Gluing device for luggage production

A gluing device, luggage technology, applied in the direction of the surface coating liquid device, spraying device, coating, etc., can solve the problems of poor gluing quality, low gluing efficiency, etc., to improve the effect of gluing, improve effect, the effect of improving flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

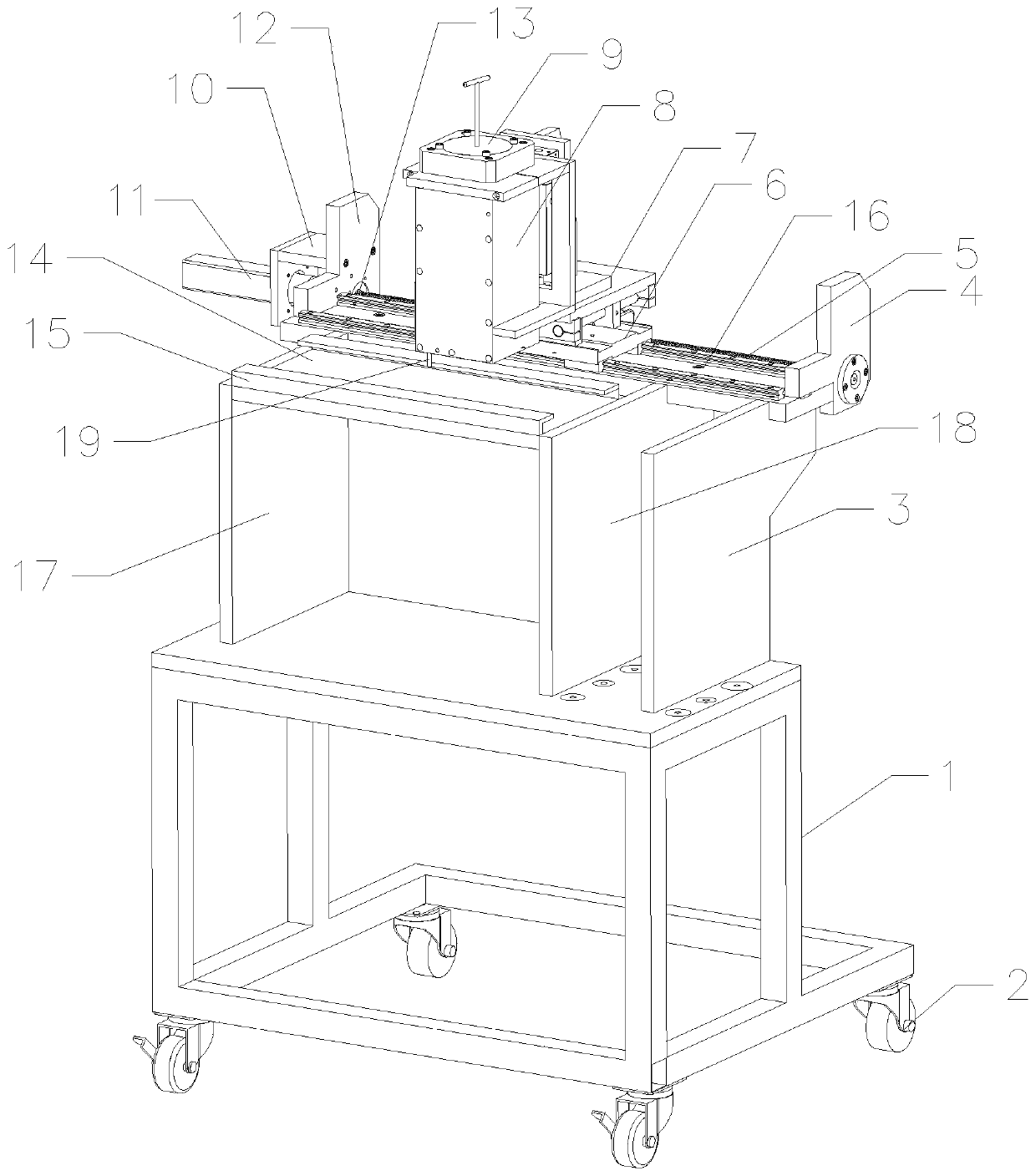

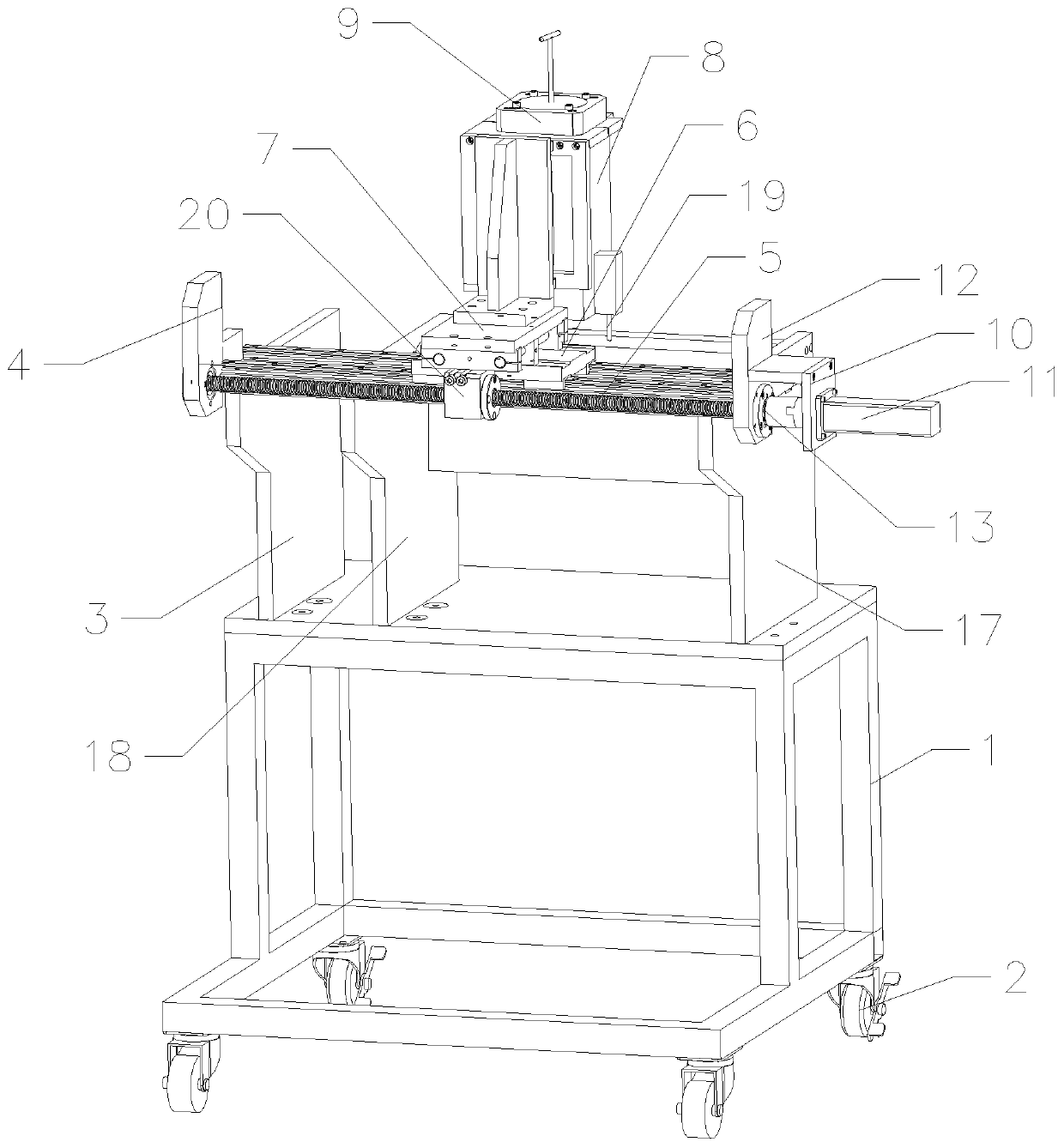

[0034] A gluing device for the production of bags, such as figure 1 and figure 2 As shown, it includes a bracket 1 and a roller 2 installed on the lower end of the bracket 1. The upper end of the bracket 1 is equipped with a first mounting plate 3, a second mounting plate 17 and a third mounting plate 18, and the upper end of the first mounting plate 3 is equipped with a first mounting plate. Four mounting plates 4, the 5th mounting plate 12 is installed on the 2nd mounting plate 17, guide rail 16 is provided between the 4th mounting plate 4 and the 5th mounting plate 12, between the 3rd mounting plate 18 and the second mounting plate 17 Connected with a bearing plate 14, the bearing plate 14 is set parallel to the guide rail 16, the guide rail 16 is provided with a slider 6 that can slide along the guide rail 16, the slider 6 is equipped with a material box mounting seat 7, and the material box mounting seat 7 is equipped with a material box 8. A nozzle 19 is provided on th...

