Cutting and processing equipment for wooden structure building materials

A construction material and cutting processing technology, applied in the field of wood processing, can solve the problems of wood affecting the cutting track, reduce the tenon forming rate, time-consuming and labor-intensive, etc., to achieve good cutting effect and increase the speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways as defined and covered by the claims.

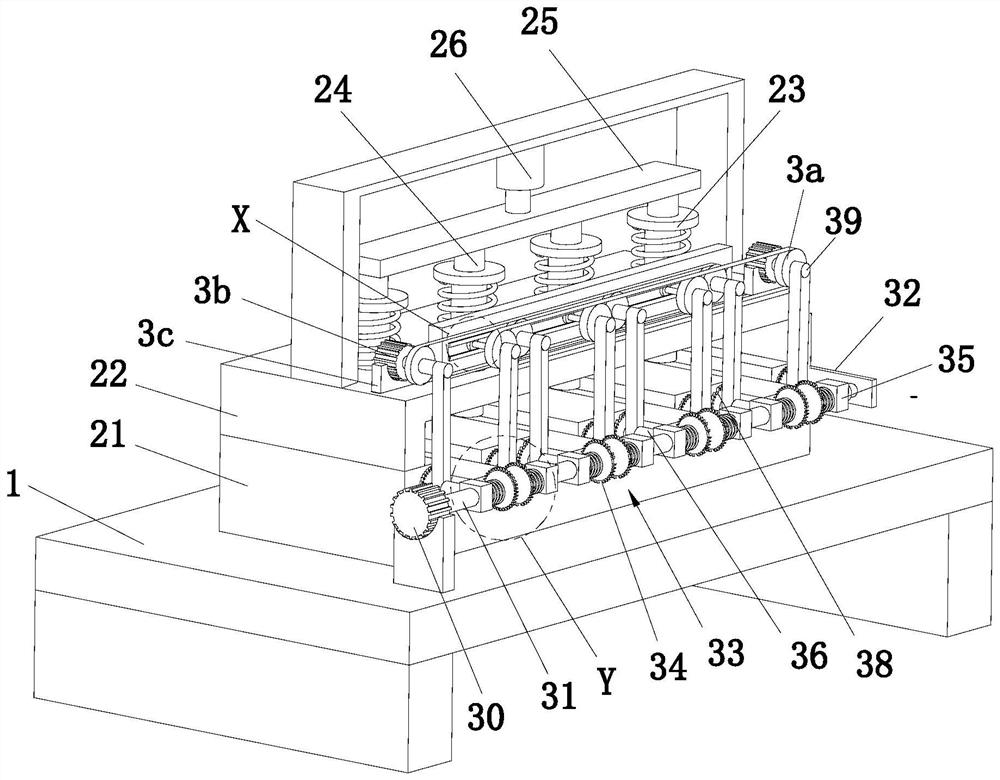

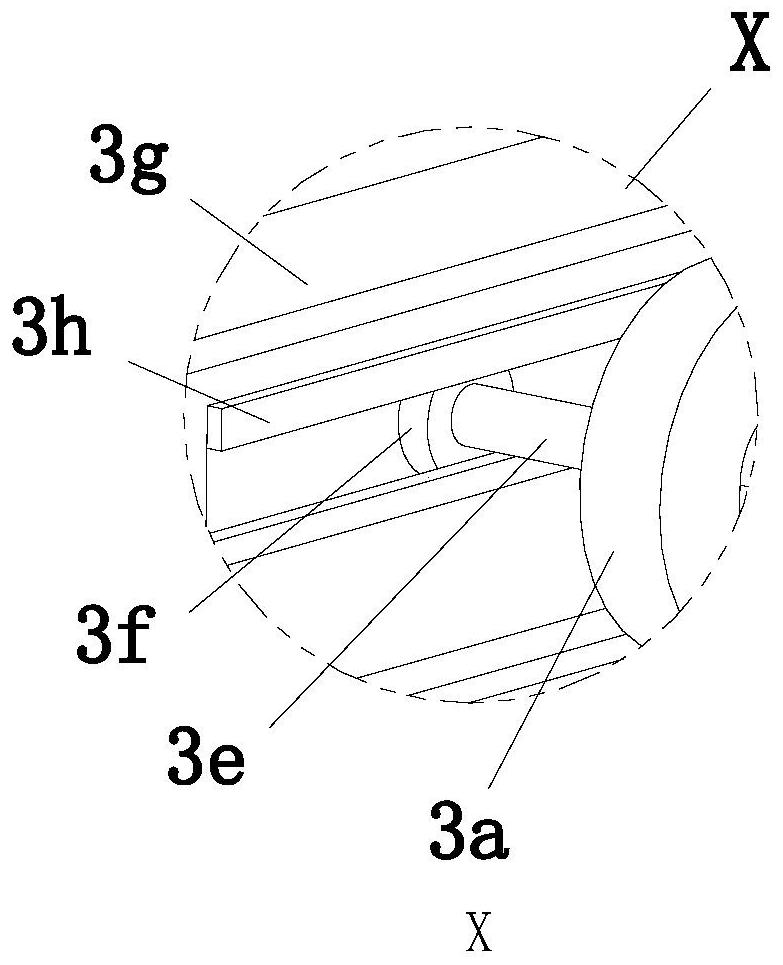

[0026] Such as Figure 1 to Figure 5 As shown, a wooden structure building material cutting processing equipment includes a base 1, a fixed table 2 and a cutting device 3, the middle part of the upper end surface of the base 1 is installed with a fixed table 2, and the front side of the fixed table 2 is provided with a cutting device 3.

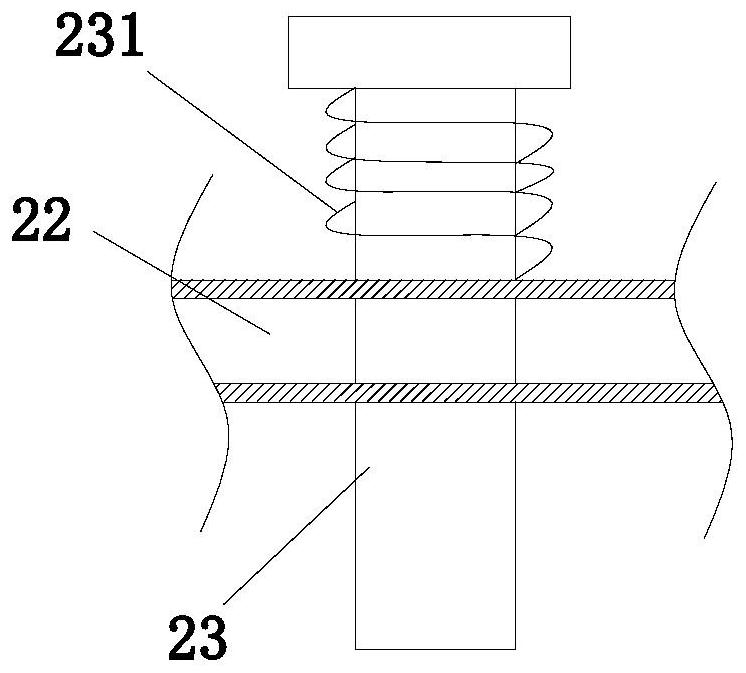

[0027] The fixed platform 2 is made up of a rectangular base 21 and a U-shaped frame 22 with the opening facing downward. A plurality of through slots are provided at a distance, and the number of the through slots is the same as that of the cutting unit 33. A T-shaped post 23 is arranged above the through slot. The upper end of the T-shaped frame 22 runs through the upper end of the U-shaped frame 22 and exte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com