mounting plate; a linear motor is arranged on the linear motor mounting frame; a through hole is formed in the fifth mounting plate; a screw rod penetrating through the through hole is arranged on the linear motor; the screw rod penetrates through the fourth mounting plate;and a threaded sleeve connected to the screw rod in a sleeving mode is arranged on the sliding block. According to the gluing device for luggage production, the gluing quality and the gluing efficiency in the luggage production process can be improved.

Owner:耒阳市康意电子箱包科技有限公司

A Positioning and Fixing Mechanism for Drilling Wooden Boards

ActiveCN105415451BReduce structural damageRealize the function of limit fixationDrilling machinesSlide plateDrill hole

The invention discloses a location-fixation mechanism for wood plate drilling. The location-fixation mechanism for wood plate drilling comprises a workbench, wherein a fixed base is arranged on the workbench; a support table is fixedly connected to the fixed base; a support rod is fixedly connected to the support table; an adjustment panel is slidably connected to the support rod; a first slide plate is slidably connected to the adjustment panel; a fixed shaft is arranged at the bottom of the first slide plate; a press block is arranged at one end of the fixed shaft; a slide support frame is arranged on the workbench; a second slide plate is slidably connected to the slide support frame; a rotary shaft is arranged on the second slide plate; a rotary disc is rotationally connected to the rotary shaft; and a location device is arranged on the rotary disc. According to the invention, a wood plate is accurately located in a drilling area, and bidirectional limit and fixation effects on a horizontal surface and a vertical surface are conducted on the wood plate to avoid a displacement phenomenon of the wood plate during drilling; drilled holes are uniform in shape and size, and thus the drilling quality is improved; and moreover, the position adjustment of 90-degree rotation can be carried out on the wood plate according to the actual needs of operating personnel, and thus the drilling efficiency is increased.

Owner:闼闼盈佳(江苏)工贸有限公司

Leg nursing trainer for medical rehabilitation department

InactiveCN114870326ASpeed up recoveryImprove experienceChiropractic devicesRoller massageMedical equipmentLeg exercise

The invention discloses a leg nursing trainer for the medical rehabilitation department, and relates to the technical field of medical equipment, the leg nursing trainer comprises a concave base, and the left side face and the right side face in the concave base are fixedly connected with the left ends and the right ends of four fixing rods respectively. Through mutual cooperation of the foot fixing assembly, the elastic training assembly, the sliding blocks and the fixing rods, the feet of a patient can be fixed in the leg exercising process of the patient, and the patient drives the foot fixing assembly to move in the left-right direction through the feet; the effect of exercising the legs of the patient can be achieved, the rehabilitation process of the patient is accelerated, meanwhile, when the patient does not want to do active exercise or the patient is difficult to do active exercise, the feet of the patient can be driven to move in the left-right direction through the arranged foot fixing assembly, and then the legs of the patient can be driven to do flexion and extension training; therefore, the effect of assisting passive training is achieved, and the actual experience of the patient in the using process is improved.

Owner:菏泽家政职业学院

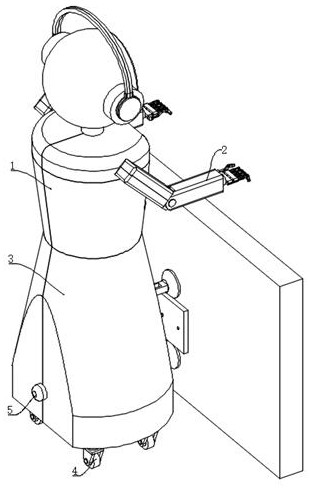

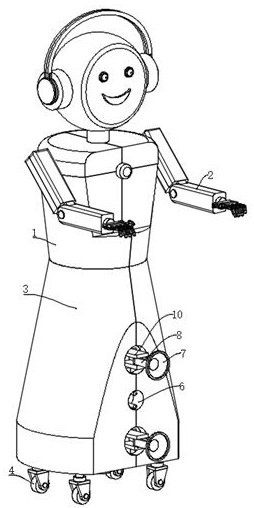

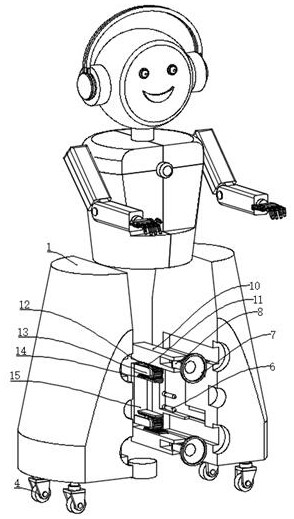

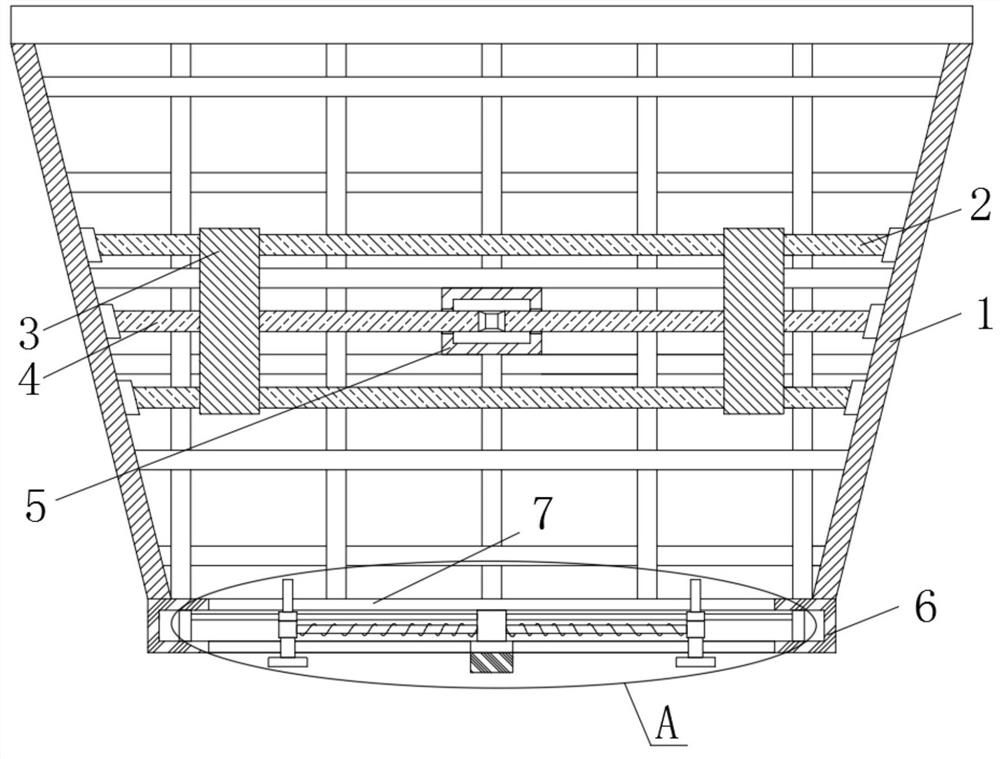

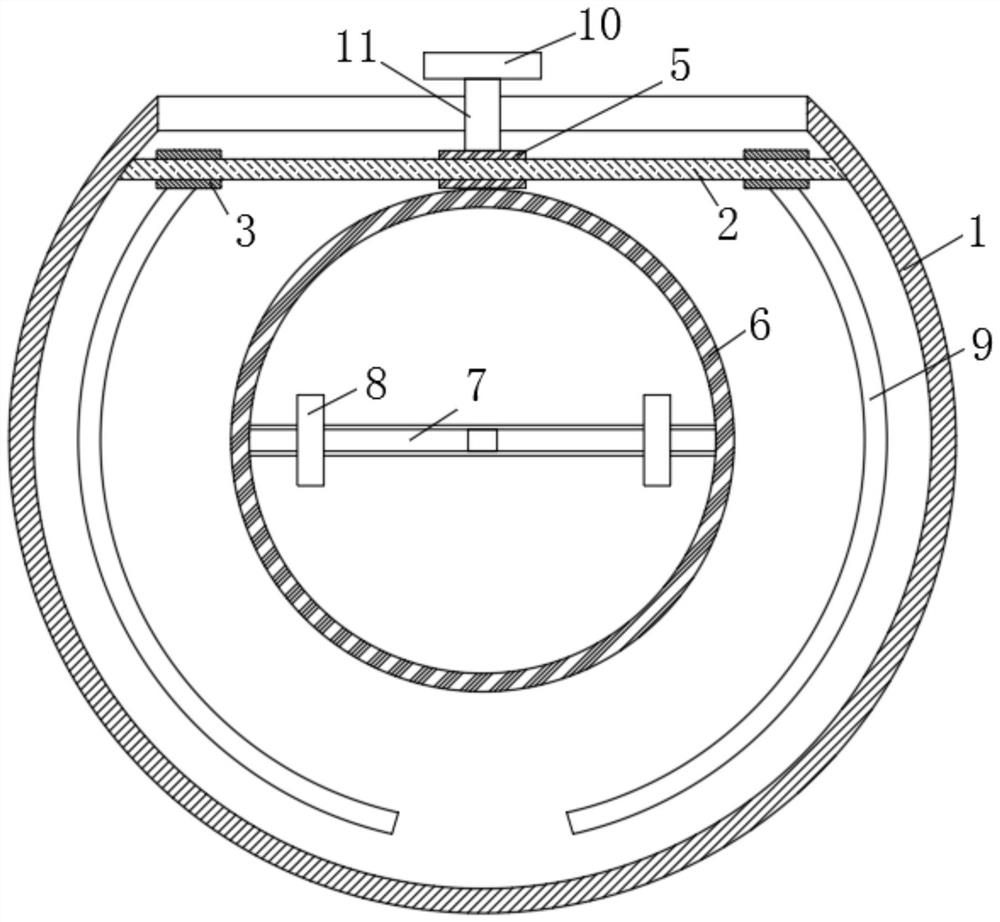

An intelligent calling robot for a call center

ActiveCN113510723BImprove the immunityLift the limit effectProgramme-controlled manipulatorCircuit monitoring/indicationSimulationMachine learning

