Rewinding machine for cigarette receiving and packaging paper

A technology for cigarette tipping paper and rewinding machine, which is applied in the directions of winding strips, transportation and packaging, thin material handling, etc., can solve the problems of inconvenient handling or moving process, uneven edges on both sides, equipment damage, etc. Achieve the effect of good cutting effect, good stability and shock absorption, and strong limit fixation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

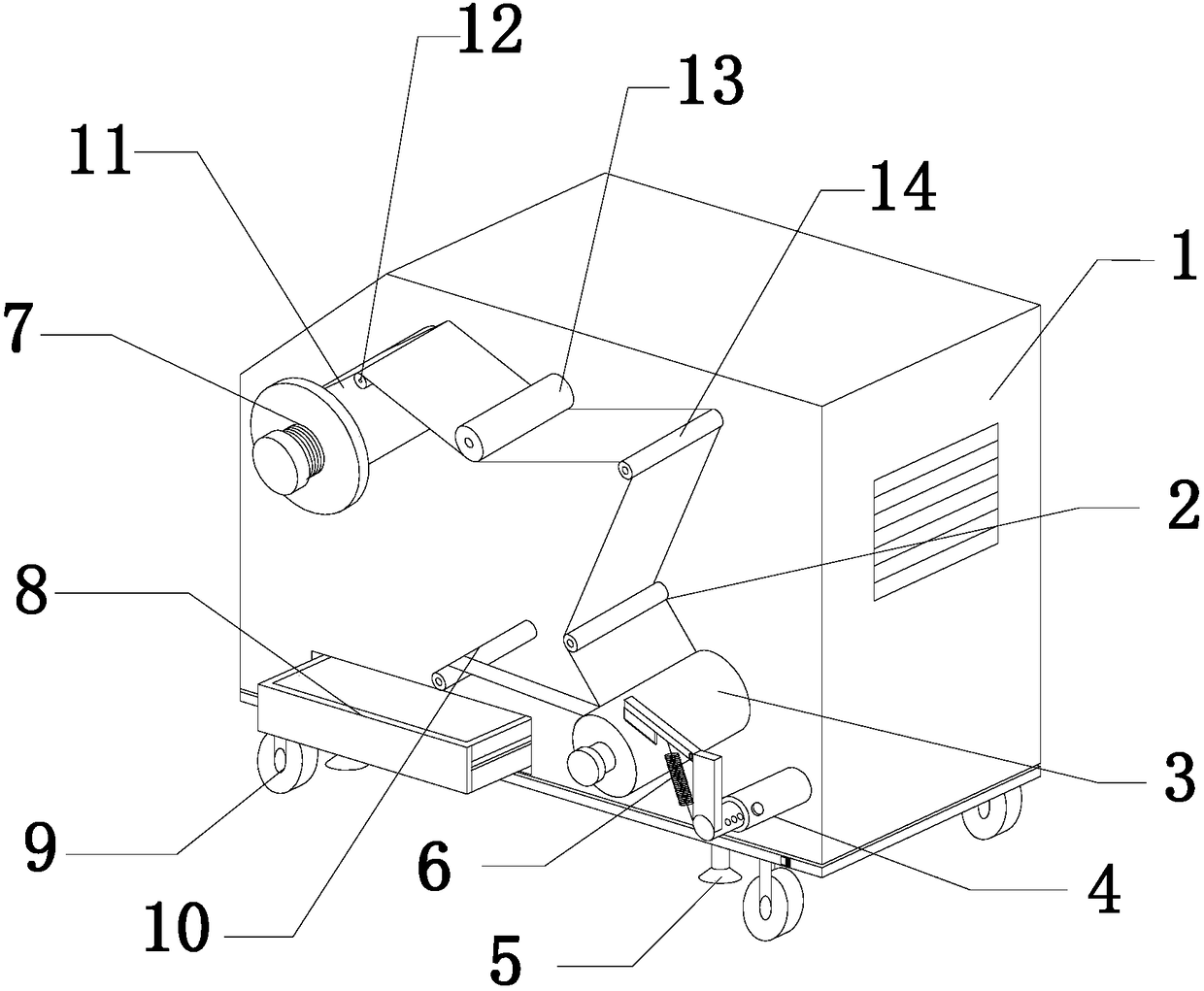

