Location-fixation mechanism for wood plate drilling

A technology for fixing mechanisms and boards, which is applied in the direction of drilling machines, wood processing equipment, manufacturing tools, etc. It can solve the problems of board vibration, shape, and size, and affect the installation of decorative blocks, so as to increase stability and improve drilling quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

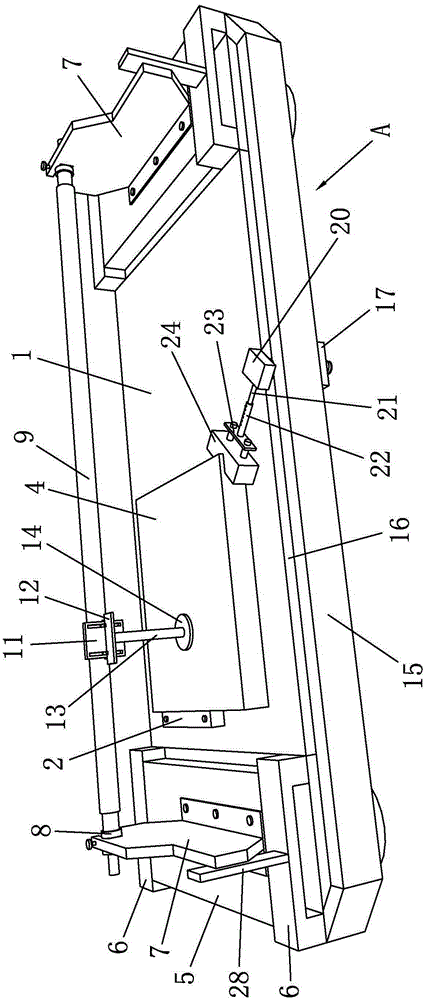

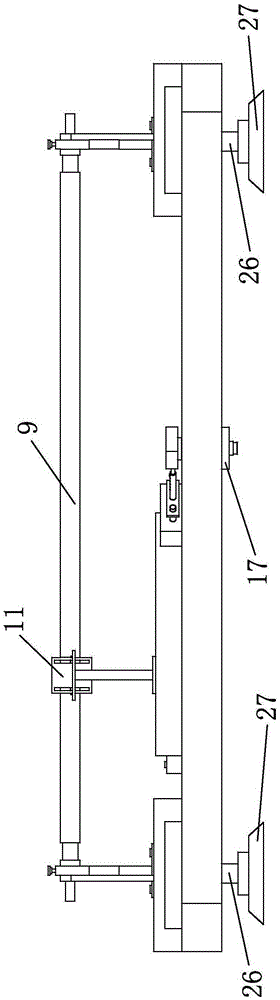

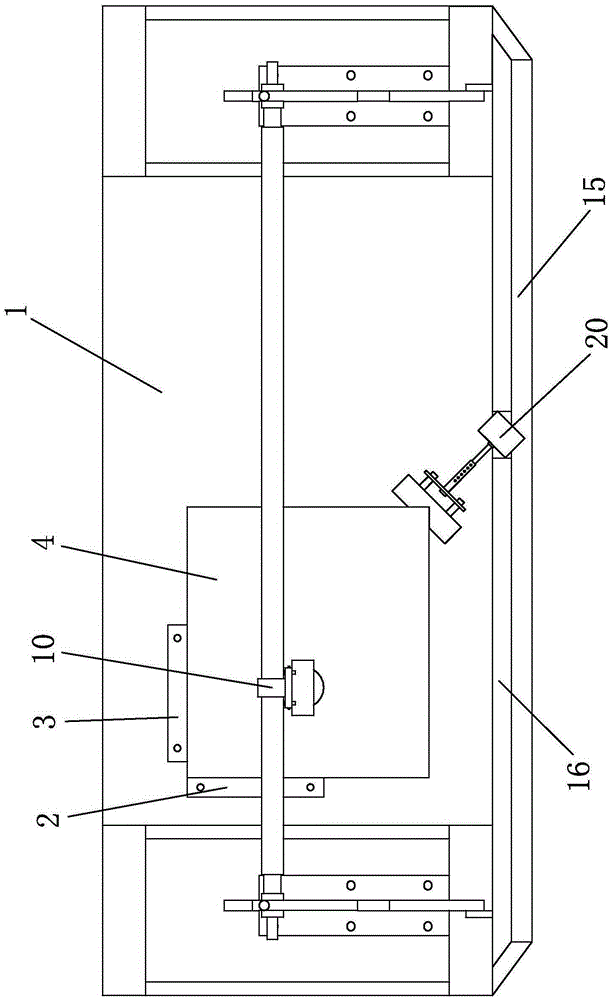

[0028] Such as Figure 1 to Figure 10As shown, it is a positioning and fixing mechanism for plank drilling according to the present invention, which includes a workbench 1, and the bottom of the workbench 1 is provided with an adjustment rod 26. The adjustment rod 26 adopts a metal rod with a threaded structure, and the adjustment rod 26 A leg 27 is provided, and the leg 27 is made of plastic. Support foot 27 can be arranged on the drilling platform, and adjusting rod 26 adopts screw thread adjustment, can adjust the distance between workbench 1 and support foot 27, and adjustment is convenient and simple, and support foot 27 can raise workbench 1 certain height like this, avoids workbench The contact between 1 and the drilling table causes the bottom of the table 1 to wear, and the fixing work on the table 1 can be separated from the drilling work on the drilling table, and the two works do not affect each other. A first limit block 2 and a second limit block 3 are fixedly c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com