Tunnel waterproof cloth construction platform

A technology for construction platforms and tarpaulins, applied in tunnels, tunnel linings, shaft linings, etc., can solve problems such as reduced construction efficiency, obstacles in the construction process, and complicated processes, and achieve the effects of facilitating use and improving structural stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

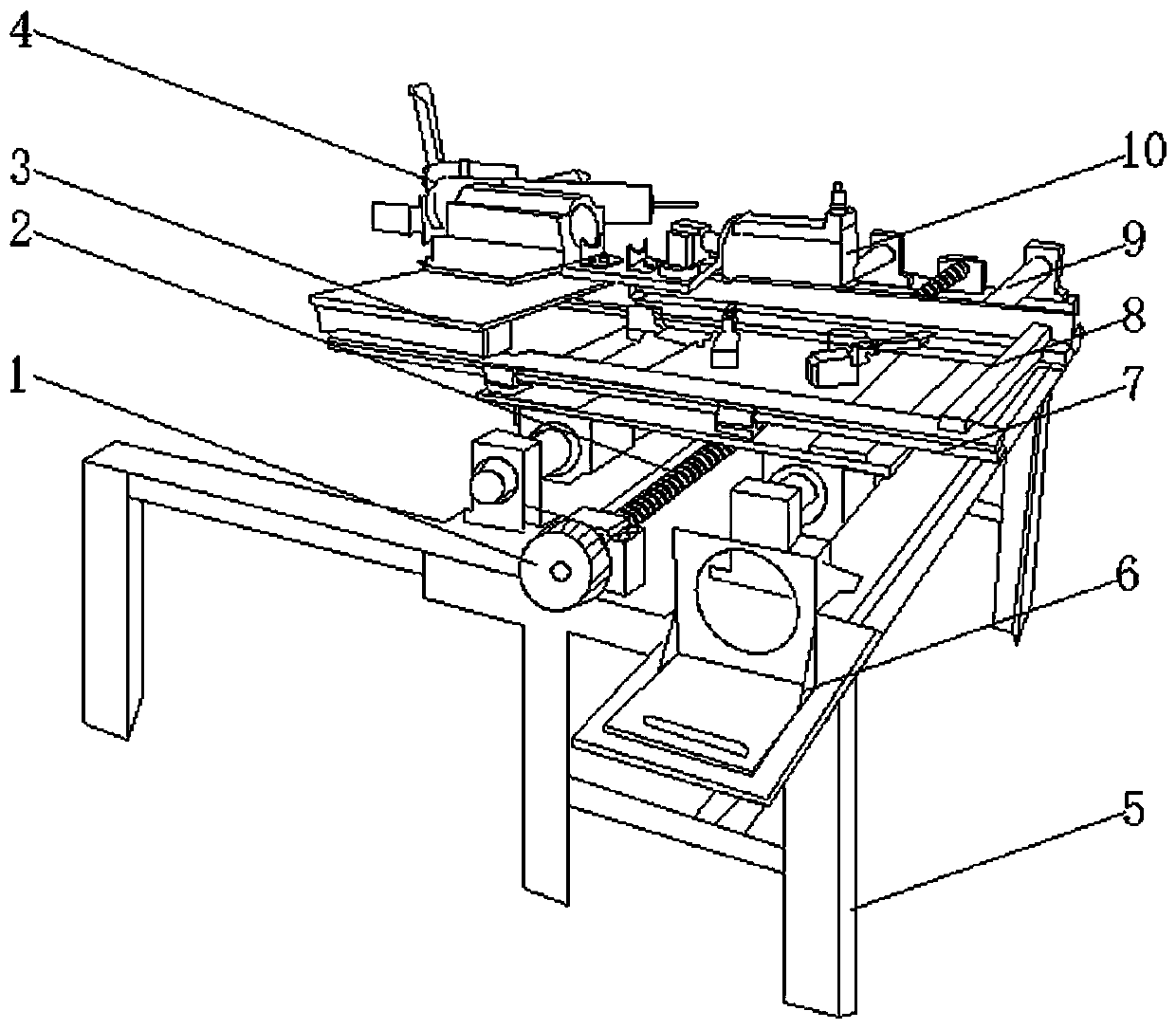

[0028] Such as figure 1 As shown, the tunnel tarpaulin construction platform of this embodiment includes a support frame 5, and the support frame 5 is made of metal material as a whole. In actual use, it needs to be installed on construction equipment, such as a tunnel trolley. The top of the support frame 5 passes through the bearing seat The drive screw 2 is installed, and the surface is provided with a specific threaded body, which can be rotated under the action of an external force, and one end of the drive screw 2 is installed with a shaft disk 1, which is actually connected to the input end of the drive screw 2. The surface of the disk 1 is provided with hard gear teeth, and the surface of the driving screw 2 is equipped with a transverse carriage 8 through a slip ring, and the two are connected to each other through a threaded body. It can push the horizontal sliding frame 8 to carry out the sliding movement in the front and rear directions. The surface of the horizont...

