Patents

Literature

30 results about "Buckypaper" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

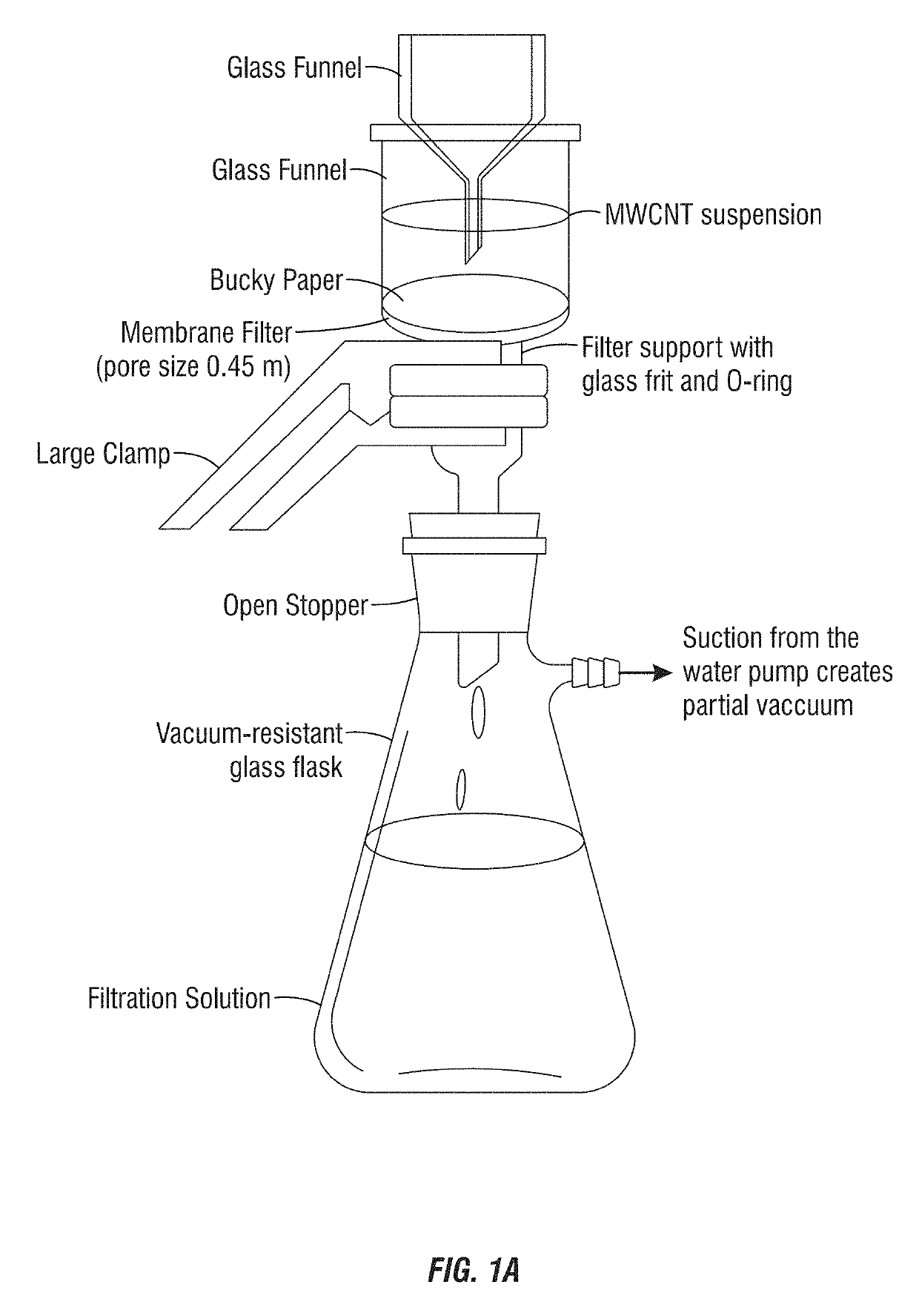

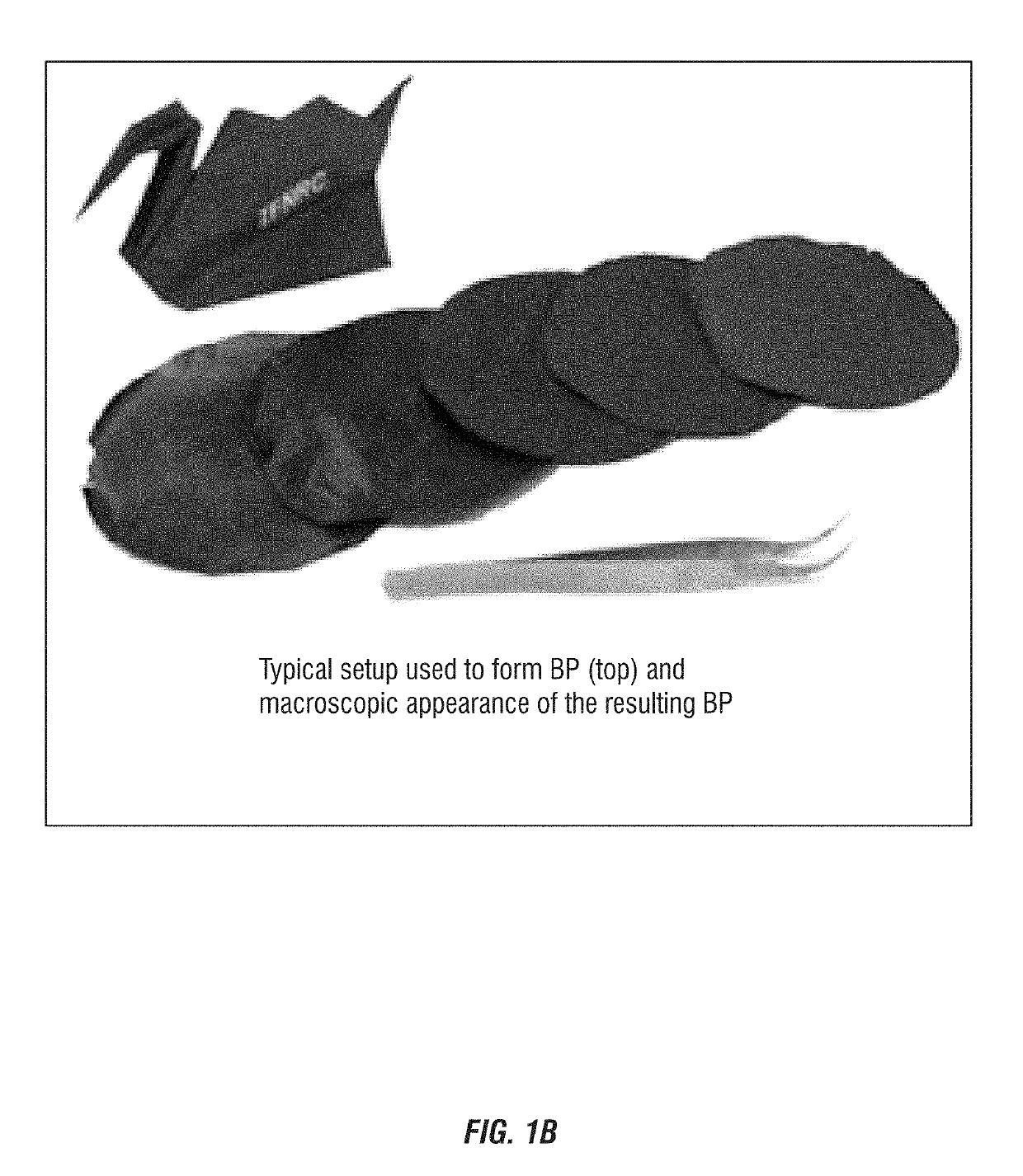

Buckypaper is a thin sheet made from an aggregate of carbon nanotubes or carbon nanotube grid paper. The nanotubes are approximately 50,000 times thinner than a human hair. Originally, it was fabricated as a way to handle carbon nanotubes, but it is also being studied and developed into applications by several research groups, showing promise as vehicle armor, personal armor, and next-generation electronics and displays.

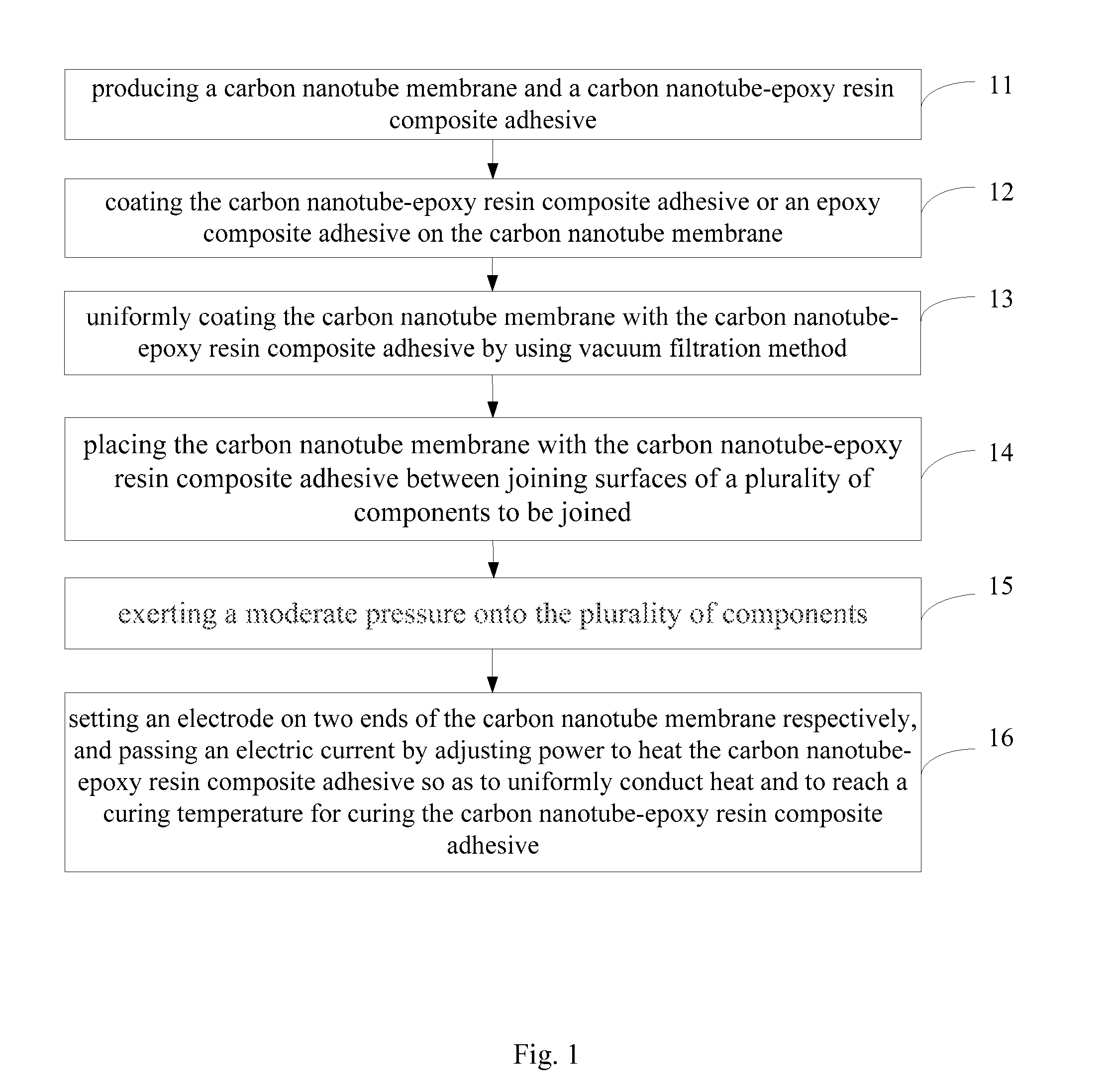

Method for bonding components by utilizing joule heating to cure carbon nanotube-epoxy resin composite adhesive

InactiveUS20130087278A1Achieve effectLow costMaterial nanotechnologyLamination ancillary operationsEpoxyBuckypaper

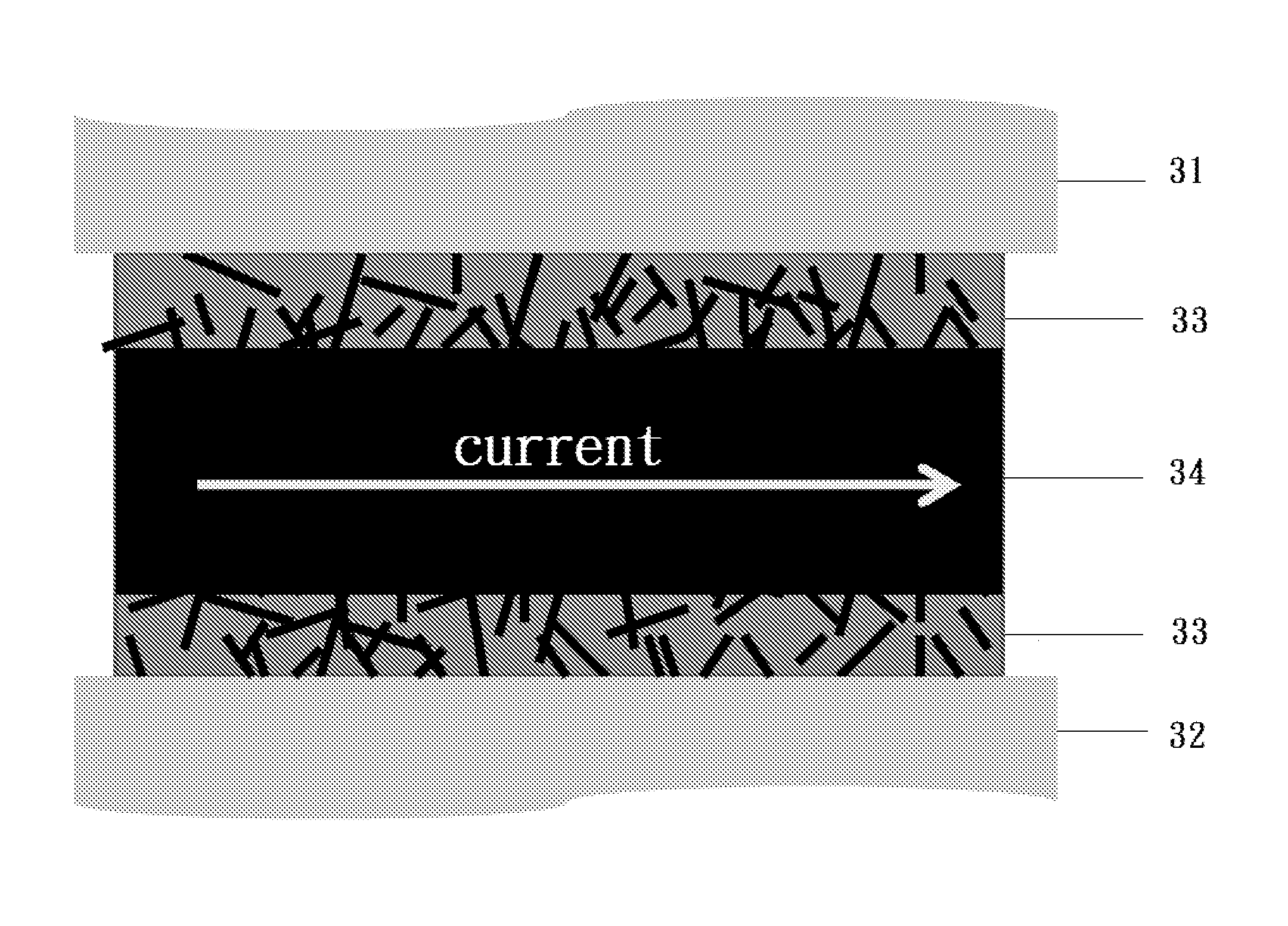

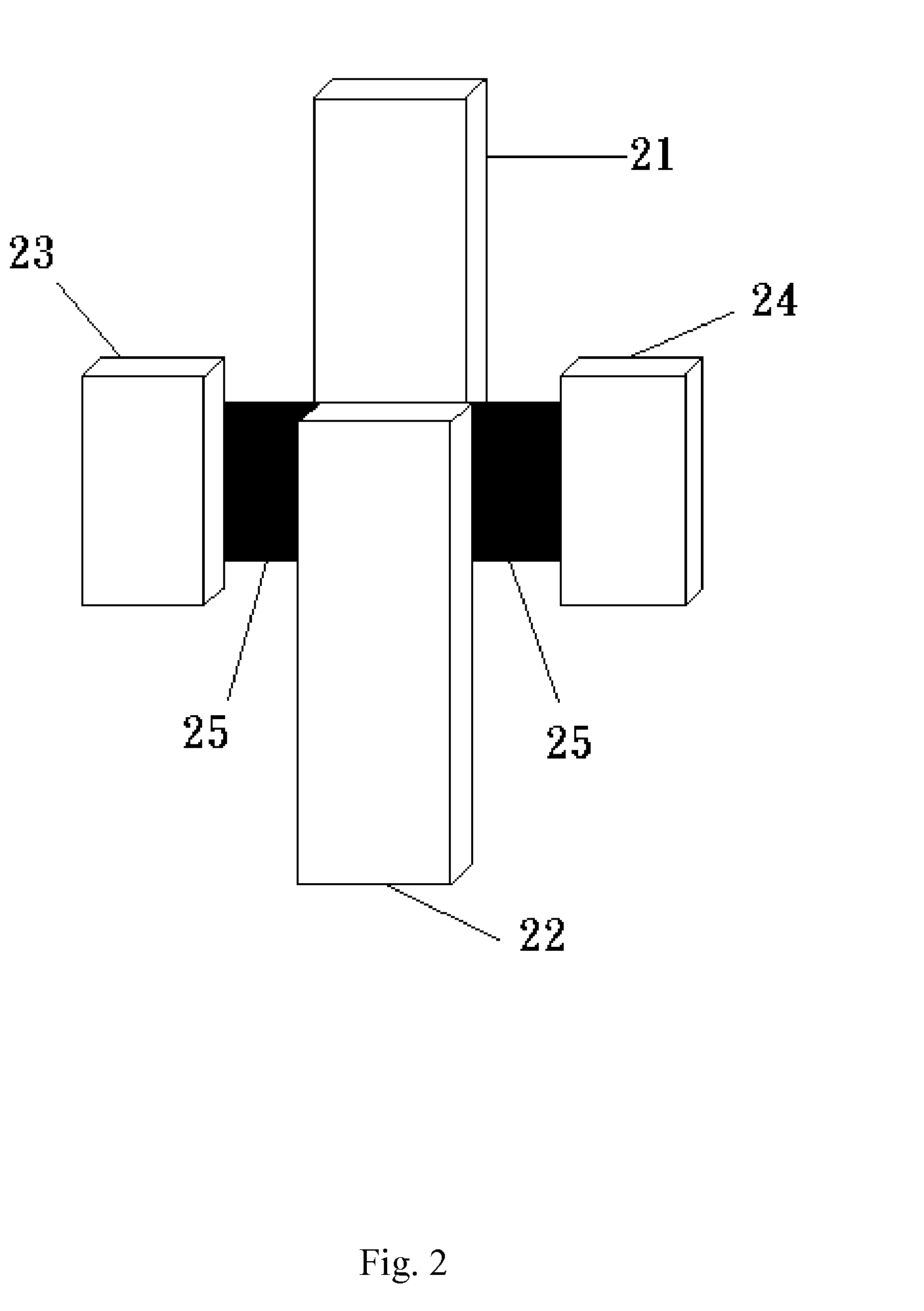

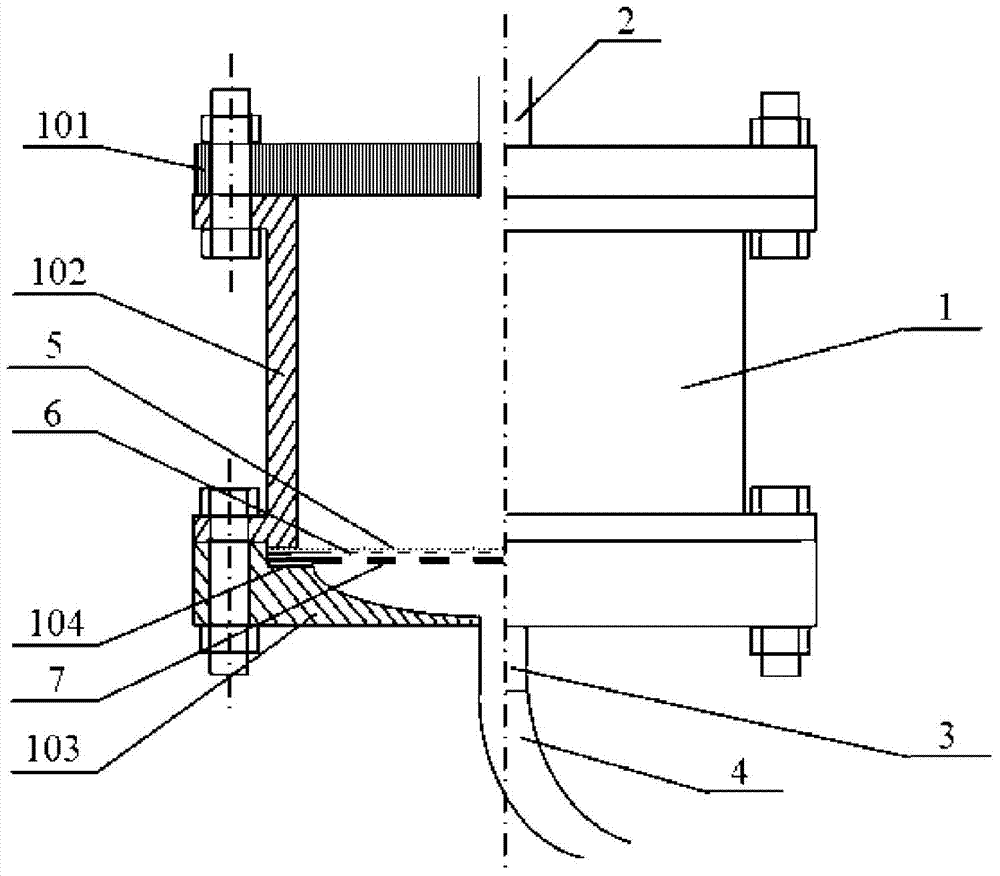

The using of carbon nanotubes to produce a thin film or buckypaper, hereafter referred to as carbon nanotube membrane, which is soaked with epoxy resin or a carbon nanotube-epoxy resin composite adhesive, and then placed between the joining edges of components, where after an electric current is passed through to heat up the carbon nanotube membrane. This leads to the curing temperature of the epoxy resin or carbon nanotube-epoxy resin composite adhesive, thereby hardening the epoxy resin or carbon nanotube-epoxy resin composite adhesive to achieve bonding. This invention utilizes simple equipment, and the method of an electric current passing through for heating, which can rapidly and uniformly heat the epoxy resin or carbon nanotube-epoxy resin composite adhesive, resulting in hardening and bonding. This method is not affected by the environment, and greatly reduces the time and resources required to harden the epoxy resin, and achieves a stronger effect additionally.

Owner:NATIONAL TSING HUA UNIVERSITY

Method for mechanically chopping carbon nanotube and nanoscale fibrous materials

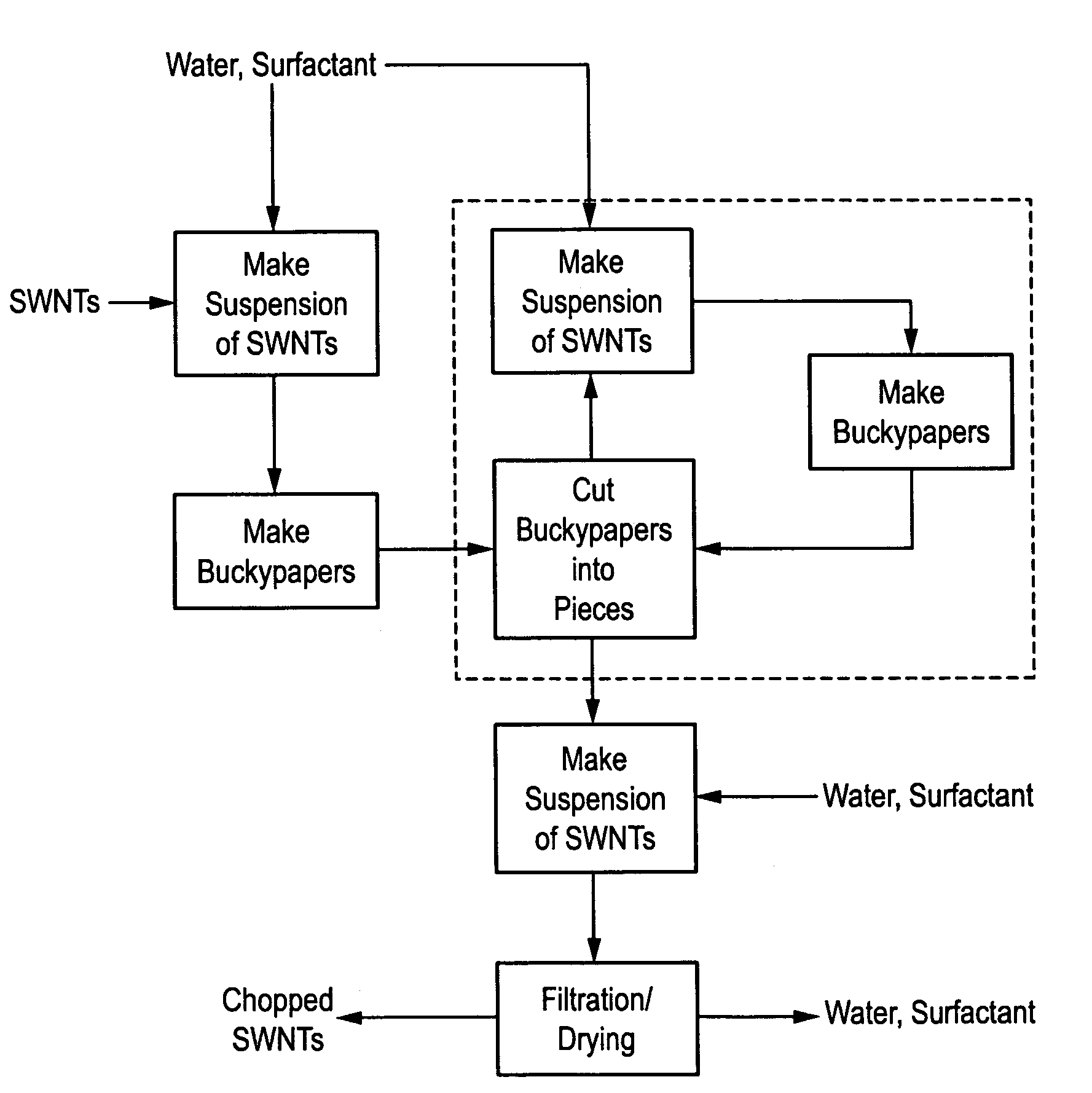

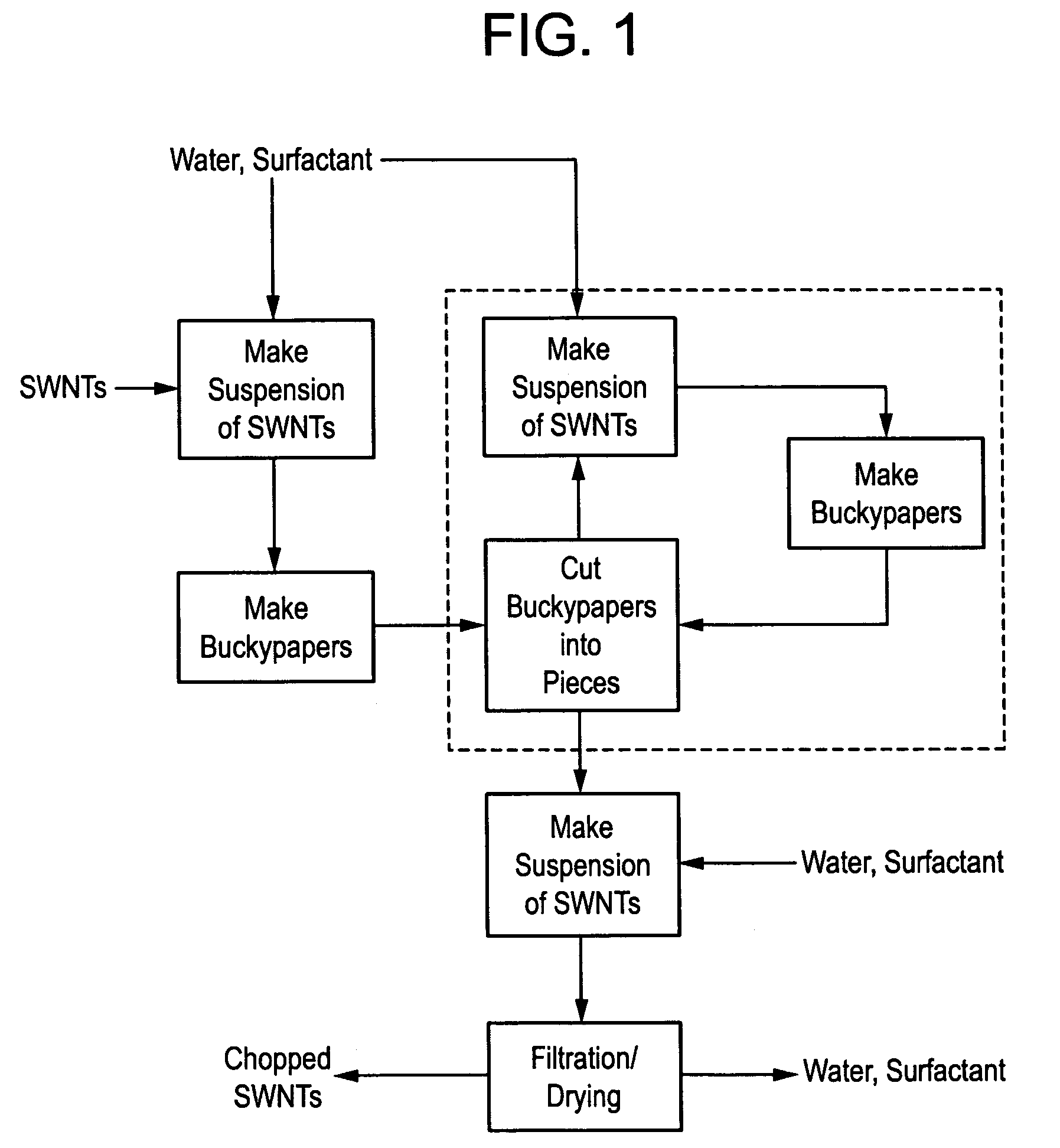

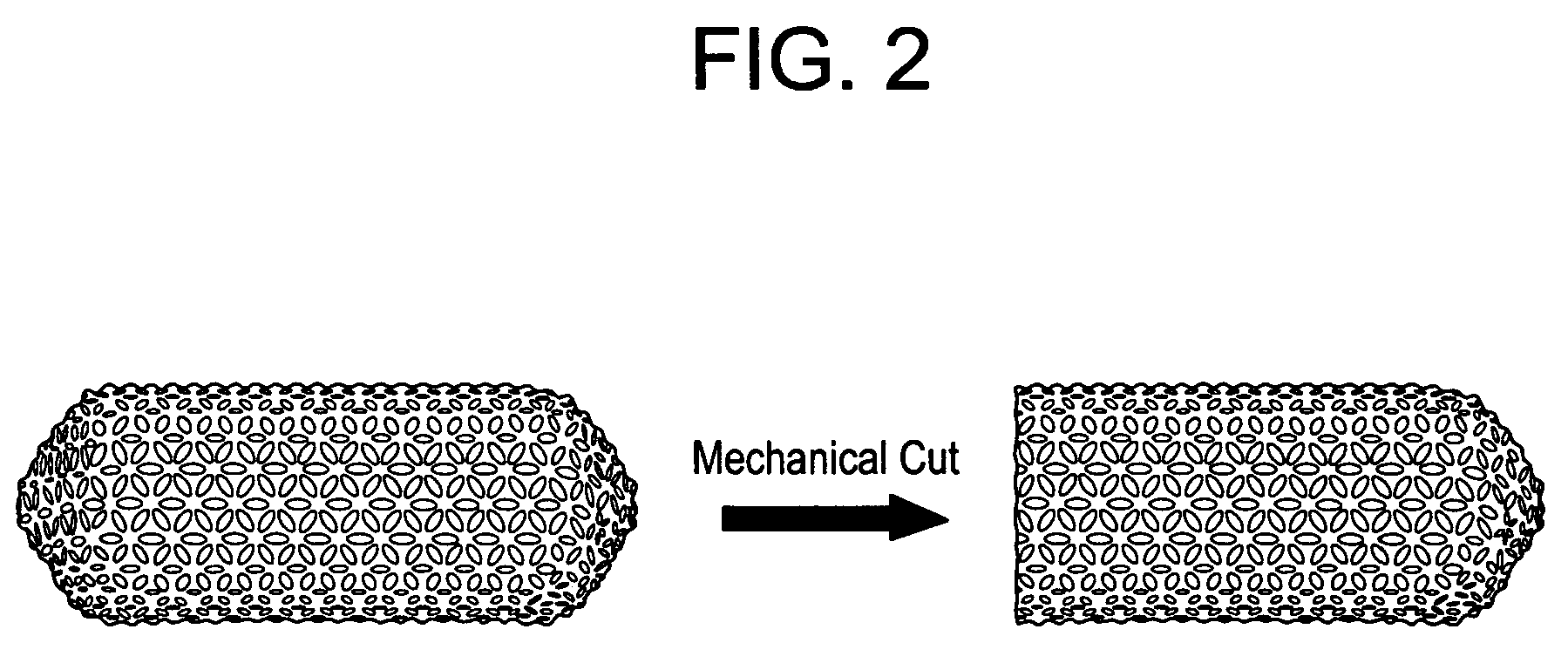

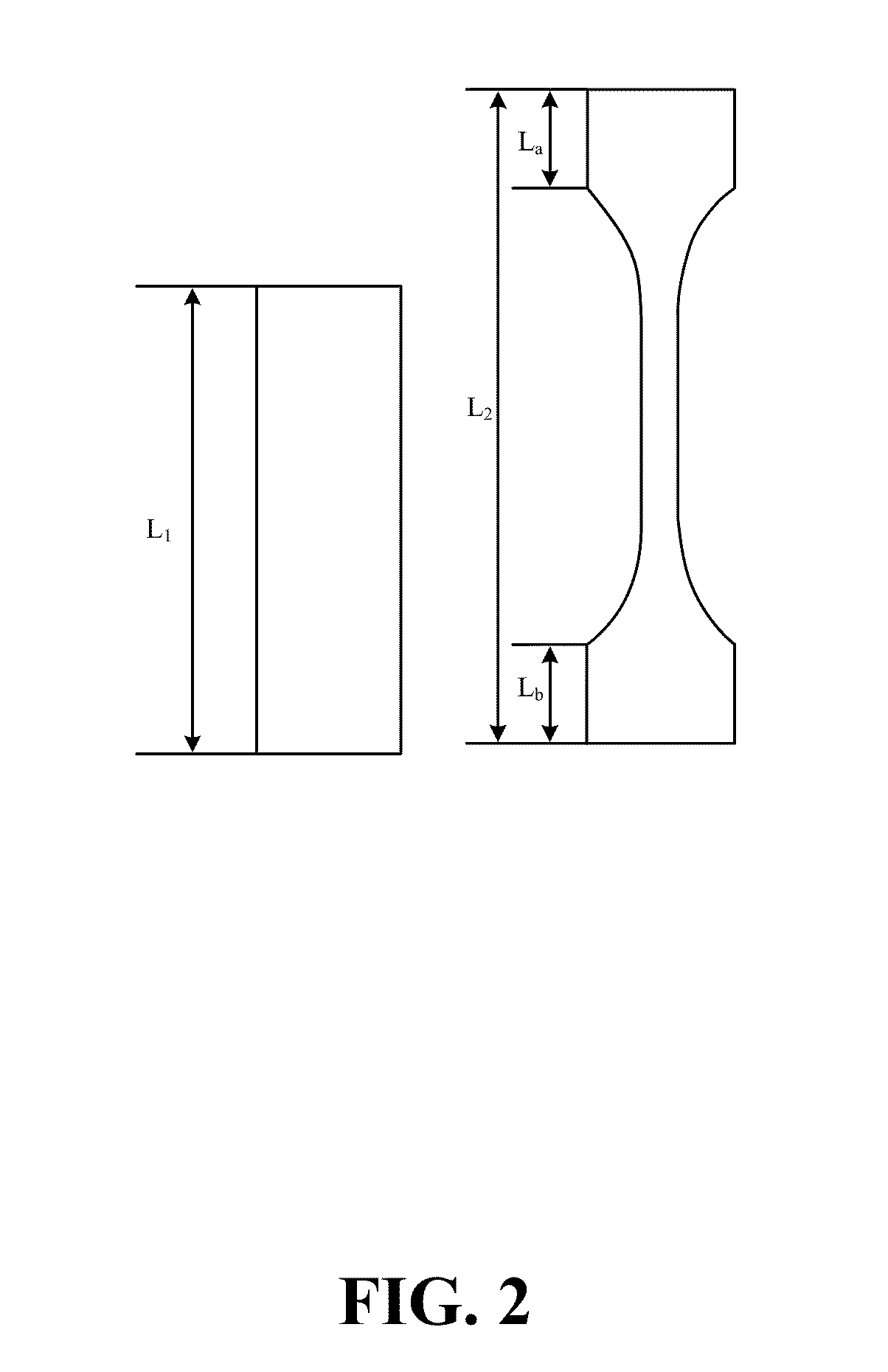

Methods are provided for mechanically chopping nanotubes and other nanoscale fibrous materials. The method includes forming a macroscale article which include the nanoscale fibers, and then mechanically cutting the macroscale article into a finely divided form. In one embodiment, these steps are repeated. The nanoscale fibers may be carbon nanotubes, which optionally are aligned in the macroscale article. The macroscale article may be in the form of or include one or more buckypapers. In one embodiment, the macroscale article further includes a solid matrix material in which the nanoscale fibers are contained or dispersed. The forming step can include making a suspension of nanoscale fibers dispersed in a liquid medium and then solidifying the liquid medium to form the macroscale article. After the mechanical cutting step, the medium can be dissolved or melted to enable separation of the chopped nanoscale fibers from the medium.