Owner:深圳特为科创信息技术有限公司

Bicycle basket with helmet lock

ActiveCN112519933APlay a fixed effectServe a fixed purposeCycle containersClassical mechanicsStructural engineering

A bicycle basket with a helmet lock comprises a bicycle basket body, a fixing box is arranged in the bicycle basket body, the fixing box is fixedly connected to the inner wall of the bicycle basket body, a rotating mechanism is arranged in the fixing box, the rotating mechanism comprises a rotating rod, threaded rods, a rotating disc and a first sliding rod, and the threaded rods are arranged on the two sides of the fixing box correspondingly; and first sliding rods are arranged at the top and the bottom of each threaded rod correspondingly, a base is fixedly connected to the bottom end face of the bicycle basket body, two partition plates are symmetrically and fixedly connected into the base, a second fixing block is arranged between the two partition plates, the top end and the bottom end of the second fixing block are fixedly connected to the inner wall of the base, and moving mechanisms are arranged on the two sides of the second fixing block correspondingly. The bicycle basket hasthe beneficial effects that the helmet is fixed more stably in a twice fixing mode in the bicycle basket body, the phenomenon that the helmet shakes is not likely to happen, meanwhile, the helmet isconvenient to take, and a large amount of fixing and taking time does not need to be consumed.

Owner:无锡众行车业科技有限公司

A semi-precision plastic-encapsulated resistor

ActiveCN113851288BImprove the problem that it is difficult to solder uniformly for electrical connectionReliable electrical connectionResistor terminals/electrodesResistor mounting/supportingElectrical resistance and conductanceElectrical conductor

The invention discloses a semi-precision plastic-encapsulated resistor, specifically relating to the field of resistance, including a resistance mechanism for adjusting the size of the current blocking effect in a circuit. Both ends of the resistance mechanism are electrically connected with conductor connections for auxiliary connection of components at various levels. Mechanism, the interior of the conductor connection mechanism is equipped with a reset mechanism as a transmission power source. When the connecting section of the torsion spring is disconnected from the fuse block, the reset-type ruler spring section drives the center positioning sleeve to rotate, and uses the meshing of the corresponding external thread groove and the guide piece internal thread groove to push the outer ring sleeve to guide The end of the body connection mechanism moves, thereby pushing the conductor-type cantilever and the elastic arc conductor to bind the rod-shaped wires outside the conductor connection mechanism, which relatively improves the problem that small circuit board components are difficult to weld evenly for electrical connection.

Owner:蚌埠市爱瑞特电子有限责任公司

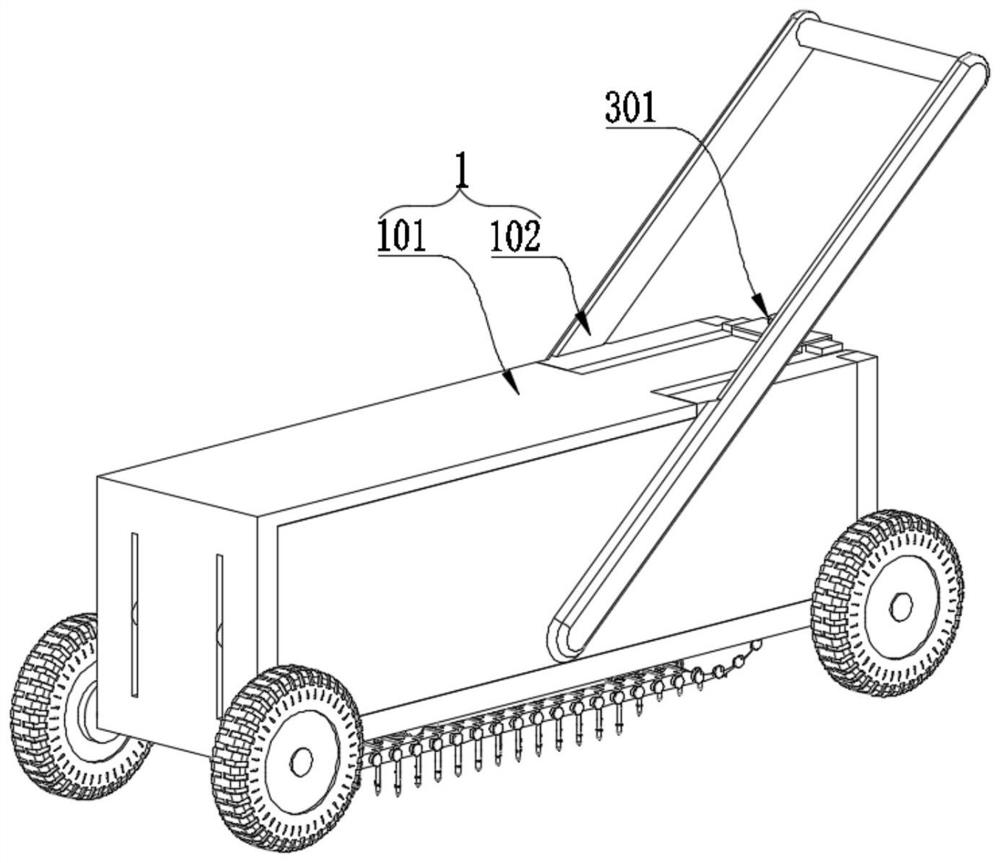

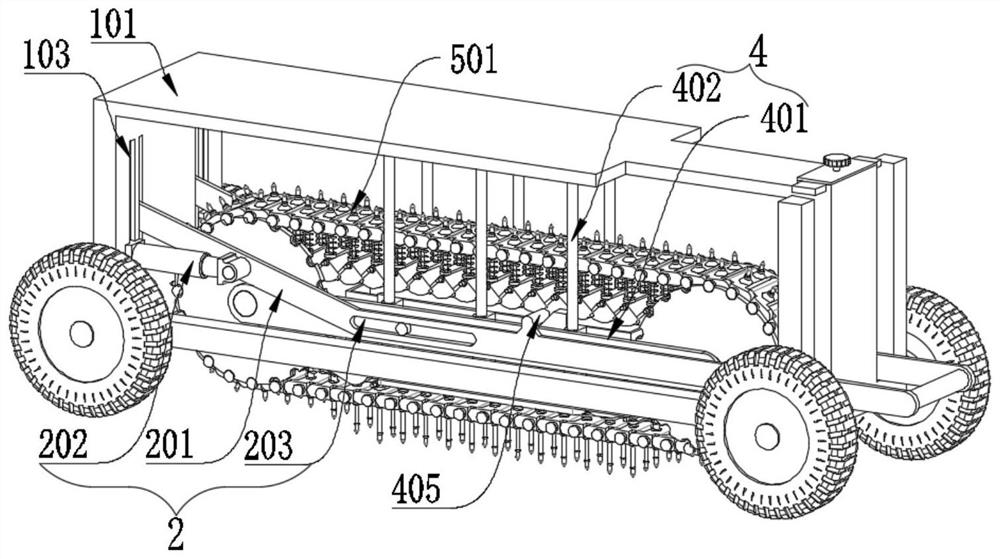

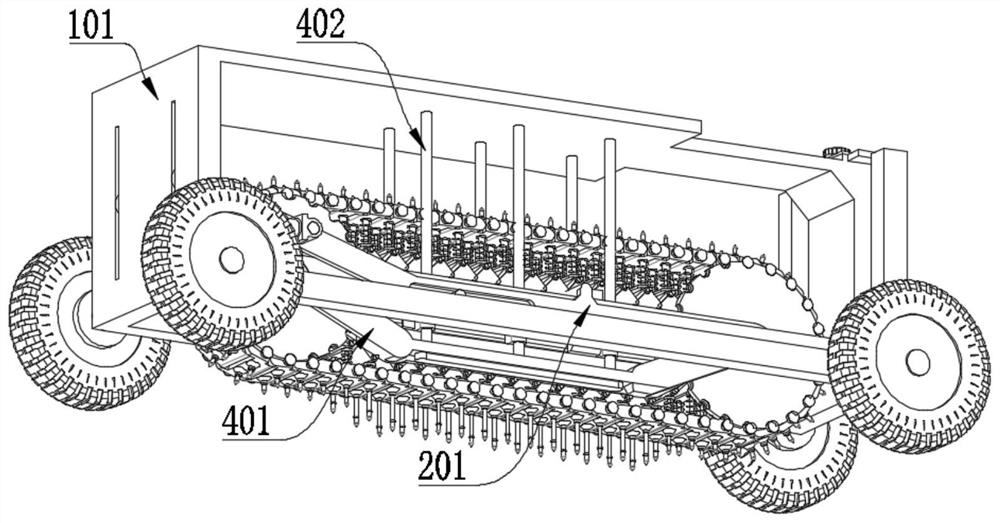

A local turf control device based on greening construction

ActiveCN112753339BRealize the function of limit fixationEasy to fallClimate change adaptationDirect liquid fertiliser deliveryArchitectural engineeringGreening

The invention provides a local turf management device based on greening construction, comprising a box structure; a fixed structure is installed at the right end of the box structure; a frame structure is slidably installed inside the box structure; The control structure is hingedly installed; the crawler structure is installed on the frame structure; the box structure also includes a main box, a pusher, and an installation slot, and two sides of the main box are clamped and fixed with a separate outer wall, and the outer wall is A push handle is fixed on it, a mounting slot is opened at the left end of the inner wall of the main box, the end of the hinged connecting rod extends directly to the outside of the main box, and a tension rod is hingedly installed at the hinge position near the connecting rod, and the root of the tension rod slides In the installation groove, when the connecting rod swings up or down, the connecting rod can be directly fixed to a certain position by the tension rod, thereby effectively realizing the limited and fixed effect of the tension rod on the connecting rod.