Embodiment 2

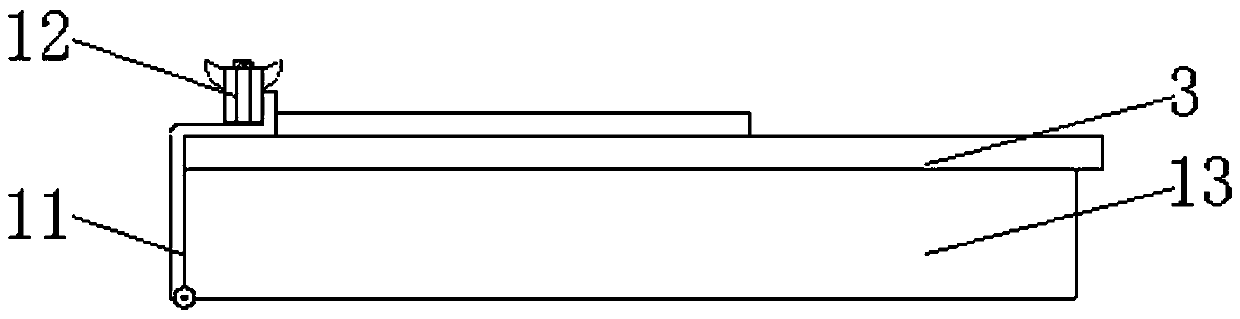

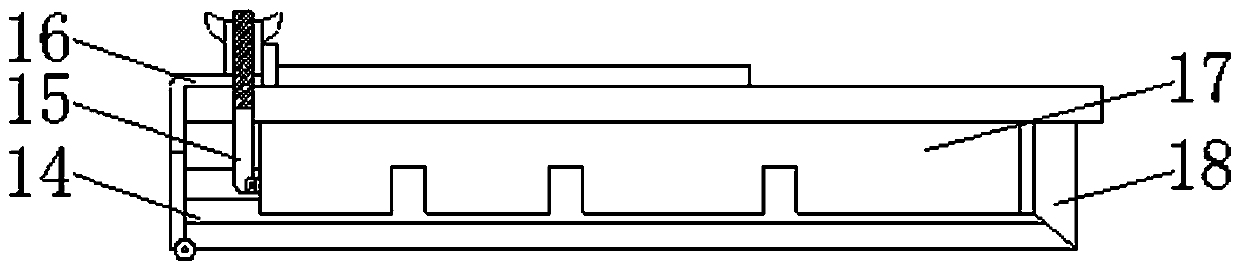

[0033] The structure of the tunnel tarpaulin construction platform in this embodiment is basically the same as that of the tunnel tarpaulin construction platform in Embodiment 1, the difference is that: one end surface of the connecting frame 13 is movably installed with a spacer 11 through a hinge shaft, and the connecting frame 13 A baffle 18 is fixedly installed on the surface of the other end, and the surfaces of the limiting sheet 11 and the connecting frame 13 are all provided with movable grooves 16 (see Figure 2~4 ). The connecting frame 13 is not fixedly connected with the movable table 3, and the actual entire limiting piece 11 is in a Z shape, and the end is in a vertical state, and the limiting piece 11 and the baffle plate 18 can simultaneously block and seal the two ends of the connecting frame 13, realizing For the fixed limit effect of internal components, when the limit piece 11 is limited and sealed to one end of the connection frame 13, the limit piece 11 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com