Owner:FLORIDA STATE UNIV RES FOUND INC

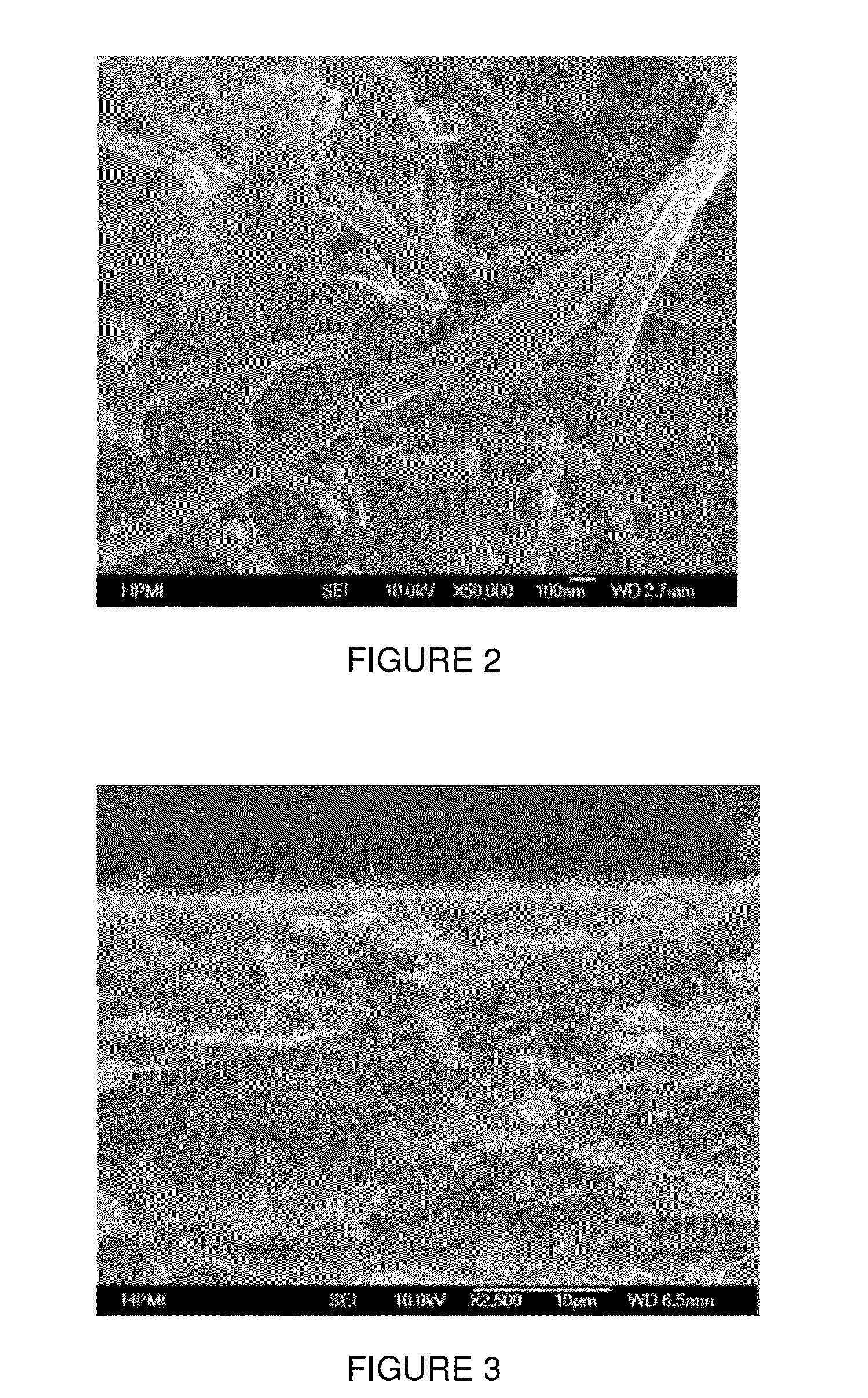

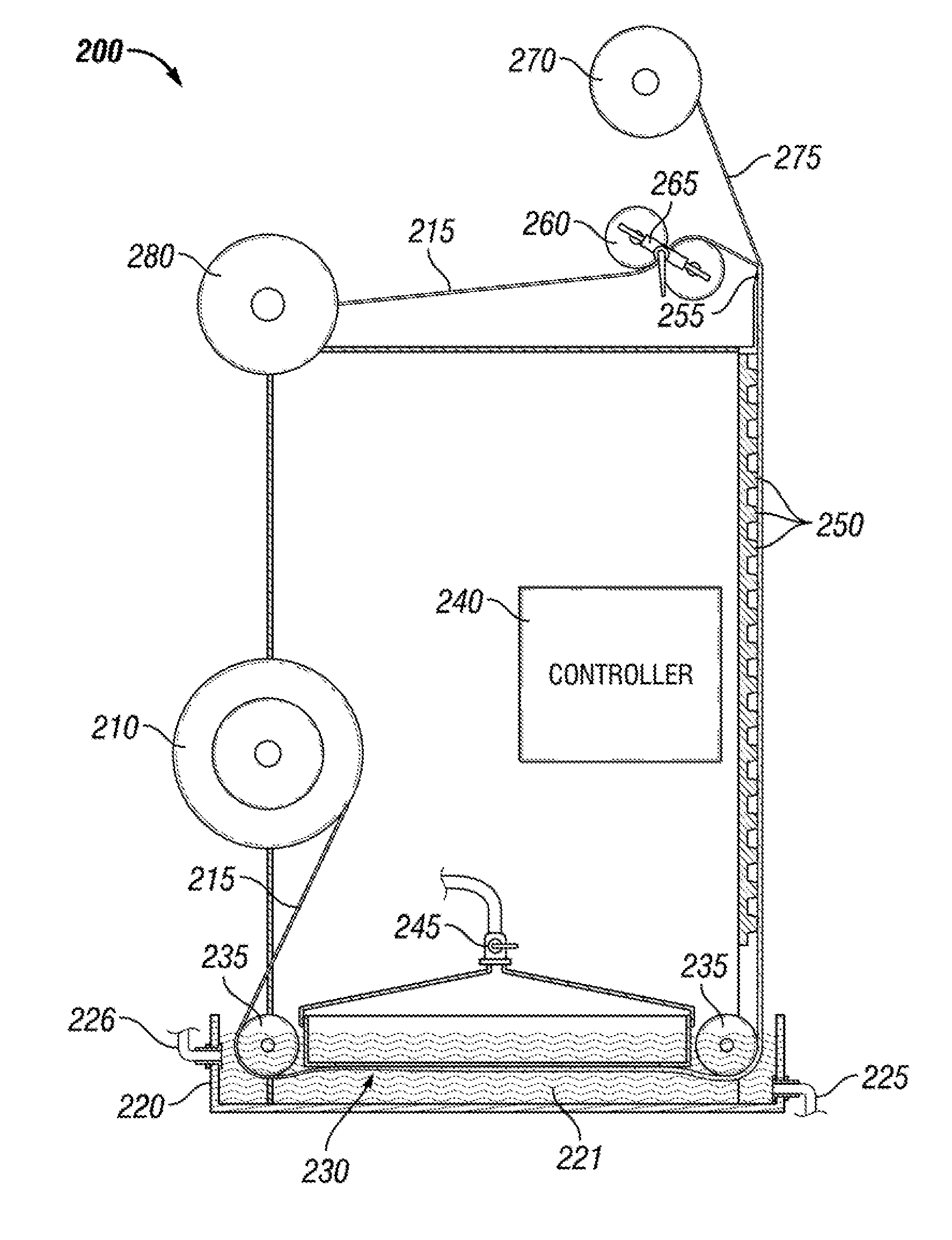

Functionalized nanoscale fiber films, composites, and methods for functionalization of nanoscale fiber films

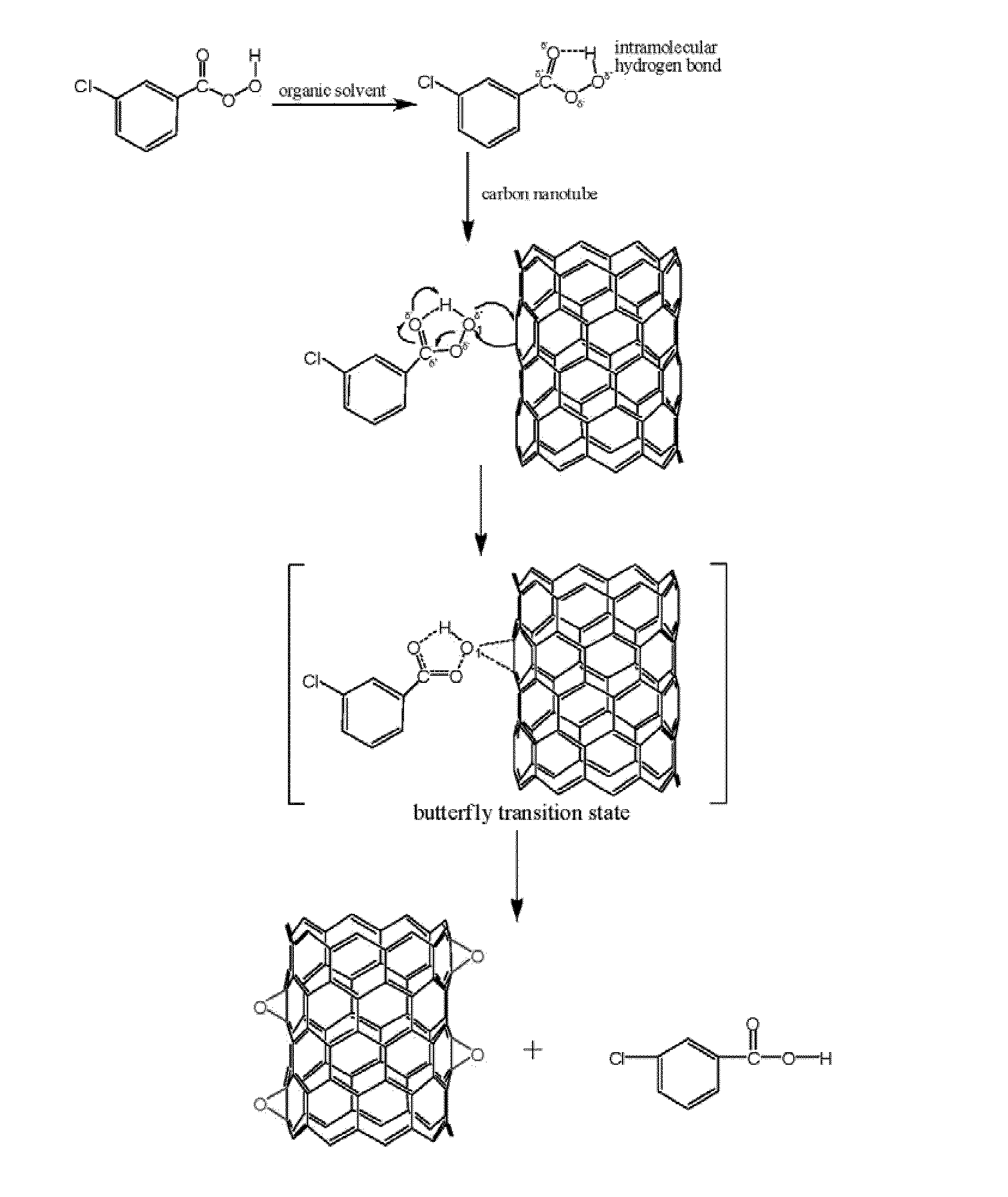

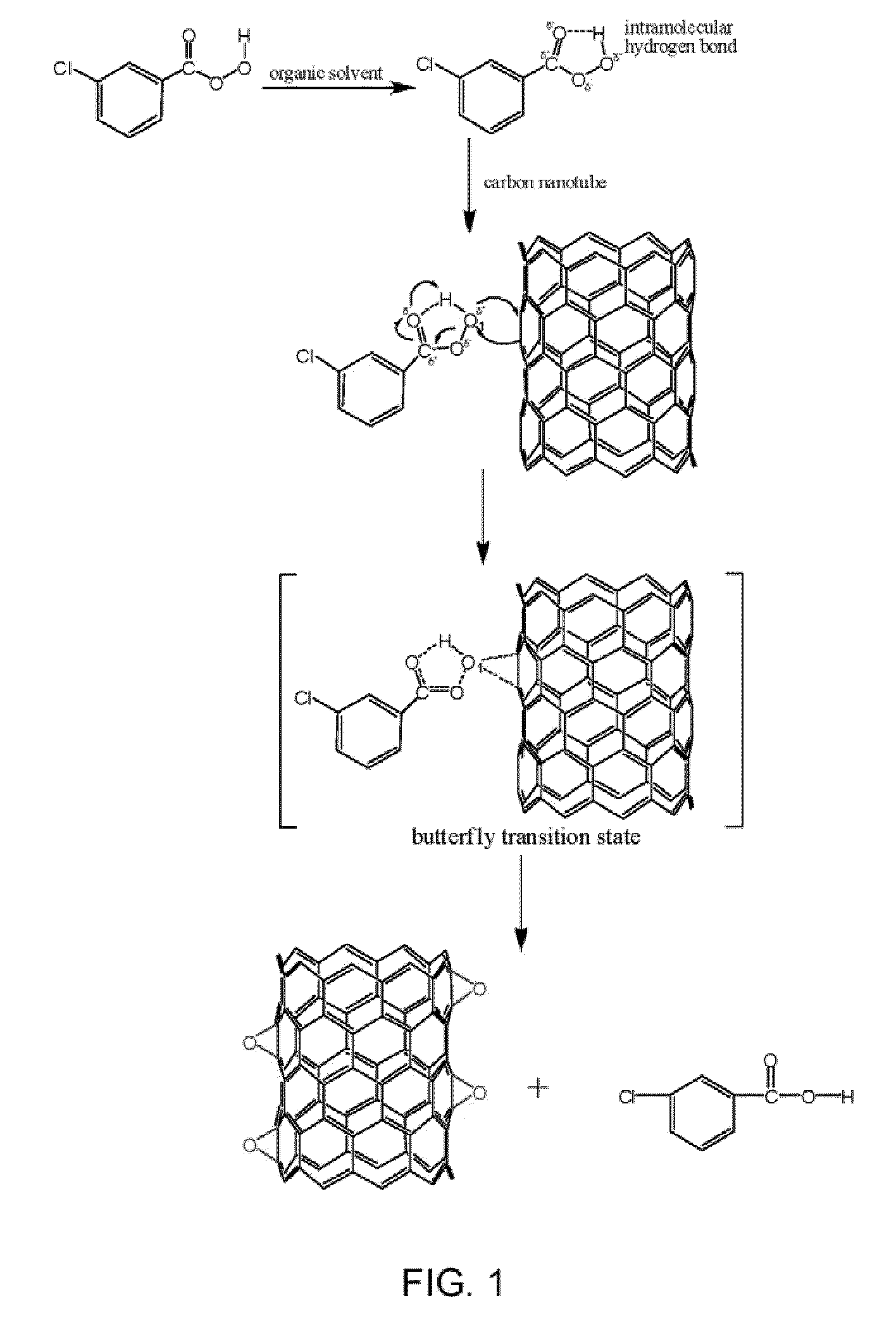

Methods are provided for functionalizing nanoscale fibers and for making composite structures from these functionalized nanomaterials. The method includes contacting a network of nanoscale fibers with an oxidant to graft at least one epoxide group to at least a portion of the network of nanoscale fibers. A network of functionalized nanoscale fibers or buckypapers may include carbon nanotubes having a mean length of at least 1 mm and having an epoxide group grafted onto the nanotubes.