Owner:厦门怡亭绿化工程有限公司

Bluetooth sound box

InactiveCN114531626ARealize the function of limit fixationEasy to disassembleNon-rotating vibration suppressionSound producing devicesSound boxEngineering

The invention provides a Bluetooth sound box, and relates to the technical field of sound boxes. The Bluetooth sound box comprises an upper shell and a lower shell, a first connecting shell is arranged in the lower shell, a first charging port is formed in the outer surface of one side of the first connecting shell, a second charging port is formed in the outer surface of one side of the first connecting shell, and a card slot is formed in the outer surface of one side of the first connecting shell in a penetrating mode; a storage battery is arranged on the inner bottom wall of the first connecting shell, a circuit board is arranged on the inner wall of the first connecting shell and located above the storage battery, foam is arranged above the circuit board, and a first guide column is fixedly connected to the inner bottom wall of the lower shell. A first guide column upwards penetrates through a first inserting groove to limit and fix the first connecting shell, a second guide column upwards penetrates through a second inserting groove and is matched with a fixing screw to fix the upper shell and the lower shell, the whole body can be conveniently disassembled and overhauled, the practicability is high, the size is small, and carrying is convenient.

Owner:深圳市鑫东声电子科技有限公司

Workpiece stabilizing and fixing mechanism for machining grinding machine

ActiveCN110000701AEasy to useConvenient positioning and processingGrinding work supportsSlide plateMachining

The invention discloses a workpiece stabilizing and fixing mechanism for a machining grinding machine. The workpiece stabilizing and fixing mechanism comprises a bottom box. The top of the bottom boxis fixedly connected with a fixed shell. The top of the fixed shell is fixedly connected with a top plate. The top of the top plate is fixedly connected with a grinding device. The two sides of the top of the top plate are both movably connected with movable plates. The opposite sides of the two movable plates are both fixedly connected with positioning shells. The top of each positioning shell ismovably connected with a positioning mechanism. The workpiece stabilizing and fixing mechanism for the machining grinding machine is provided with the bottom box, limiting mechanisms, the positioningmechanisms, fixing mechanisms, the fixed shell, the top plate, protection plates, the grinding device, the positioning shells, telescopic rods, first ports, springs, the movable plates, sliding plates, connecting plates, vertical plates, fixing grooves, second ports and pull rings to be used cooperatively. The problems that a user cannot conduct positioning on different sizes of workpieces conveniently through an existing machining grinding tool workpiece stabilizing and fixing mechanism and the positioning effect of the workpieces is poor are solved.

Owner:河南工学院

Tunnel waterproof cloth construction platform

PendingCN110939469AEasy swivel movementSuitable for forward and backward movementUnderground chambersTunnel liningArchitectural engineeringSupport plane

The invention discloses a tunnel waterproof cloth construction platform. The tunnel waterproof cloth construction platform comprises a supporting frame, wherein a driving screw rod is mounted at the top end of the supporting frame, a shaft plate is mounted at one end of the driving screw rod, a transverse sliding frame is mounted on the surface of the driving screw rod, a pneumatic sliding rail ismounted on the surface of the transverse sliding frame, and a movable table is mounted on the surface of the pneumatic sliding rail. According to the tunnel waterproof cloth construction platform, through arrangement of a series of structures, the tunnel waterproof cloth construction platform can be installed on construction equipment such as a tunnel trolley when in actual use, construction of the front, rear, left and right direction can be carried out, actual tunnel construction requirements are met, partial components have the functions of being convenient to disassemble and install, andthe actual operation such as transportation is facilitated.

Owner:ZHOUKOU NORMAL UNIV +1

Cutting and processing equipment for wooden structure building materials

ActiveCN112454539BIncrease the speed of cutting processRealize functionCircular sawsArchitectural engineeringMechanical engineering

Owner:杭州八分园景观设计工程有限公司

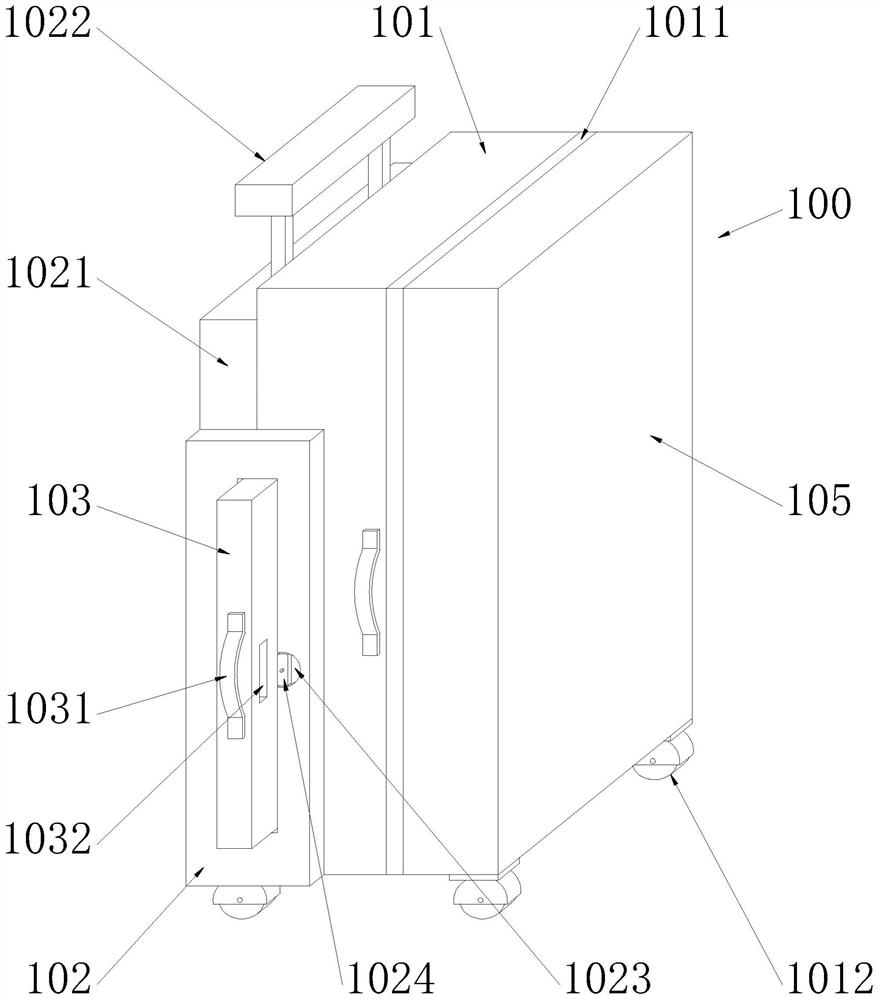

Internally-separated and protected air-riding safety draw-bar box

InactiveCN113712357ARealize functionAchieve protectionLuggageOther accessoriesStructural engineeringMechanical engineering

The invention discloses an air-riding safety draw-bar box with internal separation and protection. The draw-bar box comprises a box body, a zipper, rollers, magnets, a partition plate, a connecting rod, a metal rod, a connecting plate, an opening, a protection plate, a mounting base, a pull rod, a circular groove, a rotating rod, a pull plate, a handle, a clamping groove, a limiting plate, a fixing base, a long hole, a sliding block, a reset spring, a fixing plate, a box cover, a guide plate, a groove, an inserting groove, an adjusting plate, a notch, a clamping block, a guide plate, a shell, an inserting rod, a connecting spring, a connecting block, a movable wedge block, a movable plate, a top plate and a fixed wedge block. The draw-bar box is advantaged in that the separation function of the draw-bar box can be achieved, meanwhile, the partition plate has limiting and fixing effects, the safety protection function of the draw-bar box can be effectively improved by arranging the protection plate on the outer side, storage stability of articles is guaranteed by arranging the adjusting plates in the box cover, and the corresponding positions can be adjusted according to the sizes of the articles; practicability of the draw-bar box is improved, and the adjusting plate is convenient to disassemble and take down.