Embodiment 2

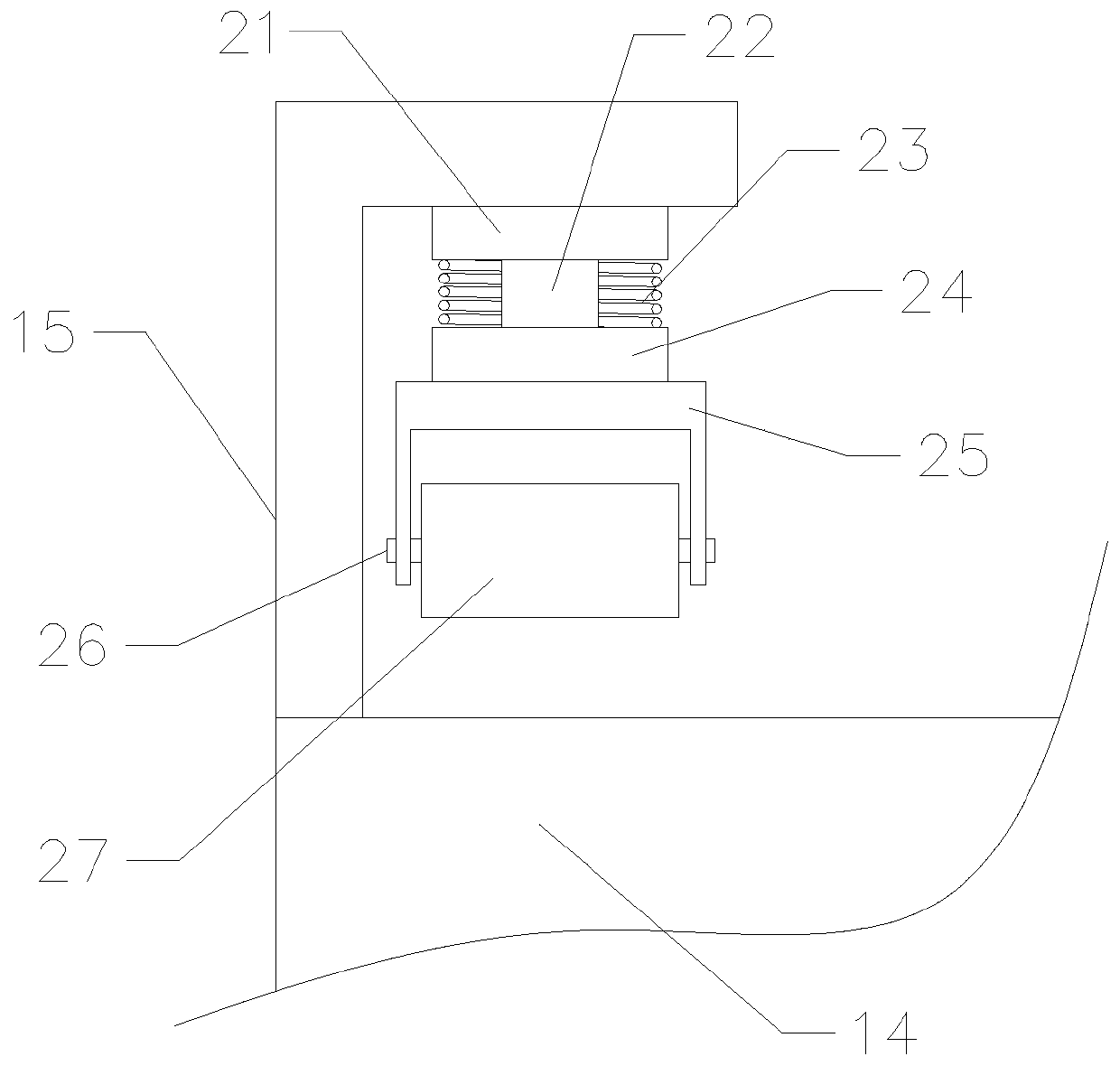

[0038] A gluing device for the production of bags, such as image 3As shown, in order to meet the problems of different limiting plates; this embodiment makes the following improvements on the basis of Embodiment 1: the side of the limiting plate 15 near the bearing plate 14 is equipped with a guide wheel mount 25, and on the guide wheel mount 25 A rotating shaft 26 is installed, and a guide wheel 27 is sleeved on the outer periphery of the rotating shaft 26 . Guide wheel 27 has not only played the guiding effect to case bag fabric, has also realized simultaneously the effect that the limit of fabric is fixed, has guaranteed fabric to carry out gluing with smooth state, has further improved the effect of case bag fabric gluing.

[0039] In order to meet different limit plate problems; such as image 3 As shown, a first piston 21 is installed on the side of the limit plate 15 close to the bearing plate 14, a piston shaft 22 is installed on the side of the first piston 21 close...

Embodiment 3

[0042] A gluing device for the production of bags, such as Figure 4-5 As shown, in order to solve the problem that the glue hardening time is fast; This embodiment makes the following improvements on the basis of Embodiment 1: an electric box 28 is installed at the lower end of the carrying plate 14, and a heat conducting layer 32 is provided in the carrying plate 14, and the heat conducting layer 32 A heating resistance wire 30 is arranged inside, and an energizing wire 29 is connected between the heating resistance wire 30 and the electric box 28 . The heating resistance wire 30 is energized by the electric box 28, and the heating resistance wire 30 generates heat after being energized, and then the heat is transferred by the heat conduction layer 32, thereby realizing the heating of the luggage fabric on the carrier plate 14 and prolonging the time for the glue to harden. The effect of gluing has been improved.

[0043] In order to solve the problem of fast hardening time...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com