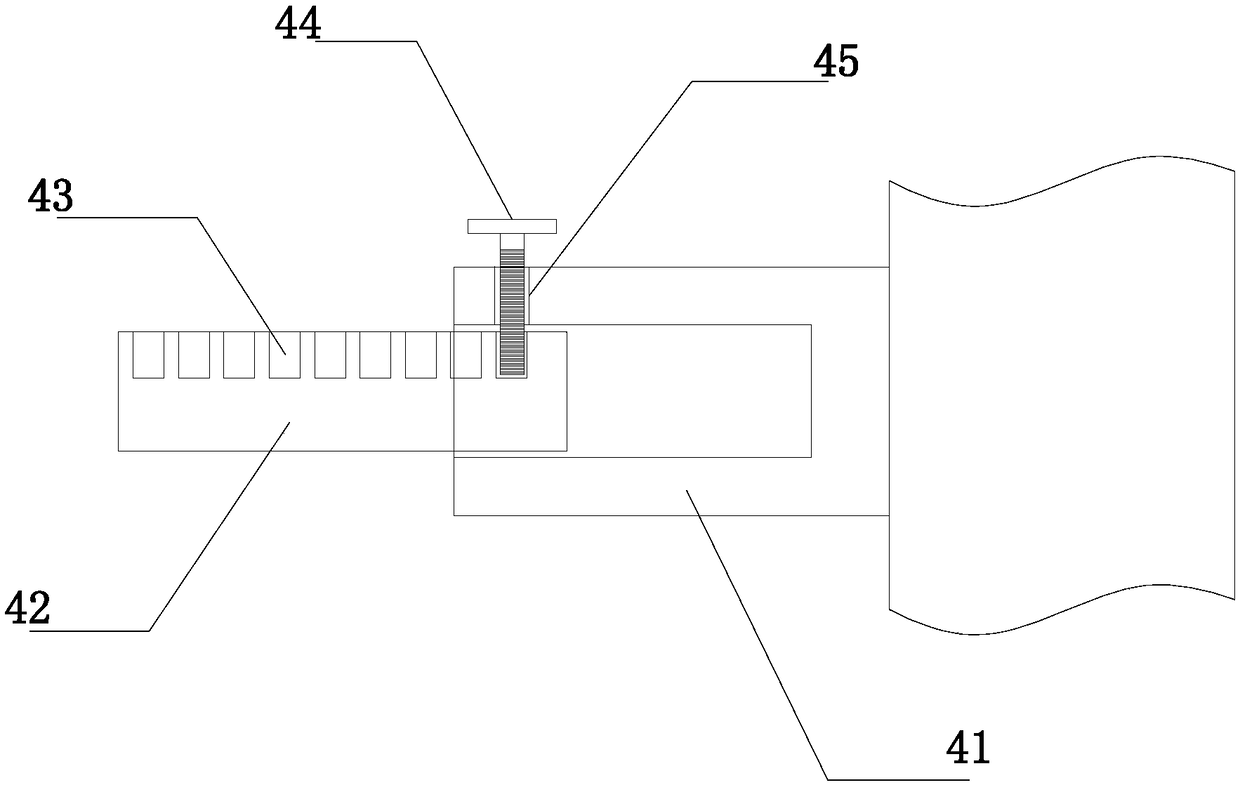

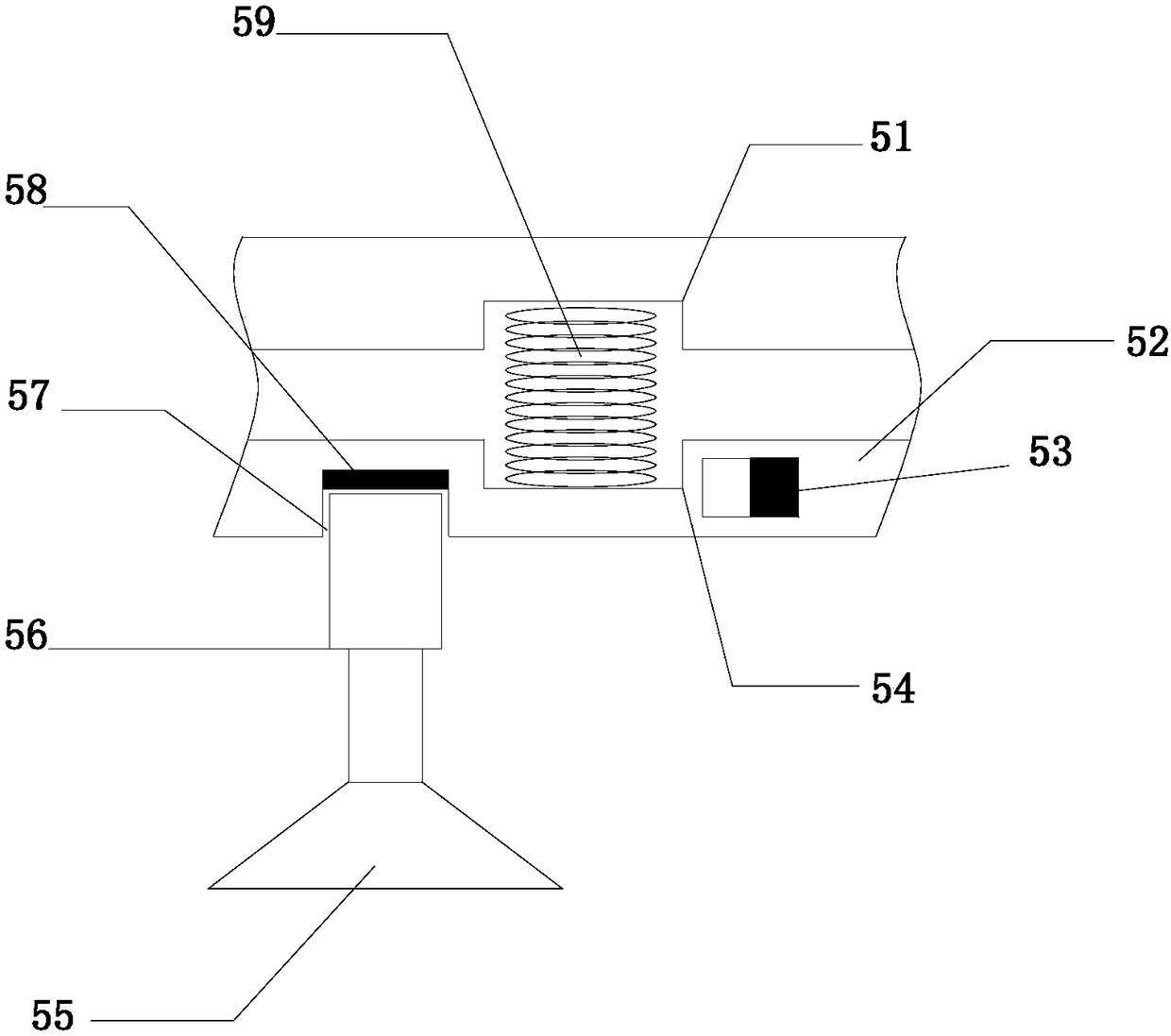

[0034] Specific embodiments: when the present invention is in use, the round rod 2 42 is first moved in the cavity of the round rod 1 41, and the inner lengths of the round rod 2 42 and the round rod 1 41 are adjusted. When the length is adjusted to a suitable length, the fixing bolt 44 Align the slot one 43 with the slot two 45, and tighten the fixing bolt 44. At the same time, the blade 64 installed at the lower end of the pole two 63 is aligned with the paper roll on the ring release roller 3 for cutting. When cutting, the collection box 83 in the groove four 81 slides in the chute 84 through the combination pulley 82, the cut waste paper falls into the collection box 83 through the paper guide roller two 10, and the roll paper used for production passes through the guide roller The third paper roll 12 , the pressure paper roll 13 and the fourth paper guide roll 14 are connected to the winding shaft 11 .

[0035] When collecting roll paper for production, bearing 71 is inst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com