Owner:浙江安防职业技术学院

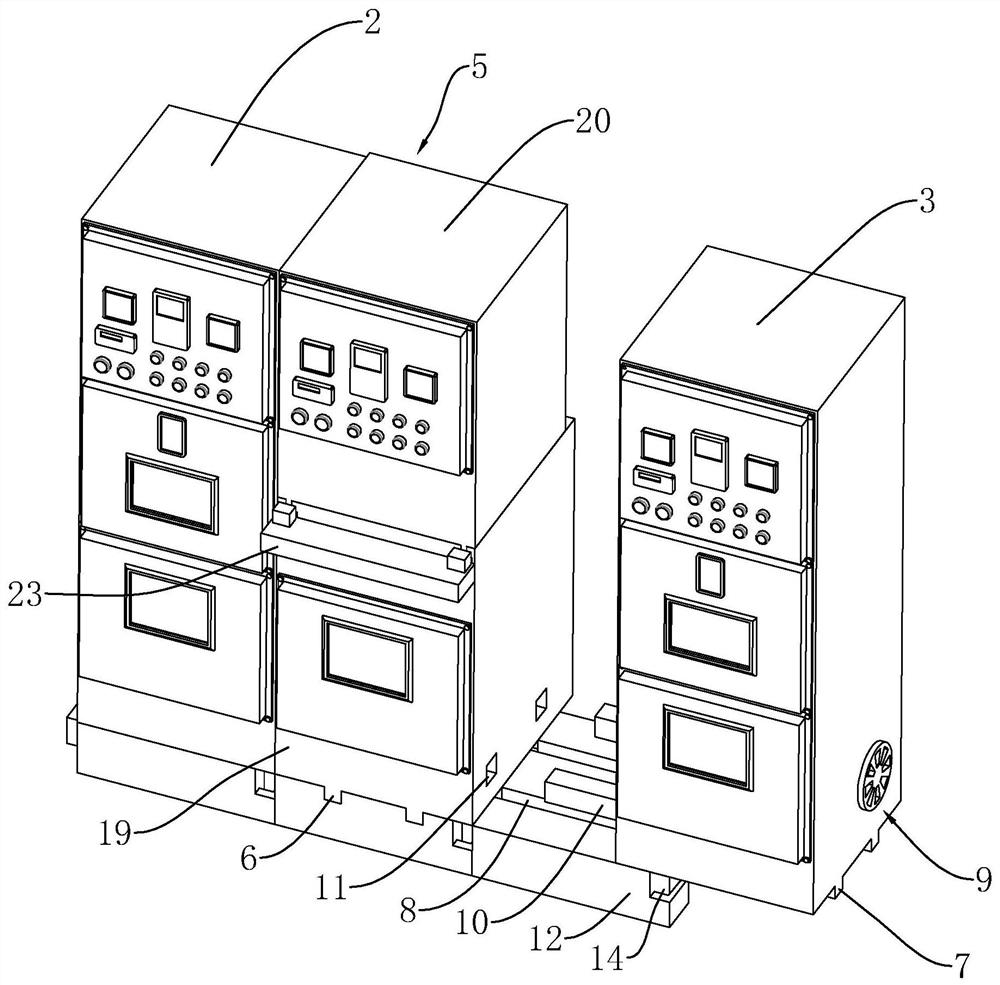

A complete set of primary and secondary fusion ring cages

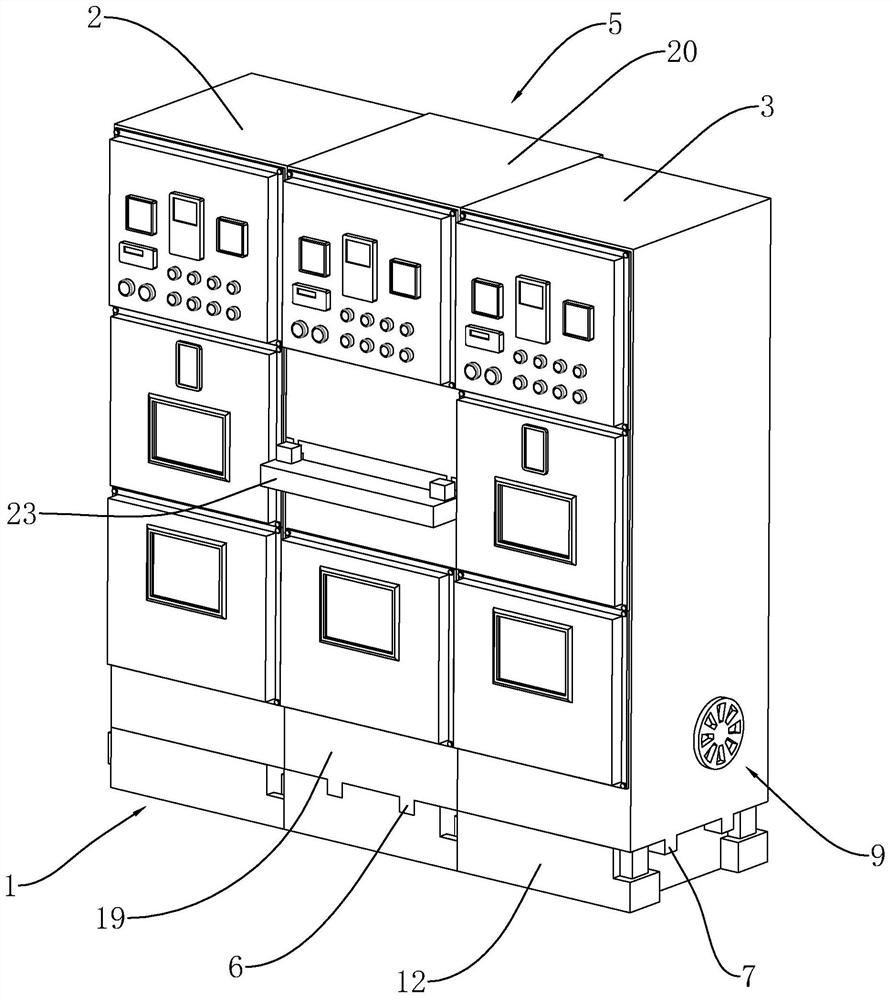

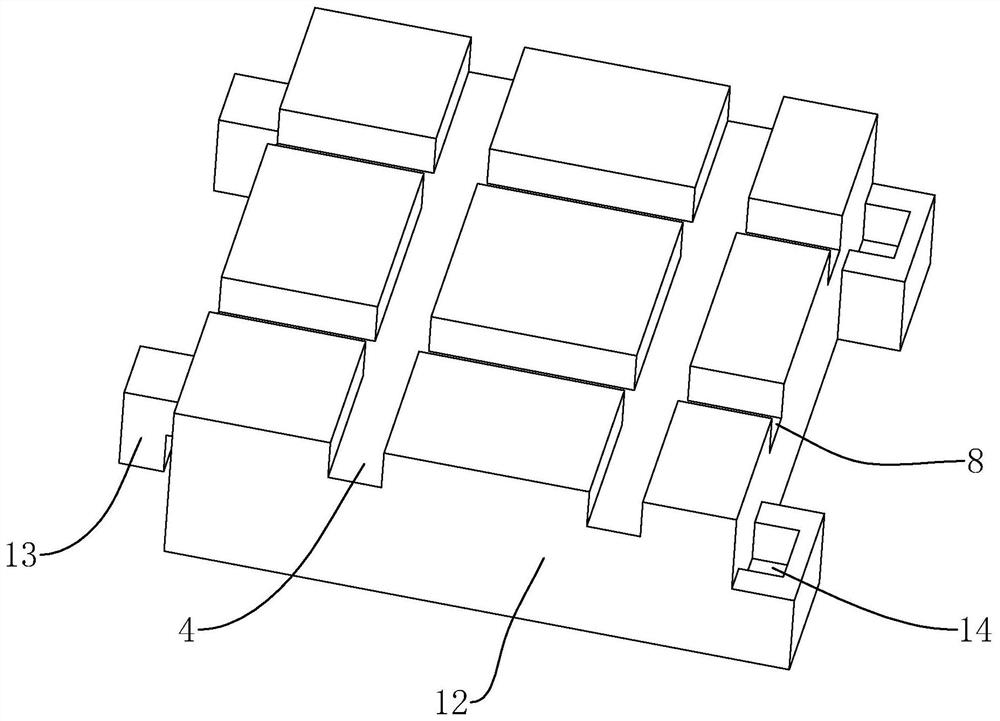

ActiveCN111541163BEasy to replaceRealize the effect of free assembly and combinationBus-bar/wiring layoutsFeeder lineRing network

The invention relates to a complete set of primary and secondary fusion ring network cabinets, and relates to the technical field of ring network cabinets. Between the first chute, the first chute is opened along the width direction of the base; a number of transition units are installed on the base through the first chute; the bottom of the transition unit is provided with a first slide rail extending along the opening direction of the chute, the first A slide rail is slidably set in the chute; the bottom of the feeder unit is provided with a second slide rail along the length direction of the base, and the base is provided with a second slide slot along the length direction of the second slide rail, and the second slide rail is slidably set In the second chute; the first chute and the second chute are perpendicular to each other, and the feeder unit is also provided with a limit mechanism for limiting the transition unit; the present invention has the ability to meet the needs of users to add or delete units , the user can freely combine the number of units according to actual needs.

