Composite film having electromagnetic shielding interlayer structure and preparation method thereof

A technology of composite film and sandwich structure, applied in the direction of chemical instruments and methods, laminated, layered products, etc., can solve the problems of product reliability and safety impact, deterioration, increase of electromagnetic radiation, etc., and achieve excellent electromagnetic shielding Performance, application value improvement, and the effect of excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

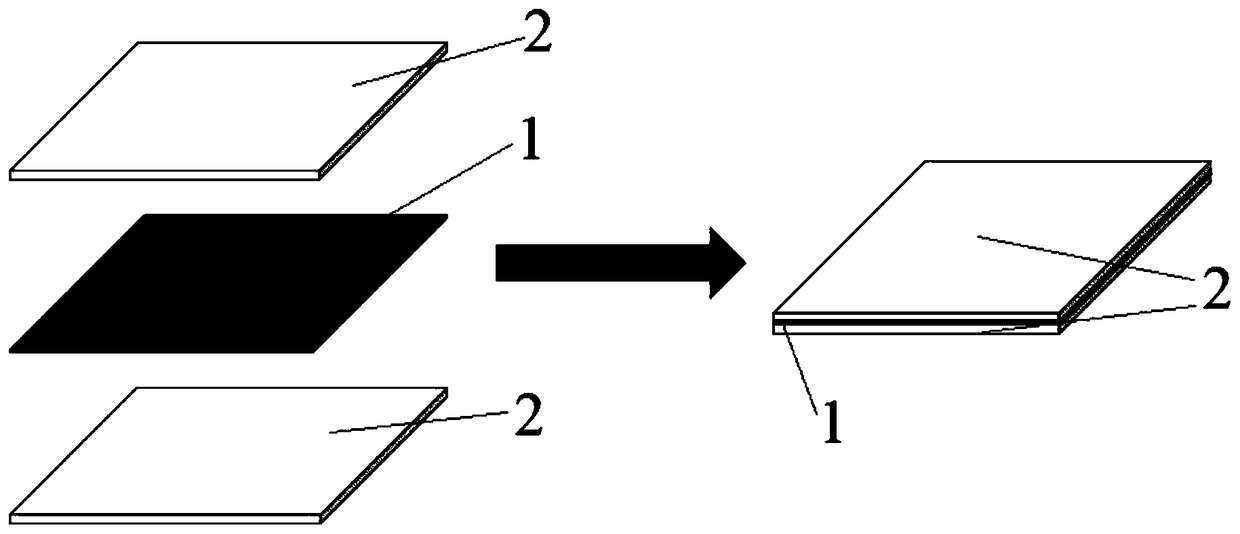

[0018] The present invention provides a kind of preparation method (abbreviation method) of electromagnetic shielding interlayer structure composite film simultaneously, it is characterized in that the method comprises the following steps:

[0019] (1) Carbon nanotubes are prepared into bucky paper by vacuum filtration: carbon nanotubes are put into deionized water, and configured into a mass-volume concentration of 0.5-0.8mg / ml (preferably 0.5mg / ml) Mixture, then add non-ionic surfactant, with the power of 600-1000W (preferably 600W) ultrasonic oscillator vibration 25-30min (preferably 30min), make it disperse evenly; Then it is poured on the porous cellulose filter membrane, Carry out suction filtration with a vacuum suction filtration device, then use deionized water to remove residual nonionic surfactants, and obtain entangled carbon nanotubes on the filter membrane; in an oven at 60-80°C (preferably 60°C) After drying for 0.75-1h (preferably 1h), dissolve the cellulose fi...

Embodiment 1

[0027] (1) Prepare carbon nanotubes into bucky paper by vacuum filtration: put 1.5 g of multi-walled carbon nanotubes with a purity of more than 98% into 3000 ml of deionized water, and add 0.45 g of nonionic surfactant; Use 600W ultrasonic oscillation for 30 minutes to make it evenly dispersed; then pour it into a porous cellulose filter membrane with a pore size of 0.45um, and filter it with a vacuum suction device; use deionized water to remove residual non-ionic surface activity entangled multi-walled carbon nanotubes on the filter membrane; dried in an oven at 60°C for 1 hour, and then dissolved the cellulose filter membrane with a small amount of acetone to obtain bucky paper with a thickness of 90 μm;

[0028] (2) Prepare PP / PLA / TiO by melt mixing and hot pressing 2 film:

[0029] First, the PP / PLA / TiO 2 Mixture: PP and PLA are mixed and then added to a mixer with a temperature of 200°C and a screw speed of 130rpm; the mass of PP accounts for 80% of the total mass of ...

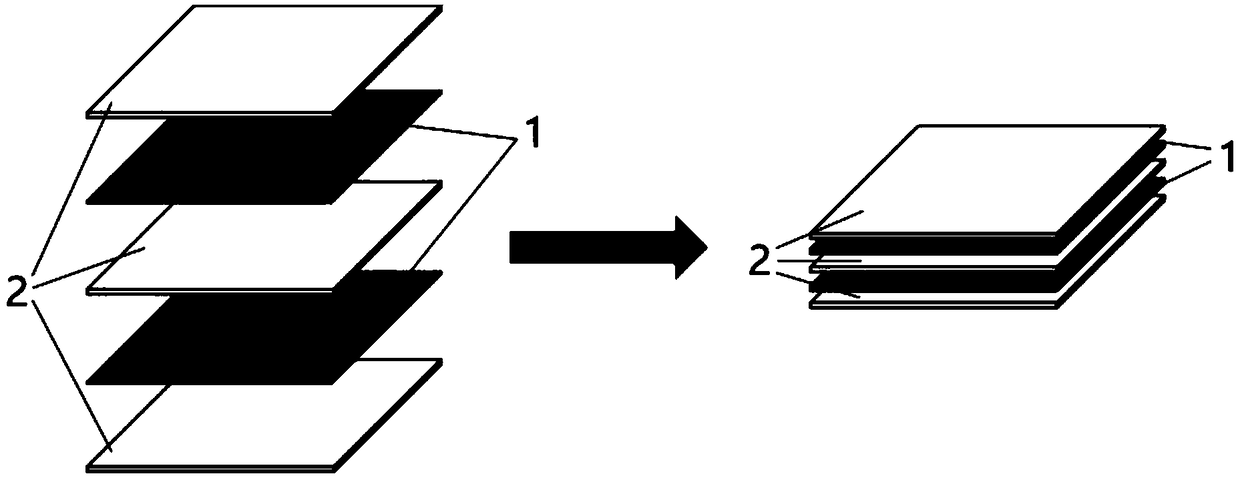

Embodiment 2

[0035] Steps (1) and (2) are consistent with Example 1, step (3) alternately place two layers of bucky paper on three pieces of PP / PLA / TiO 2 Between the films, heat press in a hot press for 30s at a temperature of 180°C and a pressure of 2 MPa, take out and cool to obtain a five-layer composite film with a thickness of 380±50 μm.

[0036] After testing, it is concluded that bucky paper has a good effect on PP / PLA / TiO 2 The film has a good reinforcing effect. When the thickness of the bucky paper is 90 μm, the tensile strength and elastic modulus of the composite film are higher than those of the single-layer PP / PLA / TiO 2 The film was increased by 178% and 43%, respectively, and the crystallinity and thermal stability of the composite film were also improved; 2 The original function of blocking ultraviolet rays of the film has no negative impact, and the transmittance of UVB to the composite film is close to 0%. The electromagnetic shielding performance of the composite film i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com