Owner:FLORIDA STATE UNIV RES FOUND INC

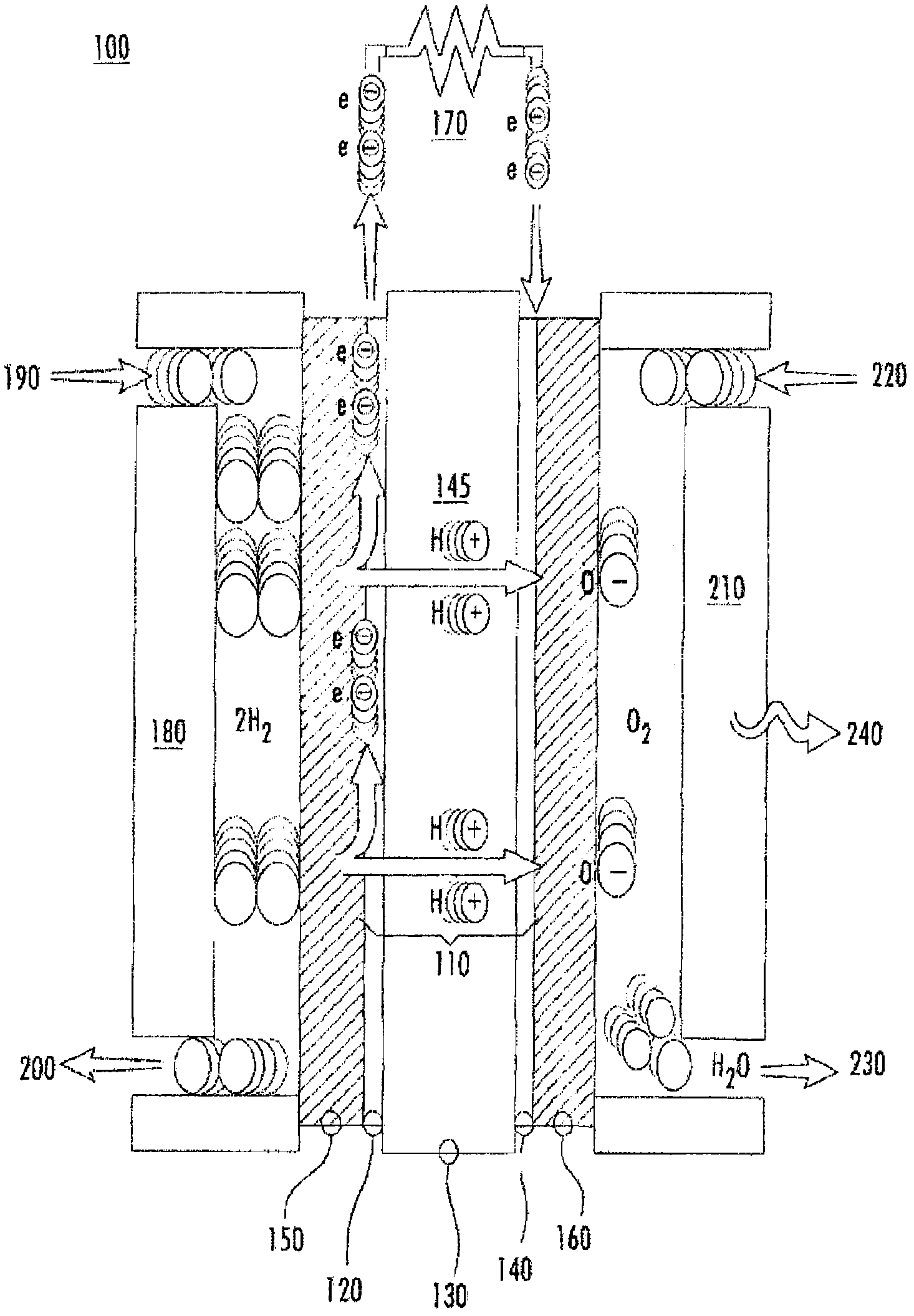

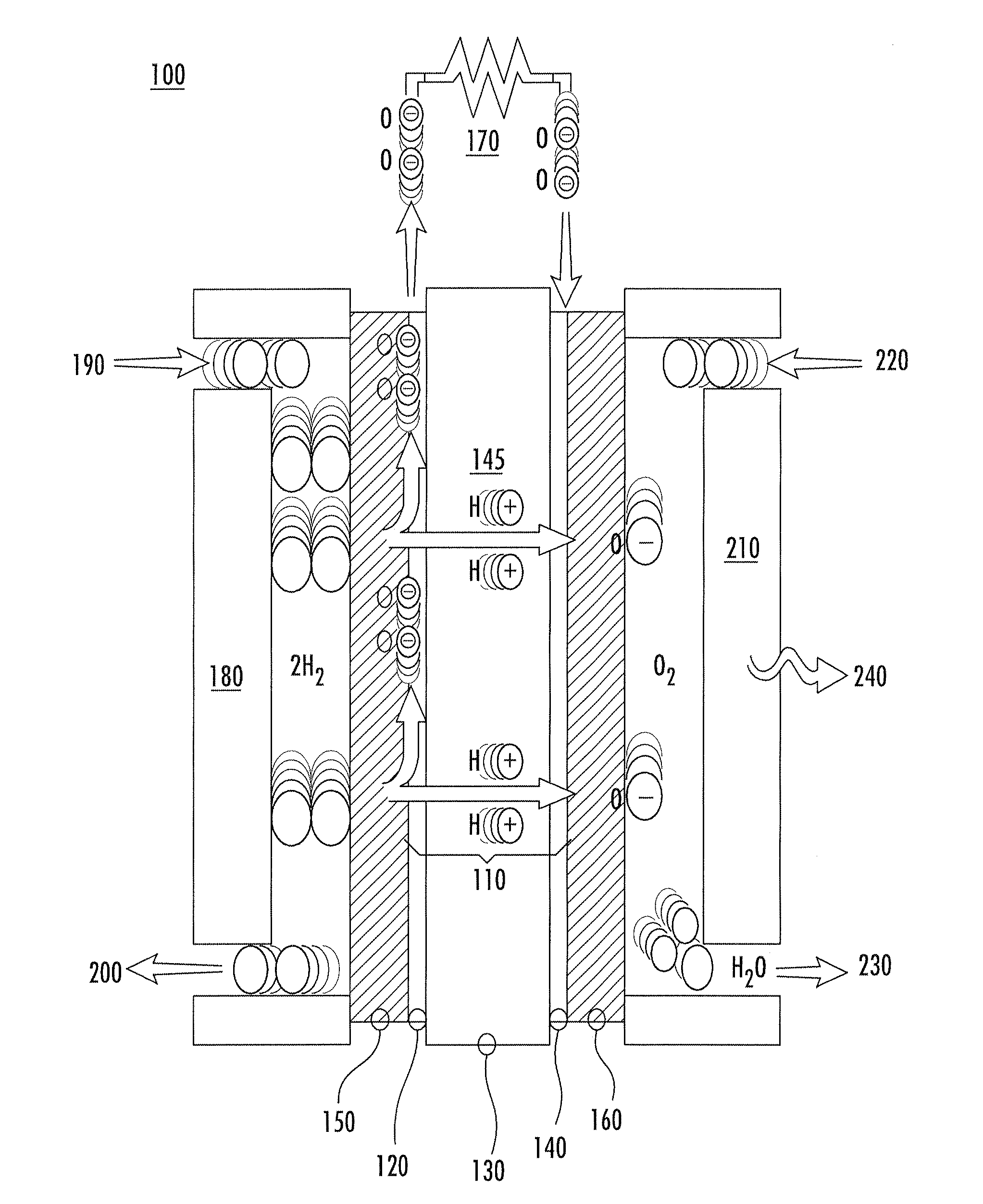

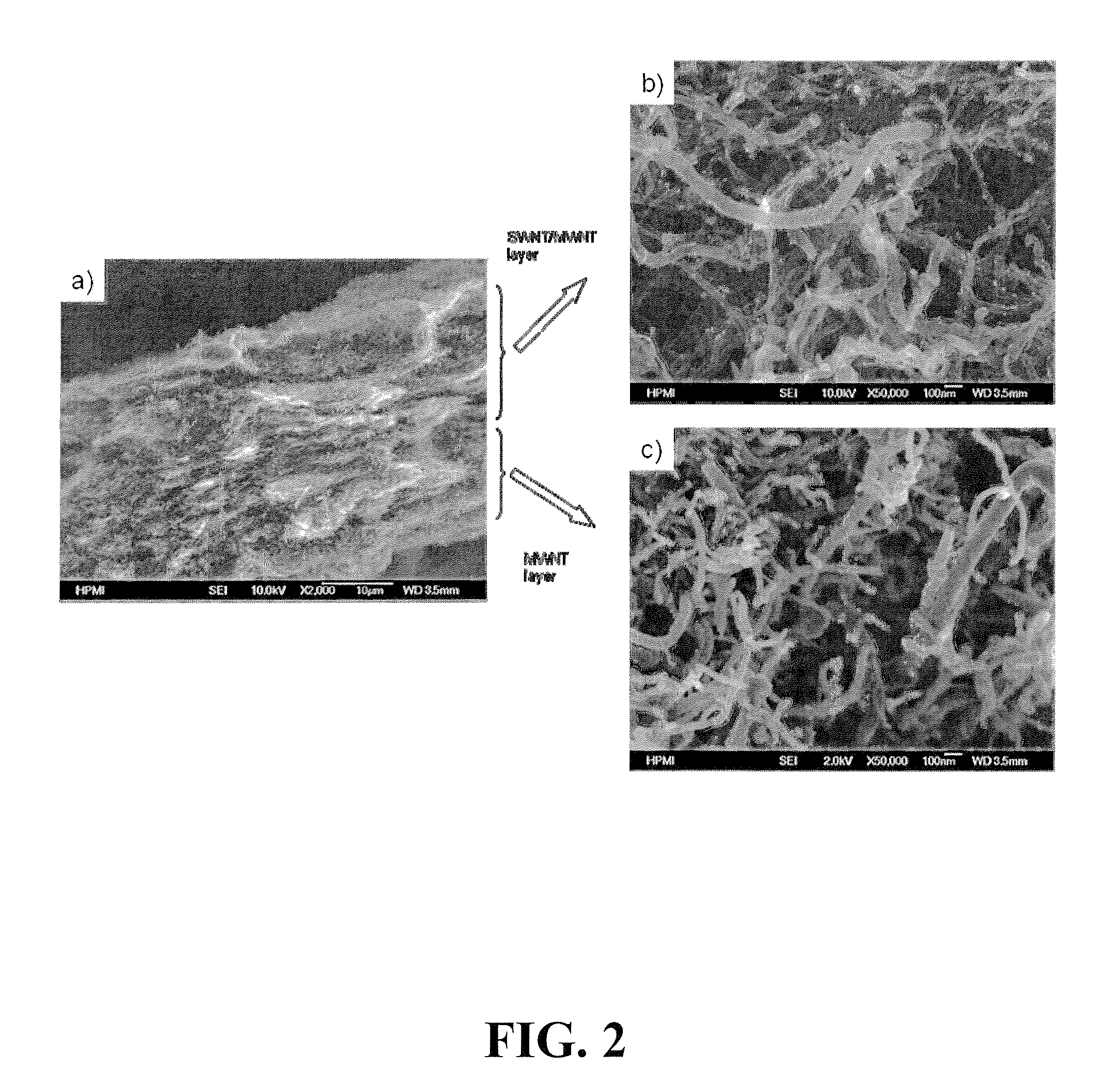

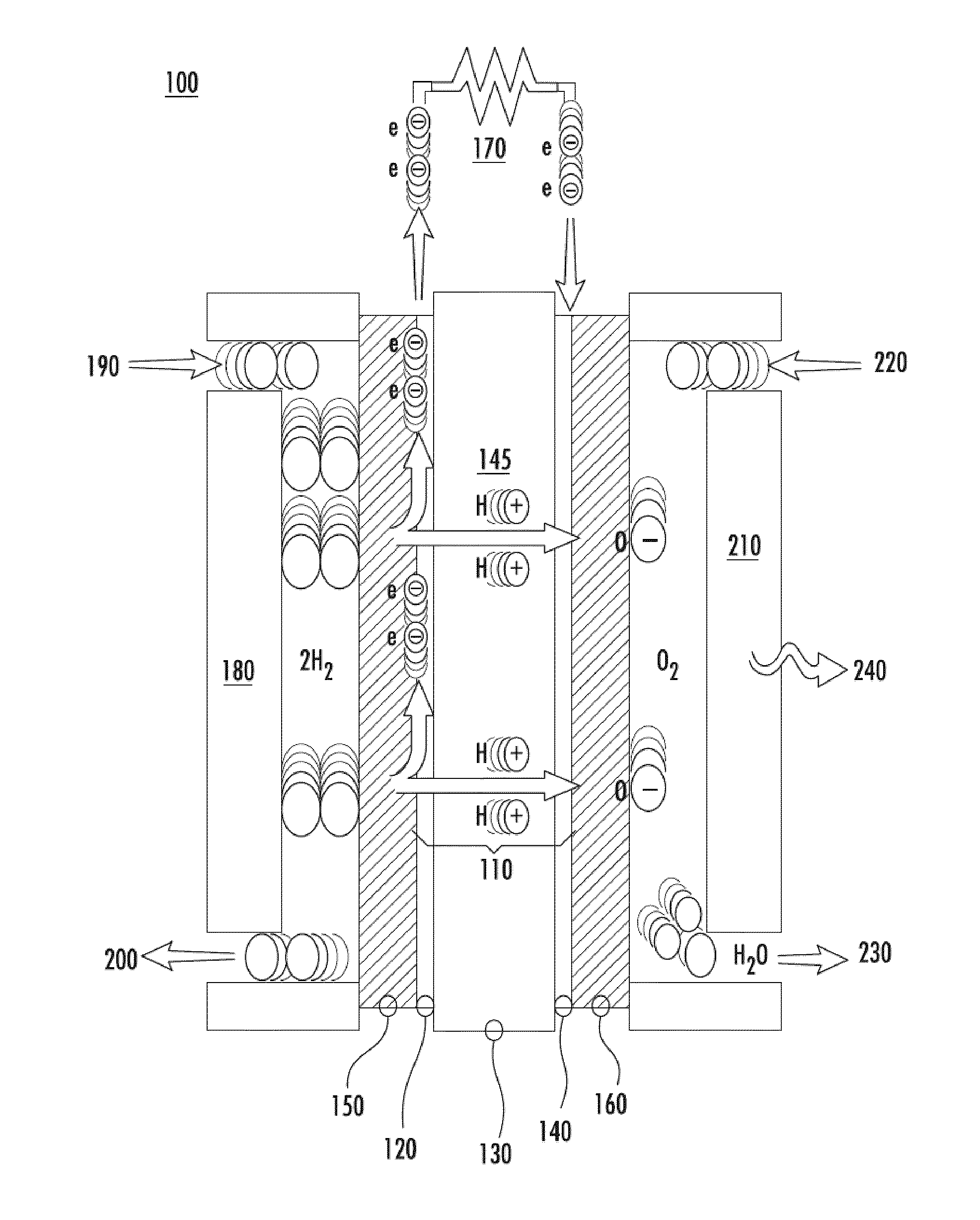

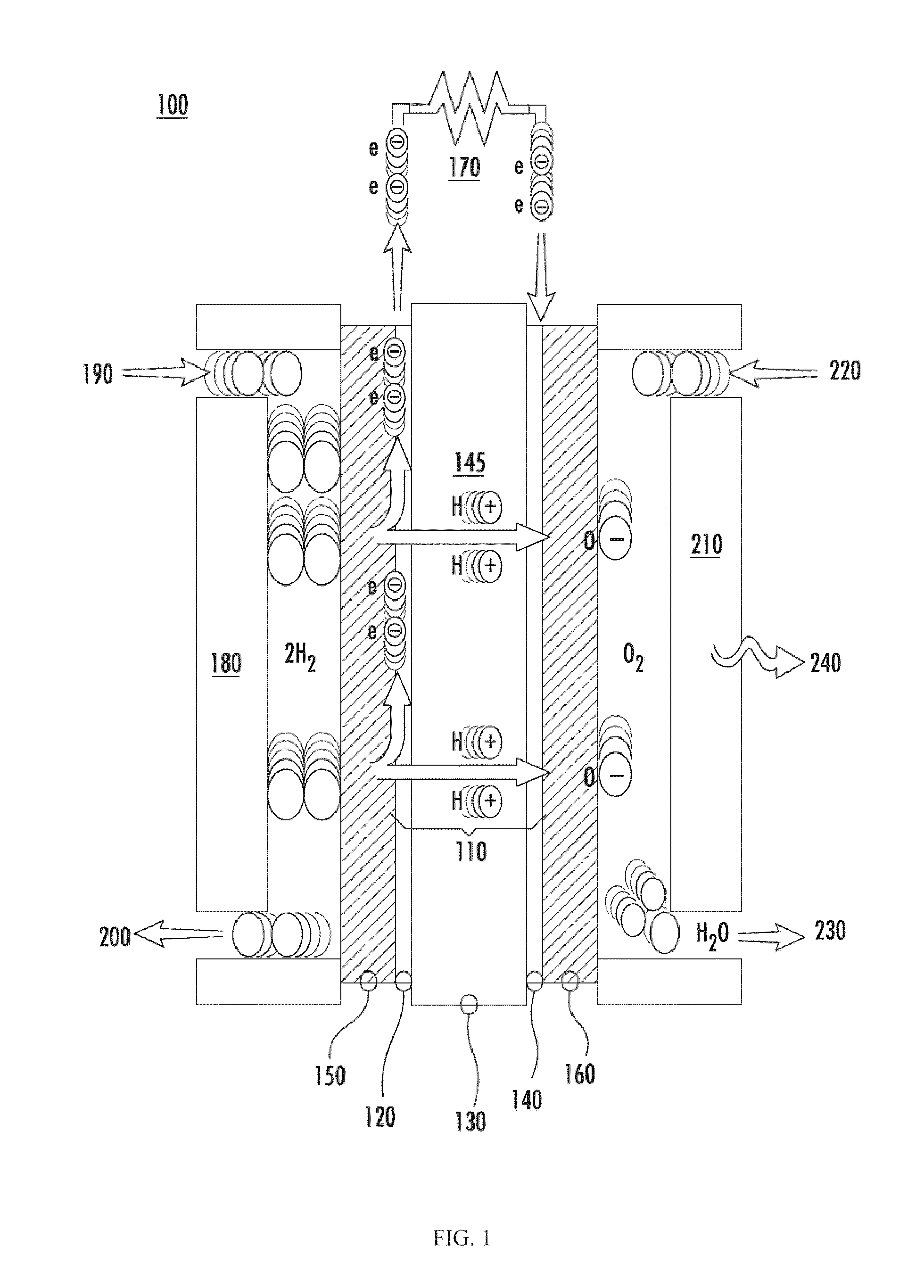

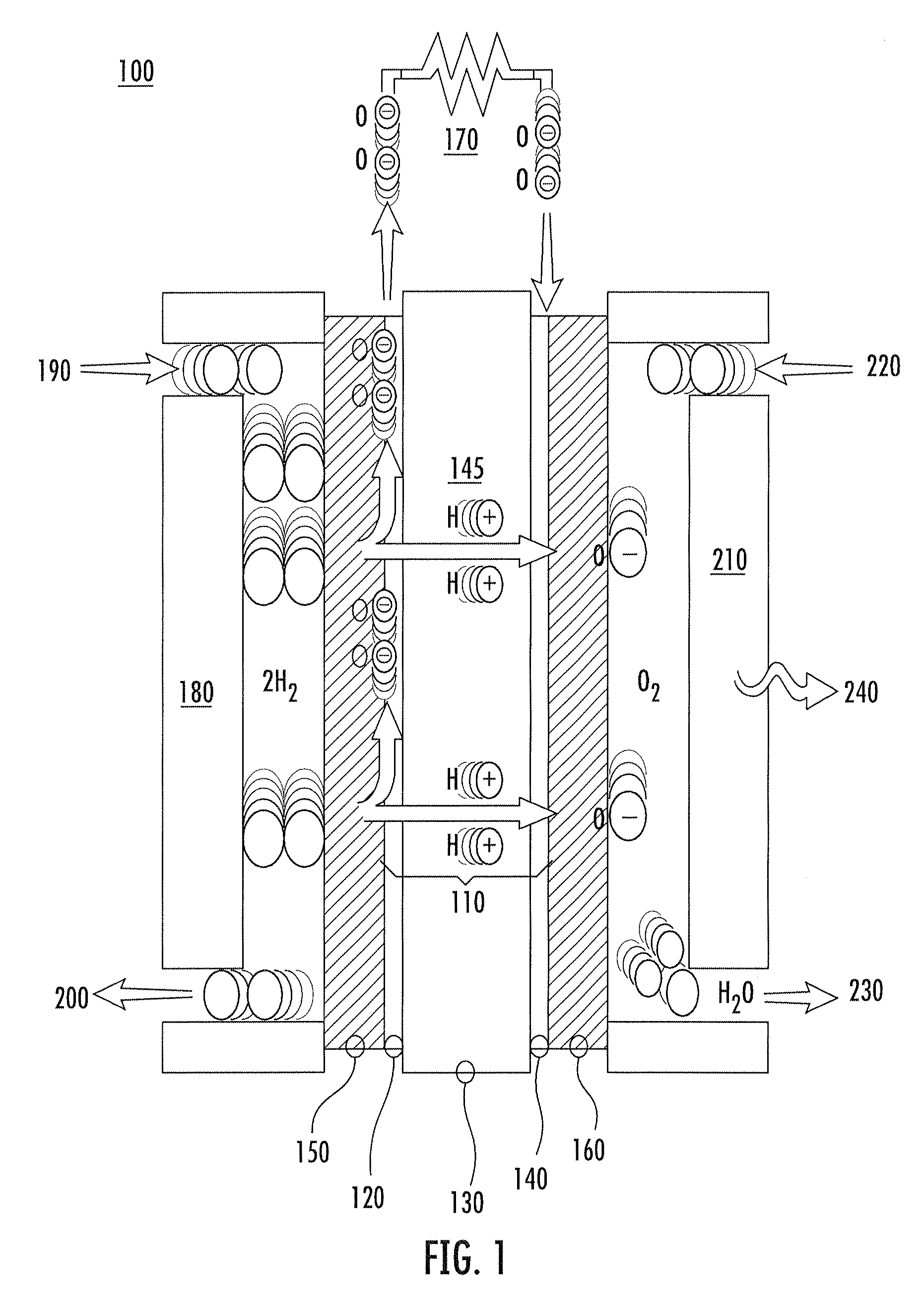

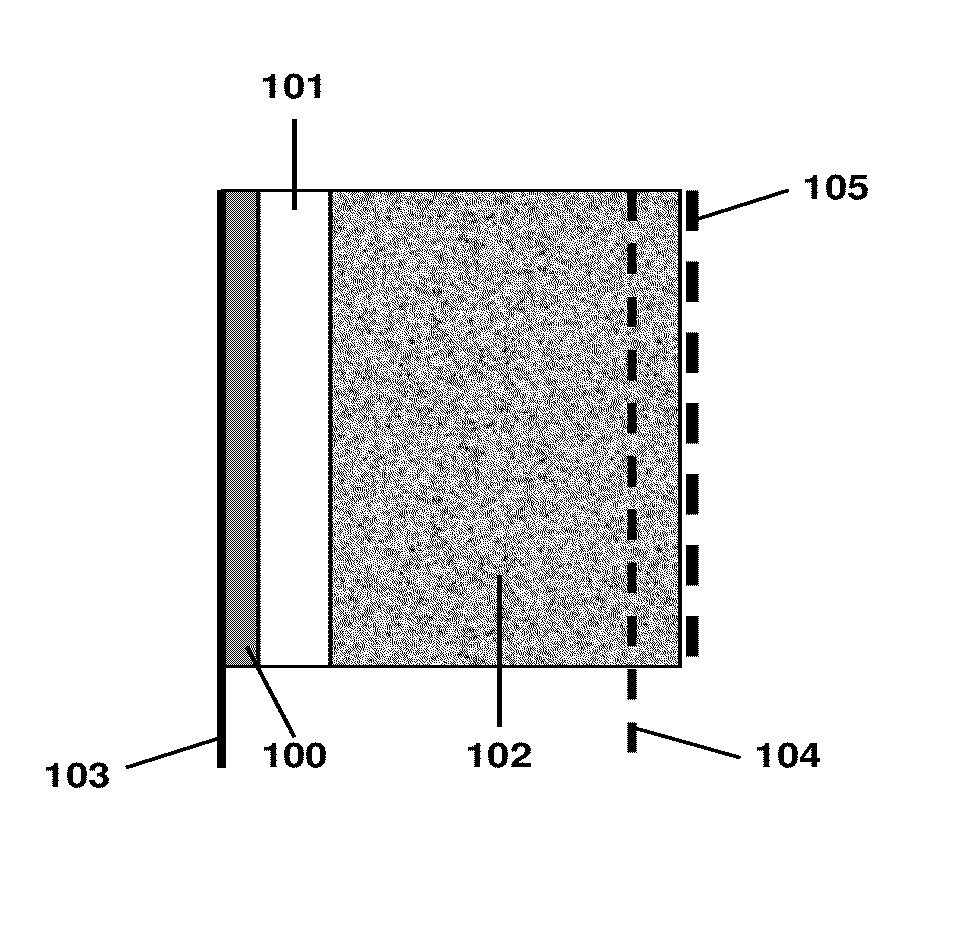

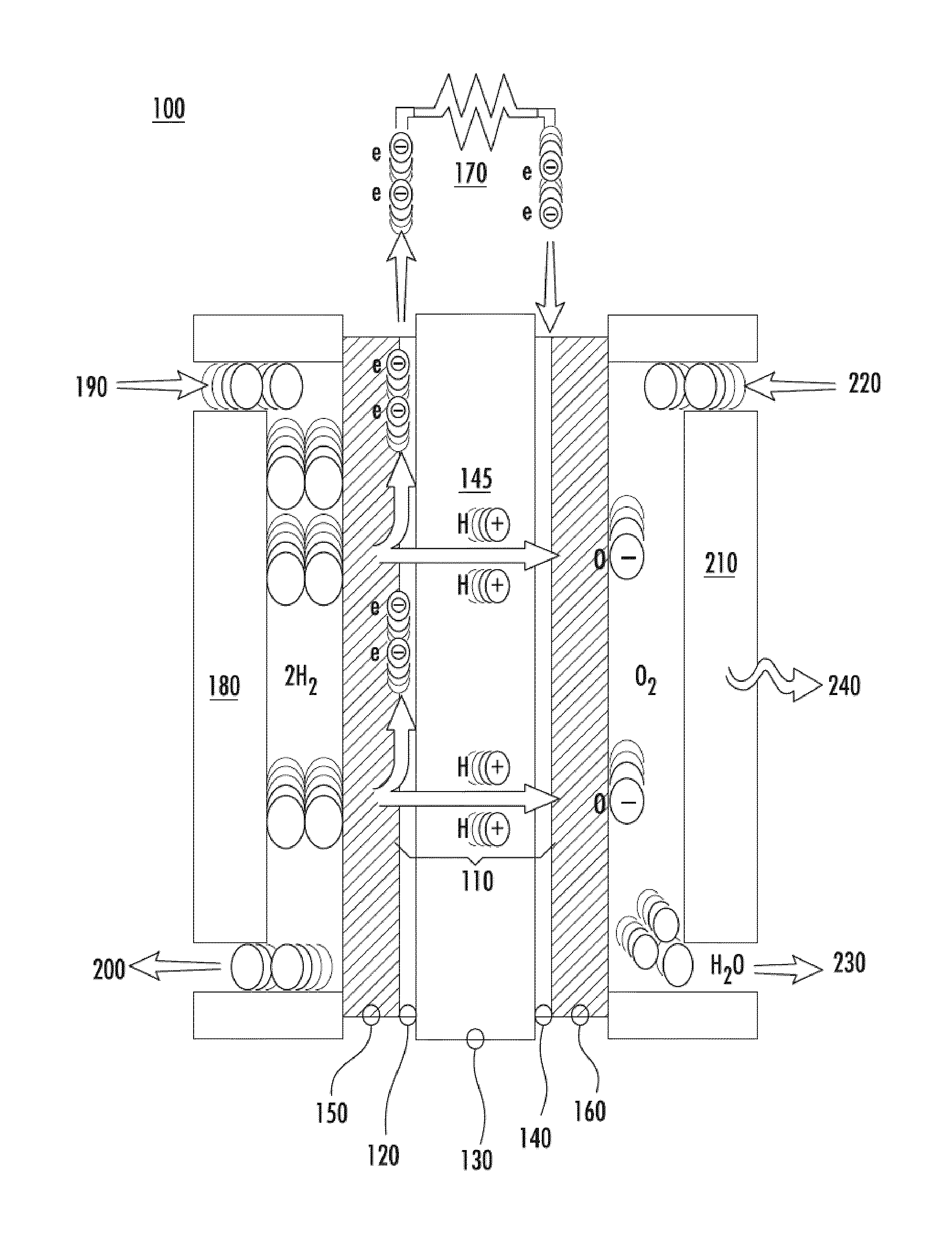

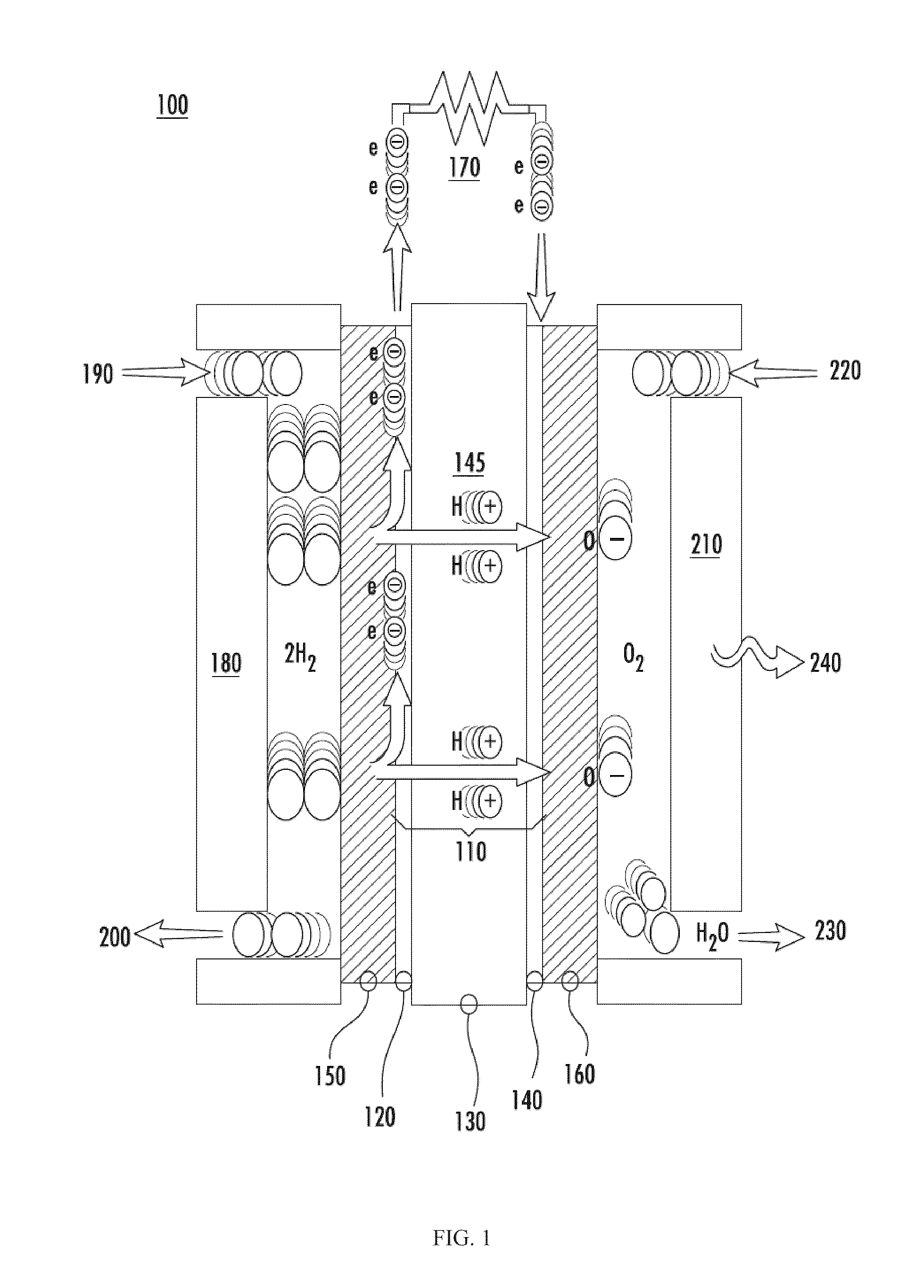

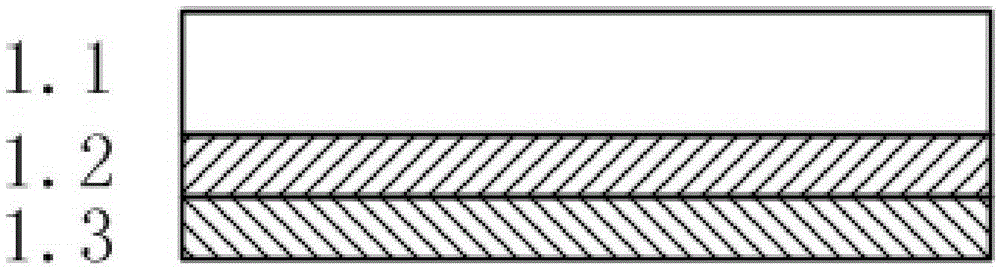

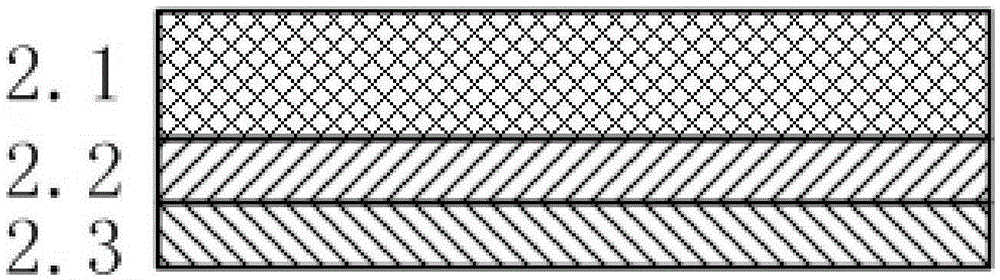

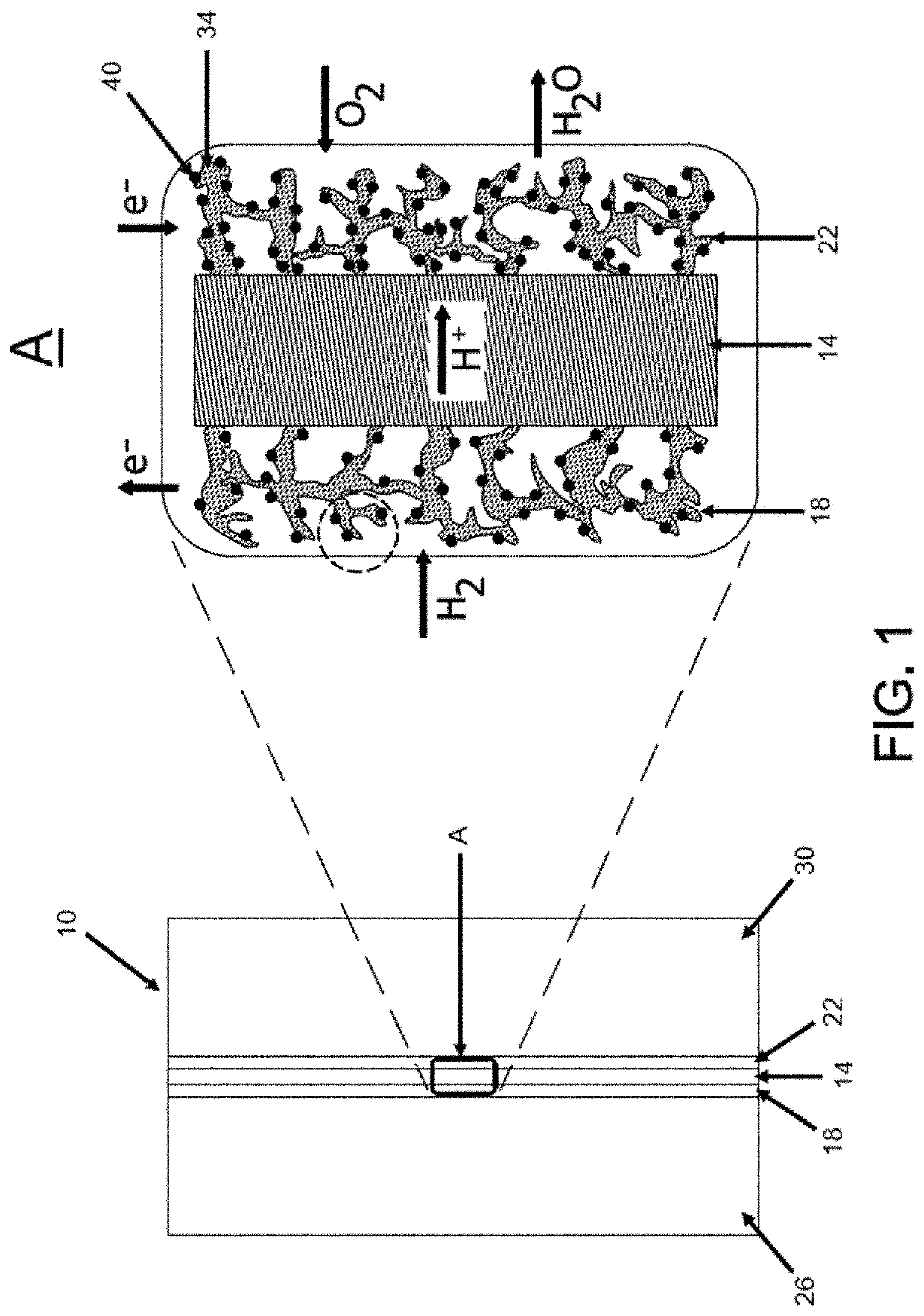

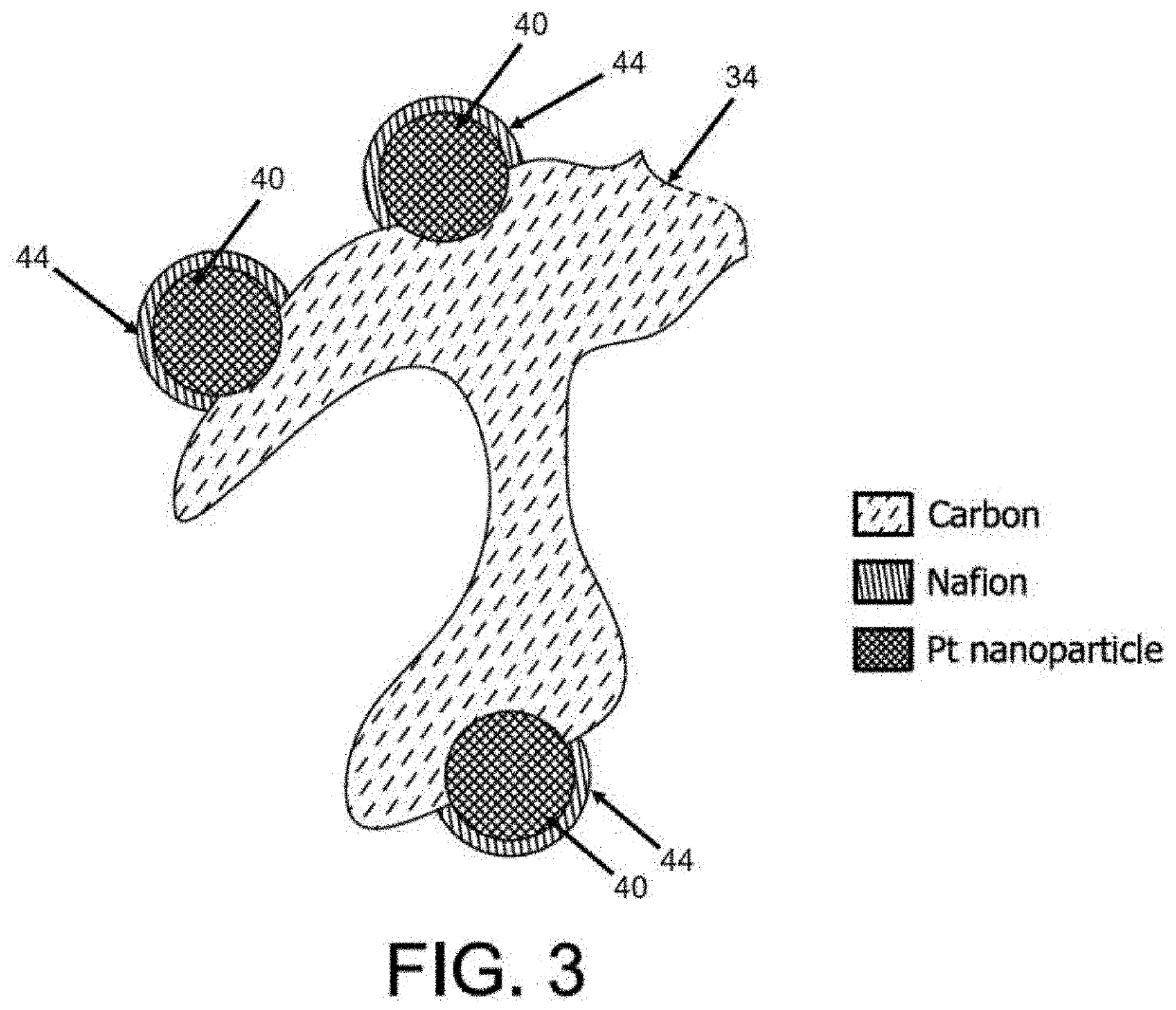

Catalytic electrode with gradient porosity and catalyst density for fuel cells

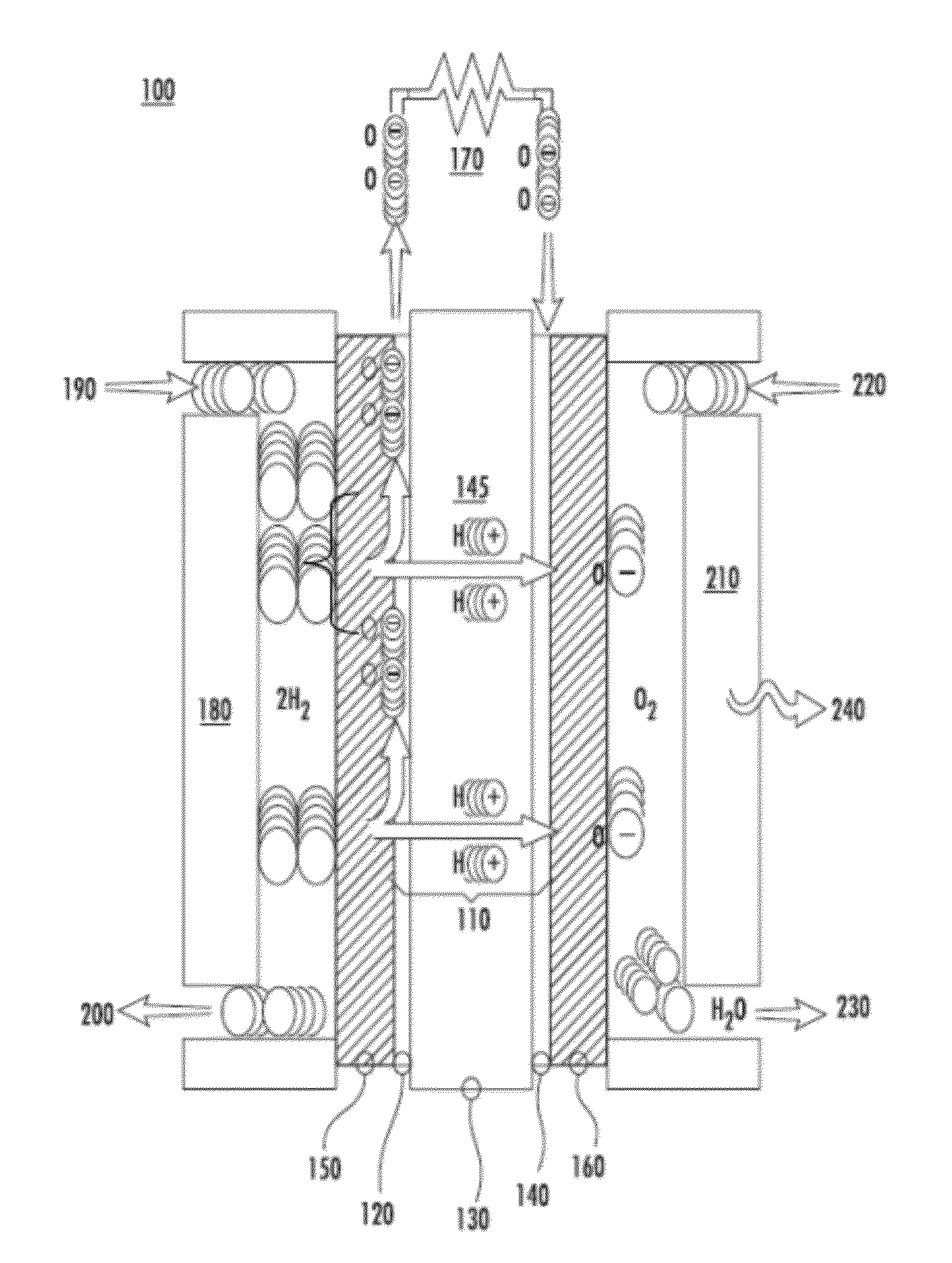

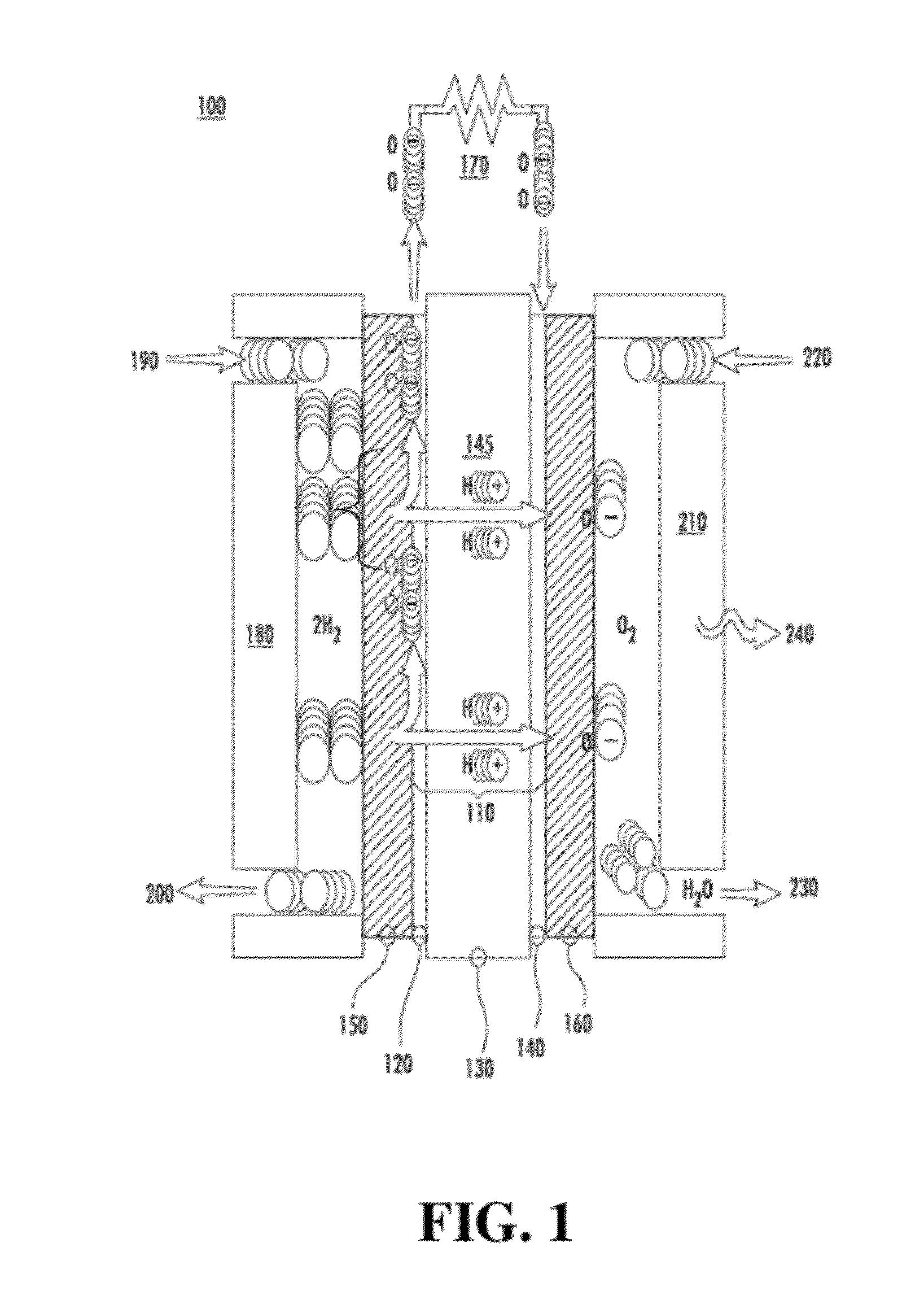

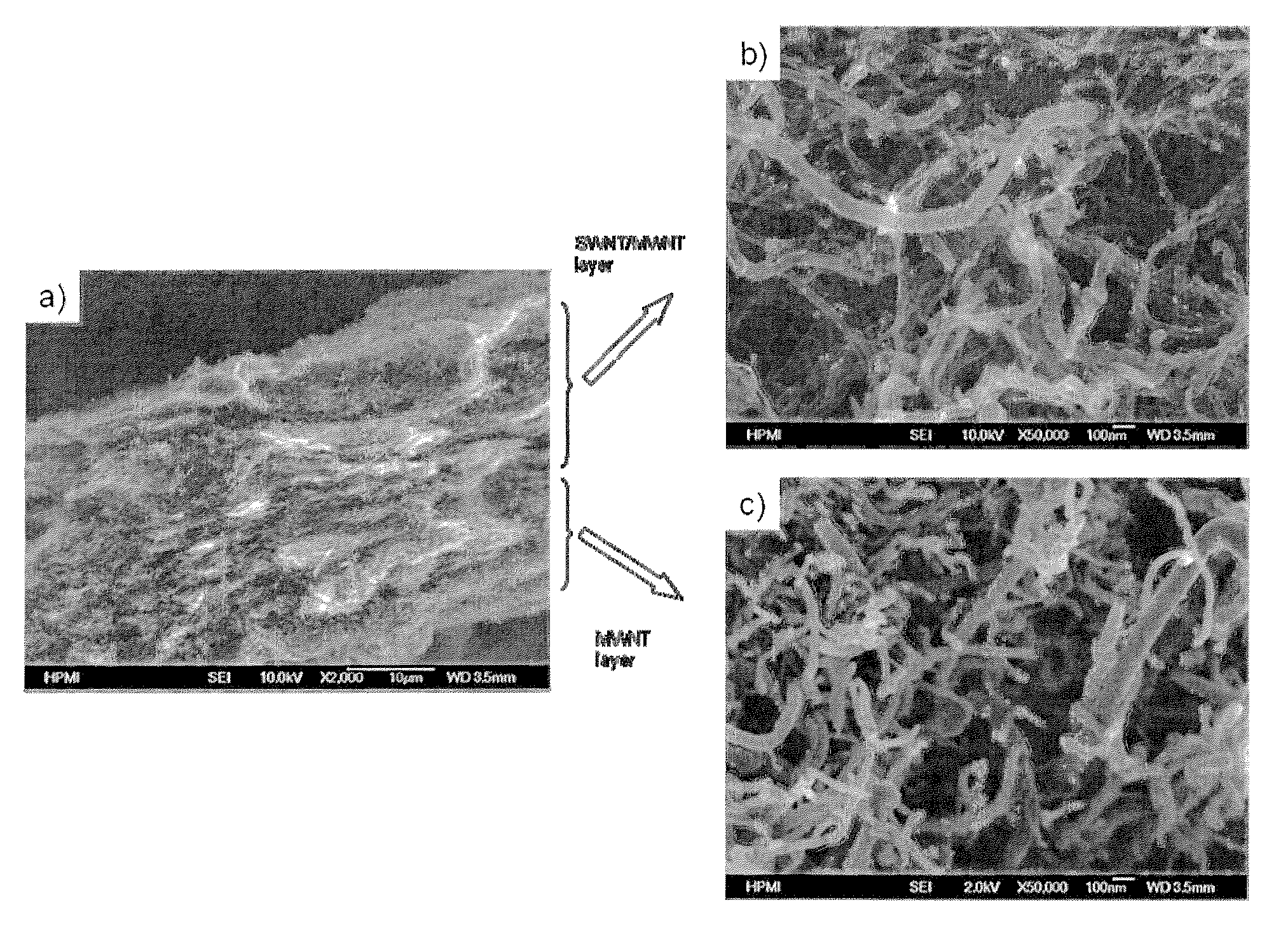

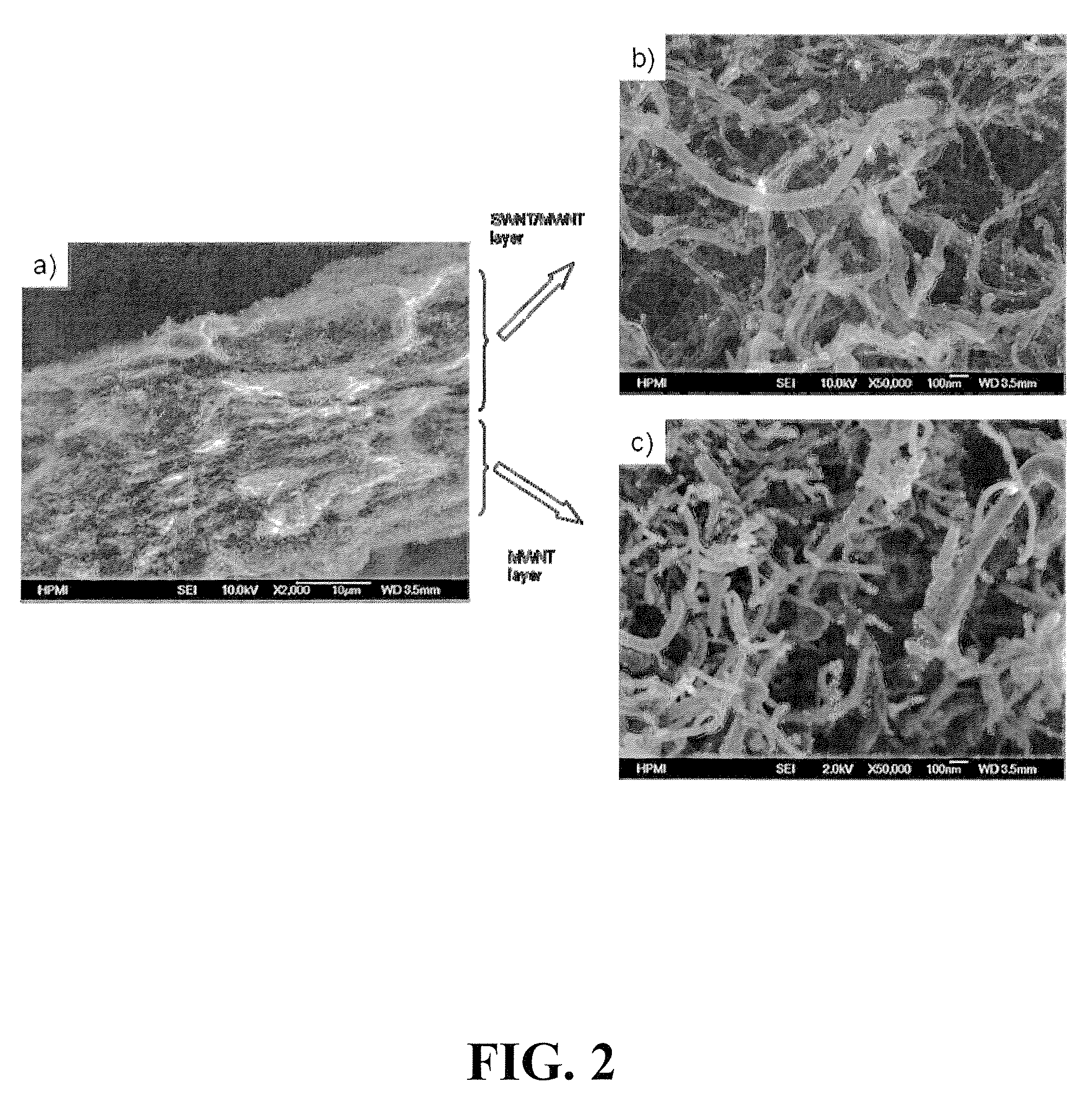

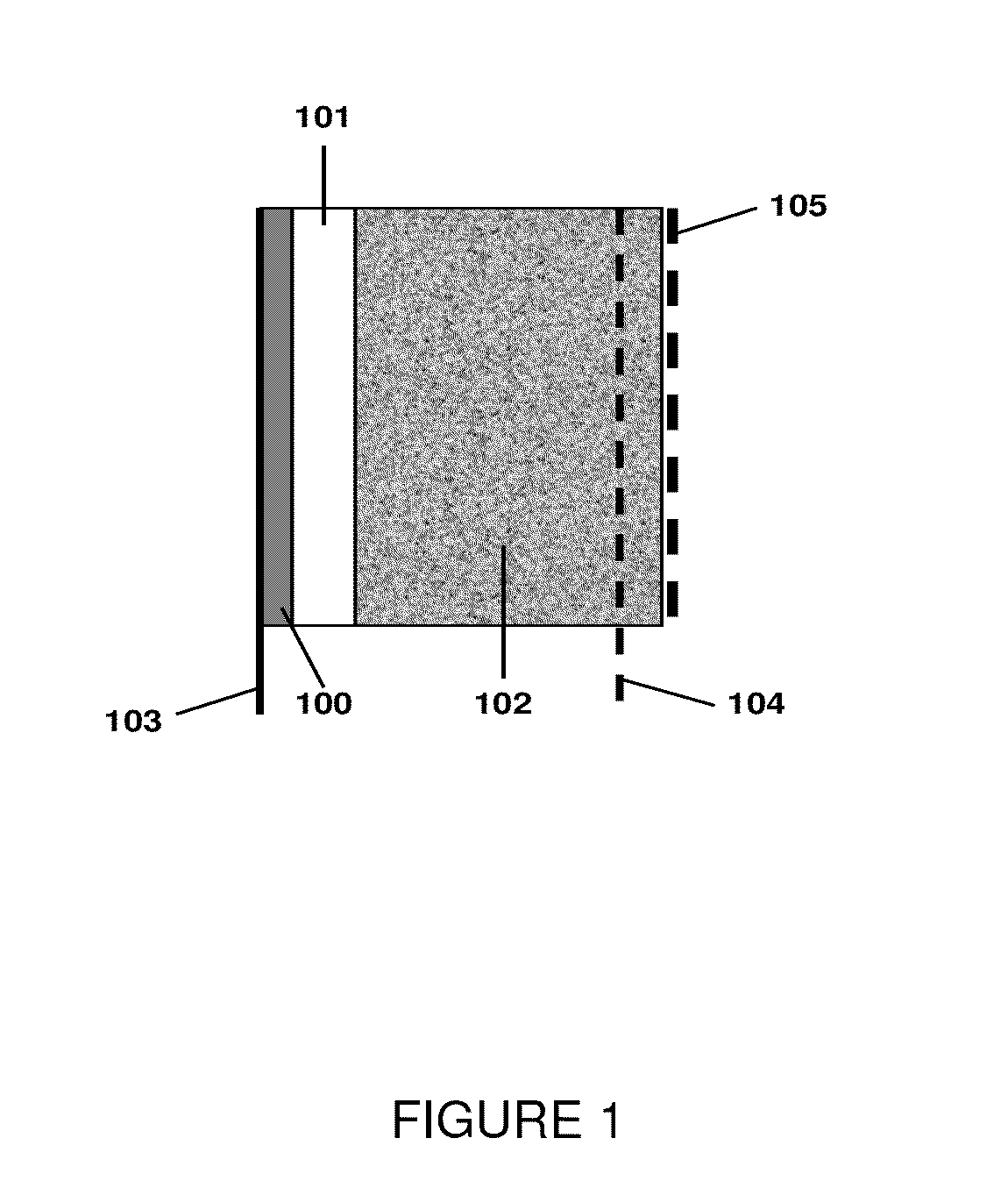

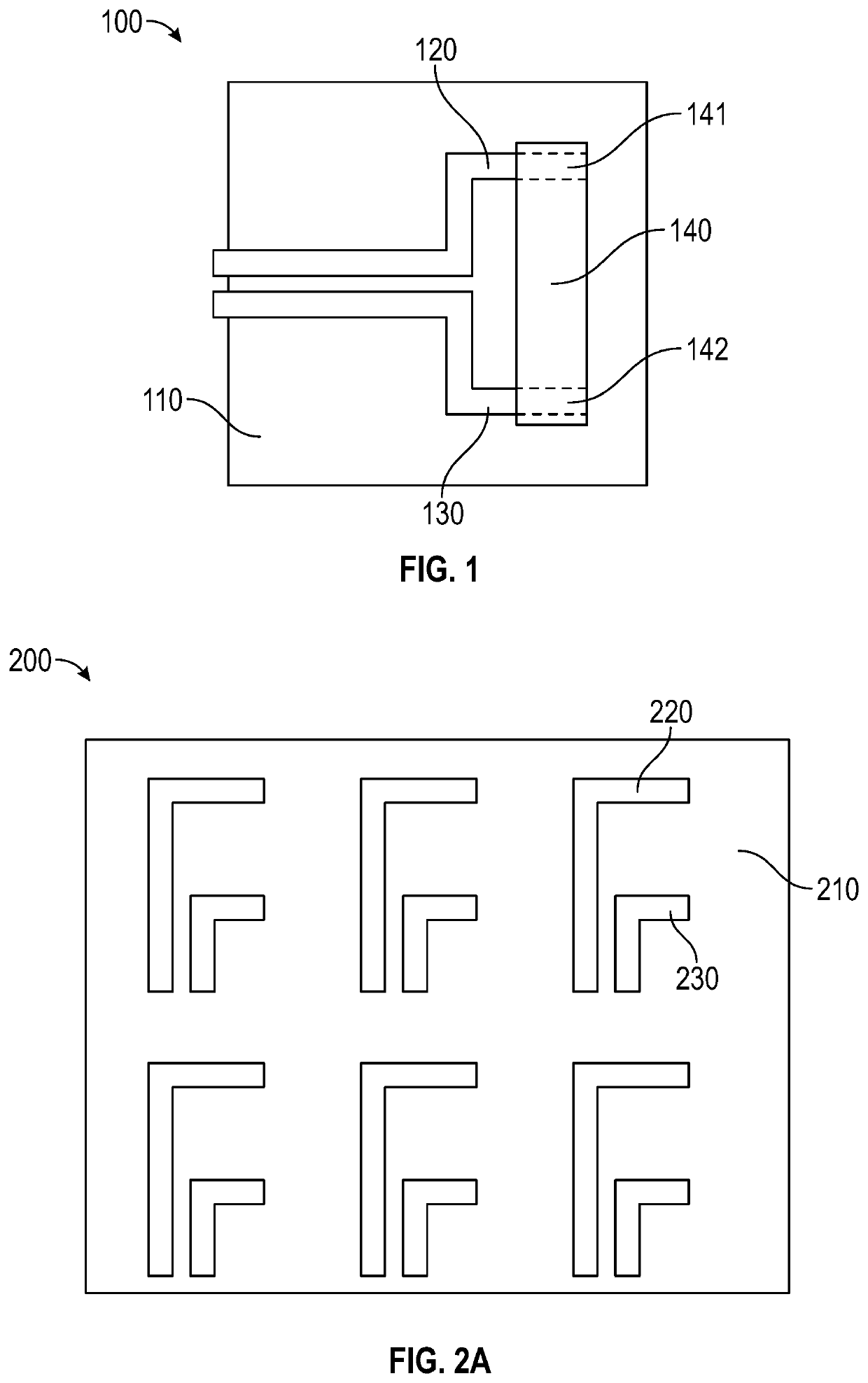

A membrane electrode assembly (110) for a fuel cell (100) comprising a gradient catalyst structure (120 or 140) and a method of making the same. The gradient catalyst structure (120 or 140) can include a plurality of catalyst nanoparticles, e. g. , platinum, disposed on layered buckypaper. The layered buckypaper can include at least a first layer and a second layer and the first layer can have a lower porosity compared to the second layer. The gradient catalyst structure (120 or 140) can include single-wall nanotubes, carbon nanofibers, or both in the first layer of the layered buckypaper and can include carbon nanofibers in the second layer of the layered buckypaper. The membrane electrode assembly (110) can have a catalyst utilization efficiency of at least 0. 35 gcat / kW or less.