Owner:德锐电气有限公司

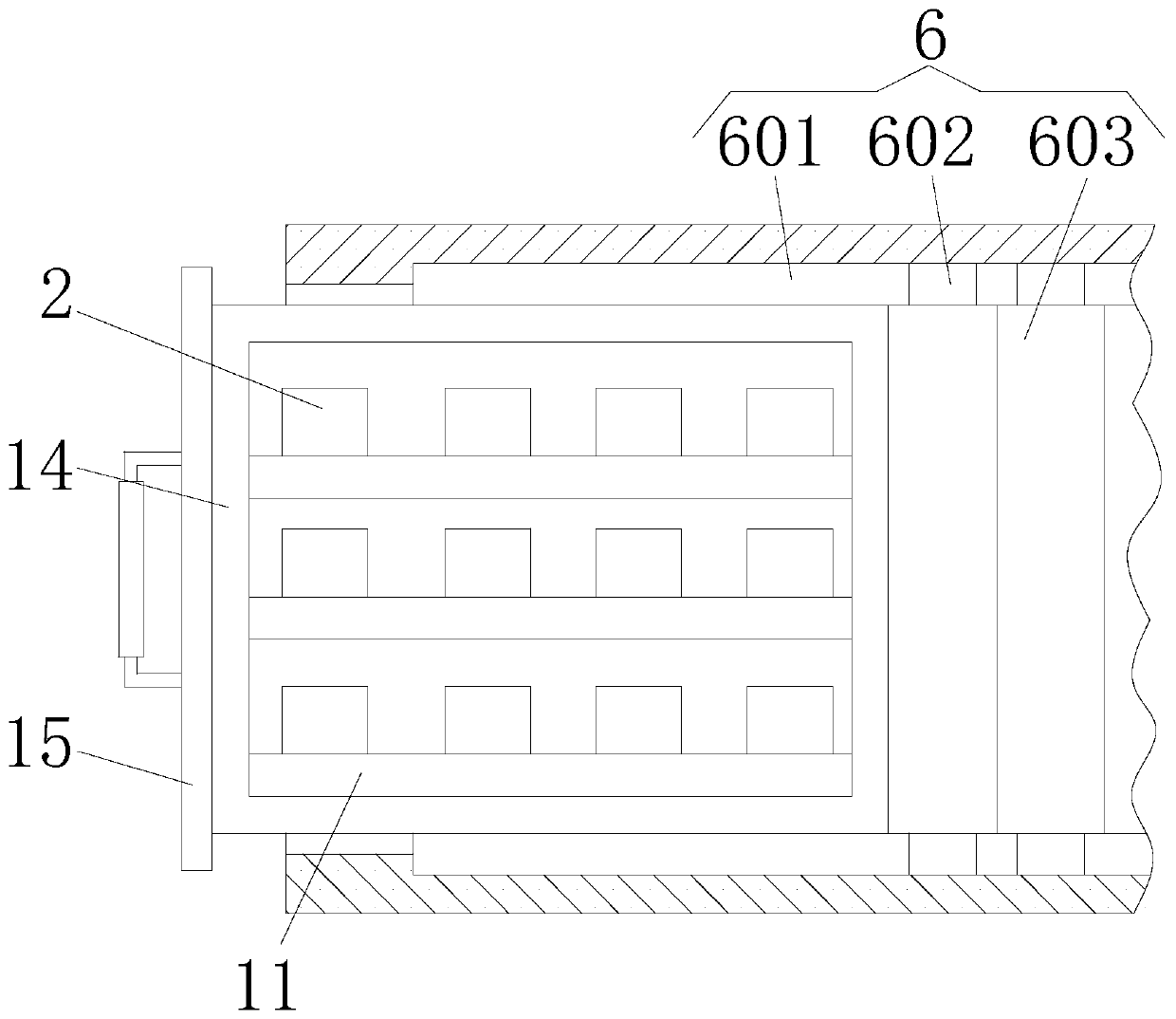

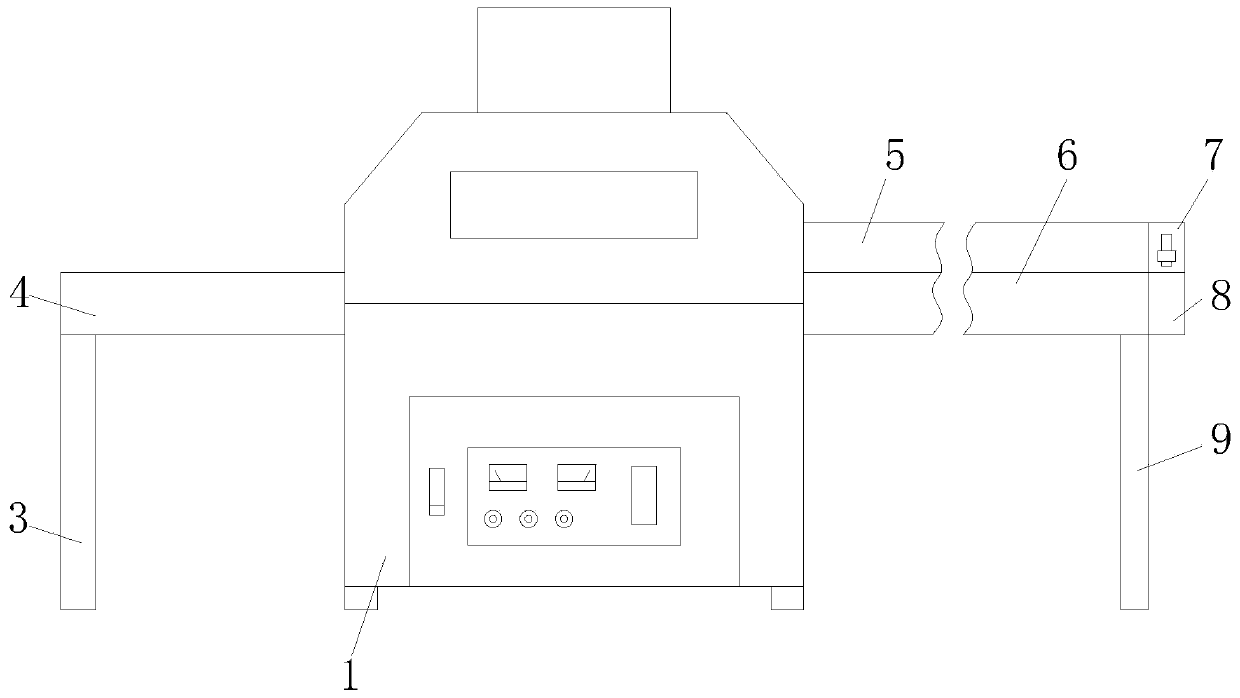

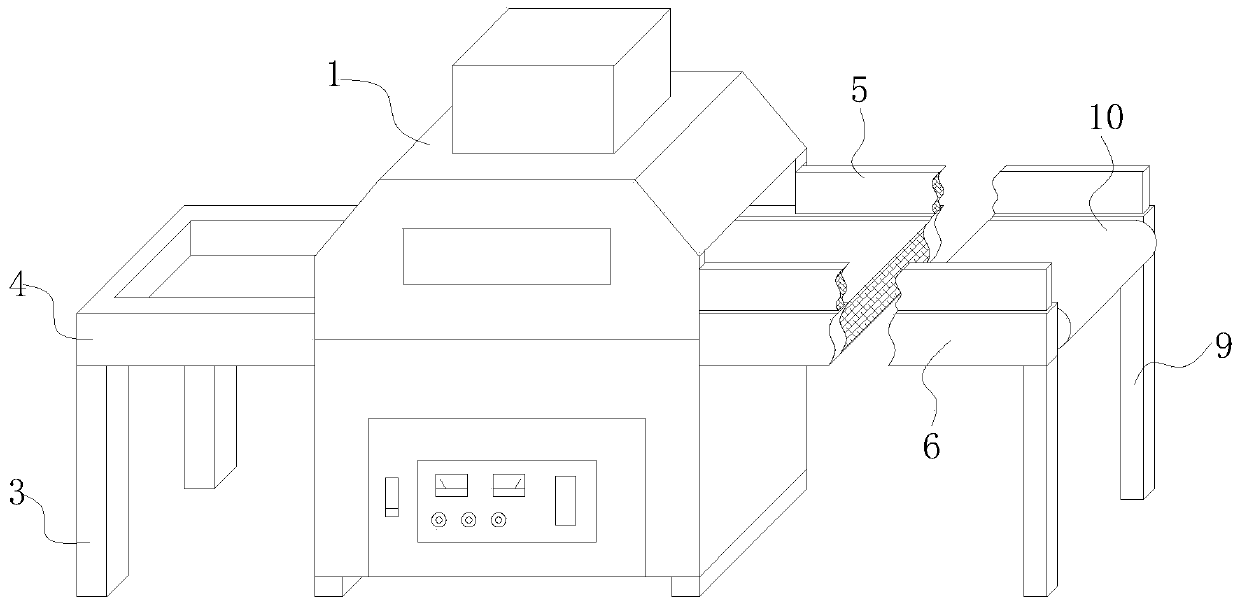

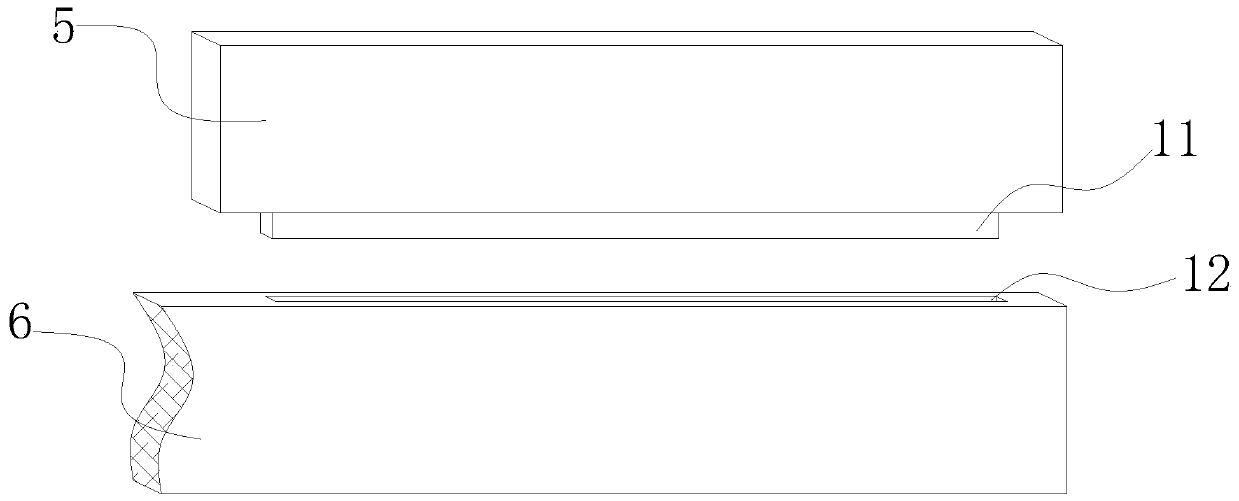

Feeding mechanism of kiln for producing sagger for lithium-ion battery cathode material

InactiveCN109883205ARealize the function of limit fixationEasy to assemble and disassembleCharge manipulationSheet joiningEngineeringLithium-ion battery

The invention discloses a feeding mechanism of a kiln for producing a sagger for lithium-ion battery cathode material, comprises a kiln body, wherein a storage platform is fixedly connected to the left side of the kiln body, first support legs are fixedly connected to the front side and the rear side of the bottom of the storage platform, fixing plates are fixedly connected to the front side and the rear side of the right side of the kiln body, a conveyor belt is movably connected between the opposite sides of the two fixing plates, and a baffle plate is fixedly connected to the tops of the fixing plates. By cooperative use of the kiln body, a limiting mechanism, the first support legs, the storage platform, the baffle plate, the fixing plates, a first housing, a second housing, second support legs, the conveyor belt, a clamping plate, a clamping groove, a movable plate, a movable rod, a first spring, a first through port, a sliding knob, a connecting block, a clamping block, a secondthrough port, a handle and a connecting rod, the problem that the existing feeding mechanism of the kiln for producing the sagger for the lithium-ion battery cathode material cannot prevent the saggerfrom falling and is not convenient for a user to disassemble and assemble.

