Method of laser lift-off for light-emitting diode

A technology of light-emitting diodes and laser stripping, applied in laser welding equipment, electrical components, circuits, etc., can solve problems such as damage to the adhesive metal layer, and achieve the effect of reducing stress damage to the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Therefore, the details and technical descriptions of the present invention will be further described through examples, but it should be understood that these examples are only examples and should not be construed as limitations on the implementation of the present invention.

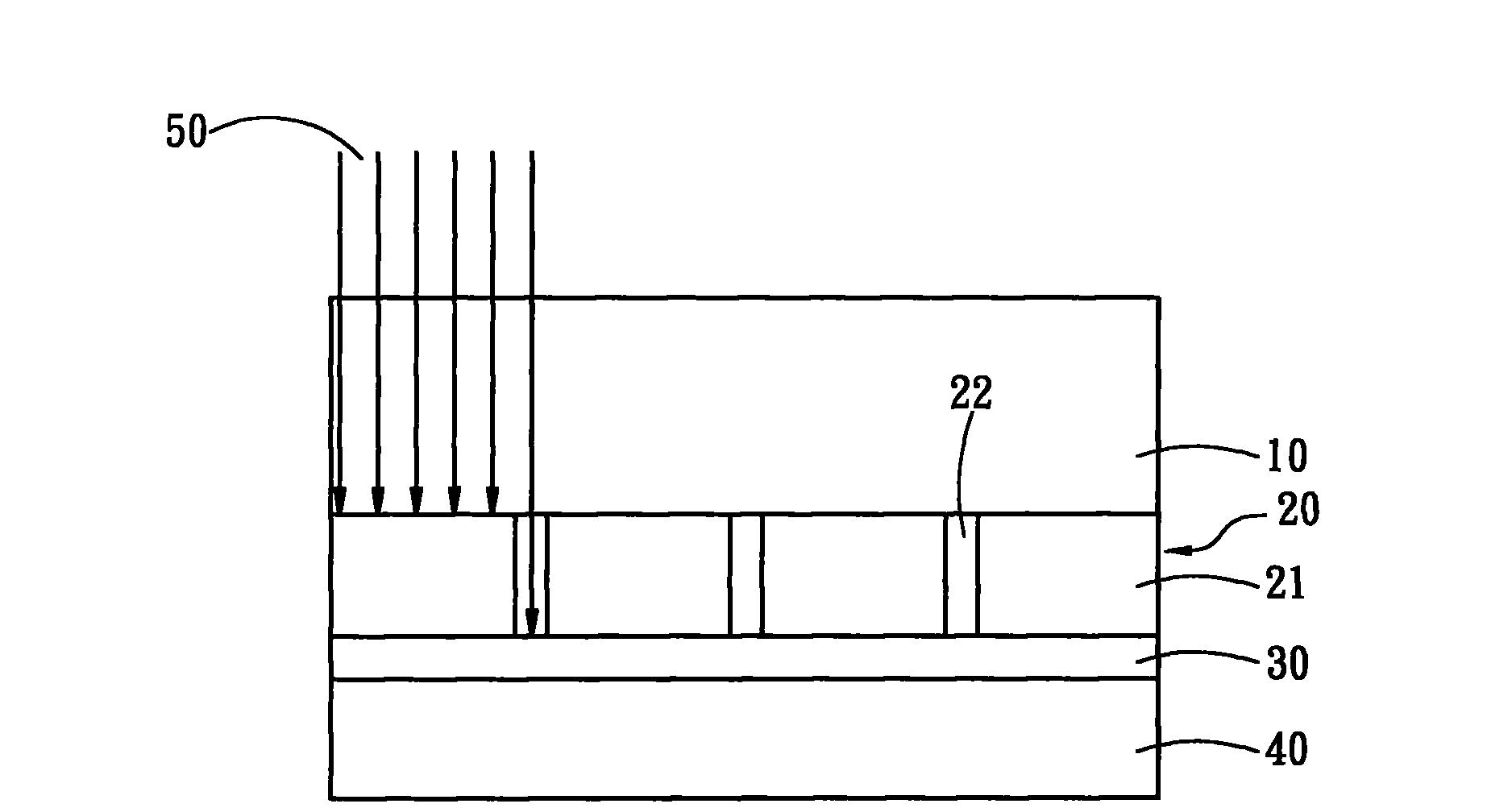

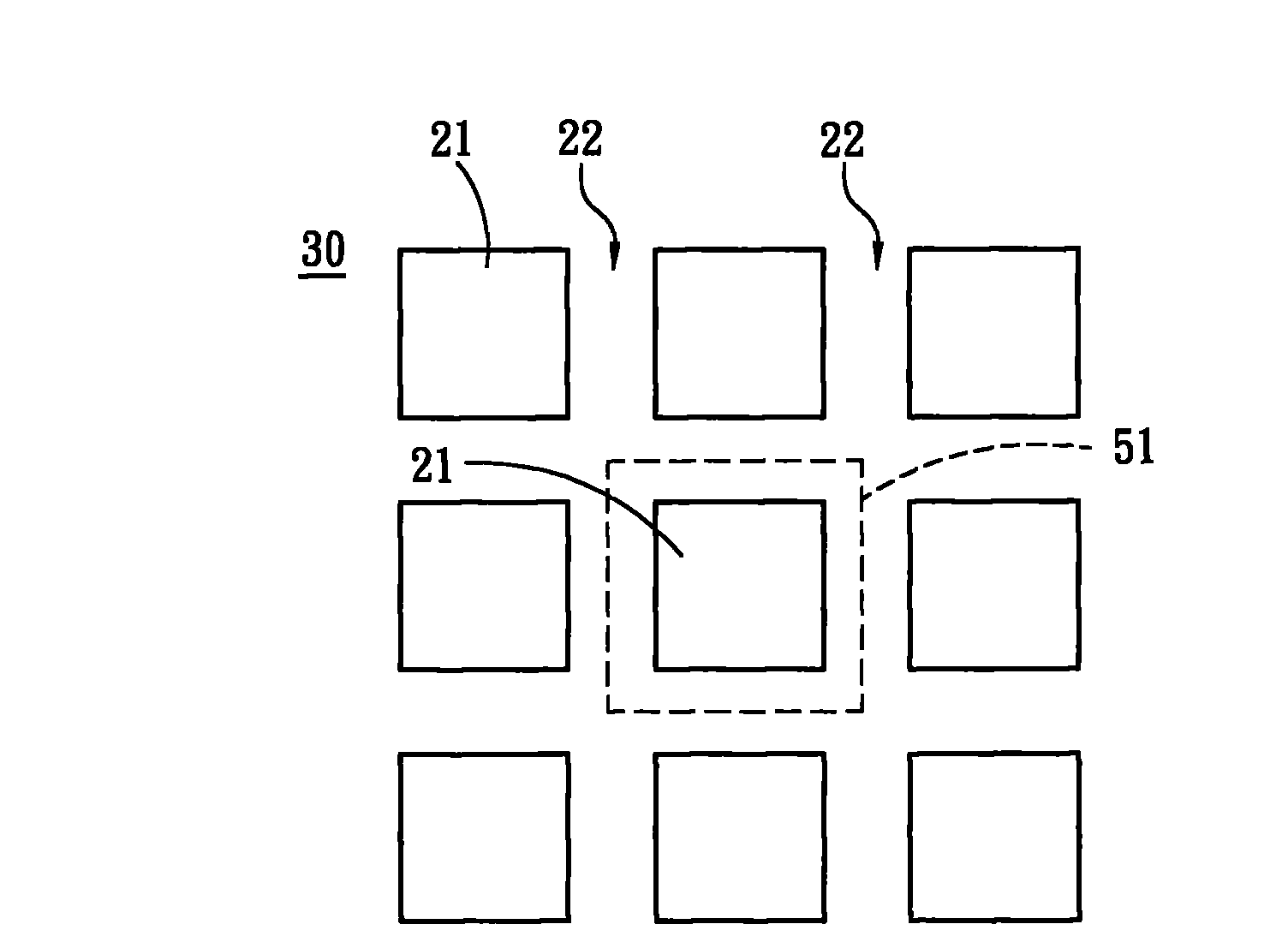

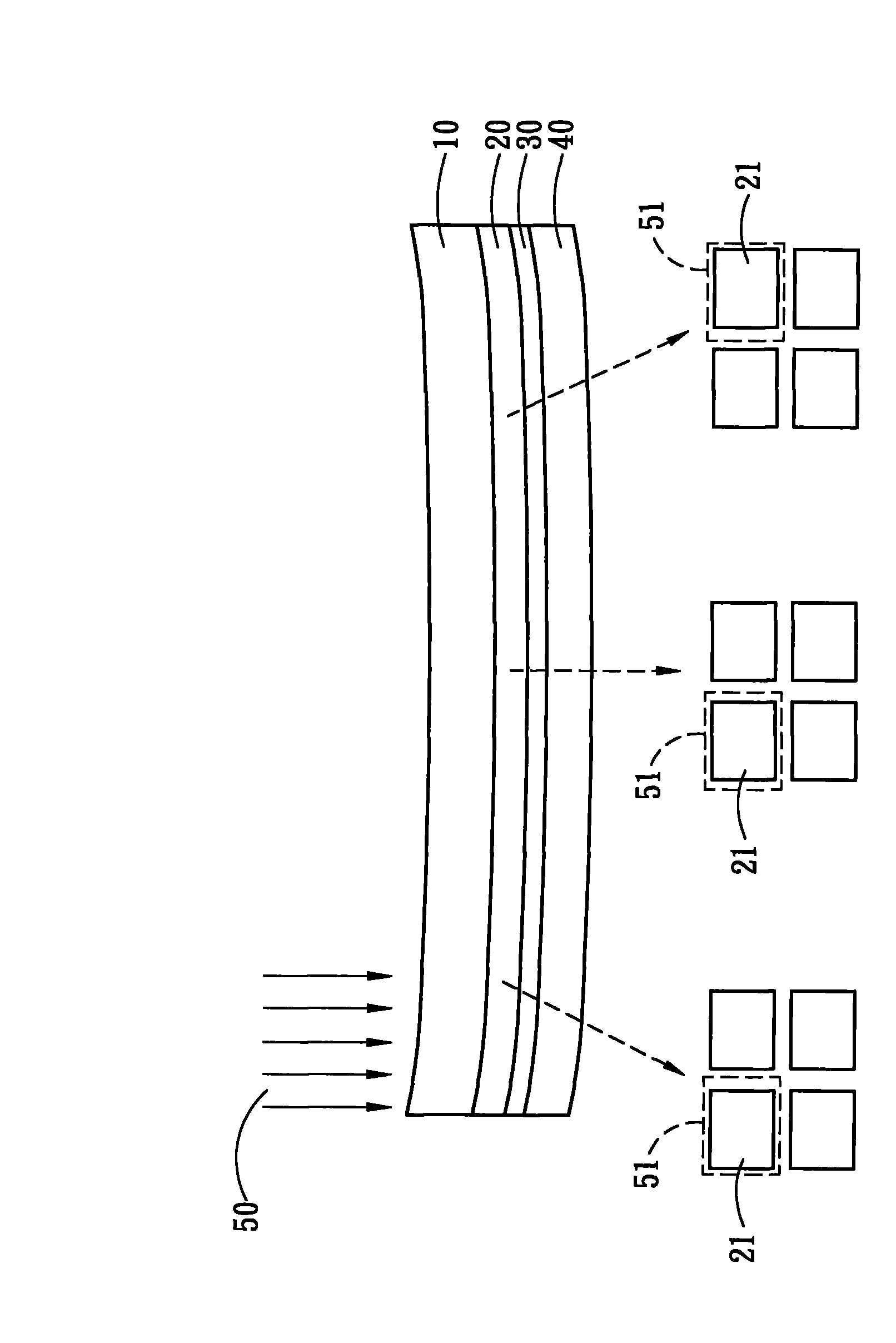

[0027] refer to Figure 5 , The present invention is applied to the existing method of laser lift-off of light-emitting diodes. In the implementation of the method of laser lift-off of light-emitting diodes, an epitaxial layer 200 for light emission is sequentially formed on a conversion substrate 100 (such as a sapphire substrate). Different from the known method of laser lift-off of light-emitting diodes, the present invention etches the epitaxial layer 200 to define an isolation road 220 around each grain region 210, and between two adjacent isolation roads 220 there is an undisturbed An isolation region 230 of the material of the epitaxial layer 200 is etched. Therefore, the pitch of the die ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com