Owner:FLORIDA STATE UNIV RES FOUND INC

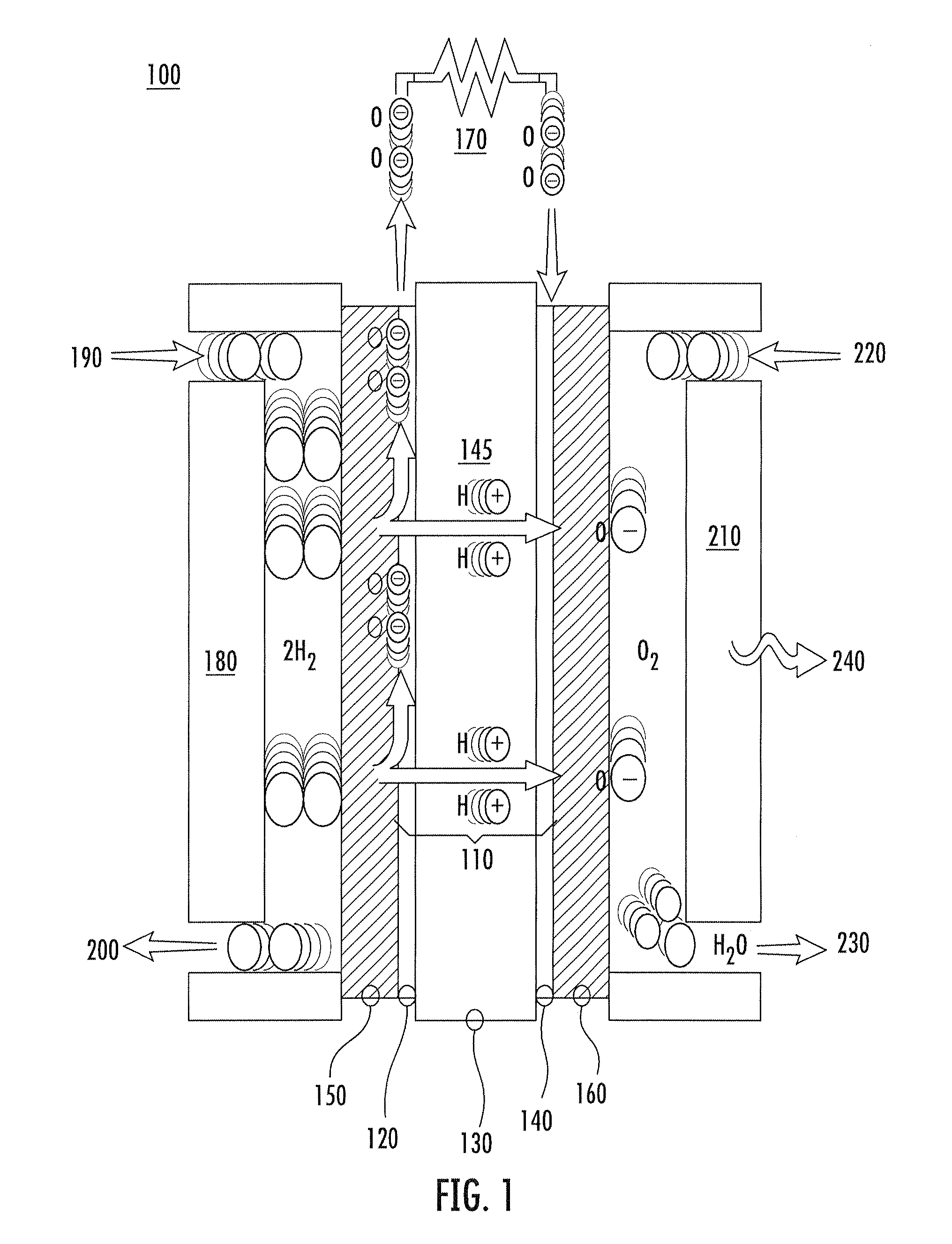

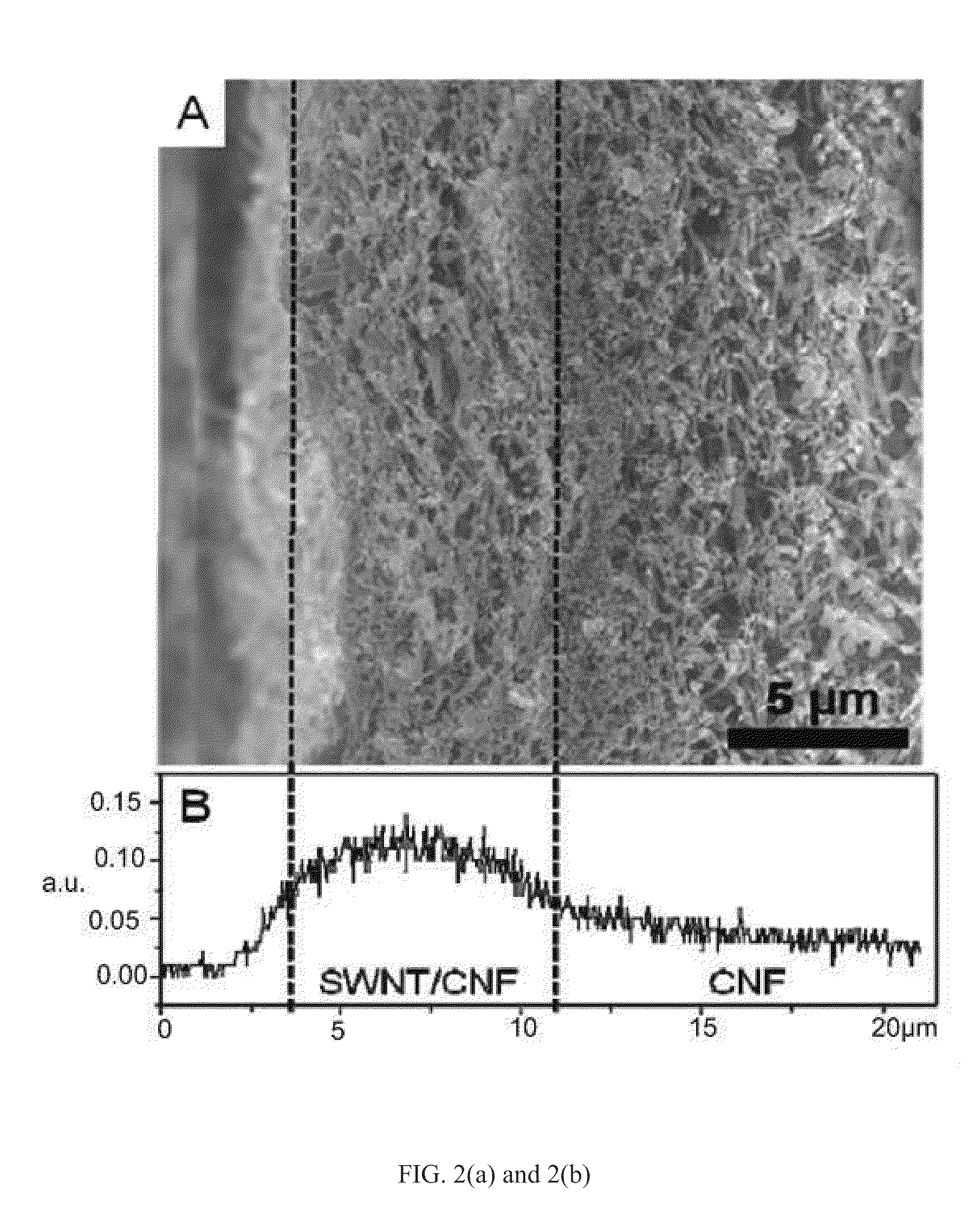

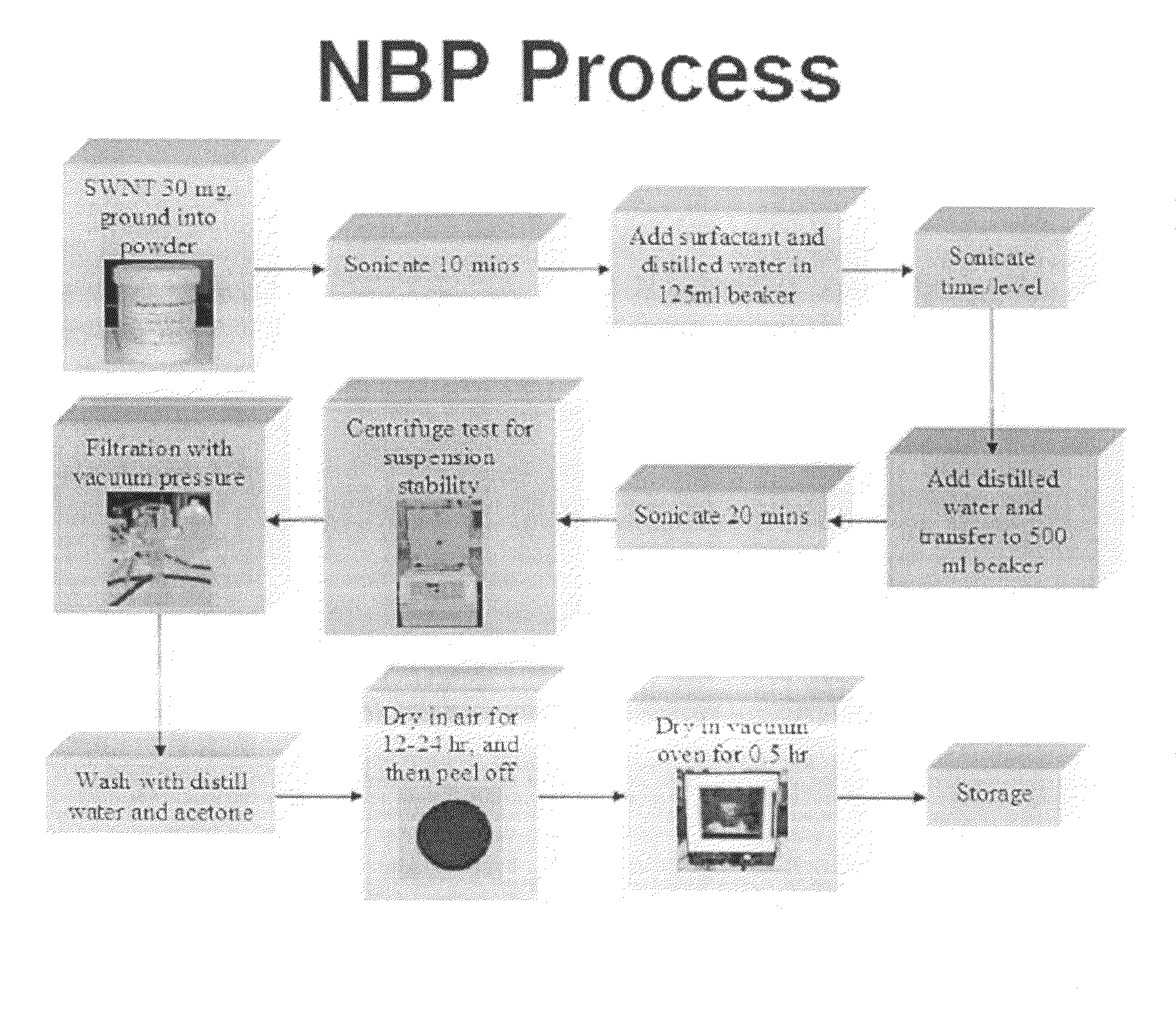

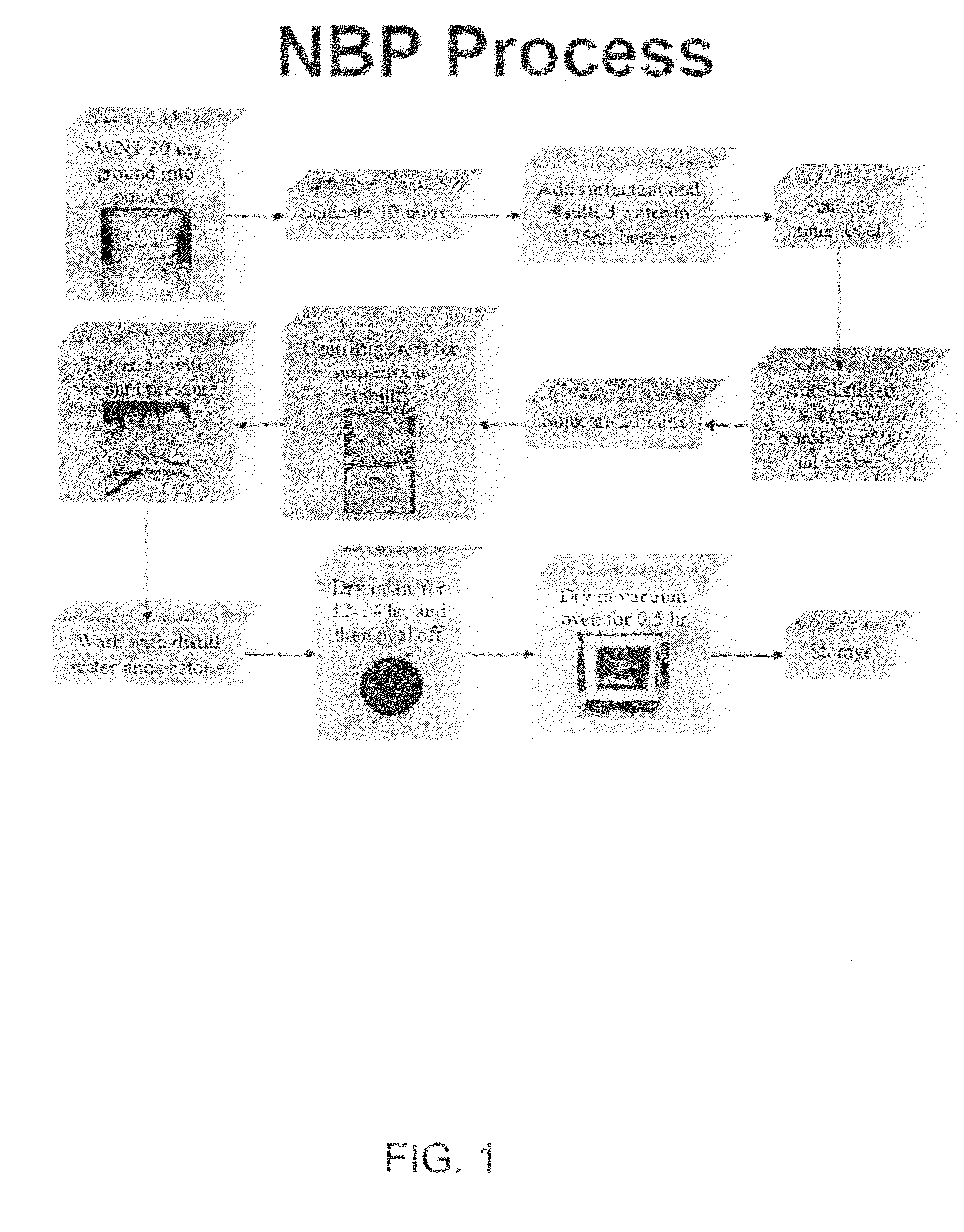

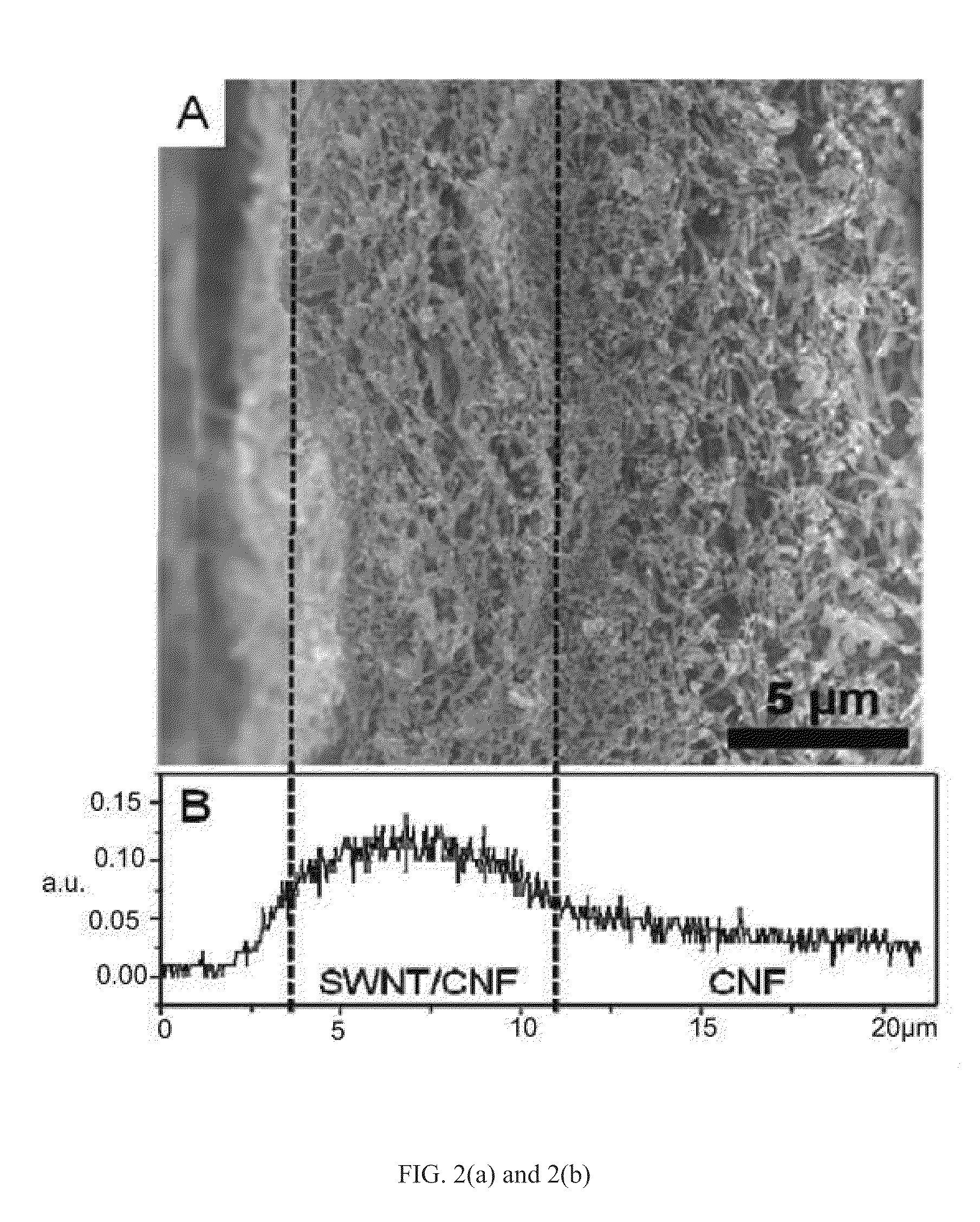

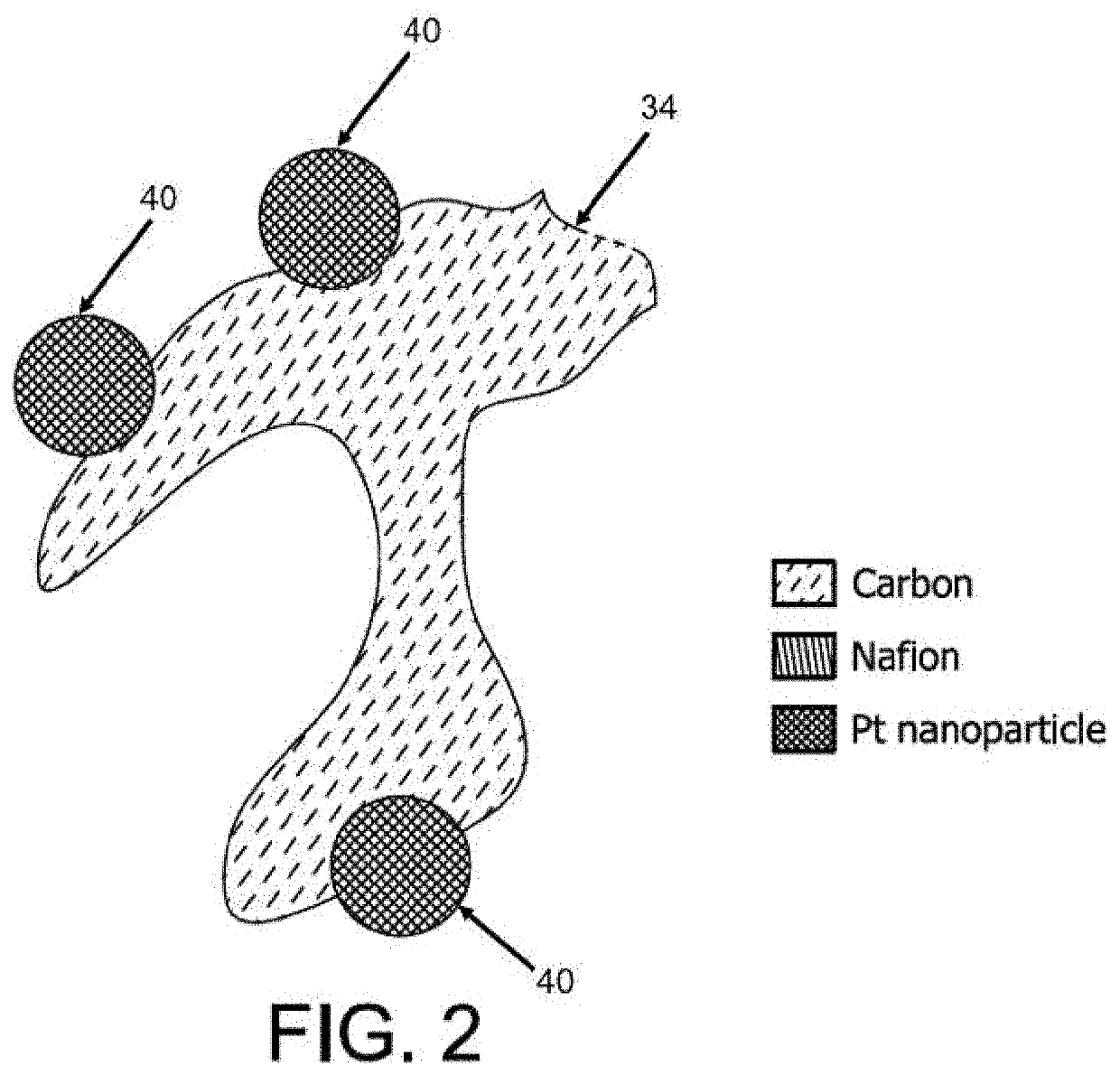

Carbon nanotube and nonofiber film-based membrane electrode assemblies

ActiveUS20100143822A1Improving electrical and mechanical propertyHigh rateMaterial nanotechnologyFinal product manufactureBuckypaperPlatinum

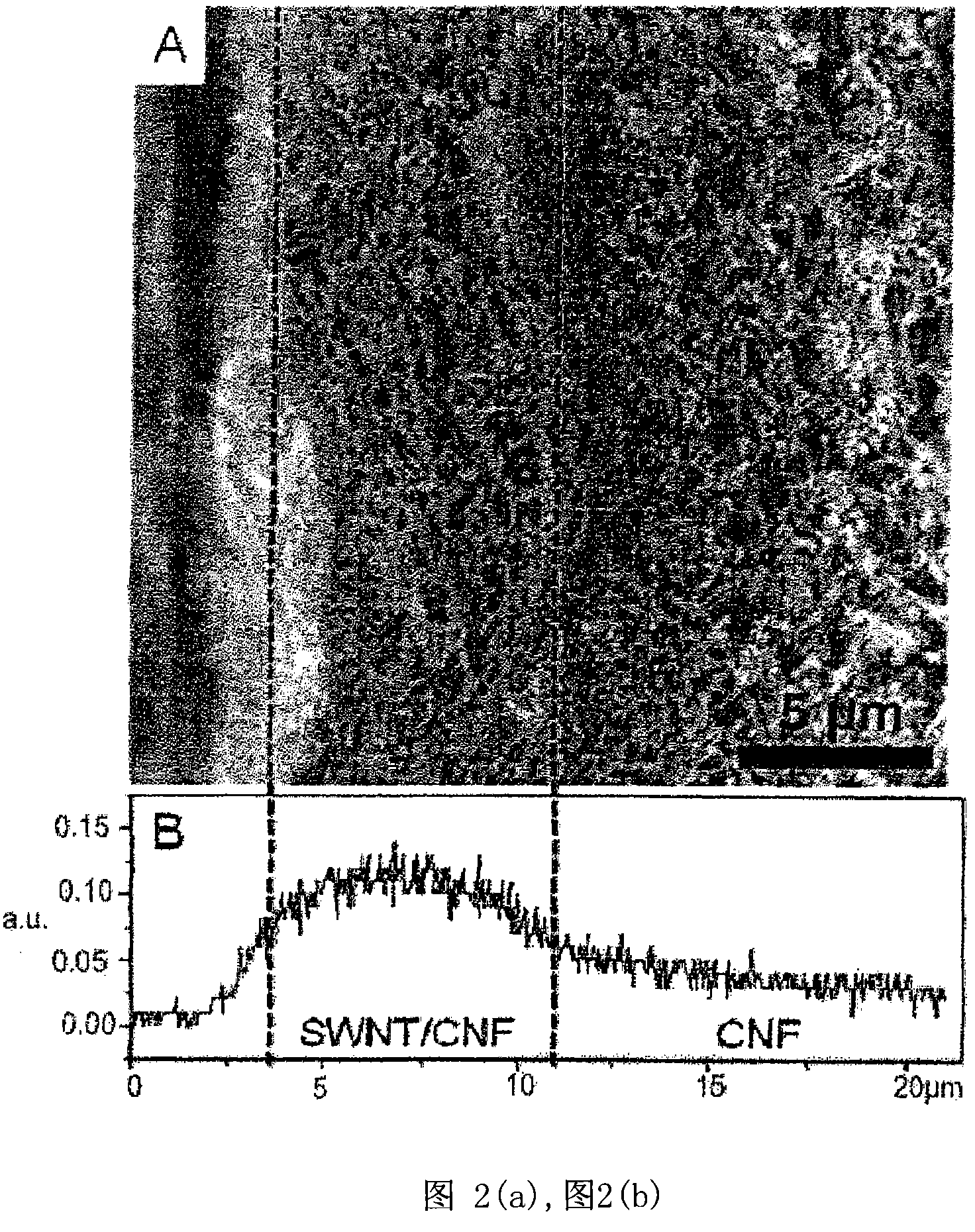

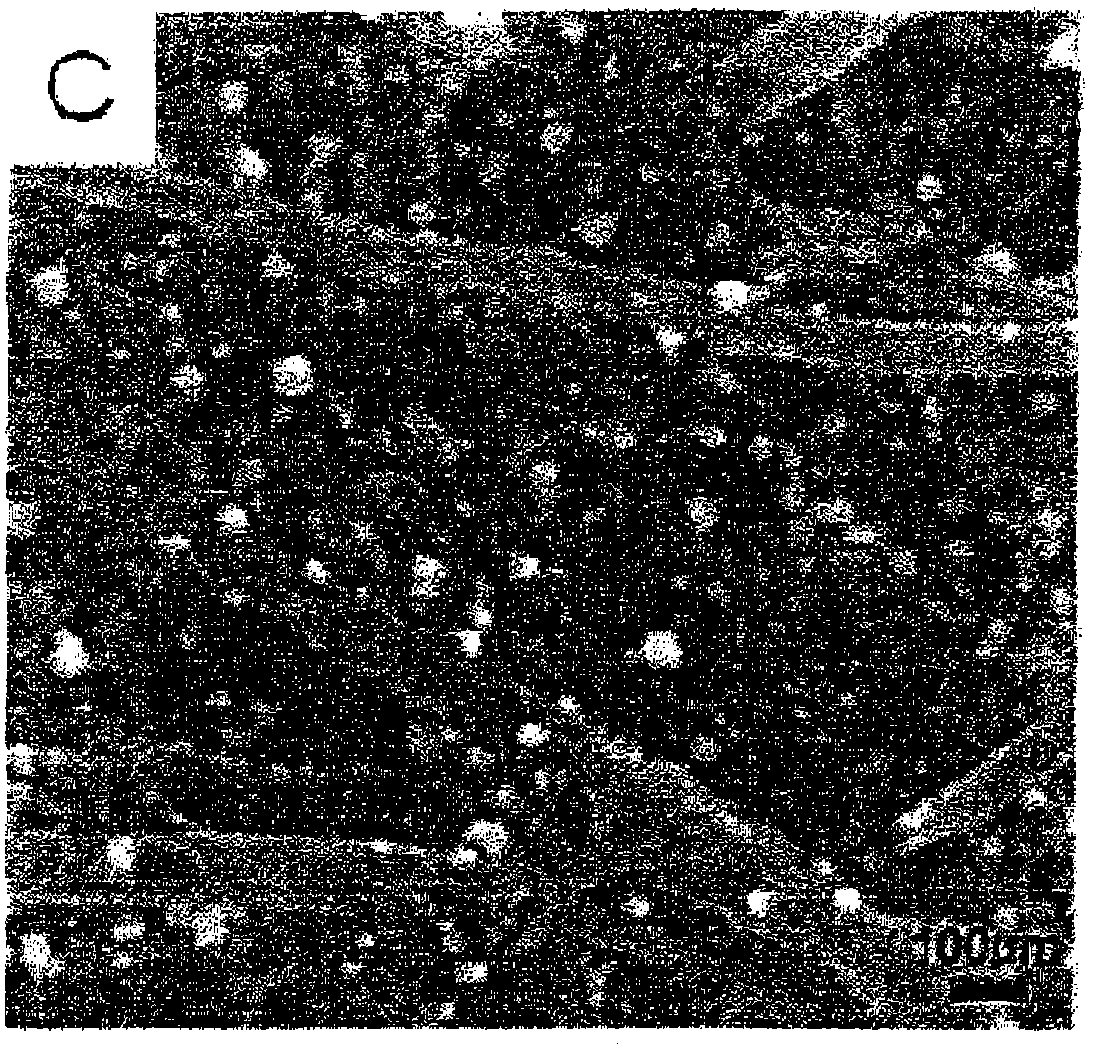

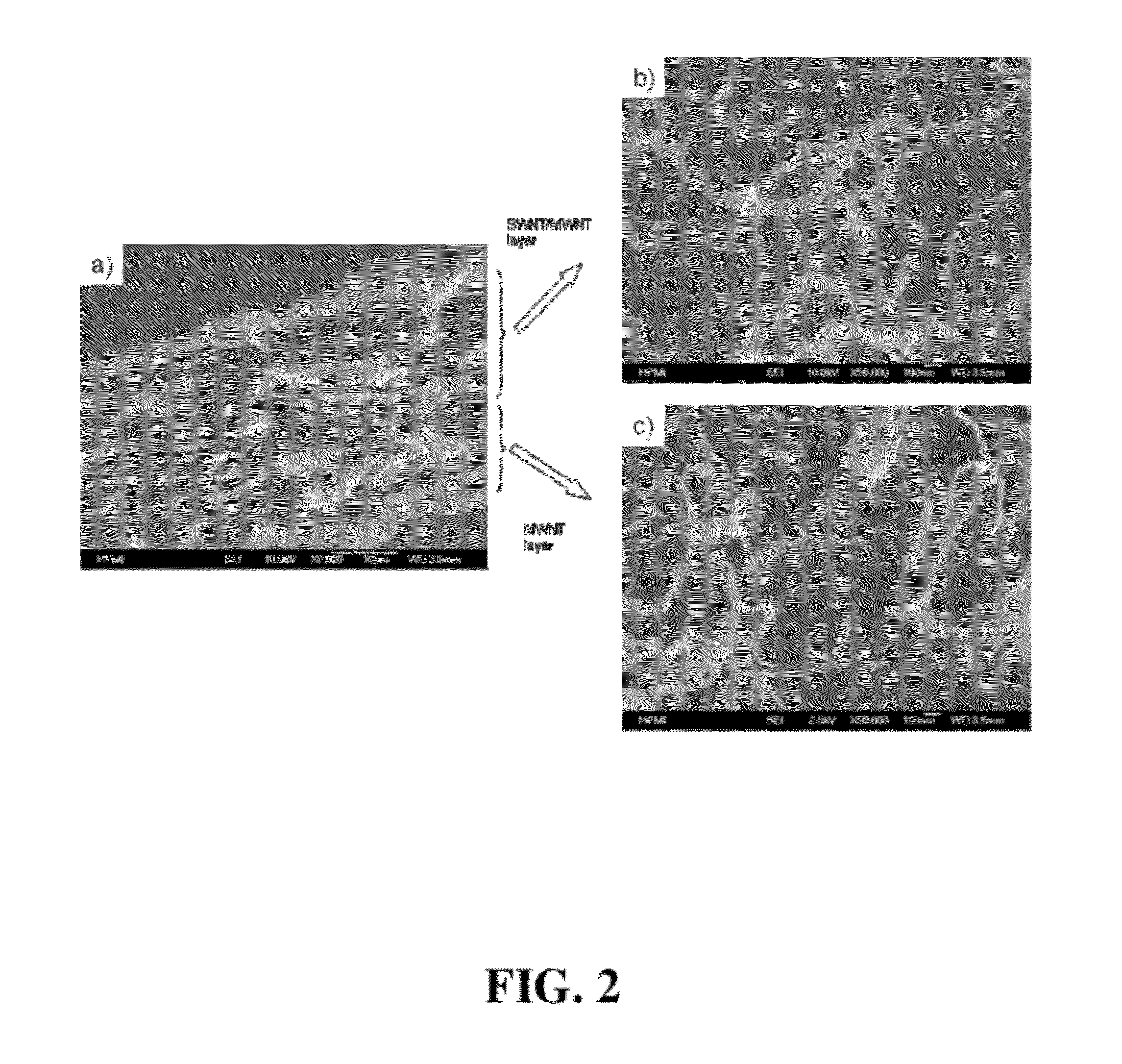

A membrane electrode assembly (MEA) for a fuel cell comprising a catalyst layer and a method of making the same. The catalyst layer can include a plurality of catalyst nanoparticles, e.g., platinum, disposed on buckypaper. The catalyst layer can have 1% or less binder prior to attachment to the membrane electrode assembly. The catalyst layer can include (a) single-wall nanotubes, small diameter multi-wall nanotubes, or both, and (b) large diameter multi-wall nanotubes, carbon nanofibers, or both. The ratio of (a) to (b) can range from 1:2 to 1:20. The catalyst layer can produce a surface area utilization efficiency of at least 60% and the platinum utilization efficiency can be 0.50 gPt / kW or less.