Owner:广东山摩新材料科技有限公司

A kind of grinding device for optical fiber lens with adjustable radian

ActiveCN113798954BAdjust the tilt angleAvoid offsetGrinding wheel securing apparatusGrinding carriagesScrew threadThreaded rod

The invention discloses a radian-adjustable optical fiber lens polishing device, comprising a worktable, a backboard and a fixed screw rod. A bearing on the worktable is connected with a bidirectional threaded rod, and a limit ring is fixed on the bidirectional threaded rod. The end of the threaded rod is fixed with a hand wheel, and at the same time, the two-way threaded rod and the movable frame are connected to each other, the fixed screw and the cylinder are connected to each other, and the bearing at the end of the fixed screw is connected to the fastening plate, and the fastening plate is fixed with a rubber pad At the same time, a slider is fixed on the fastening plate, and the slider and the workbench are connected to each other. The optical fiber lens grinding device with adjustable radian adopts a movable adjustment grinding mechanism, which can realize the adjustment of the inclination angle of the grinding plate, and then realize the processing of conical optical fibers with different radians, and can realize the processing of optical fibers of different sizes through the distance adjustment mechanism. , and cooperate with the clamping device with the pre-positioning structure, which can effectively avoid the deviation in the clamping and fixing of the optical fiber.

Owner:深圳市飞宇光纤系统有限公司

Automobile sheet metal process

InactiveCN112588876ARealize the function of limit fixationImprove practicalityMetal-working feeding devicesPretreated surfacesBilateral symmetryIndustrial engineering

The invention provides an automobile sheet metal process which adopts the following equipment for treatment: the equipment comprises a base, support frames and a clamping device. The lower end of thebase is connected with the existing ground; the support frames are mounted on the upper end surface of the base in a bilateral symmetry manner; and the clamping device is arranged between the supportframes which are opposite to each other left and right. According to the automobile sheet metal process provided by the invention, through mutual cooperation of an inner supporting module, an extrusion plate, a spring and a [-shaped frame, the periphery of an automobile sheet metal workpiece can be limited; the position of the extrusion plate can be automatically adjusted by arranging the spring,so that the function of limiting and fixing the automobile sheet metal workpiece in an all-around mode is achieved; and meanwhile, the equipment can be used for fixing and machining the automobile sheet metal workpieces with different sizes and specifications, so that the practicability of the equipment is improved.

Owner:南京柯策商贸有限公司

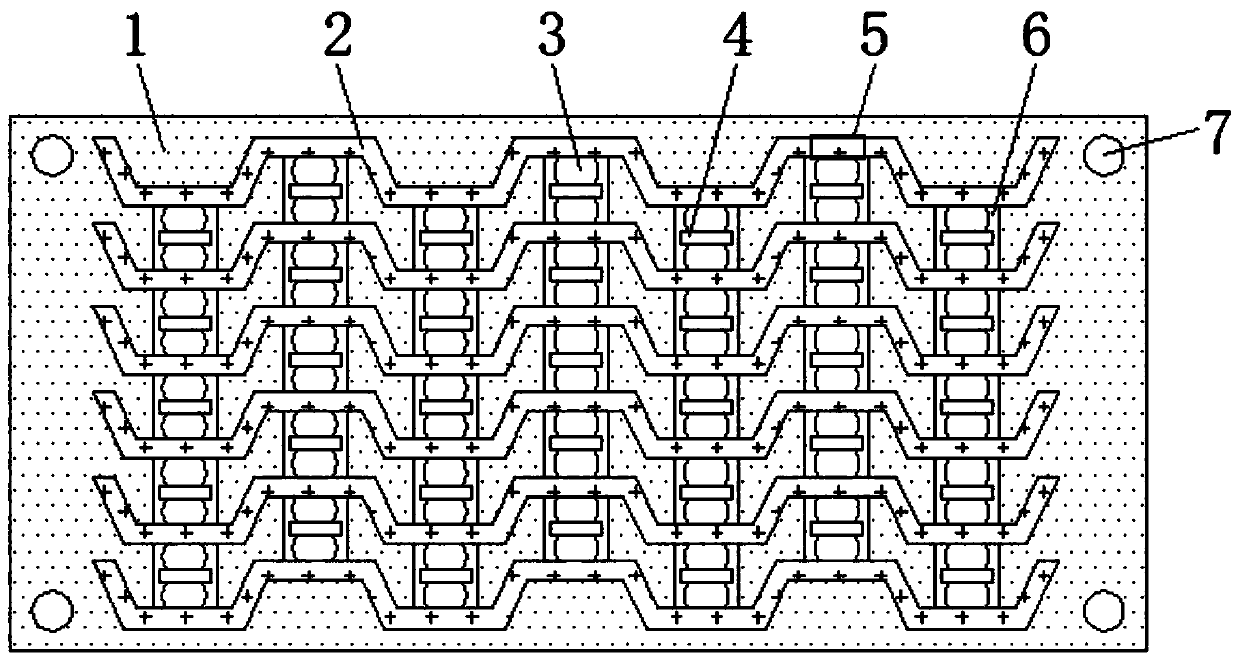

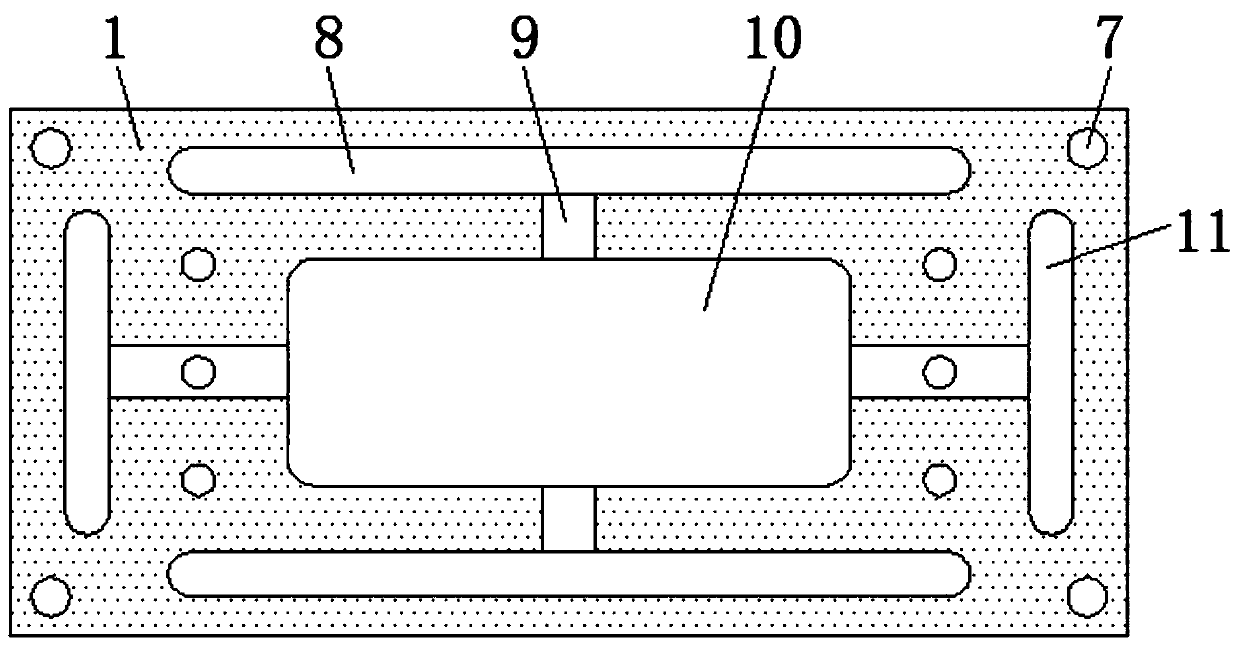

Cooling fin of ultrathin mainframe box

PendingCN110149788AImprove cooling effectExtended service lifeModifications by conduction heat transferHeat sinkWave shape

The invention discloses a cooling fin of an ultrathin mainframe box. The cooling fin comprises a sheet base, wave-shaped sheet bodies, compression-resistant structures, spacing seats and positioning holes, wherein the positioning holes are formed at the corners of the surface of the film base, the wave-shaped sheet bodies are arranged on the surface of the sheet base at equal intervals, and the spaced seats are arranged on the surface of the substrate between the adjacent wave-shaped sheet bodies at equal intervals; the compression-resistant structures are arranged in the wave-shaped sheet bodies; two groups of second heat dissipation holes are formed in the outer wall of one side of the film base at equal intervals; one end of the second heat dissipation hole extends into the center clamping cavity and is communicated with the outer wall of the copper substrate; two sets of first heat dissipation holes are formed in the outer wall of the side, away from the second heat dissipation hole, of the substrate at equal intervals, and one end of each first heat dissipation hole extends into the center clamping cavity and is communicated with the outer wall of the copper substrate. According to the invention, the phenomena that the wave-shaped sheet bodies are worn are reduced when the cooling fin is in use, the cooling effect of the cooling fin is improved when the cooling fin is in use, and the service life of the cooling fin is prolonged.