Owner:FLORIDA STATE UNIV RES FOUND INC

Catalytic electrode with gradient porosity and catalyst density for fuel cells

ActiveUS20110008705A1Maximize three-phase reaction coefficientHigh catalyst utilization rateMaterial nanotechnologyNanostructure manufacturePorosityFiber

A membrane electrode assembly (MEA) for a fuel cell comprising a gradient catalyst structure and a method of making the same. The gradient catalyst structure can include a plurality of catalyst nanoparticles, e.g., platinum, disposed on layered buckypaper. The layered buckypaper can include at least a first layer and a second layer and the first layer can have a lower porosity compared to the second layer. The gradient catalyst structure can include single-wall nanotubes, carbon nanofibers, or both in the first layer of the layered buckypaper and can include carbon nanofibers in the second layer of the layered buckypaper. The MEA can have a catalyst utilization efficiency of at least 0.35 gcat / kW or less.

Owner:FLORIDA STATE UNIV RES FOUND INC

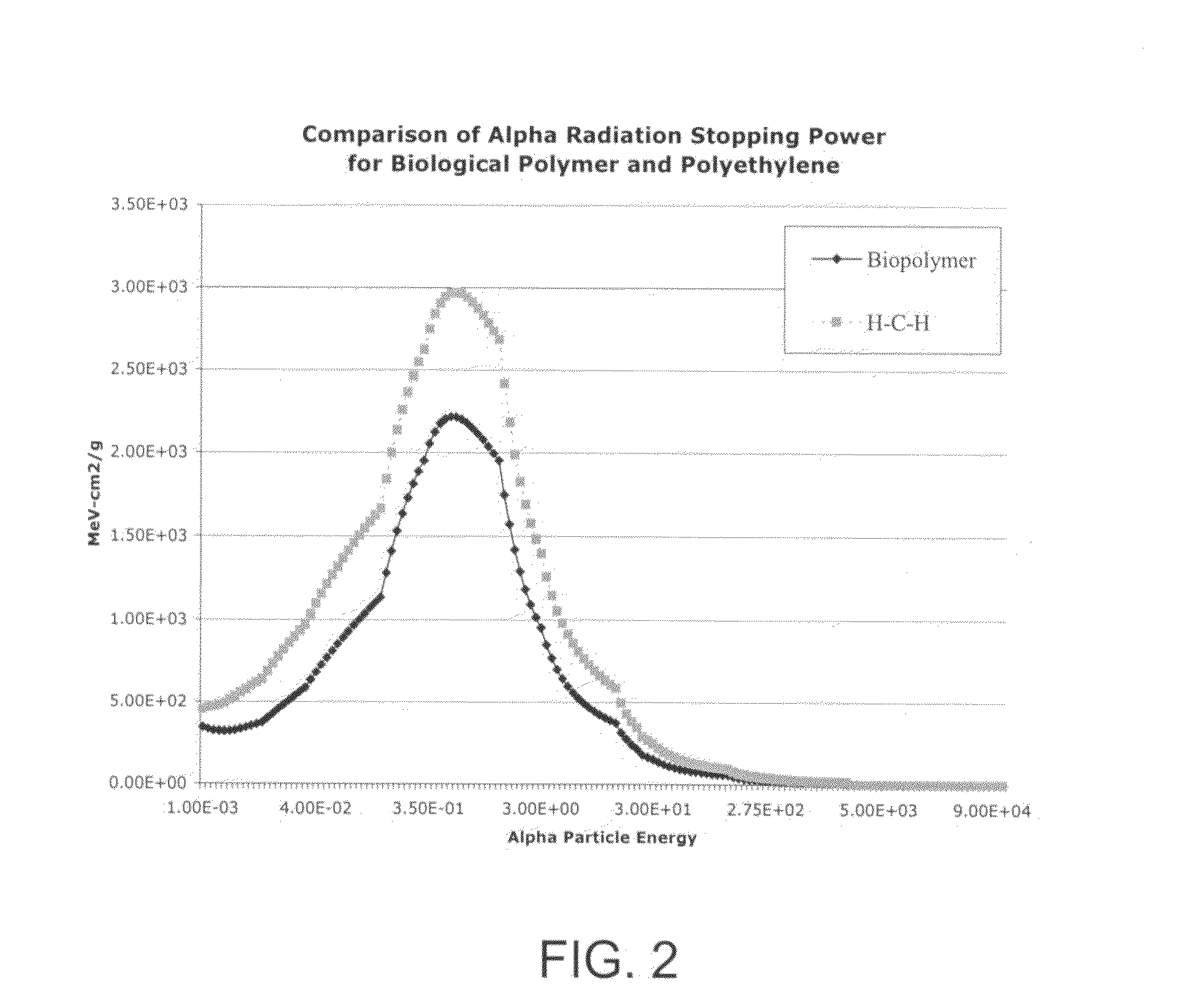

Biologically modified buckypaper and compositions

InactiveUS20080128659A1Light-weightEasy to manufactureOther chemical processesShieldingDopantBuckypaper

A composite for providing shielding against cosmic radiation, consisting essentially of carbon nanotubes, a biopolymer of lignin and a halogen as dopant.

Owner:PARKER REGINALD +2

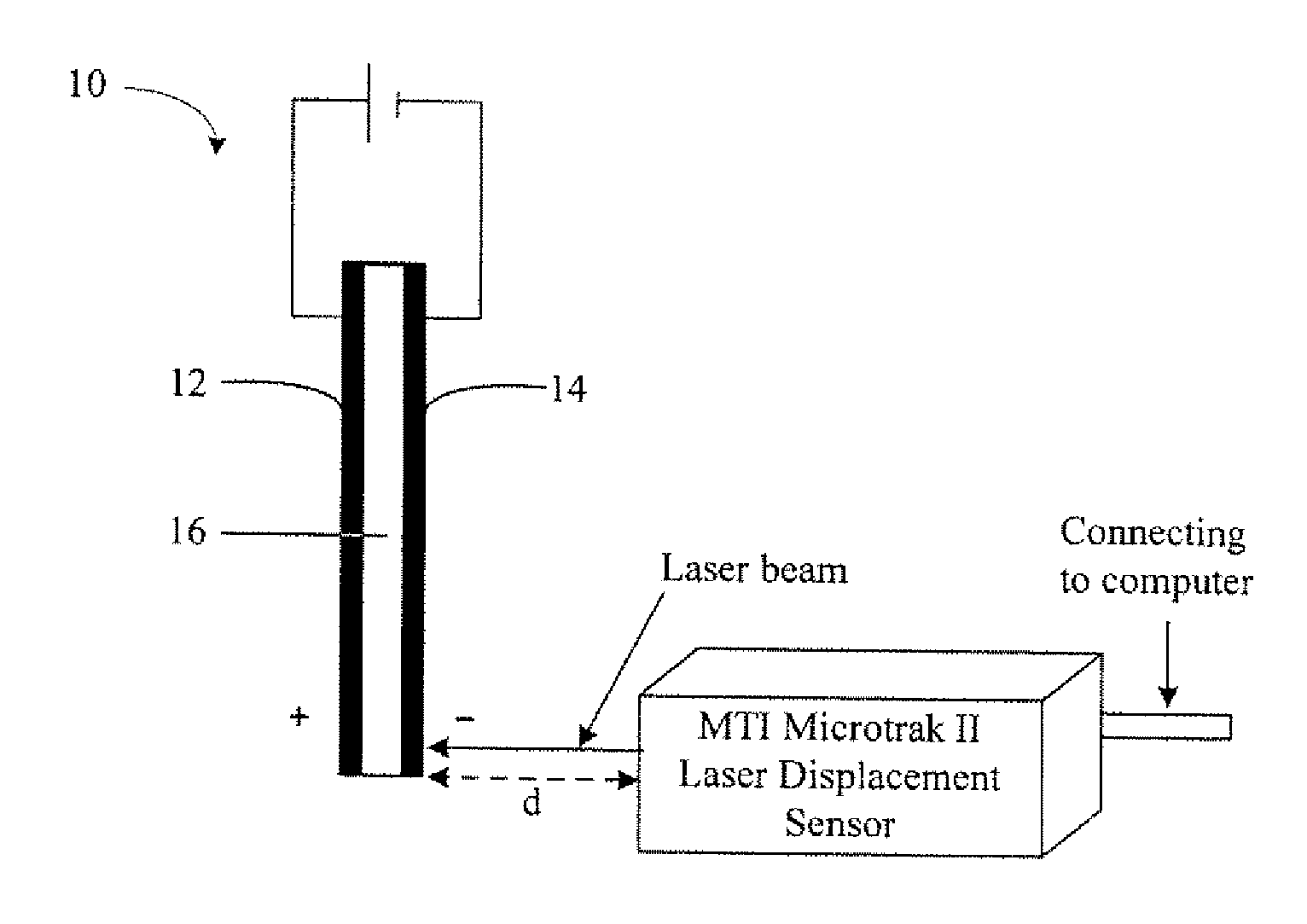

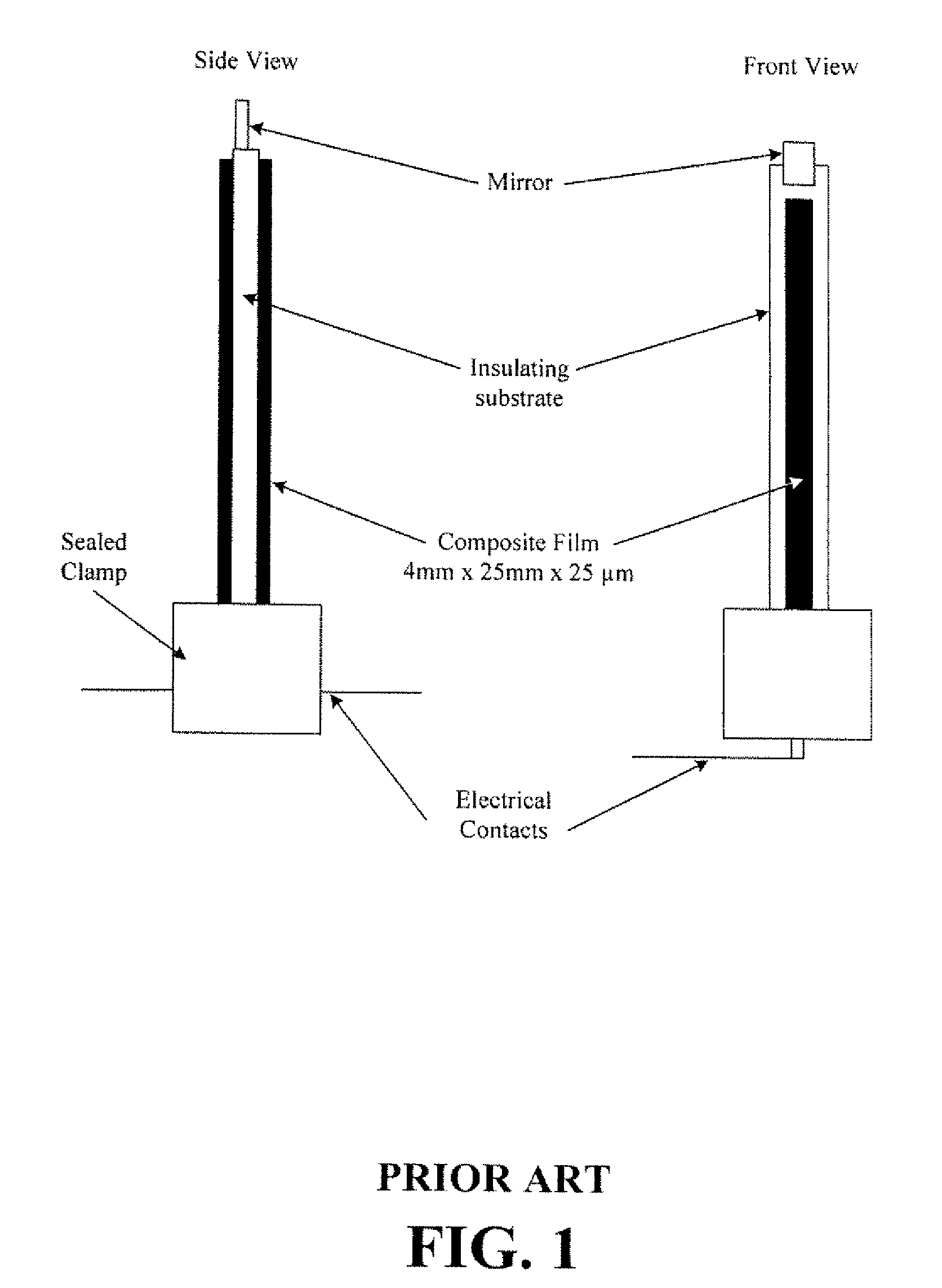

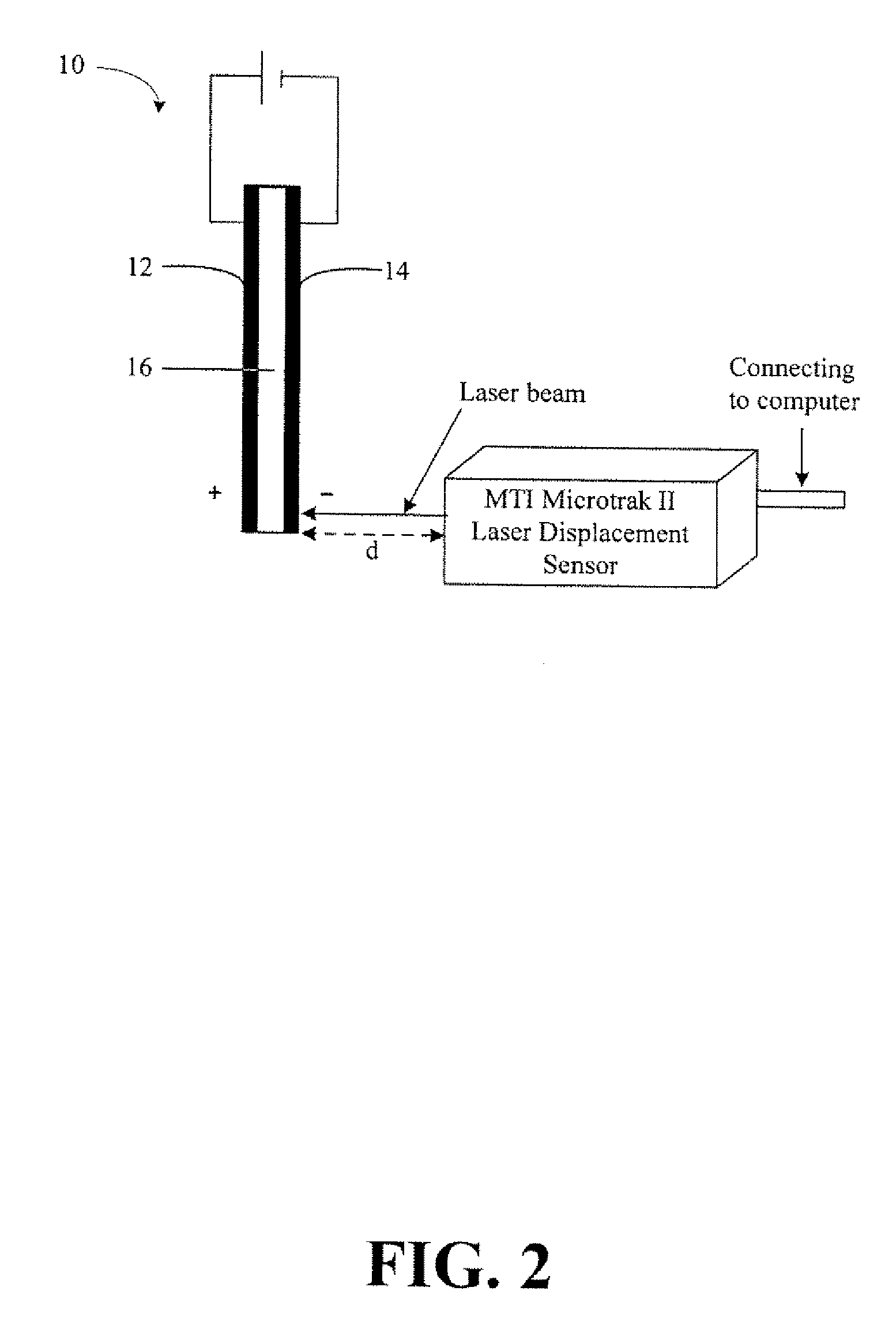

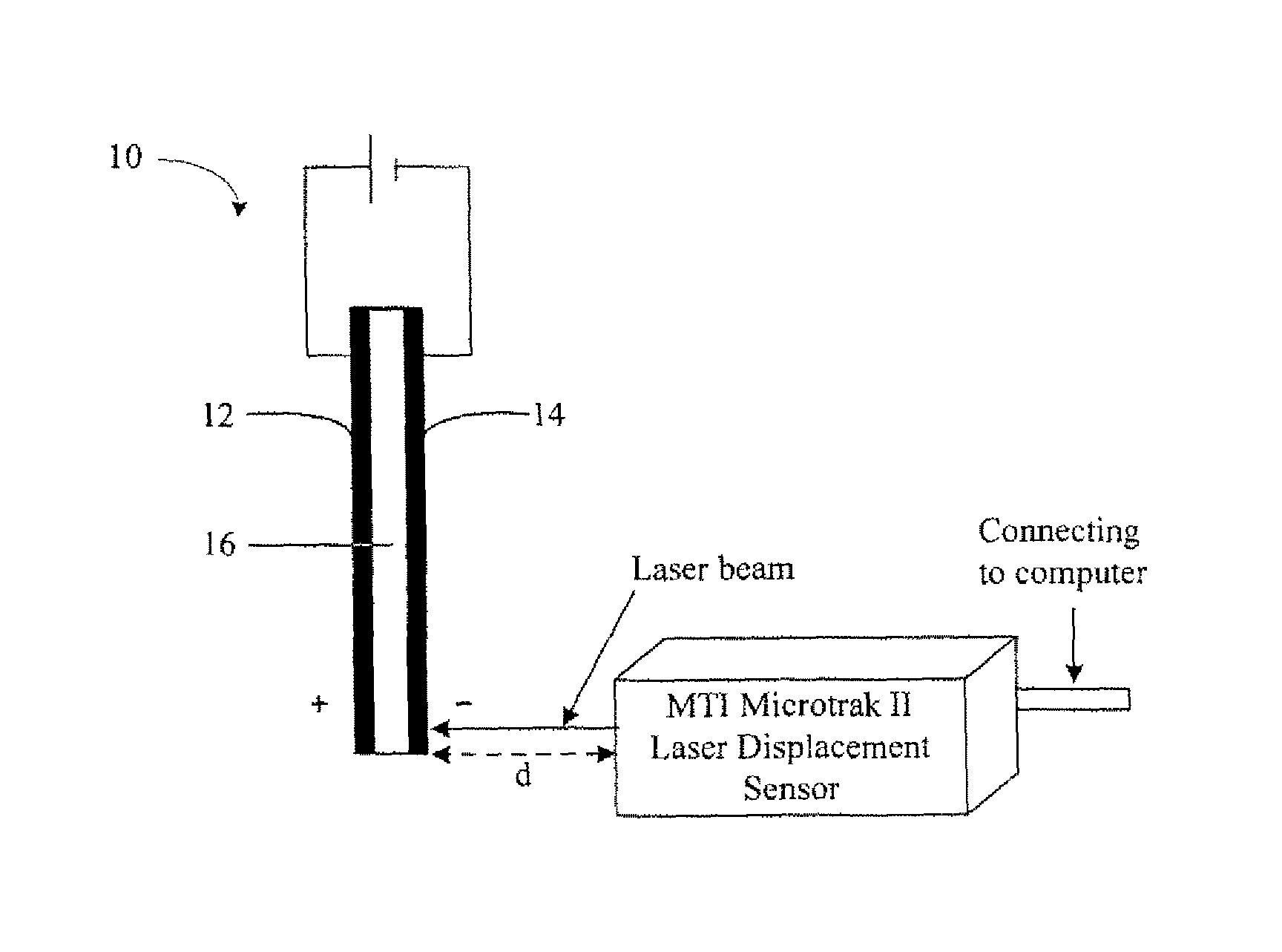

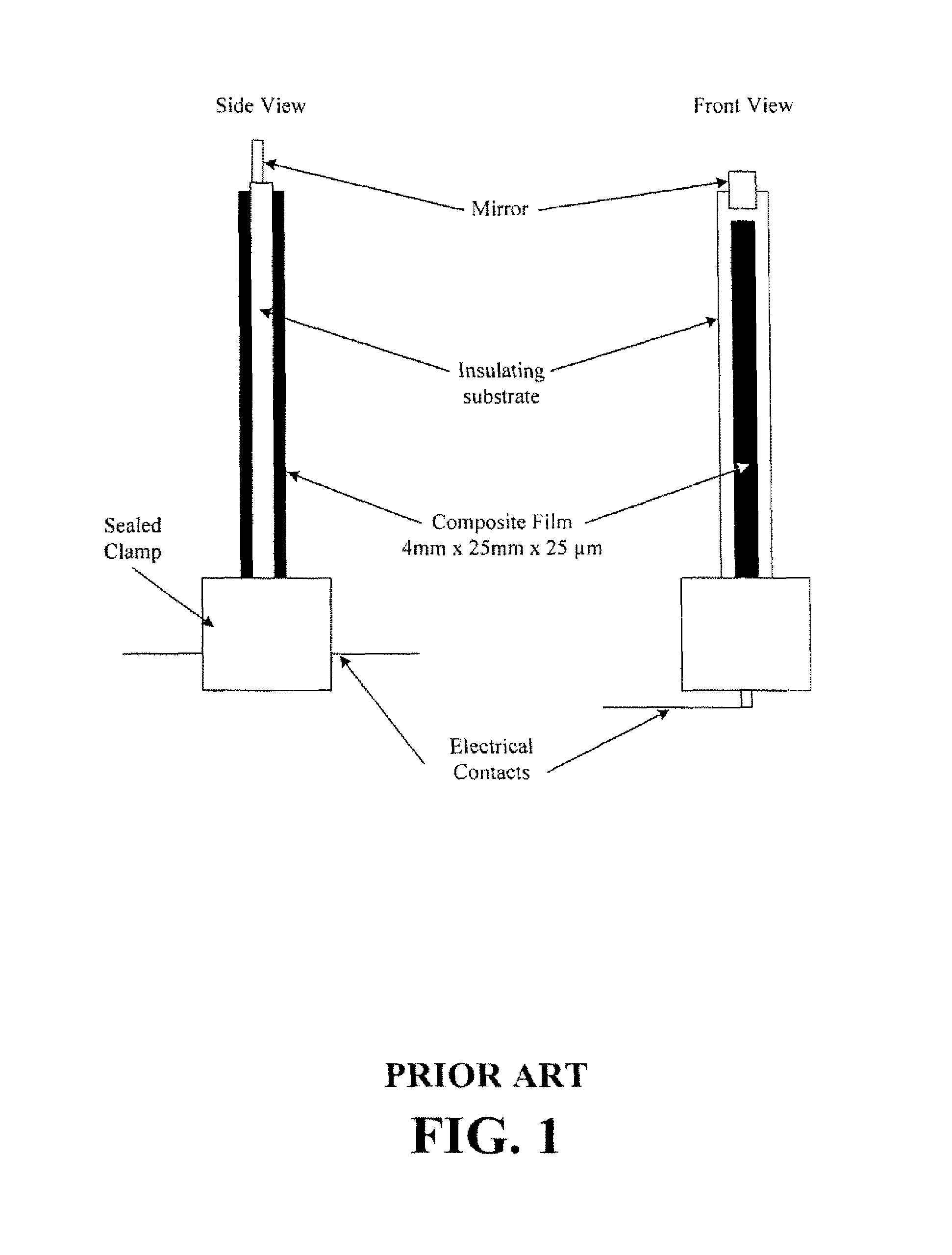

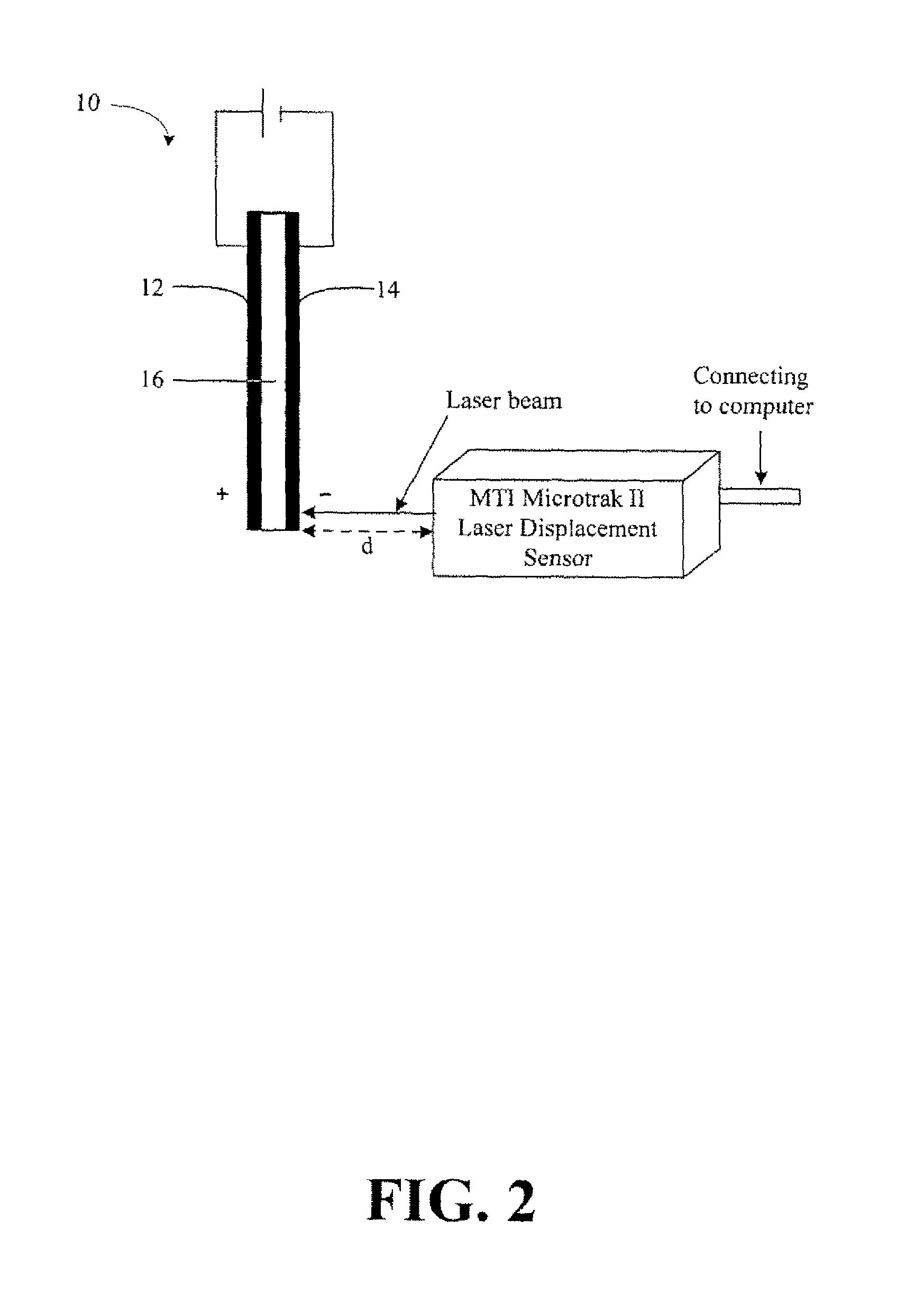

Actuator Device Including Nanoscale Fiber Films

ActiveUS20100080975A1Piezoelectric/electrostrictive device manufacture/assemblyCovering/liningsFiberPolymer electrolytes

A method for making an actuator capable of dry actuation is provided. The method includes providing a first nanoscale fiber film, providing a second nanoscale fiber film, positioning a solid polymer electrolyte at least partially between and adjacent to the first nanoscale fiber film and the second nanoscale fiber film, and then affixing the solid polymer electrolyte to the first nanoscale fiber film and the second nanoscale fiber film. The nanoscale fiber films may be buckypapers, made of carbon nanotubes. The actuator is capable of dry actuation.

Owner:FLORIDA STATE UNIV RES FOUND INC

Preparation method of carbon nanotube (CNT) enhanced SiC based nano composite material film

ActiveCN104291826AExcellent thermal and electrical conductivityHigh volume contentBuckypaperFiltration

The invention discloses a preparation method of a carbon nanotube (CNT) enhanced SiC based nano composite material film. The preparation method comprises the following steps: dispersing CNTs, B4C micro-powder and elemental silicon powder into water to prepare a suspension liquid, taking TritonTM X-100 as a dispersing agent, then performing pressure filtration on the suspension liquid by using a pressure filtration device, soaking a CNTs Buckypaper preform obtained by virtue of pressure filtration in a thermoplastic phenolic resin solution, and then sequentially performing soft curing, hard curing and post-curing to obtain a curing sample; and then carbonizing the curing sample under the protection of nitrogen, and finally sintering to obtain the CNT enhanced SiC based nano composite material film. The nano composite material film prepared by using the method disclosed by the invention is high in CNT volume content and good in dispersion performance, has good preferred orientation in arrangement of the CNTs, has good combination between the CNTs and a matrix, and is smooth and warping-free in film surface, uniform and compact in microscopic structure, good in thermal and electrical conduction properties, good in strength and toughness, short in period and low in cost.

Owner:XIAN XINGUI CERAMIC COMPOSITE MATERIAL CO LTD

Carbon nanotube and nanofiber film-based membrane electrode assemblies

InactiveUS20120301812A1Little and no binderImprove electricityMaterial nanotechnologyCell electrodesBuckypaperPlatinum

A membrane electrode assembly (MEA) for a fuel cell comprising a catalyst layer and a method of making the same. The catalyst layer can include a plurality of catalyst nanoparticles, e.g., platinum, disposed on buckypaper. The method can include the steps of placing buckypaper in a vessel with a catalyst-precursor salt and a fluid. The temperature and pressure conditions within the vessel are modified so as to place the fluid in the supercritical state. The supercritical state of the supercritical fluid containing the precursor salt is maintained for period of time to impregnate the buckypaper with the catalyst-precursor salt. Catalyst nanoparticles are deposited on the buckypaper. The supercritical fluid and the precursor are removed to form a metal catalyst impregnated buckypaper.

Owner:FLORIDA STATE UNIV RES FOUND INC

Carbon nanotube and nanofiber film-based membrane electrode assemblies

ActiveUS8415012B2Improving electrical and mechanical propertyHigh rateMaterial nanotechnologyLayered productsFiberCarbon nanofiber

A membrane electrode assembly (MEA) for a fuel cell comprising a catalyst layer and a method of making the same. The catalyst layer can include a plurality of catalyst nanoparticles, e.g., platinum, disposed on buckypaper. The catalyst layer can have 1% or less binder prior to attachment to the membrane electrode assembly. The catalyst layer can include (a) single-wall nanotubes, small diameter multi-wall nanotubes, or both, and (b) large diameter multi-wall nanotubes, carbon nanofibers, or both. The ratio of (a) to (b) can range from 1:2 to 1:20. The catalyst layer can produce a surface area utilization efficiency of at least 60% and the platinum utilization efficiency can be 0.50 gPt / kW or less.

Owner:FLORIDA STATE UNIV RES FOUND INC

BIFUNCTIONAL HOLLANDITE Ag2Mn8O16 CATALYST FOR LITHIUM-AIR BATTIERIES

A lithium air battery cell includes an anode having lithium, a cathode having a Ag2Mn8O16 catalyst, and an electrolyte comprising a lithium salt. A cathode for a lithium air battery cell and a lithium air battery with a cathode including buckypaper and a Ag2Mn8O16 catalyst are also disclosed.