Owner:东莞市派实达电子科技有限公司

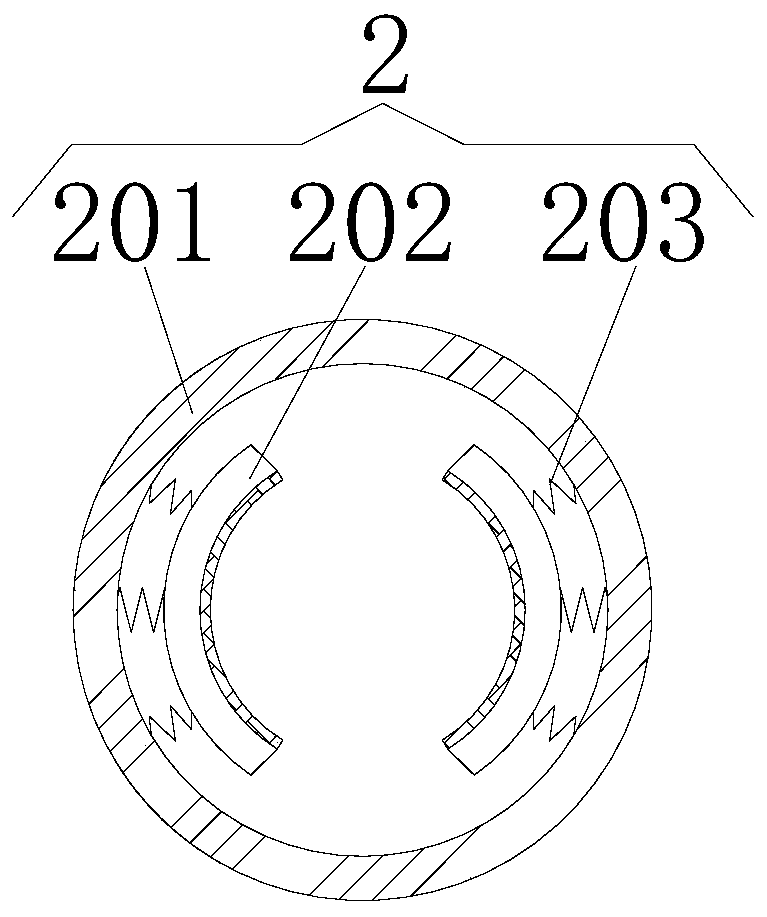

Crane traveling wheel machining equipment and machining technology

PendingCN112676945ARealize the role of fixed supportEasy to replaceGrinding wheel securing apparatusRevolution surface grinding machinesElectric machineryMachining process

The invention discloses crane traveling wheel machining equipment and machining technology. The crane traveling wheel machining equipment comprises a base, a fixing plate and an electric telescopic rod, a mounting frame is fixed on the base through welding, a motor is fixed to the mounting frame through bolts, a rotating screw is fixed to the tail end of an output shaft of the motor, meanwhile, the rotating screw and a fastening nut are mutually connected, the electric telescopic rod is fixed to the mounting frame, the electric telescopic rod is connected with a clamping plate through a columnar shaft, the clamping plate is connected with the electric telescopic rod through a torsion spring, and meanwhile the clamping plate and a grinding plate are mutually connected. According to the crane traveling wheel machining equipment, an adjustable inner supporting mechanism is adopted for fixing and supporting a traveling wheel body, a fixing mechanism can conduct supporting and limiting according to the inner diameter of a traveling wheel, therefore, the fixing and supporting effect on the traveling wheels of different sizes is achieved, the crane traveling wheel is clamped in the equipment to be ground, and the surface grinding precision of the traveling wheel can be improved.

Owner:苏州科铁机械有限公司

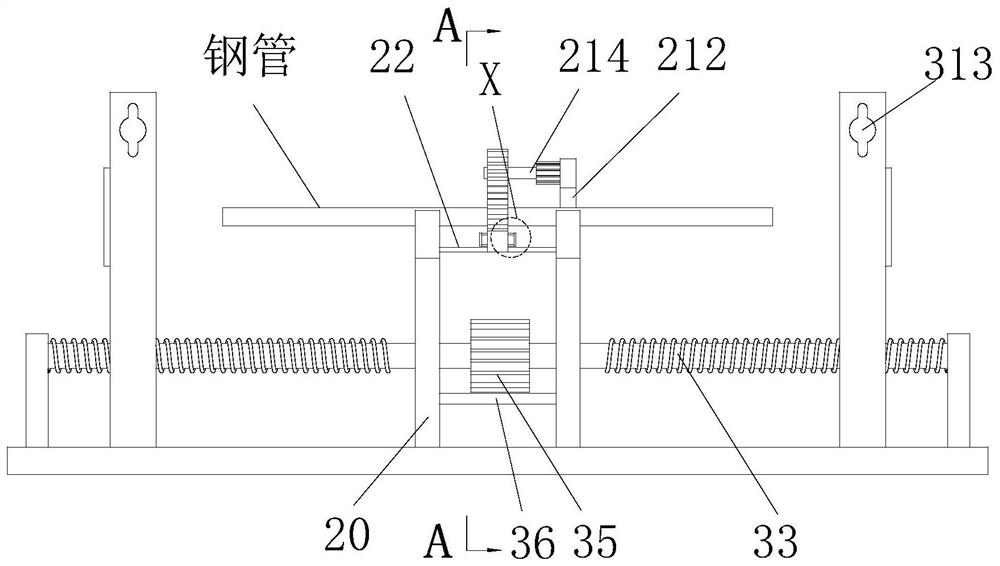

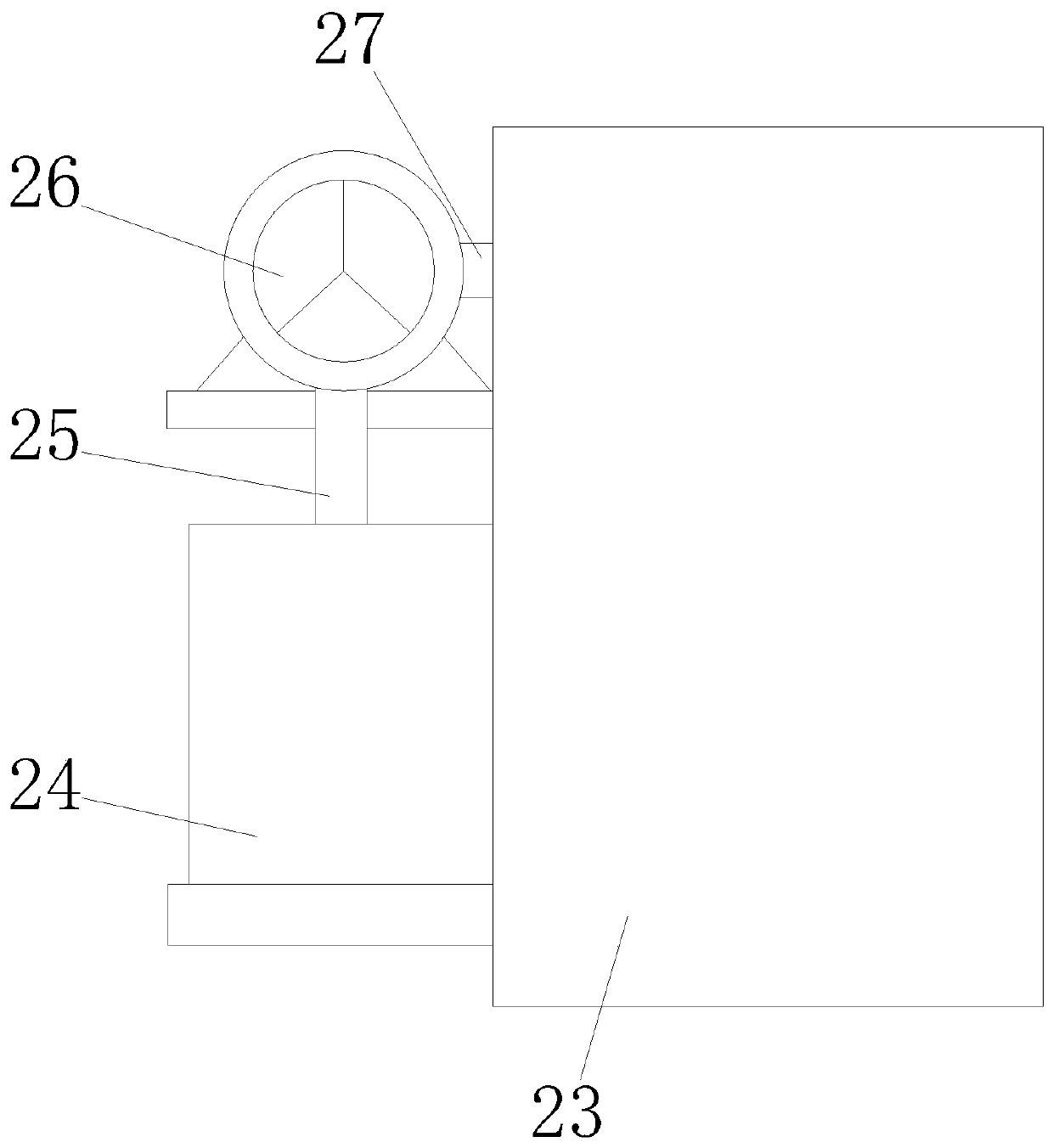

Boiler economizer manufacturing and forming machining machine and forming machining method