Owner:FLORIDA STATE UNIV RES FOUND INC

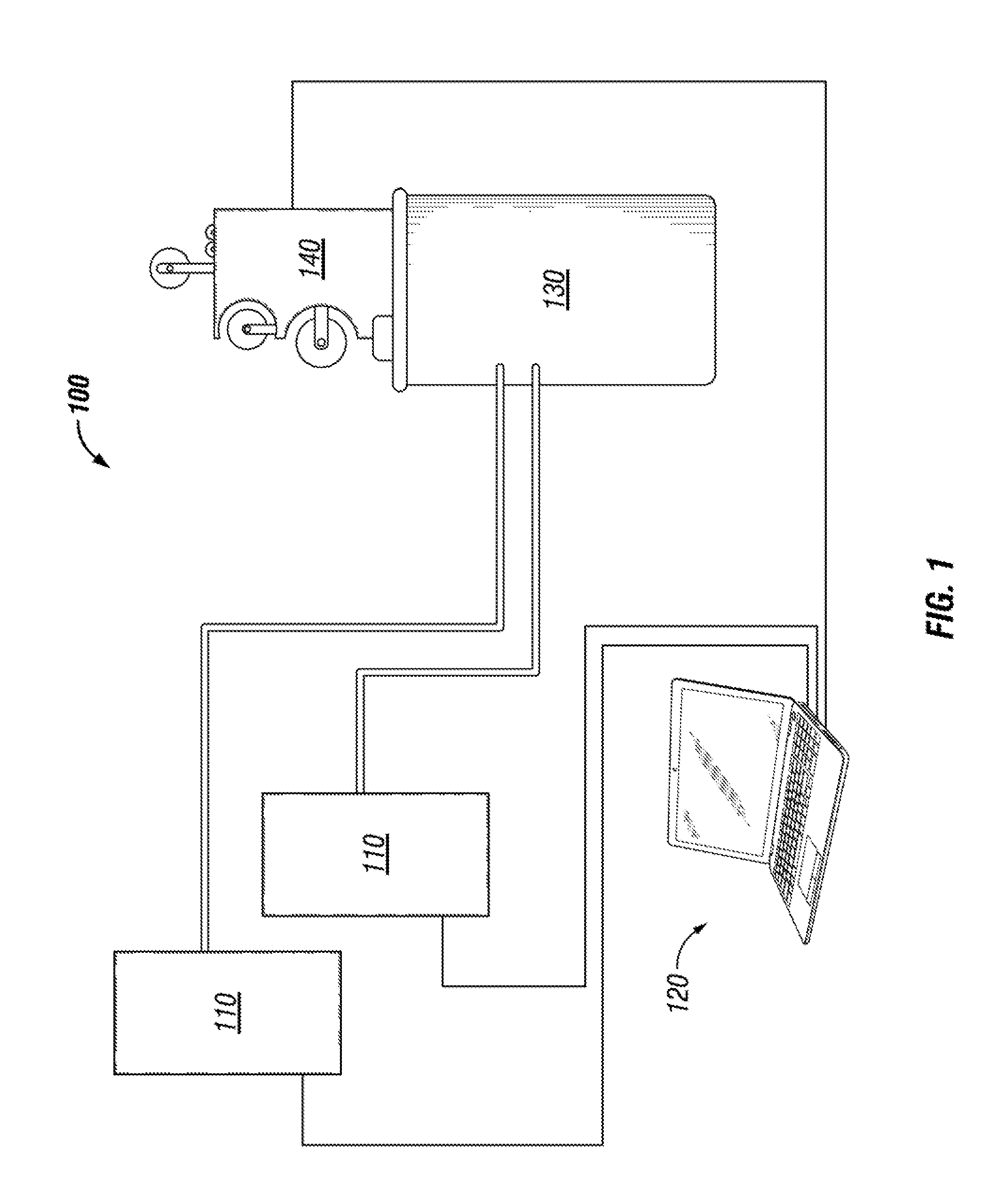

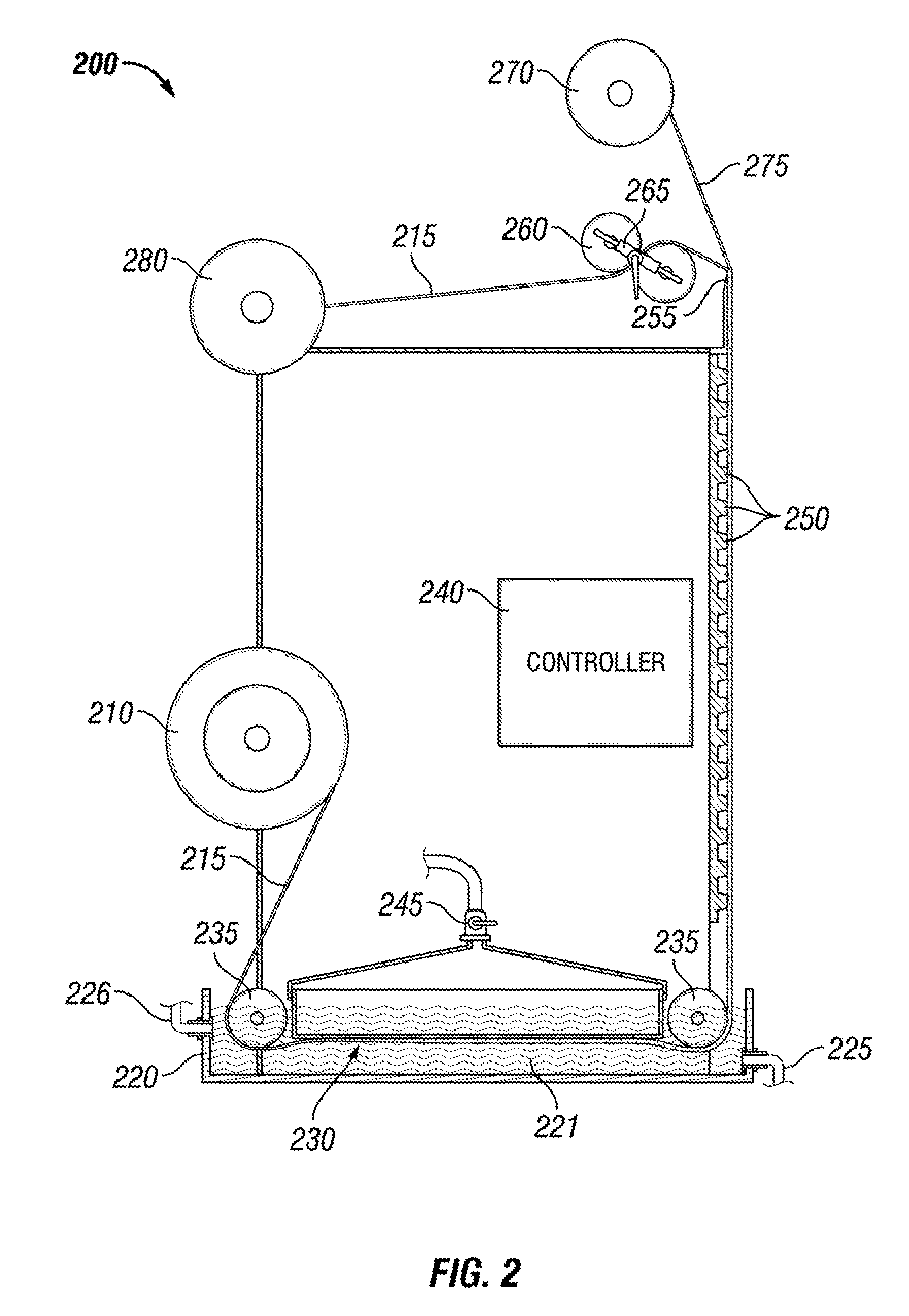

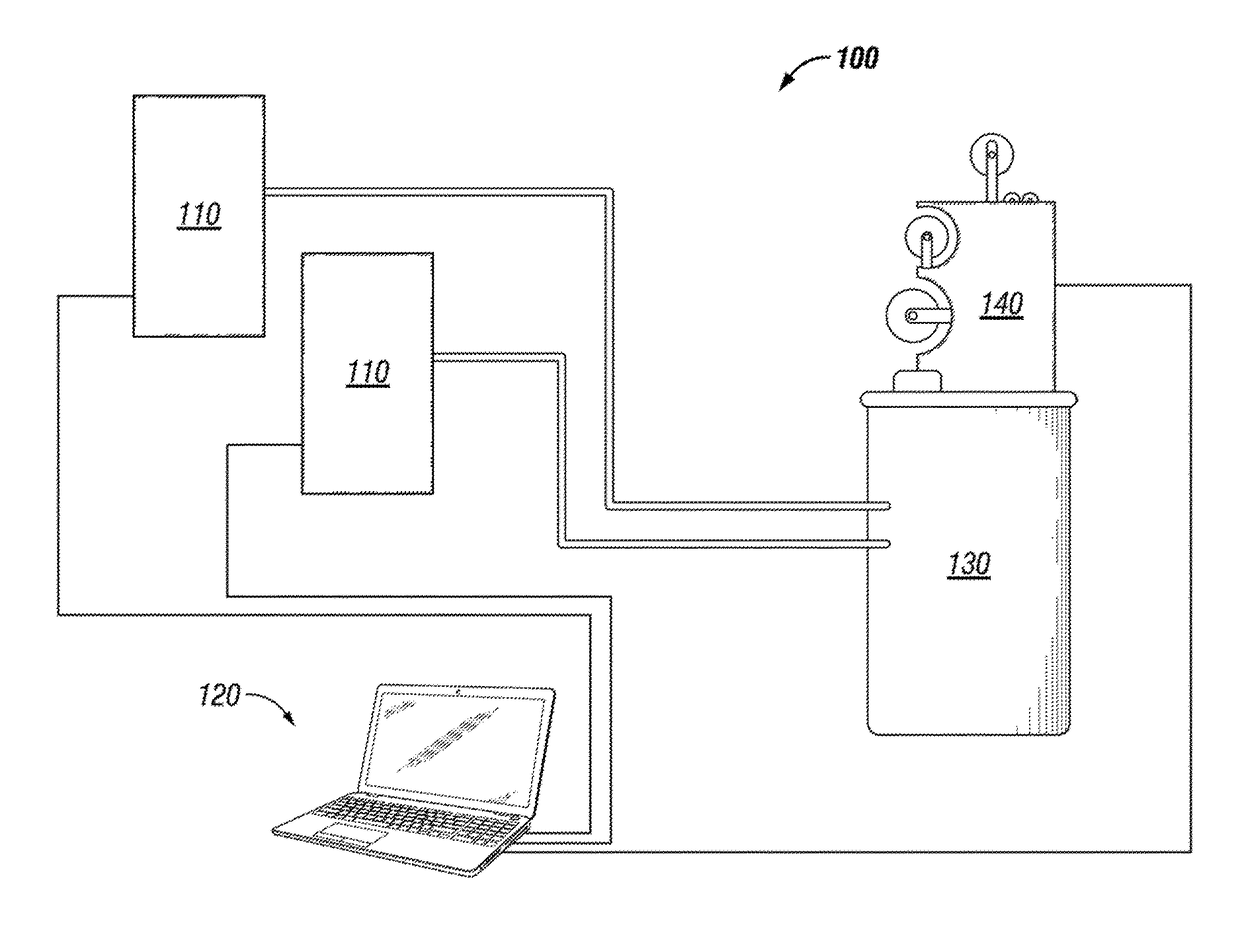

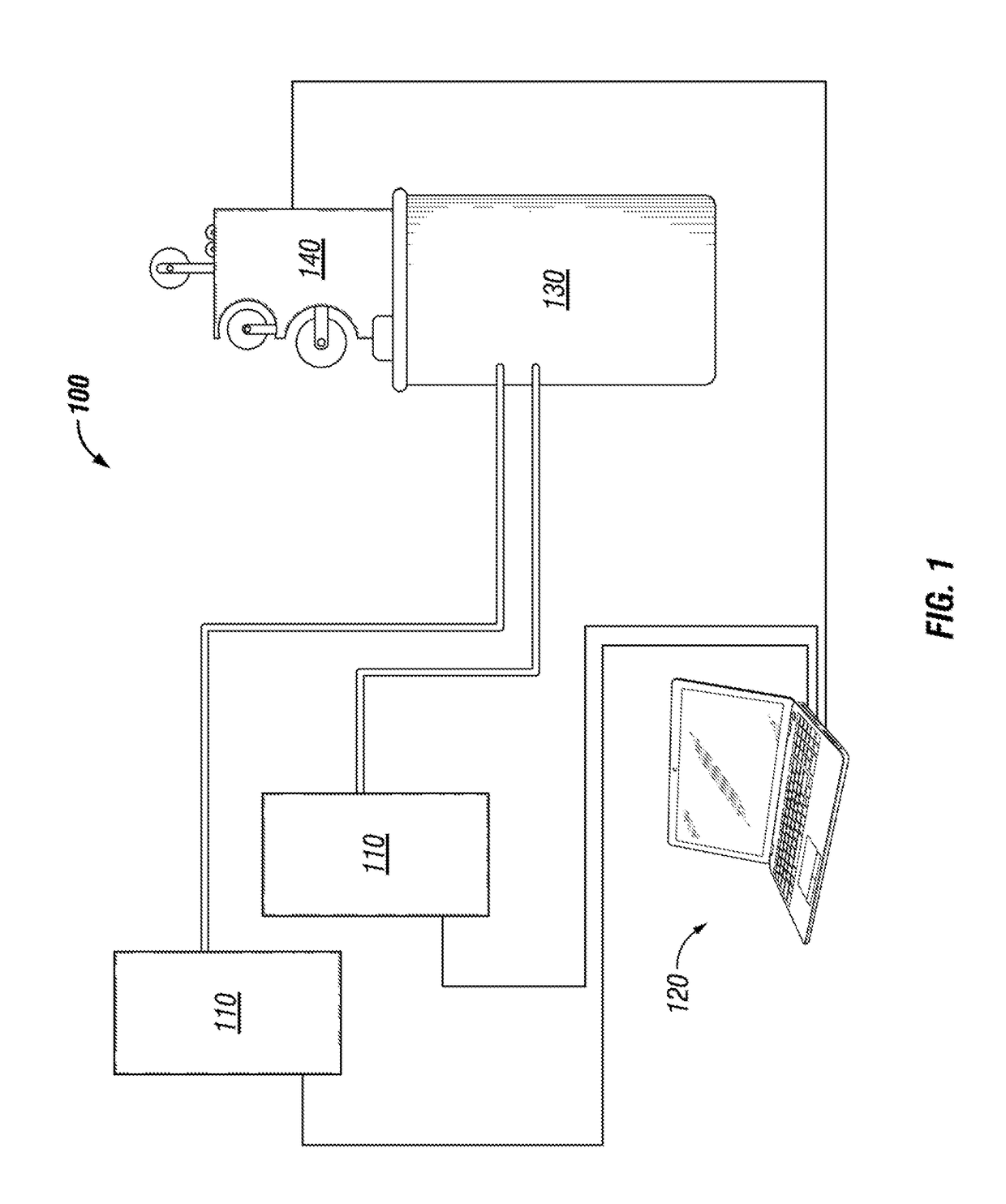

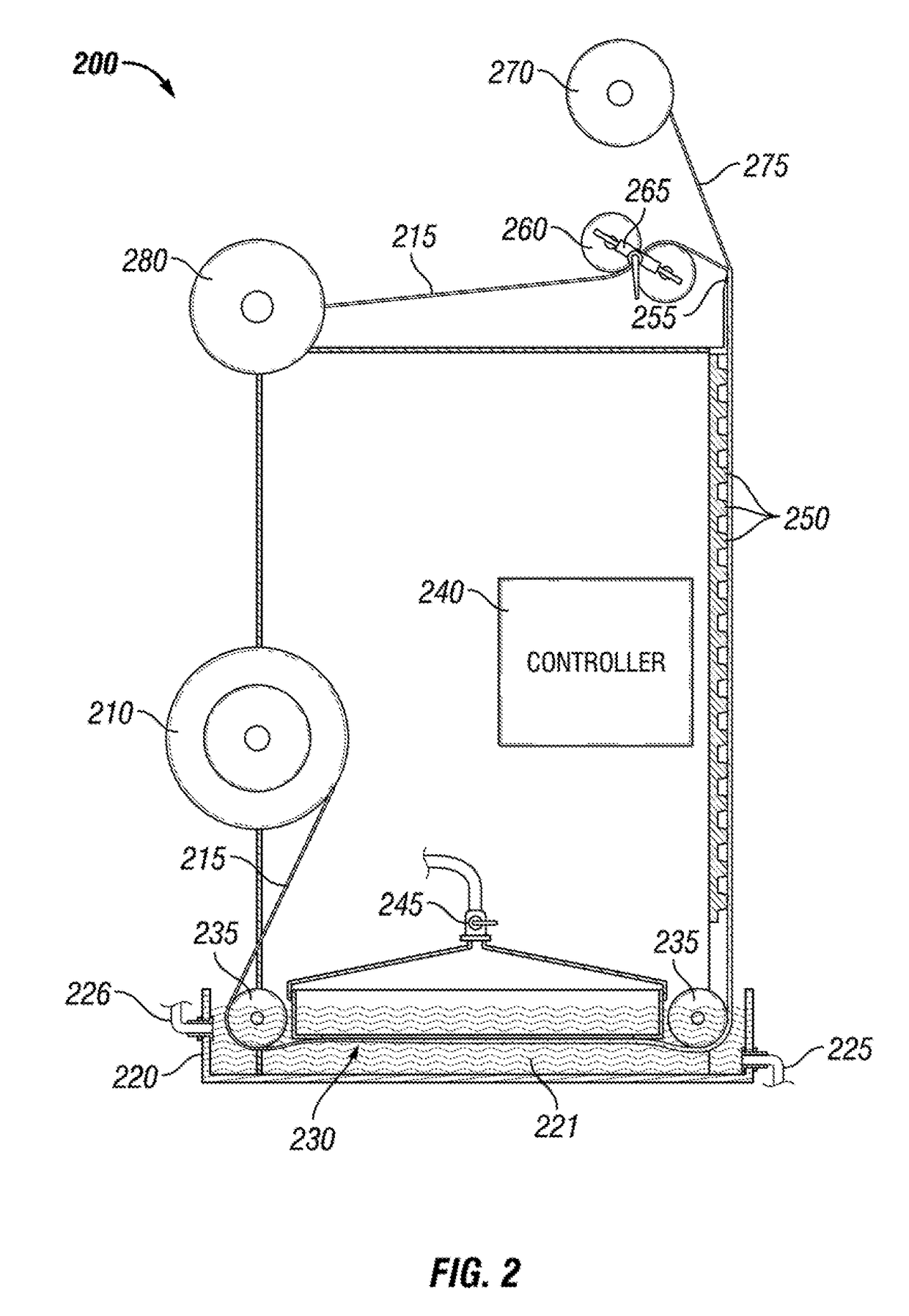

Systems and Methods for Continuous Manufacture of Buckypaper Materials

ActiveUS20160177511A1Automatic productionMaterial nanotechnologyNon-fibrous pulp additionBuckypaperProcess engineering

Systems and methods are provided for producing continuous buckypapers. The systems may permit the in-line characterization and crosslinking of the continuous buckypapers. The systems include roll-to-roll systems in which a continuous buckypaper is created and then separated from the filter paper in an automated process.

Owner:FLORIDA STATE UNIV RES FOUND INC

Catalytic electrode with gradient porosity and catalyst density for fuel cells

ActiveUS8703355B2High rateMaximizing coefficientMaterial nanotechnologyNanostructure manufacturePorosityFiber

A membrane electrode assembly (MEA) for a fuel cell comprising a gradient catalyst structure and a method of making the same. The gradient catalyst structure can include a plurality of catalyst nanoparticles, e.g., platinum, disposed on layered buckypaper. The layered buckypaper can include at least a first layer and a second layer and the first layer can have a lower porosity compared to the second layer. The gradient catalyst structure can include single-wall nanotubes, carbon nanofibers, or both in the first layer of the layered buckypaper and can include carbon nanofibers in the second layer of the layered buckypaper. The MEA can have a catalyst utilization efficiency of at least 0.35 gcat / kW or less.

Owner:FLORIDA STATE UNIV RES FOUND INC

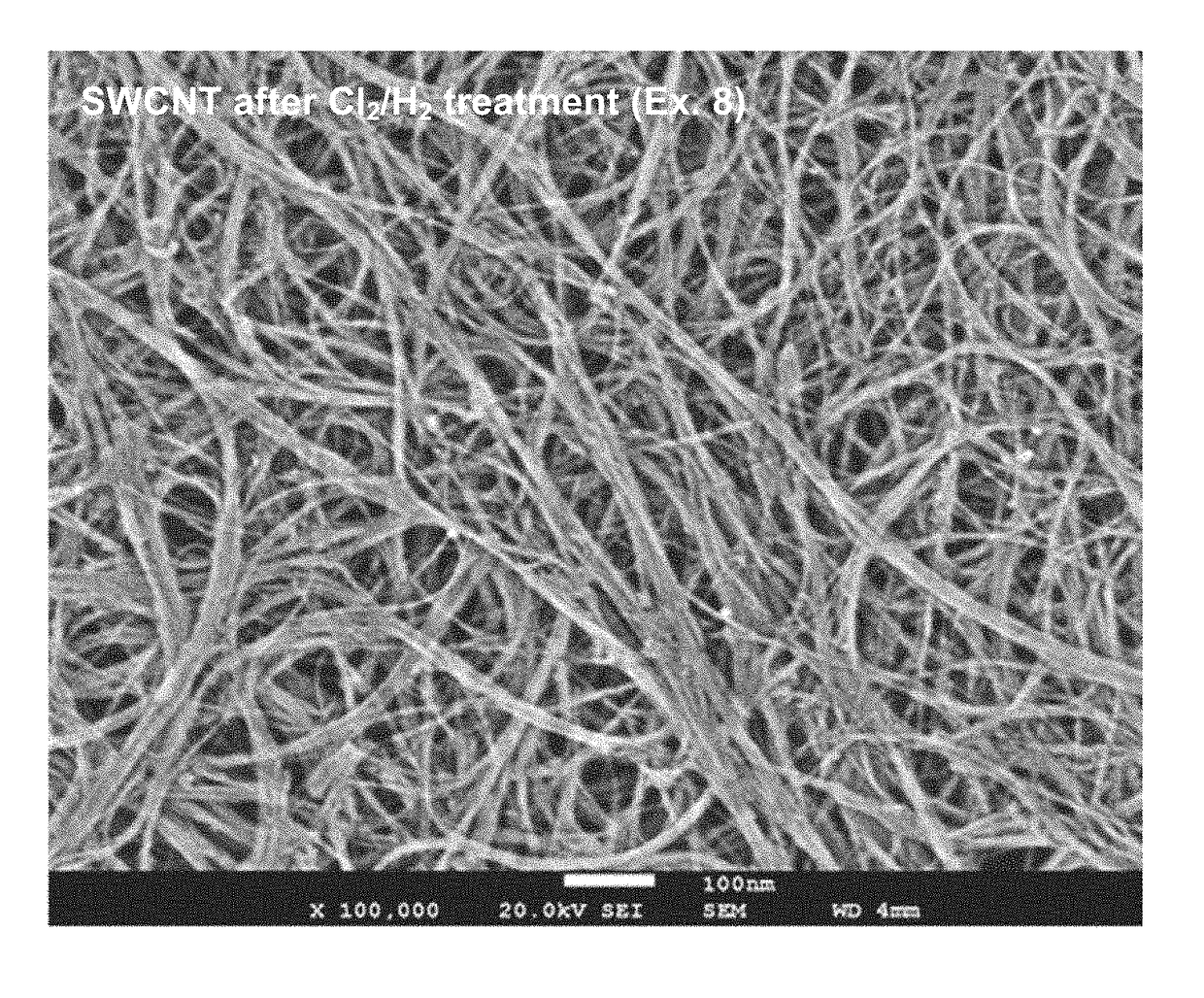

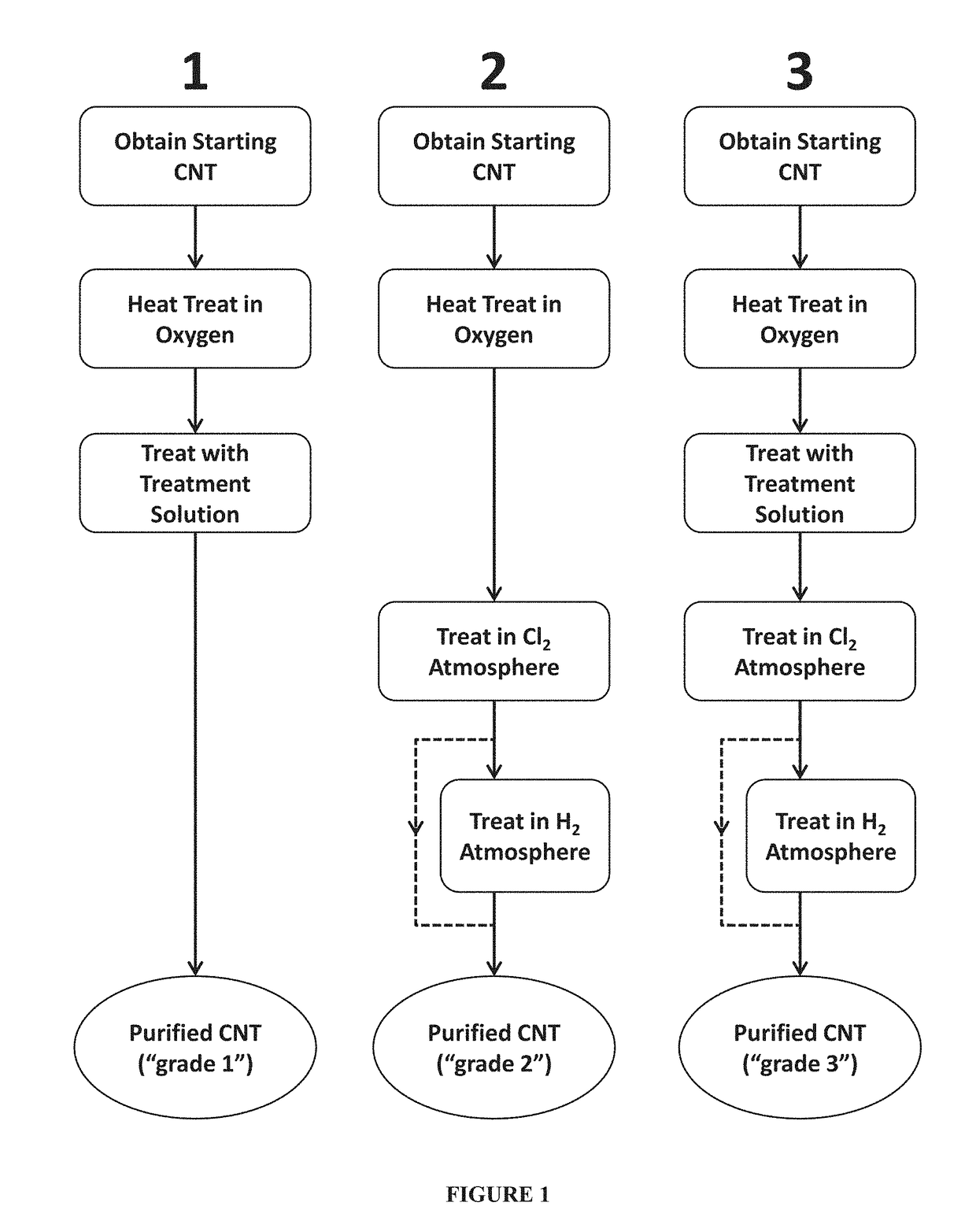

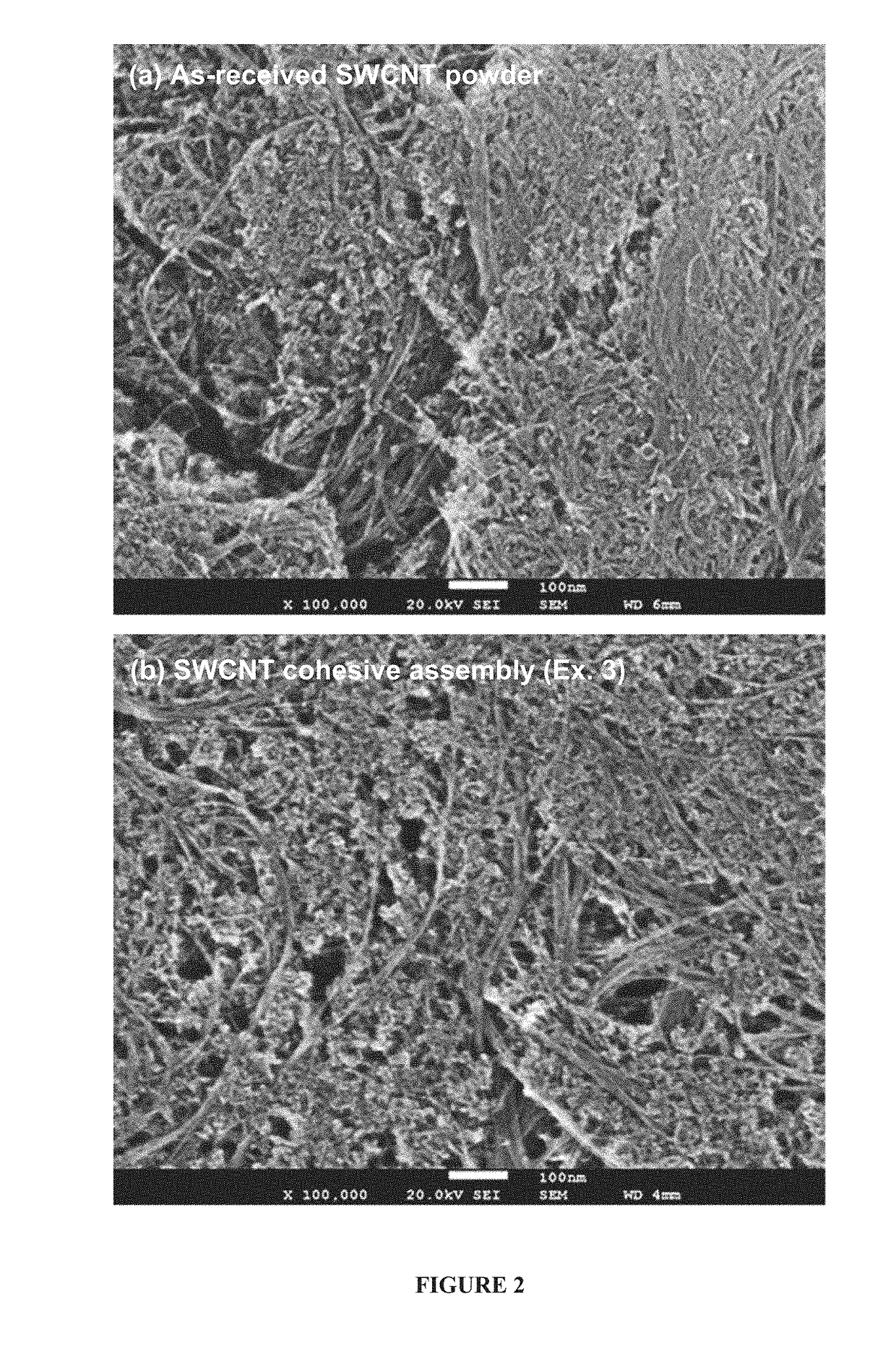

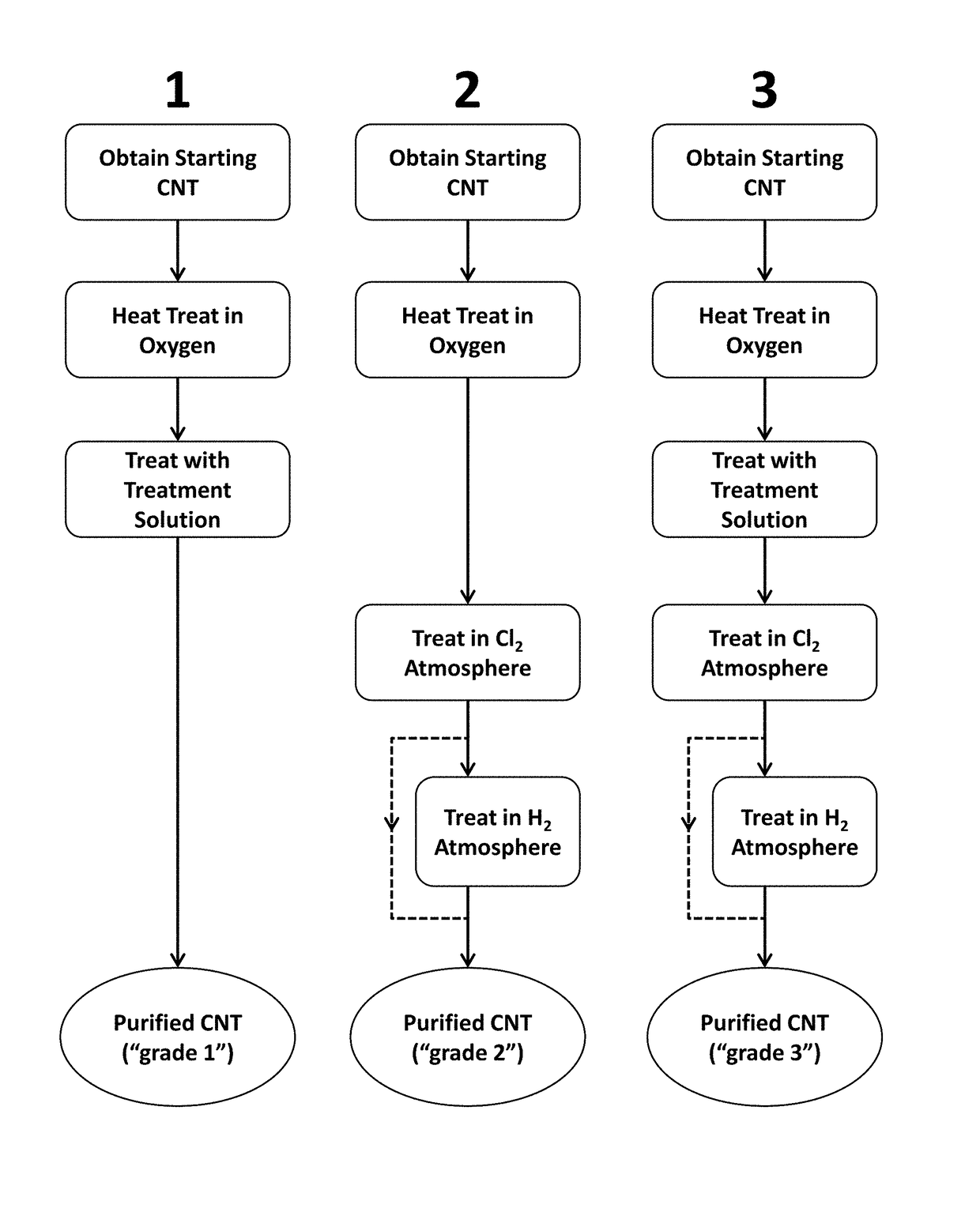

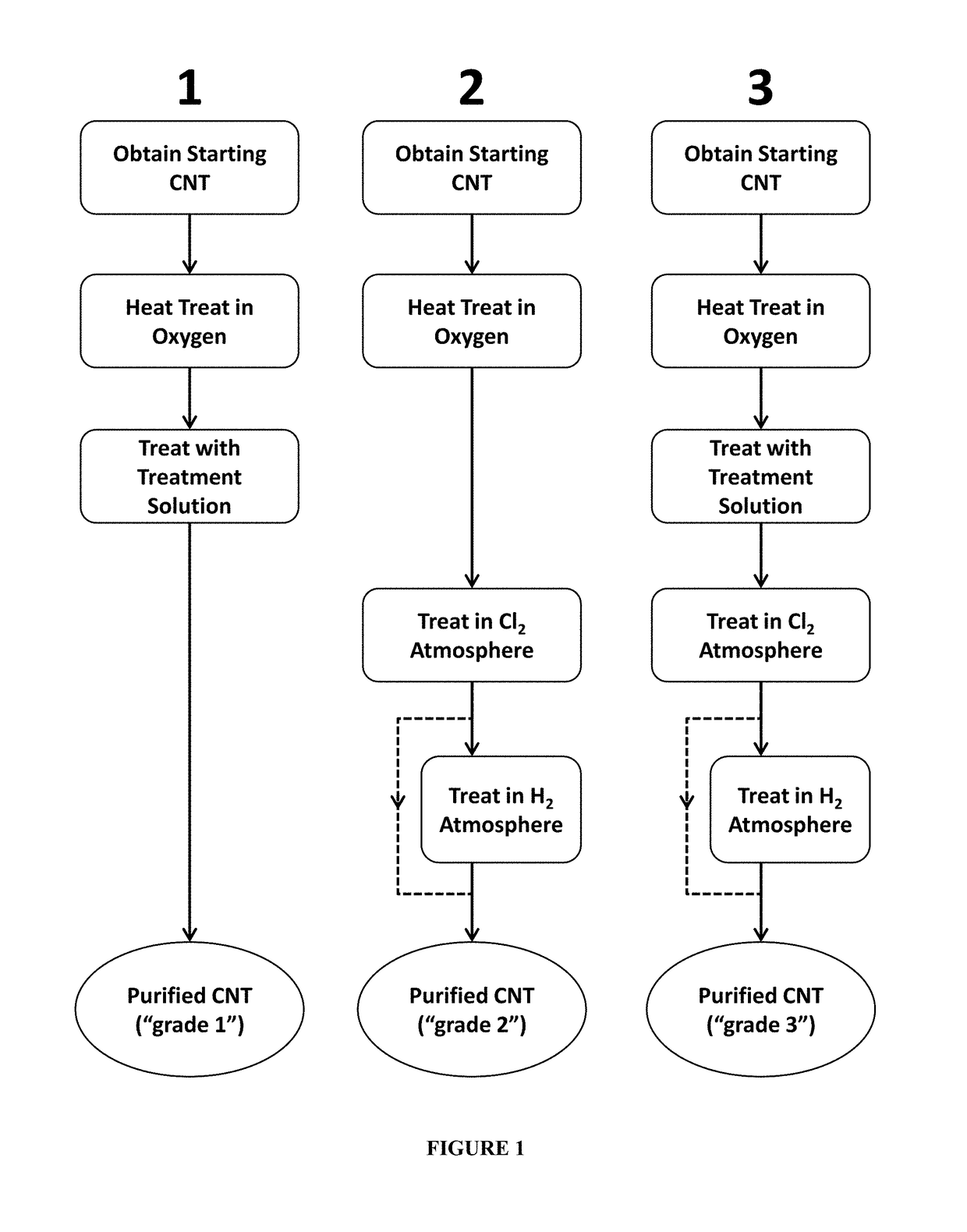

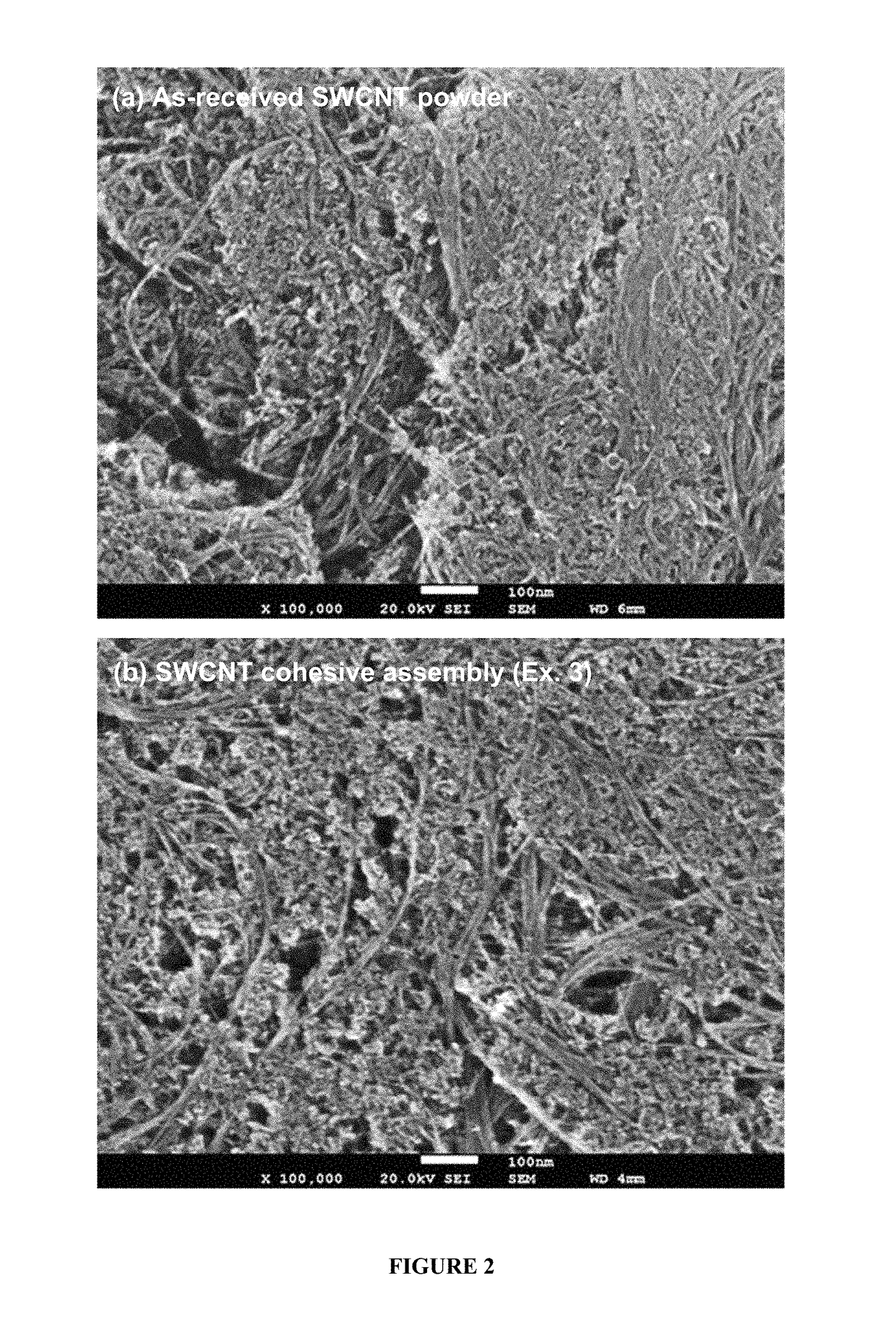

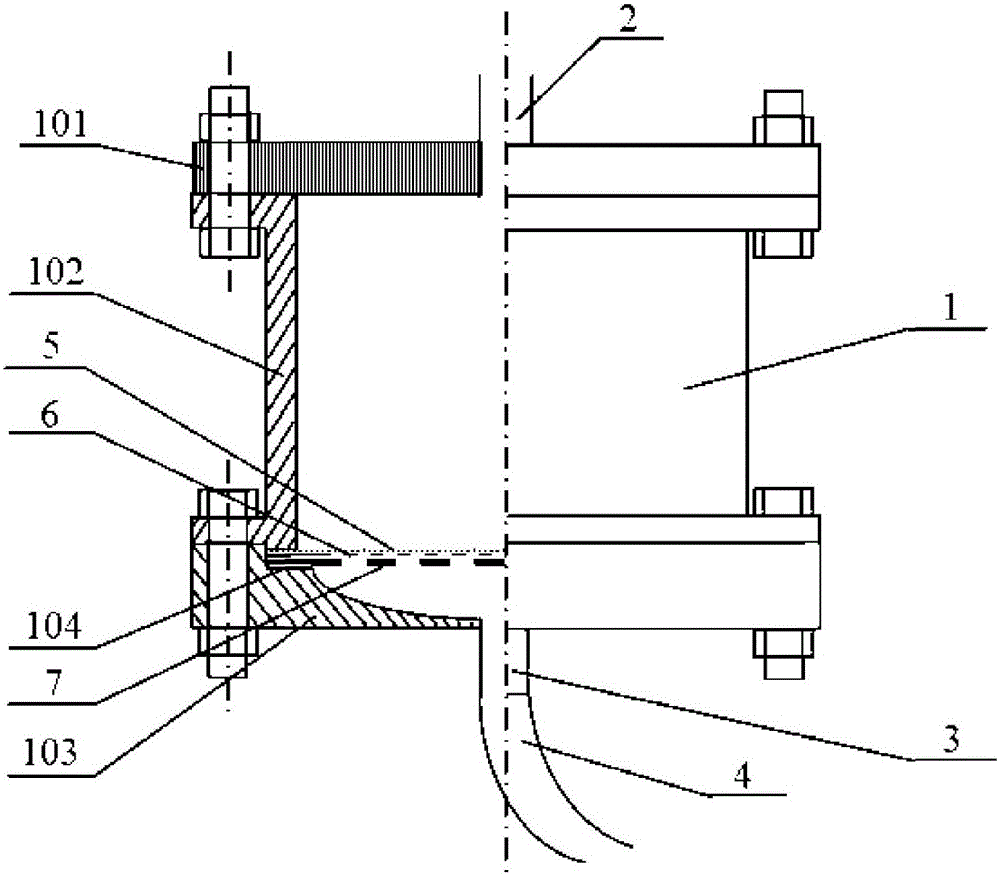

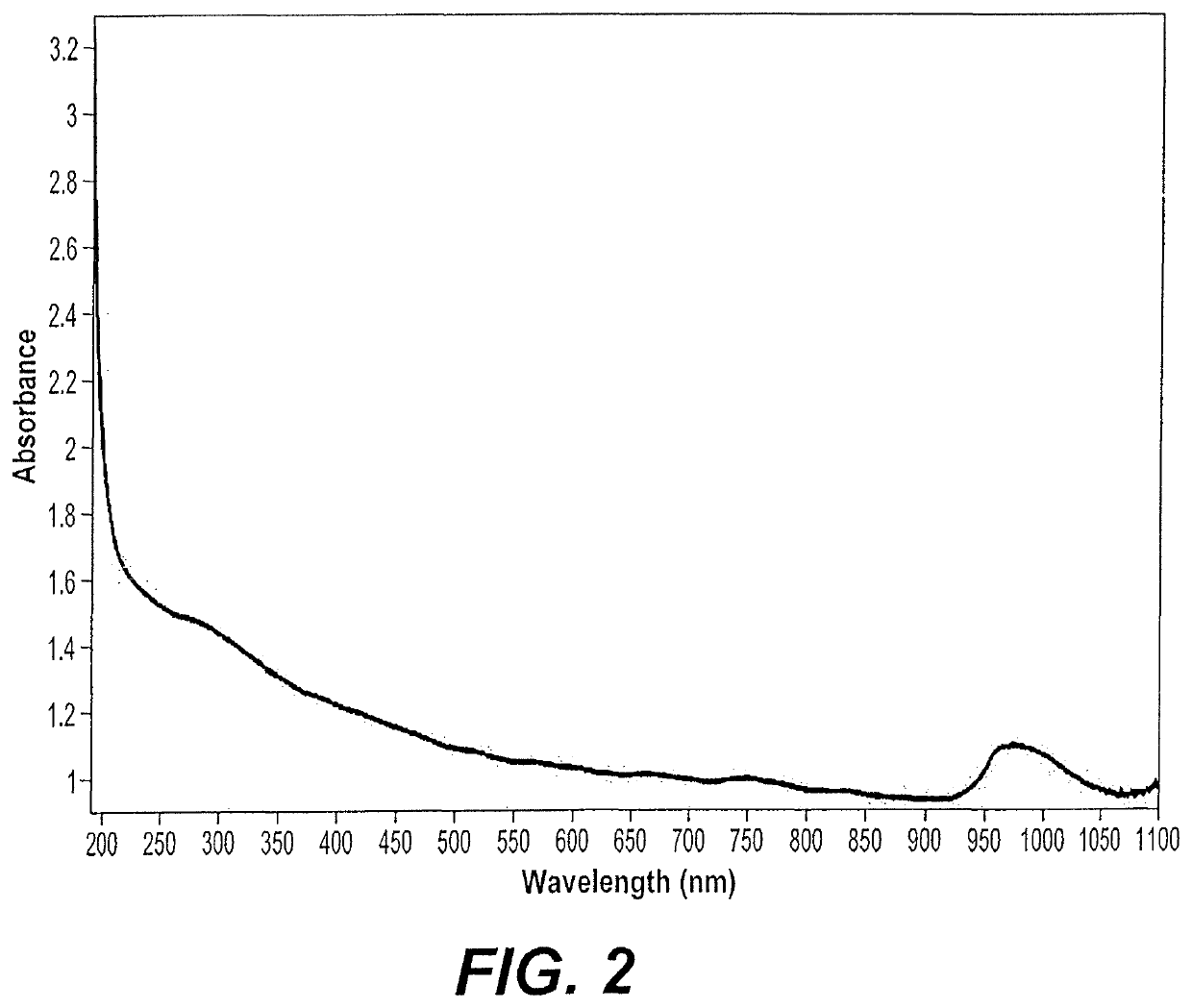

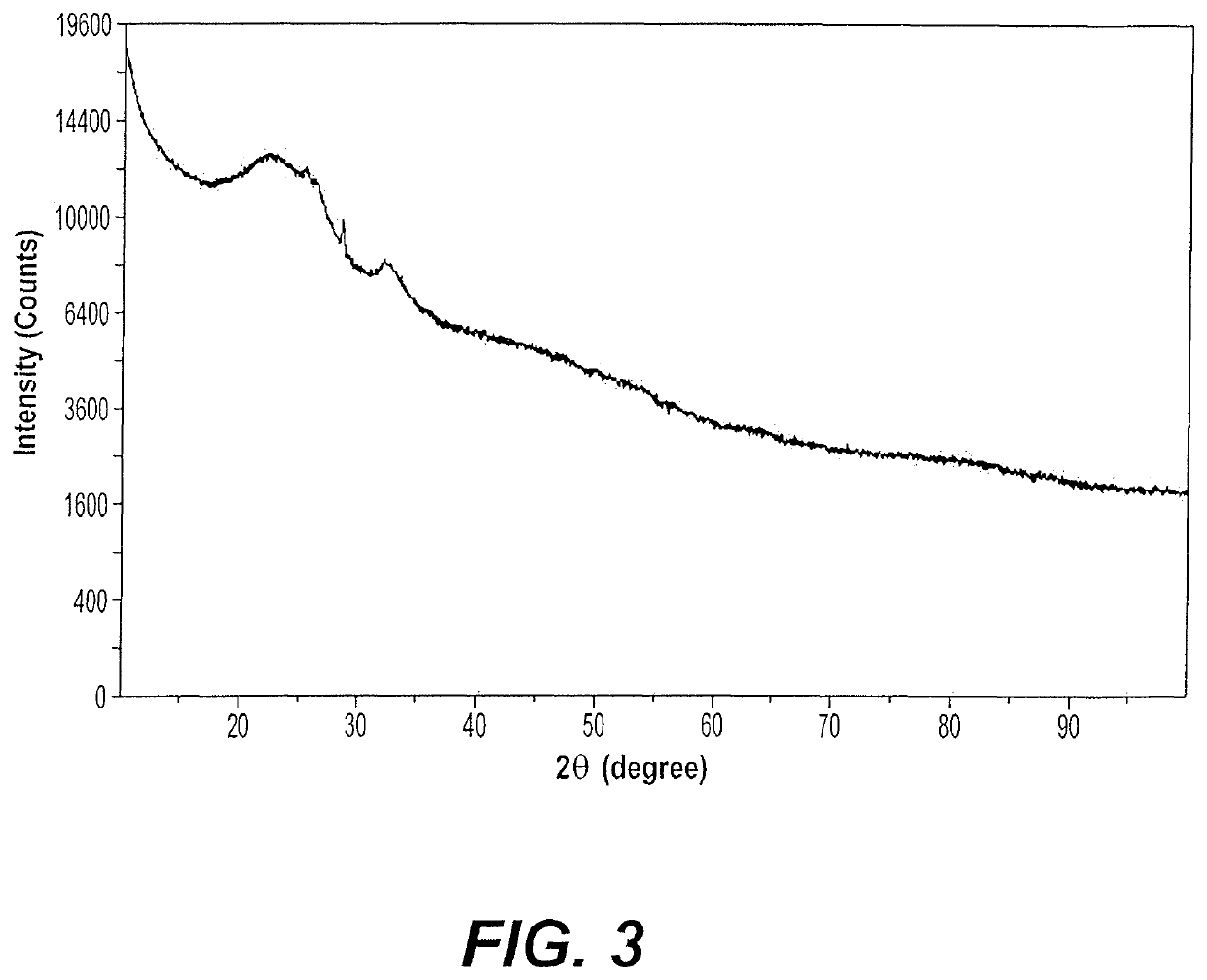

Highly purified carbon nanotubes and method of their preparation

Highly purified carbon nanotubes (CNT) having virtually no carbonaceous impurities (amorphous carbon) nor inorganic impurities (metal and metal oxides), and methods of their preparation are described. The purified CNT feature excellent electrical, mechanical, and thermal properties due to the near total absence of detrimental impurities. The CNT starting material is preferably in the form of wafer, film, or buckypaper for efficient diffusion of purifying media. The highly pure CNT are prepared by heat treating a CNT starting material in a specified amount of oxygen, then treating the CNT in a solution comprising water and acid, or further heat treating the CNT in an atmosphere comprising chlorine (Cl2). Extremely low levels of inorganic impurities may be achieved by treating sequentially with a treatment solution followed by chlorine. Removal of chloride from purified CNT may be achieved by further treating the chlorine-treated material in an atmosphere comprising hydrogen (H2).

Owner:YAZAKI CORP

Actuator device including nanoscale fiber films

ActiveUS8784603B2Piezoelectric/electrostrictive device manufacture/assemblyLaminationBuckypaperFiber

A method for making an actuator capable of dry actuation is provided. The method includes providing a first nanoscale fiber film, providing a second nanoscale fiber film, positioning a solid polymer electrolyte at least partially between and adjacent to the first nanoscale fiber film and the second nanoscale fiber film, and then affixing the solid polymer electrolyte to the first nanoscale fiber film and the second nanoscale fiber film. The nanoscale fiber films may be buckypapers, made of carbon nanotubes. The actuator is capable of dry actuation.

Owner:FLORIDA STATE UNIV RES FOUND INC

Film structure for satellite flexible heat radiator and manufacturing method of film structure

InactiveCN106671549AMeet the needs of large-area expandable heat radiatorsLamination ancillary operationsSynthetic resin layered productsBuckypaperOptoelectronics

The invention discloses a film structure for a satellite flexible heat radiator. A graphene layer is arranged on a buckypaper layer, and the graphene layer is coated with a metal copper or aluminum layer. The invention further discloses another two similar film structures and a manufacturing method thereof. According to the film structure, a graphene film is adhered to one end of buckypaper, the back side of the buckypaper is plated with aluminum, then a flexible film can be formed, the heat radiation rate epsilon of the film structure is 0.85, the heat conductivity of the film structure is 300 Wm<1>K<1>, and the thickness of the film is 10-50 [mu]m.

Owner:BEIJING INST OF SPACECRAFT ENVIRONMENT ENG

Method for making ultralow platinum loading and high durability membrane electrode assembly for polymer electrolyte membrane fuel cells

ActiveUS20200106107A1Less porosityFinal product manufactureCell electrodesPtru catalystCarbon nanofiber

A method of making a catalyst layer of a membrane electrode assembly (MEA) for a polymer electrolyte membrane fuel cell includes the step of preparing a porous buckypaper layer comprising at least one selected from the group consisting of carbon nanofibers and carbon nanotubes. Platinum group metal nanoparticles are deposited in a liquid solution on an outer surface of the buckypaper to create a platinum group metal nanoparticle buckypaper. A proton conducting electrolyte is deposited on the platinum group metal nanoparticles by electrophoretic deposition to create a proton-conducting layer on the an outer surface of the platinum nanoparticles. An additional proton-conducting layer is deposited by contacting the platinum group metal nanoparticle buckypaper with a liquid proton-conducting composition in a solvent. The platinum group metal nanoparticle buckypaper is dried to remove the solvent. A membrane electrode assembly for a polymer electrolyte membrane fuel cell is also disclosed.

Owner:FLORIDA STATE UNIV RES FOUND INC

Highly purified carbon nanotubes and method of their preparation

Highly purified carbon nanotubes (CNT) having virtually no carbonaceous impurities (amorphous carbon) nor inorganic impurities (metal and metal oxides), and methods of their preparation are described. The purified CNT feature excellent electrical, mechanical, and thermal properties due to the near total absence of detrimental impurities. The CNT starting material is preferably in the form of wafer, film, or buckypaper for efficient diffusion of purifying media. The highly pure CNT are prepared by heat treating a CNT starting material in a specified amount of oxygen, then treating the CNT in a solution comprising water and acid, or further heat treating the CNT in an atmosphere comprising chlorine (Cl2). Extremely low levels of inorganic impurities may be achieved by treating sequentially with a treatment solution followed by chlorine. Removal of chloride from purified CNT may be achieved by further treating the chlorine-treated material in an atmosphere comprising hydrogen (H2).

Owner:YAZAKI CORP

Systems and methods for continuous manufacture of buckypaper materials

Systems and methods are provided for producing continuous buckypapers. The systems may permit the in-line characterization and crosslinking of the continuous buckypapers. The systems include roll-to-roll systems in which a continuous buckypaper is created and then separated from the filter paper in an automated process.

Owner:FLORIDA STATE UNIV RES FOUND INC

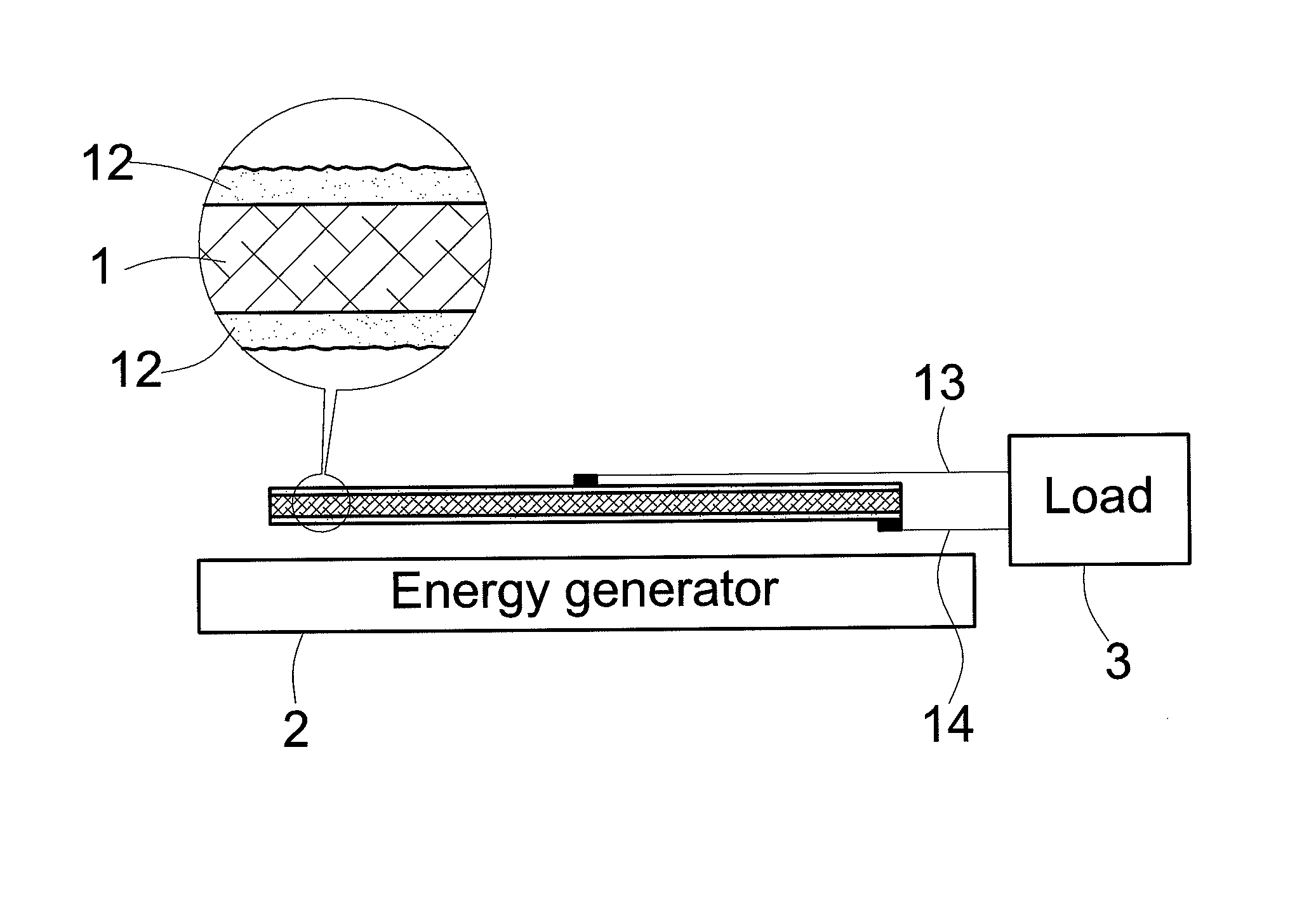

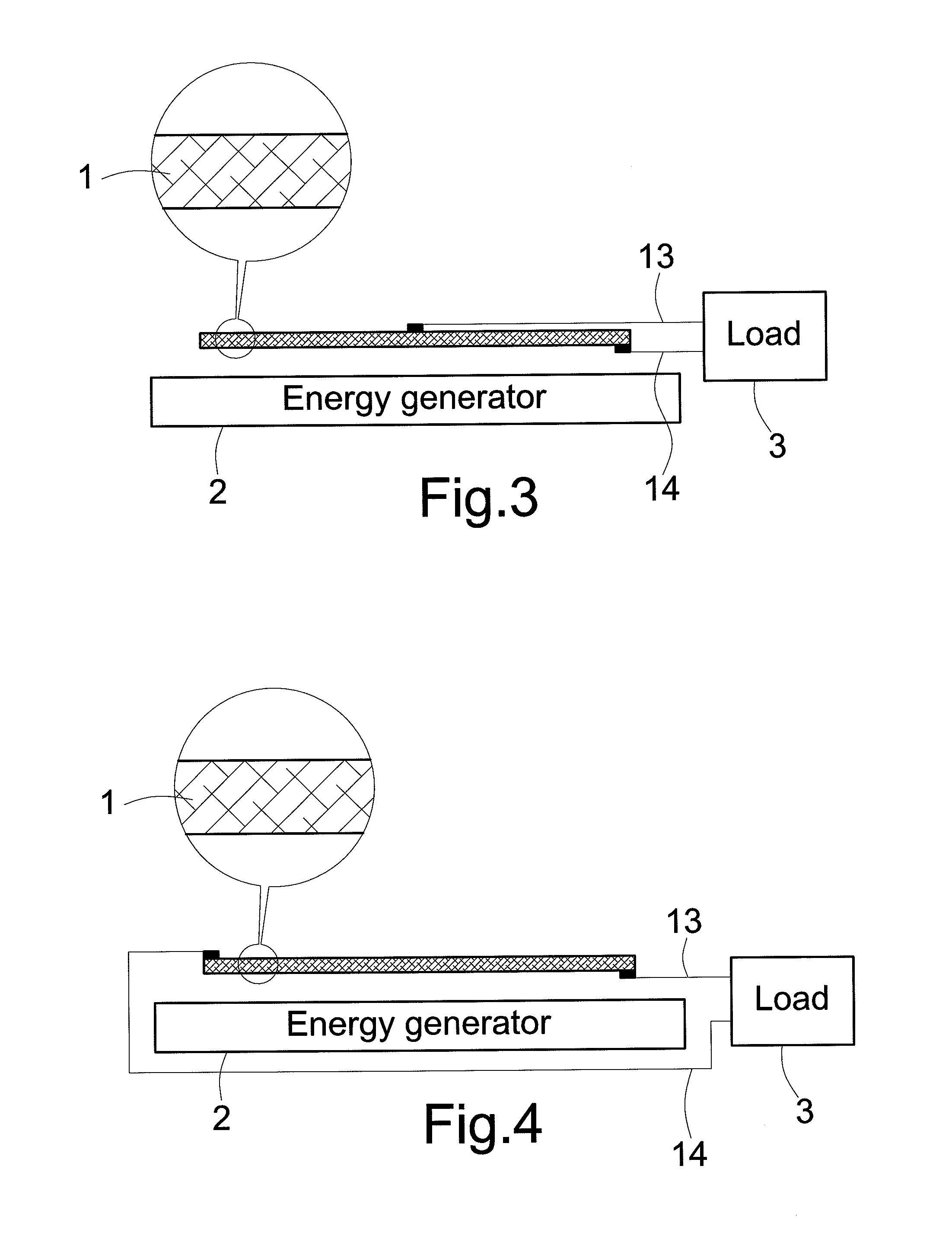

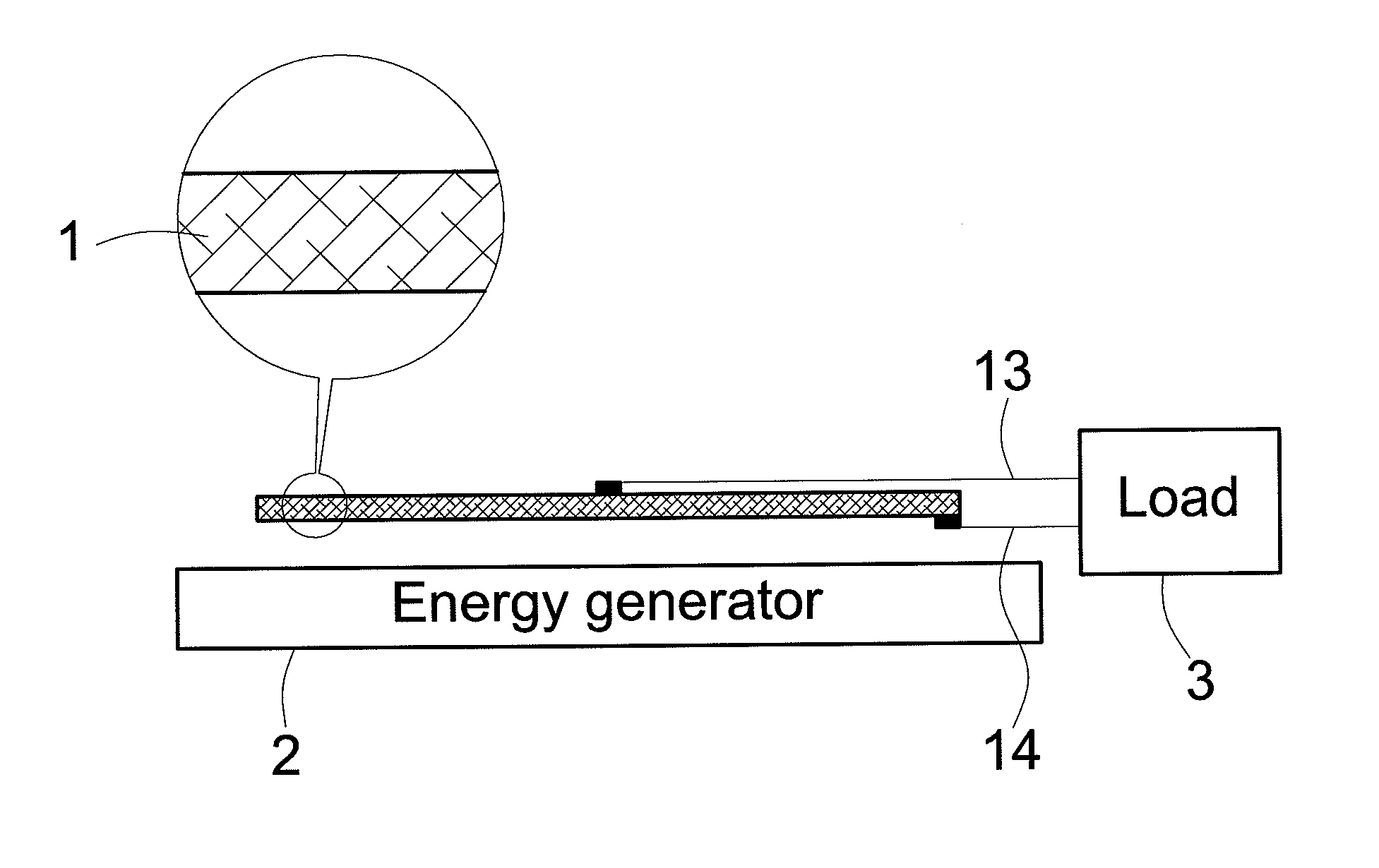

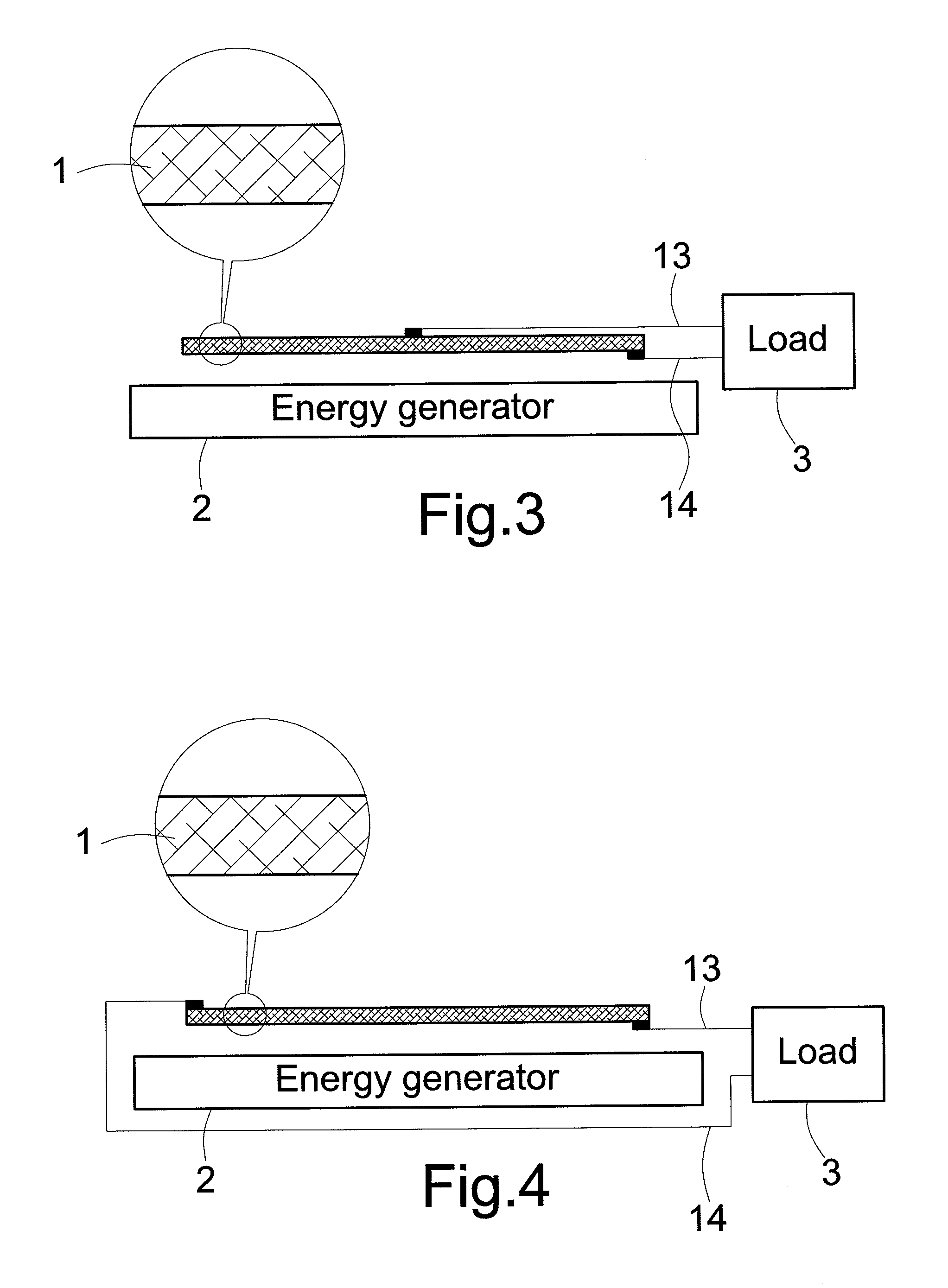

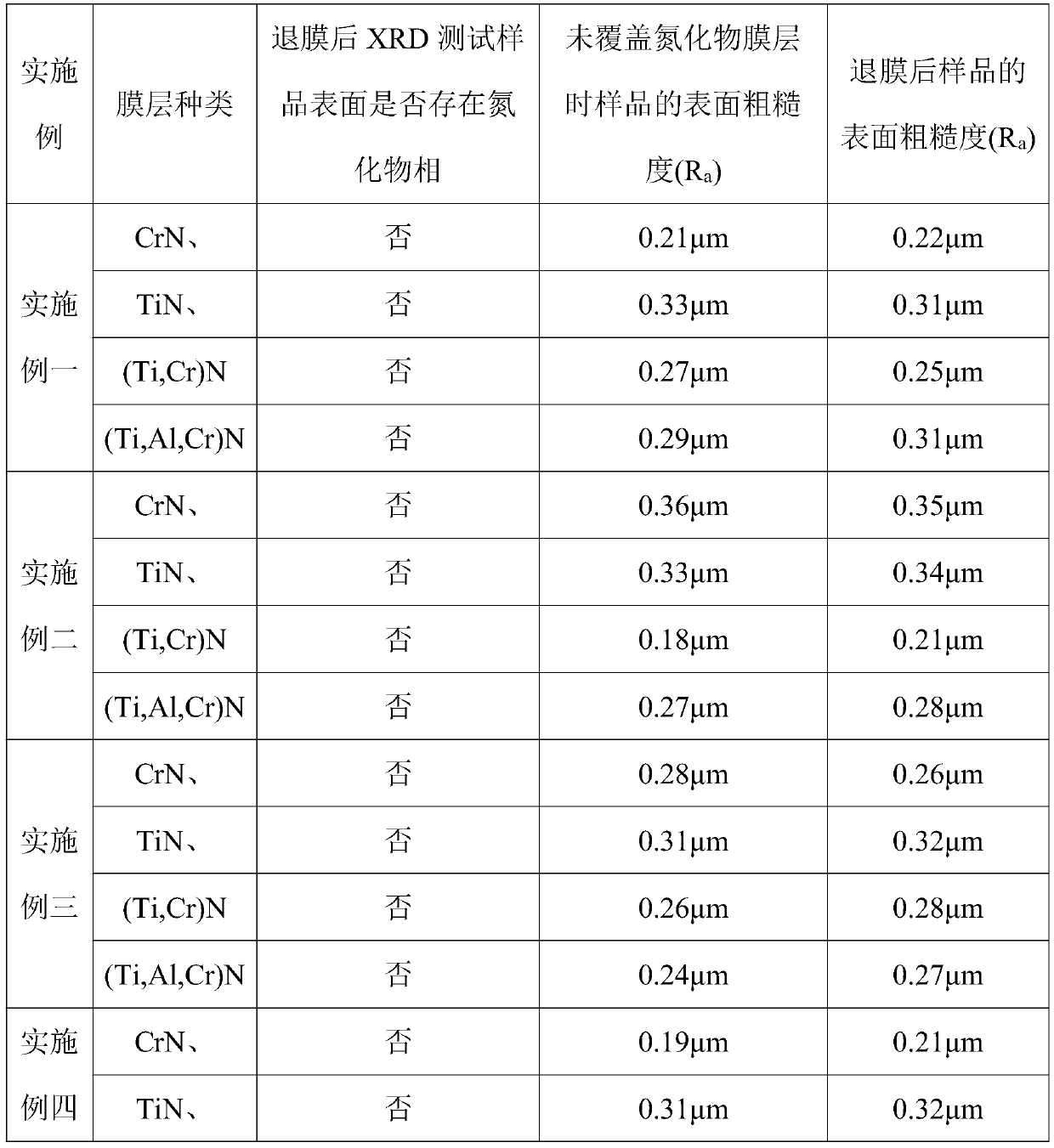

System for generating electrical energy through the input of energy to alignment buckypaper

InactiveUS20130214638A1Reduce resistanceHigh voltageNanotechThermoelectric device with peltier/seeback effectBuckypaperElectrolysis

The electrical energy generating system of the present invention comprises a piece of alignment Buckypaper, an energy generator, a thin deposition and two contacts. The alignment Buckypaper is a thin sheet made from an aggregate of carbon nanotubes. The thin deposition is formed on at least one surface of the alignment Buckypaper by electrolysis to form a semimetal material. A contact is connected with the upper surface of the alignment Buckypaper and the other contact is connected with the lower surface of the alignment Buckypaper. In use, the energy generated by the generator is inputted to the alignment Buckypaper. The energy then ionizes the molecules contained in the alignment Buckypaper. The positive charges move to the upper contact and the negative charges move to the lower contact. Such electrical energy may then be fed to a load connected with the two contacts to do work on the load.