InactiveCN113043042AQuick disassemblyImprove processing efficiencyLarge fixed membersPositioning apparatusGear wheelMachining process

The invention relates to a boiler economizer manufacturing and forming machining machine and a forming machining method. The boiler economizer manufacturing and forming machining machine comprises a base, a fixing device and chamfering devices, the lower end of the base is connected with the existing ground, the fixing device is installed at the upper end of the base, and the chamfering devices are symmetrically arranged on the front side and the rear side of the fixing device. Through mutual cooperation of a bearing frame, an annular gear, a clamping rod and a hoop, a steel pipe of a boiler economizer can be fixed to prevent the steel pipe from shaking, and meanwhile, a bearing table is arranged to play a role in bearing the steel pipe of the boiler economizer, the machining process is more stable, and through cooperation of the hoop and the clamping rod, the hoop can be conveniently and rapidly disassembled and assembled by workers, the fixing speed is increased, the machining efficiency is improved, and meanwhile, the steel pipes can be chamfered in batches by arranging multiple annular gears and hoops, and then the machining forming efficiency of the boiler economizer can be improved.

Owner:钱方

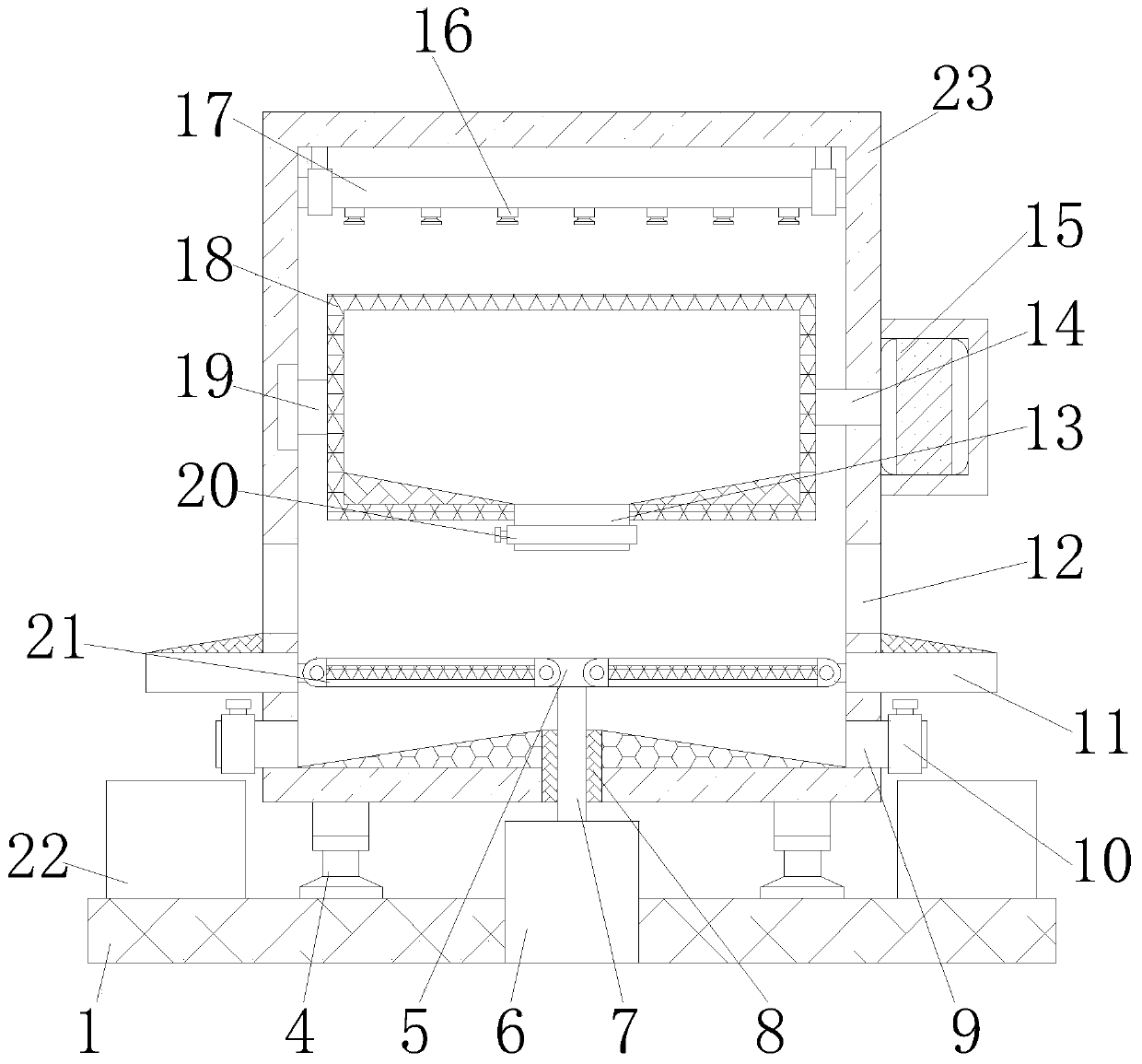

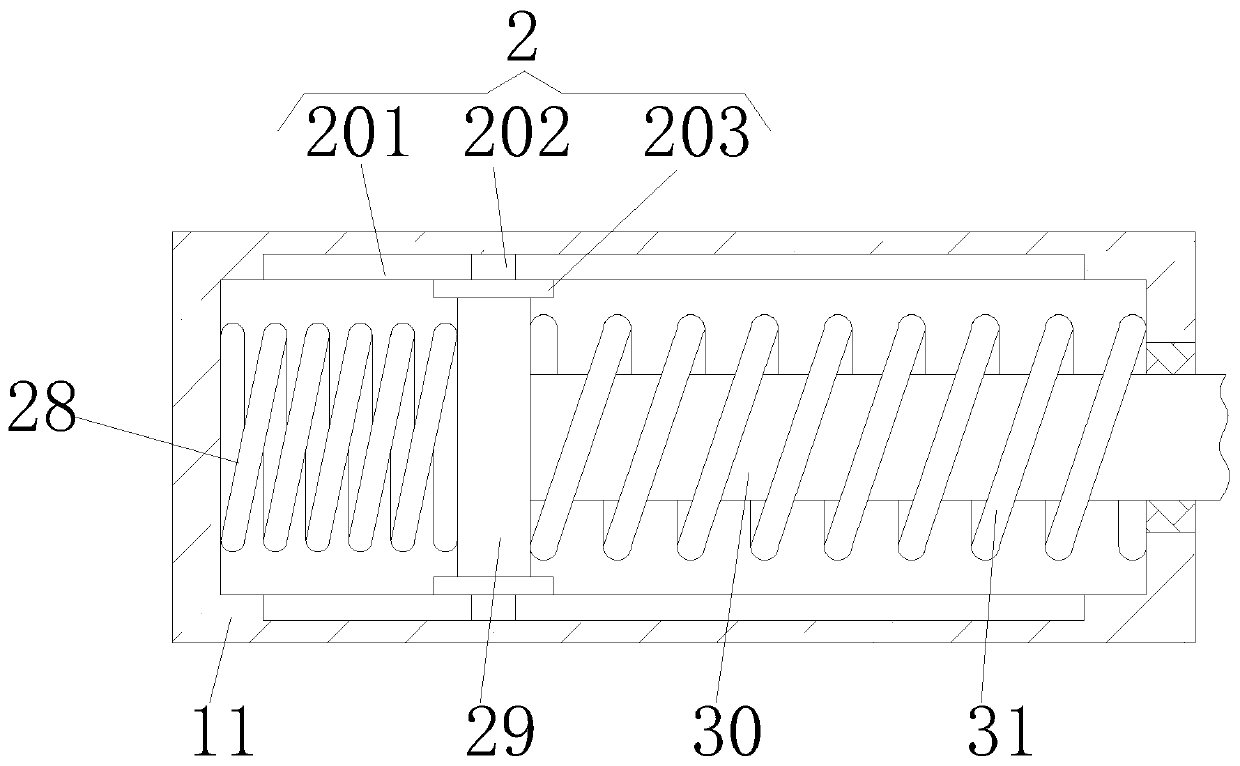

A malt pretreatment device

The invention discloses a malt pretreatment device, comprising a base, wherein a processing box is arranged at the top of the base, a box door is movably connected at the top of the front surface of the processing box, four corners of the bottom of the processing box are fixedly connected with supporting legs, and the bottoms of the supporting legs are fixedly connected with the base. By cooperation of the base, a sliding mechanism, a transmission mechanism, the supporting legs, a connecting block, a housing, a movable rod, a sealing sleeve, a drain pipe, a control valve, a fixed housing, a discharge port, a conveying pipe, a rotating rod, a first motor, a spray head, a water conveying pipe, a screen cylinder, a connecting rod, a solenoid valve, a filter screen, a receiving tank, a processing tank, a water tank, a suction pipe, a water pump, a water outlet pipe, a tension spring, a movable plate, a slide rod, a spring, a slide plate and the box door, the problems that an existing maltpretreatment device is not convenient for a user to collect the processed malt, does not have a cleaning and screening integrated function, and is not convenient for the user to use are solved.

Owner:JIANSU JINSHAN BEER RAW MATERIAL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com