Owner:MIAO HSIN YUAN

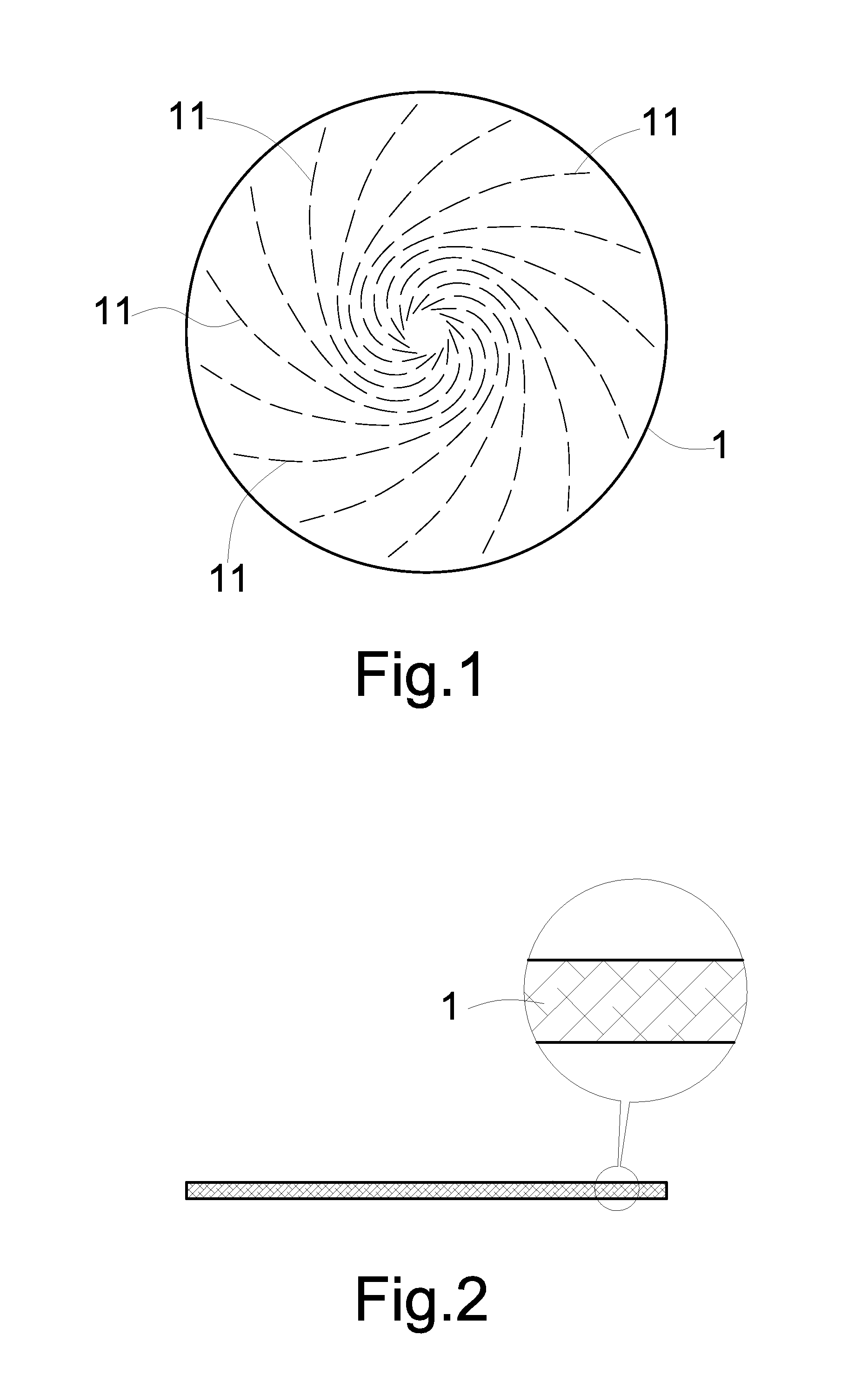

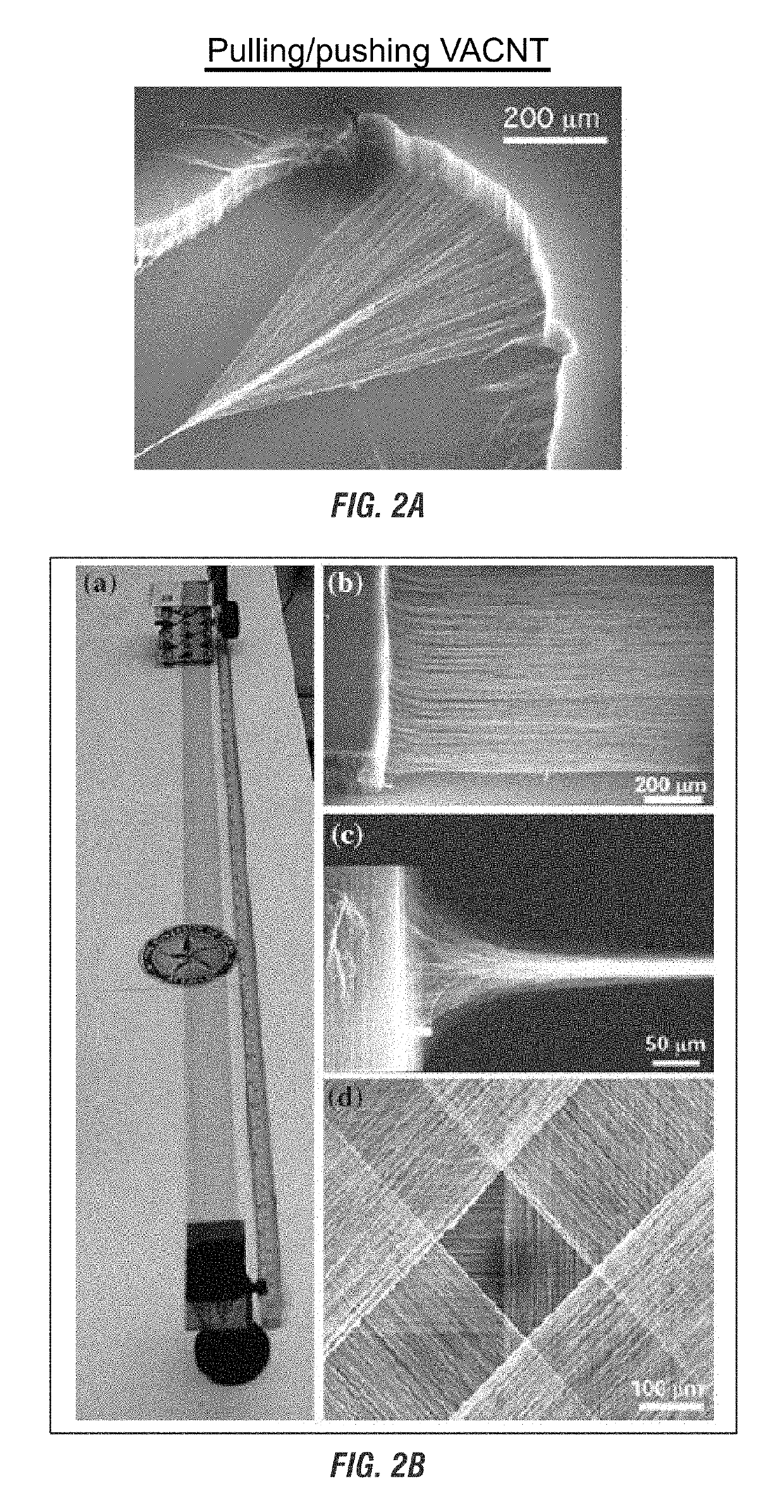

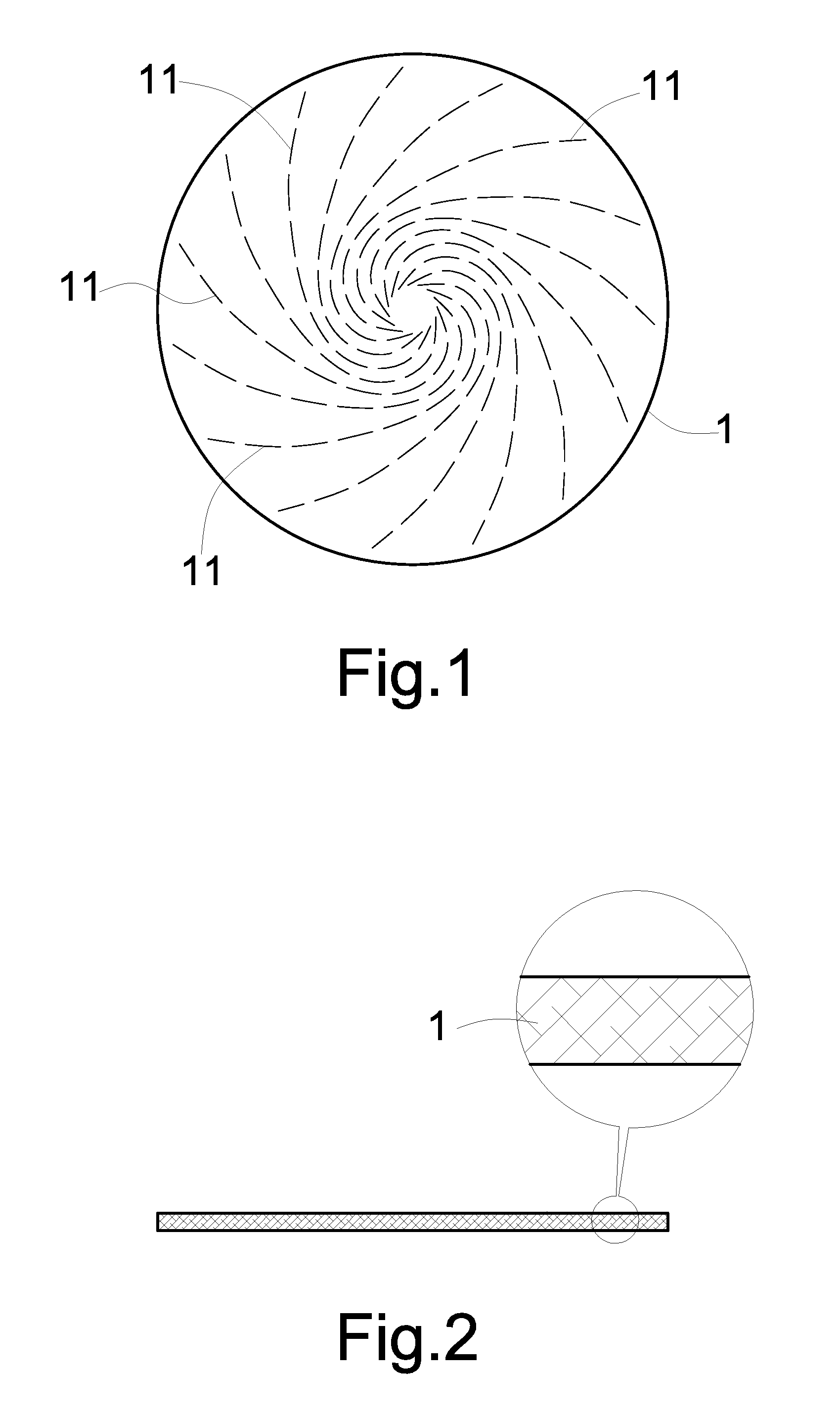

Method, apparatus, and system for producing buckypaper or similar sheet or layer of elongated nanostructures with a degree of nanostructure alignment

InactiveUS10351430B1Improve material performanceOther chemical processesNanotechnologyBuckypaperEngineering

A method, apparatus, and system for fabricating buckypaper or similar sheets of nanostructures having relatively high aspect ratios. A dispersion of nanostructures such as nanotubes is subjected to fluid dynamics / forces which promote alignment of their axes of elongation while in suspension in the flow. An agglomeration of better aligned nanostructures is isolated from the carrier fluid into a useable form. In the case of nanotubes, one form is buckypaper. One example of alignment forces is Taylor-Couette flow shear forces. One example of isolation is filtering the flowing dispersion to collect better aligned nanostructures across the filter into a sheet or film. The degree of alignment can produce anisotropic material properties that can be beneficially used in application of the sheet or film.

Owner:IOWA STATE UNIV RES FOUND

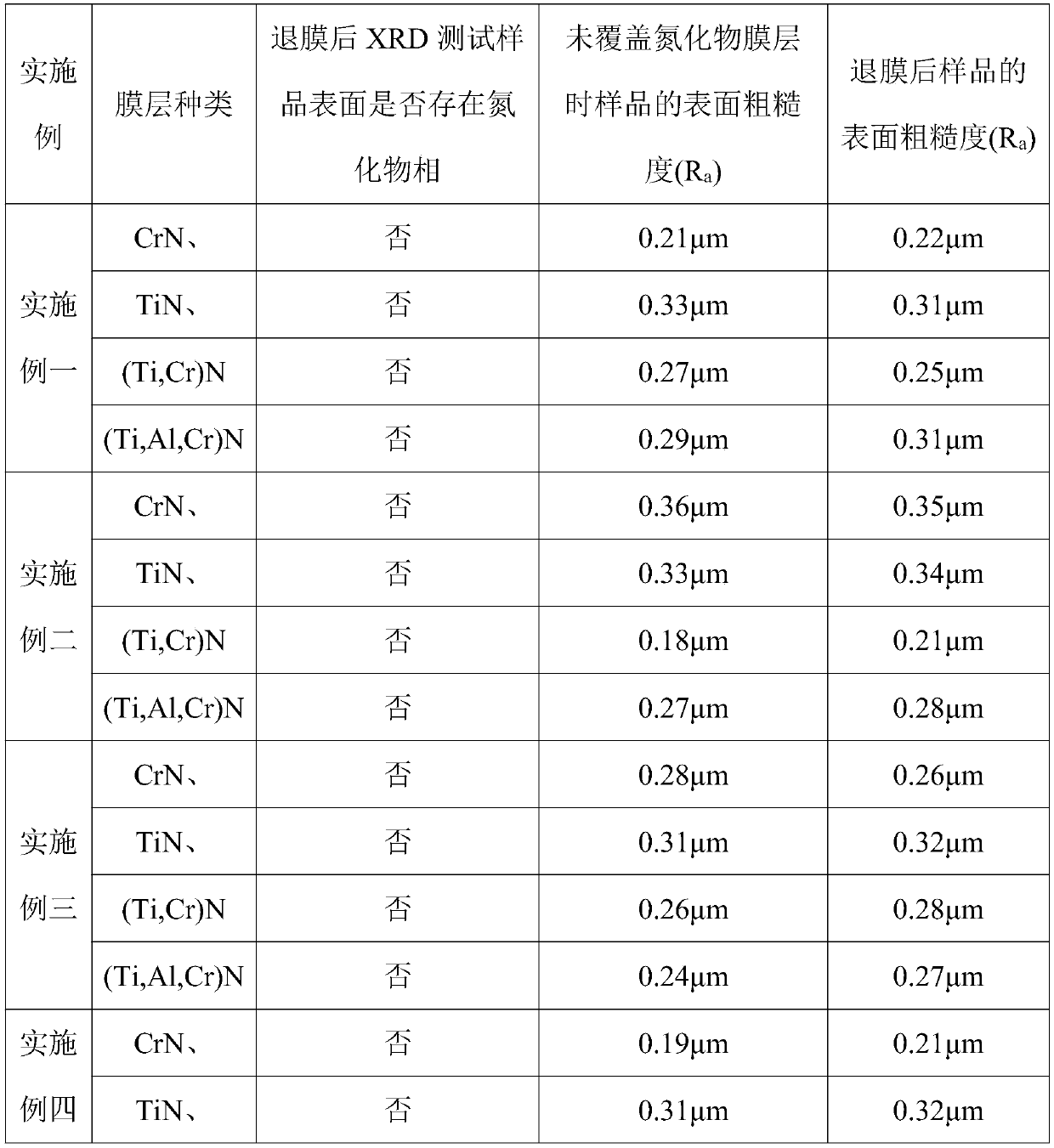

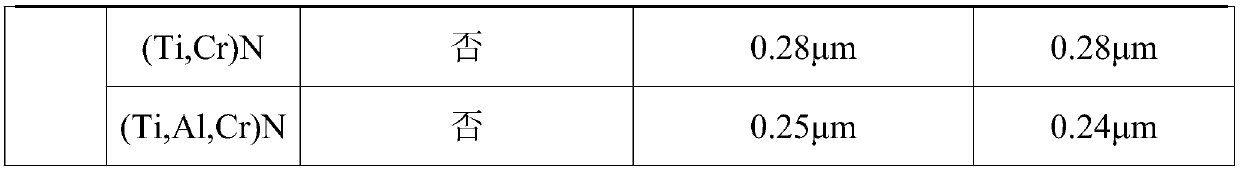

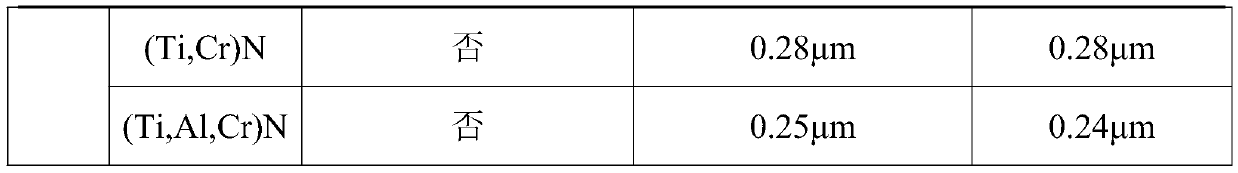

Film removing liquid and method for removing nitride film layer on surface of cobalt-based hard alloy

The invention discloses a film removing liquid and method for removing a nitride film layer on the surface of a cobalt-based hard alloy. The film removing liquid does not contain substances such as permanganate, chlorate or hydrogen peroxide, and is composed of sodium hydroxide, sodium percarbonate, tetrasodium iminodisuccinate, sodium lignin sulfonate, graphene oxide powder, isopropanol, ethanol,and deionized water, wherein the deionized water is used as a solvent. According to the film removing liquid, a buckypaper subjected to constant potential cathode polarization treatment is used as aflexible carrier of the film removing liquid, in the film removing process, only the buckypaper absorbing the film removing liquid needs to be used for covering the surface of the nitride film layer,ultrasonic vibration is combined, effective removal of the nitride film layer can be realized, and the damage on the base body cobalt-based hard alloy is extremely weak in the film removing process.

Owner:SUZHOU CHAMPION COATING TECH

A kind of preparation method of carbon nanotube reinforced SIC-based nanocomposite film

ActiveCN104291826BExcellent thermal and electrical conductivityHigh volume contentSemi-permeable membranesBuckypaperFiltration

The invention discloses a preparation method of a carbon nanotube (CNT) enhanced SiC based nano composite material film. The preparation method comprises the following steps: dispersing CNTs, B4C micro-powder and elemental silicon powder into water to prepare a suspension liquid, taking TritonTM X-100 as a dispersing agent, then performing pressure filtration on the suspension liquid by using a pressure filtration device, soaking a CNTs Buckypaper preform obtained by virtue of pressure filtration in a thermoplastic phenolic resin solution, and then sequentially performing soft curing, hard curing and post-curing to obtain a curing sample; and then carbonizing the curing sample under the protection of nitrogen, and finally sintering to obtain the CNT enhanced SiC based nano composite material film. The nano composite material film prepared by using the method disclosed by the invention is high in CNT volume content and good in dispersion performance, has good preferred orientation in arrangement of the CNTs, has good combination between the CNTs and a matrix, and is smooth and warping-free in film surface, uniform and compact in microscopic structure, good in thermal and electrical conduction properties, good in strength and toughness, short in period and low in cost.

Owner:XIAN XINGUI CERAMIC COMPOSITE MATERIAL CO LTD

Bio buckypaper synthesized with fish scales

A bio buckypaper synthesized with fish scales may be manufactured by mixing carrageenan with a bio waste solution to provide a first mixture, adding carbon nanotubes to the first mixture produce a second mixture, sonicating the second mixture, and evaporative-casting the second mixture to produce the bio buckypaper. In an embodiment, the carrageenan may be τ-carrageenan. In an embodiment, the carbon nanotubes may be single walled carbon nanotubes (SWCNTs) or multi-walled carbon nanotubes (MWCNTs). In an embodiment, the bio waste solution may be derived from fish scales.

Owner:KING SAUD UNIVERSITY

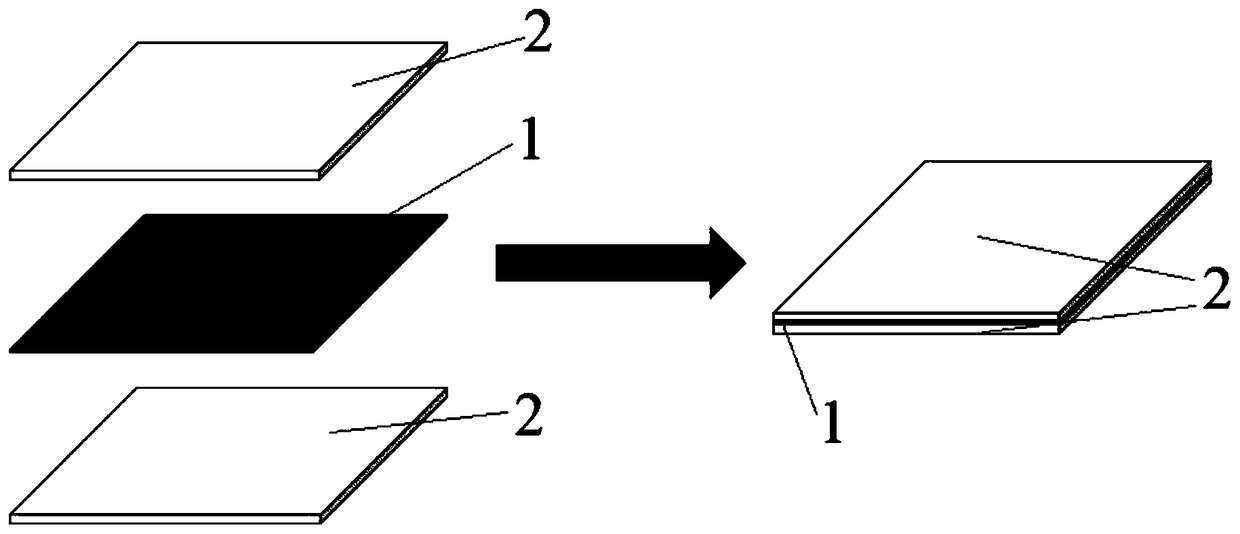

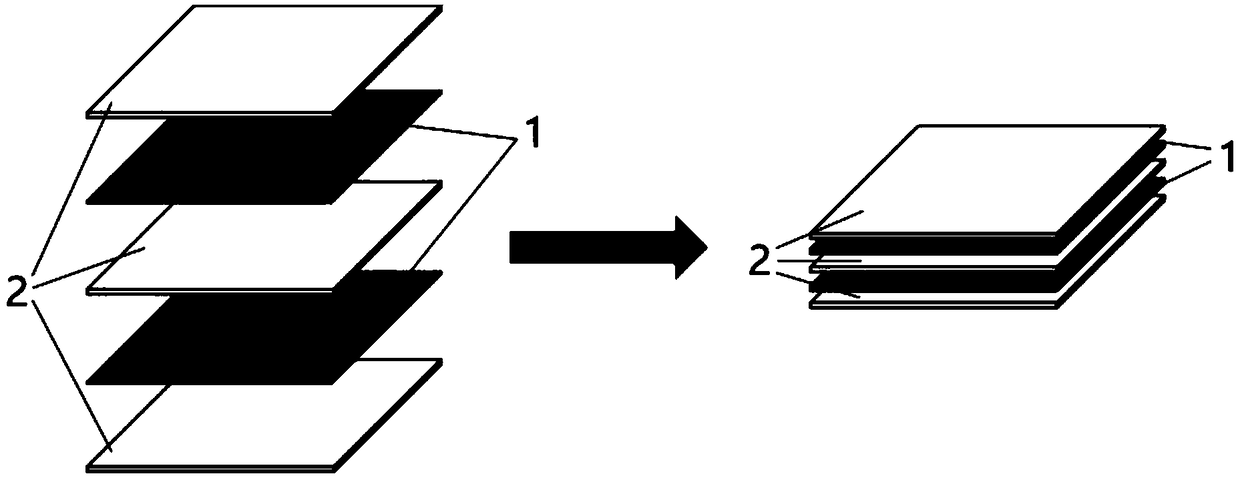

Composite film having electromagnetic shielding interlayer structure and preparation method thereof

PendingCN108749194AGood mechanical propertiesHigh tensile strengthSynthetic resin layered productsLaminationVacuum pumpingBuckypaper

The invention discloses a composite film having an electromagnetic shielding interlayer structure and a preparation method thereof. The composite film is composited by N layers of Buckypapers and N+1layers of PP / PLA / TiO2 films; N is a positive integer; the Buckypapers and the PP / PLA / TiO2 films are alternatively arranged in order, and an outermost layer employs the PP / PLA / TiO2 film. The method employs the following steps: 1) employing a vacuum pumping filtration method for preparing carbon nanotube to the Buckypapers; 2) employing a fusion mixing and hot pressing method to prepare the PP / PLA / TiO2 film; and 3) performing hot pressing on the Buckypaper and the PP / PLA / TiO2 film to obtain the composite film. The composite film uses the Buckypaper having an electromagnetic shielding function asa sandwich layer, the PP / PLA / TiO2 film having the anti-ultraviolet characteristic as a base material, and the advantages of the Buckypaper and the PP / PLA / TiO2 film are complemented. The composite film has excellent mechanical properties (tensile strength and elastic modulus) and heat stability, and has anti-ultraviolet and electromagnetic shielding functions, the application value is increased, and the composite film can be used as an electromagnetic shielding material for construction and transportation.

Owner:TIANJIN POLYTECHNIC UNIV

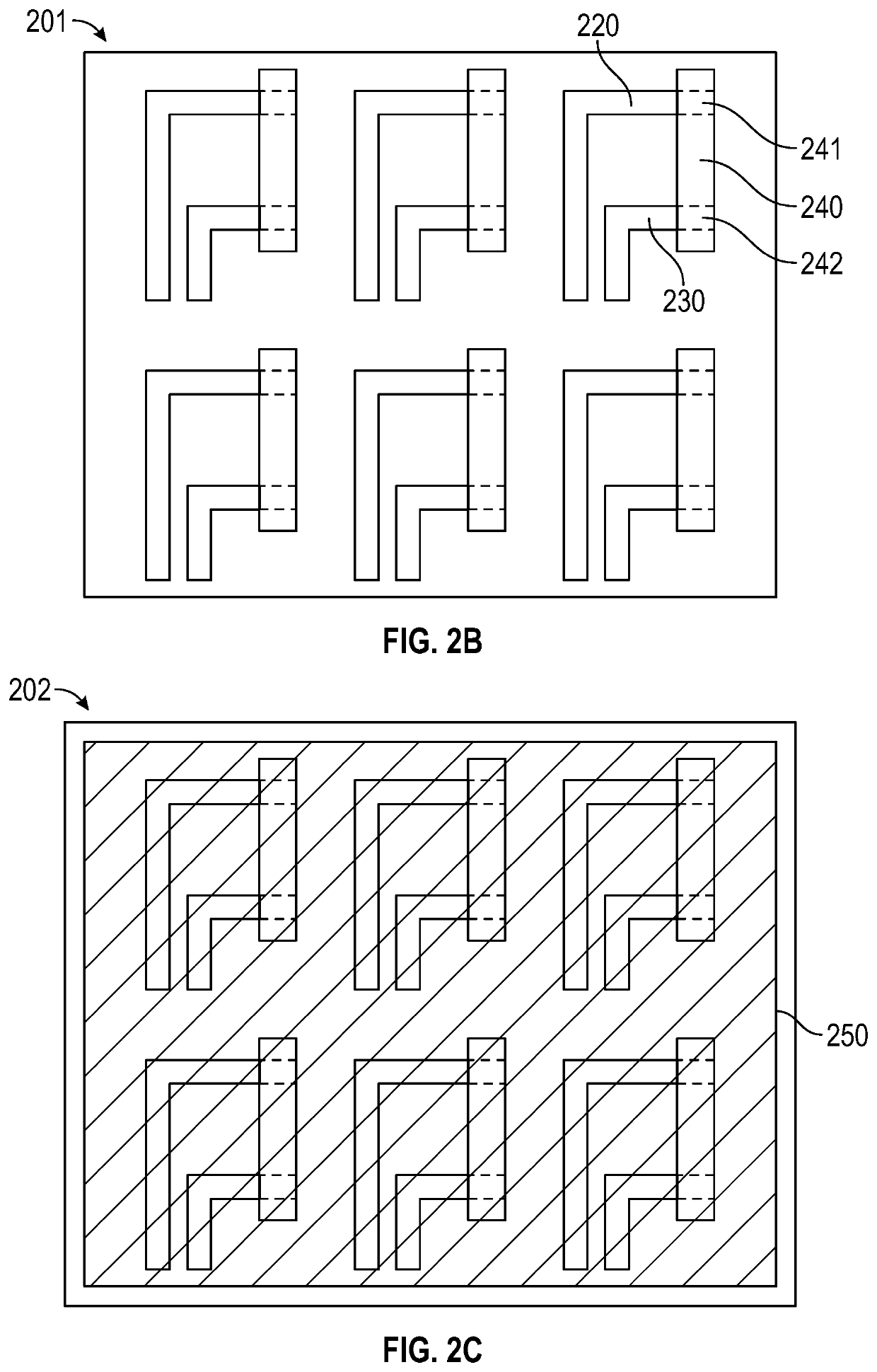

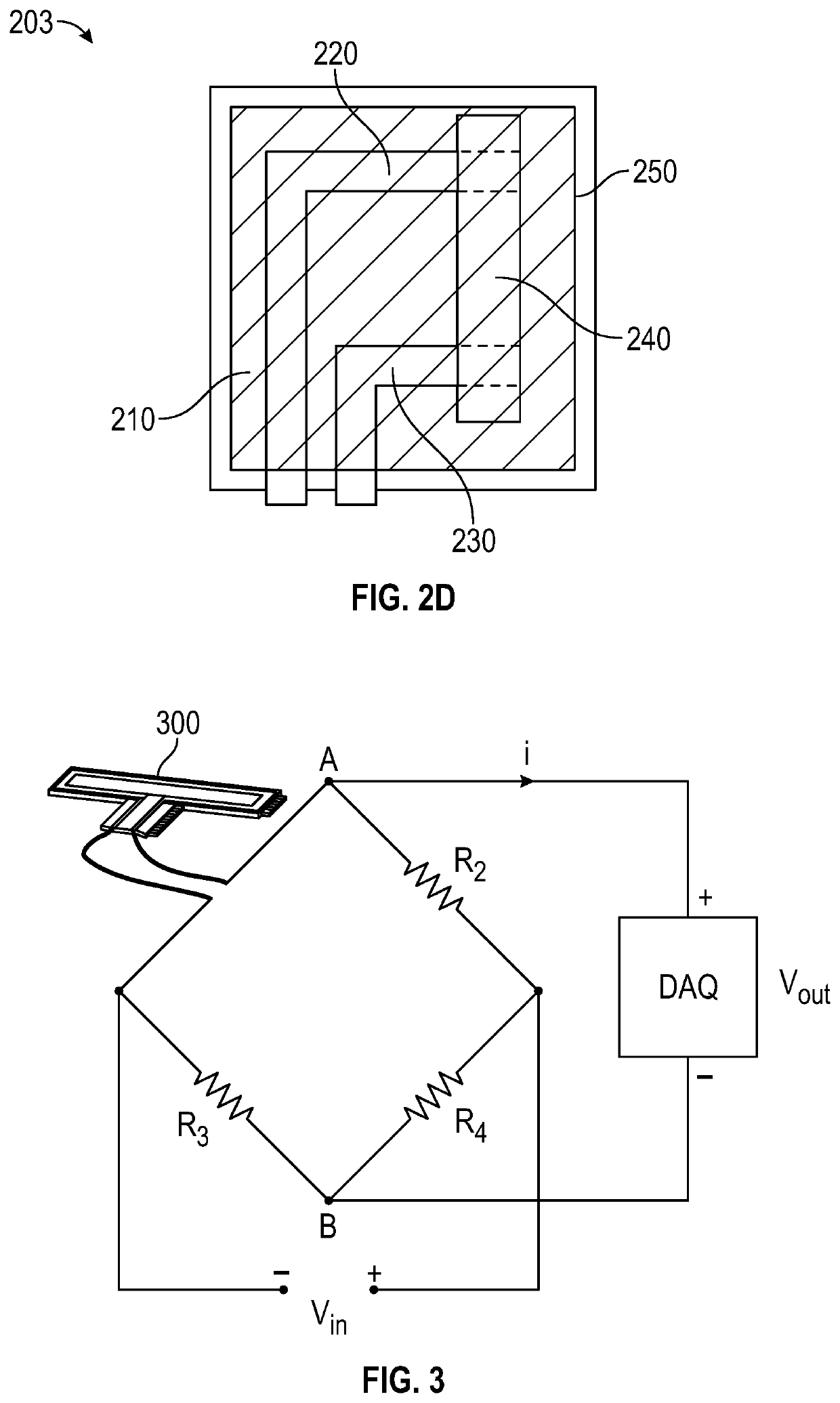

Carbon Nanotube Sensors, Articles, and Methods

PendingUS20210239548A1Strain gaugeForce measurement using piezo-resistive materialsBuckypaperComputer printing

Owner:INST NAT DES SCI APPLIQUEES DE LYON +1

A kind of preparation method of clad bucky paper composite material with composite metal layer

ActiveCN109536935BPromote formationImprove mechanical propertiesLiquid/solution decomposition chemical coatingCopper platingBiological activation

The invention provides a preparation method for a composite metal layer plated buckypaper composite material. The preparation method comprises the following steps that buckypaper sequentially undergoes acidification, sensitization and activation treatment, and then is added into deionized water for ultrasonic treatment, then a reducing agent is added, uniform mixing is performed to obtain a suspension liquid, then a nickel plating solution is added into the suspension liquid, and the nickel-plated buckypaper is obtained through reaction; mixed powder of tungsten oxide and molybdenum oxide is sprayed on the surface of the nickel-plated buckypaper, water-passing hydrogen is introduced after heating, and the modified nickel-plated buckypaper is obtained through reaction; the modified nickel-plated buckypaper is added into a copper plating solution, then the reducing agent is added, and a precursor of the composite metal layer plated buckypaper composite material is obtained through reaction; and the precursor is reduced under a reducing atmosphere, then sintering is performed, and the composite metal layer plated buckypaper composite material is obtained. The method is beneficial to improving the mechanical property, the electrical property and the service performance of the composite material, has the characteristics of being short in process, simple in equipment and high in safety operability, and enables continuous production to be realized easily.

Owner:CENT SOUTH UNIV

Vortex alignment Buckypaper generating electricity

InactiveUS9035534B2Reduce resistanceHigh voltageNanotechThermoelectric device with peltier/seeback effectElectricityBuckypaper

The electrical energy generating system of the present invention comprises a piece of alignment Buckypaper, an energy generator, a thin deposition and two contacts. The alignment Buckypaper is a thin sheet made from an aggregate of carbon nanotubes. The thin deposition is formed on at least one surface of the alignment Buckypaper by electrolysis to form a semimetal material. A contact is connected with the upper surface of the alignment Buckypaper and the other contact is connected with the lower surface of the alignment Buckypaper. In use, the energy generated by the generator is inputted to the alignment Buckypaper. The energy then ionizes the molecules contained in the alignment Buckypaper. The positive charges move to the upper contact and the negative charges move to the lower contact. Such electrical energy may then be fed to a load connected with the two contacts to do work on the load.

Owner:MIAO HSIN YUAN

Stripping solution and method for stripping nitride film layer on cobalt-based hard alloy surface

ActiveCN109576723BAvoid damageEffective withdrawalCleaning processes and apparatusPermanganate saltCobalt

Owner:SUZHOU CHAMPION COATING TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com