Patents

Literature

57results about How to "Less porosity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Energy storage device

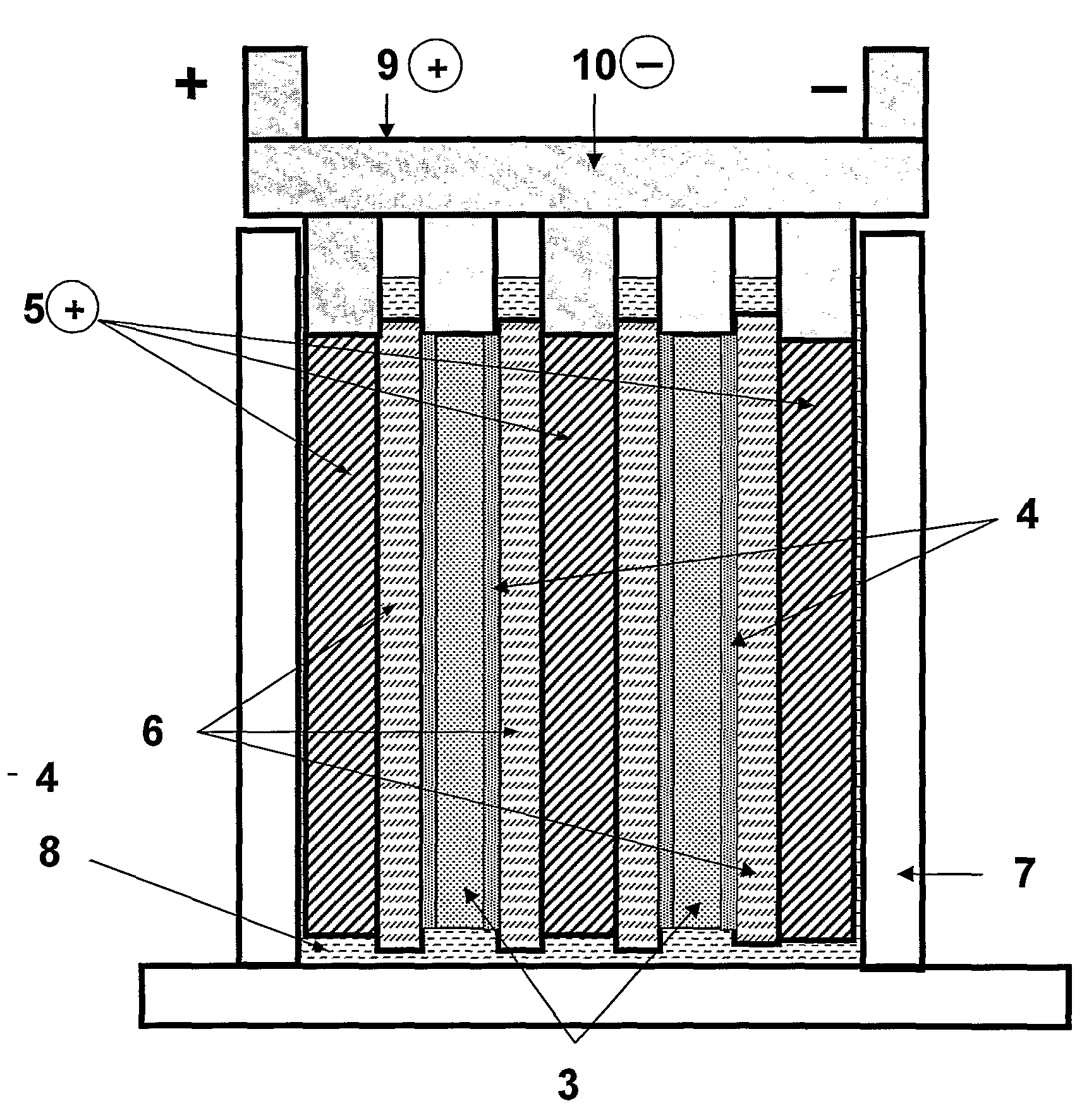

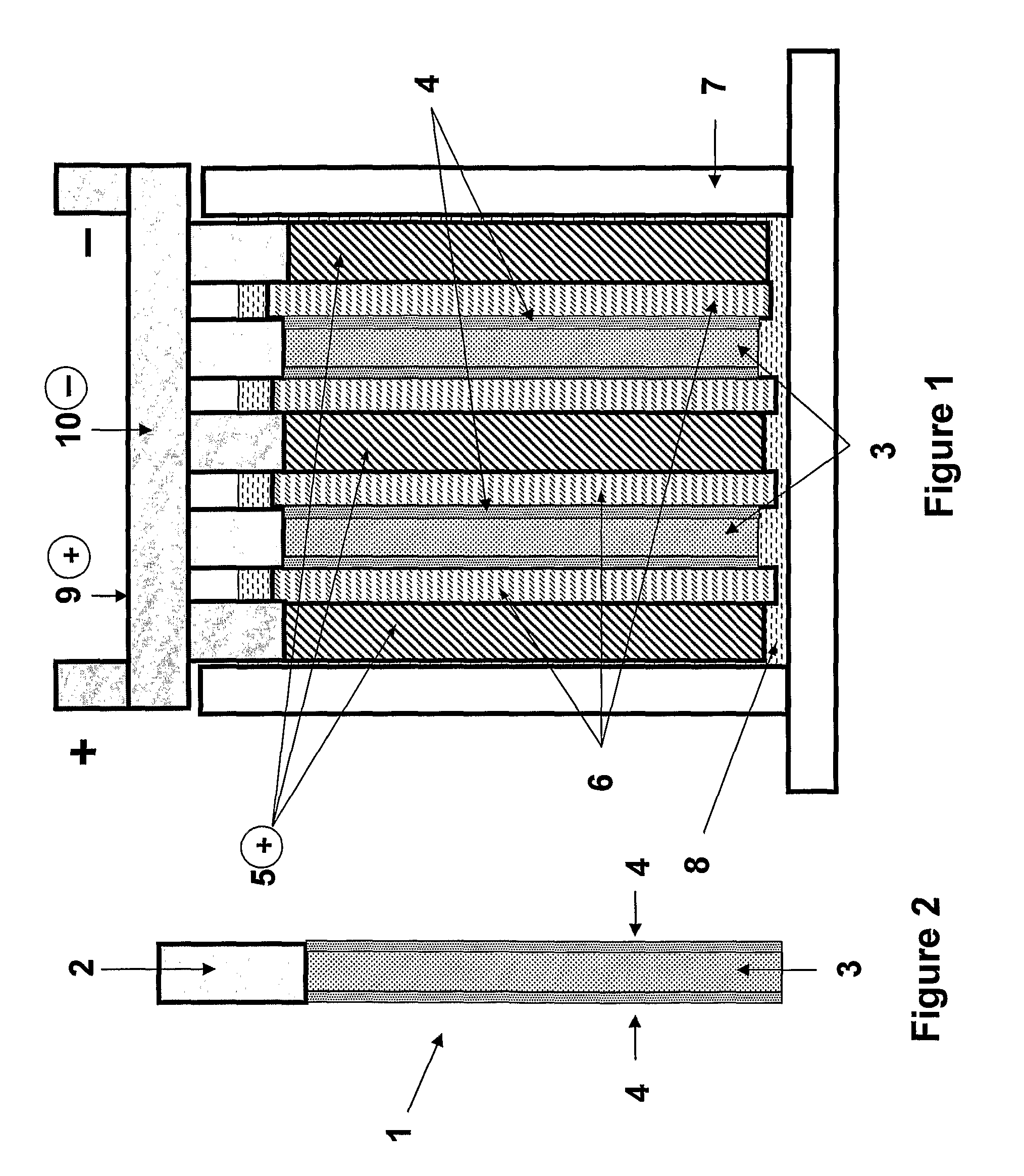

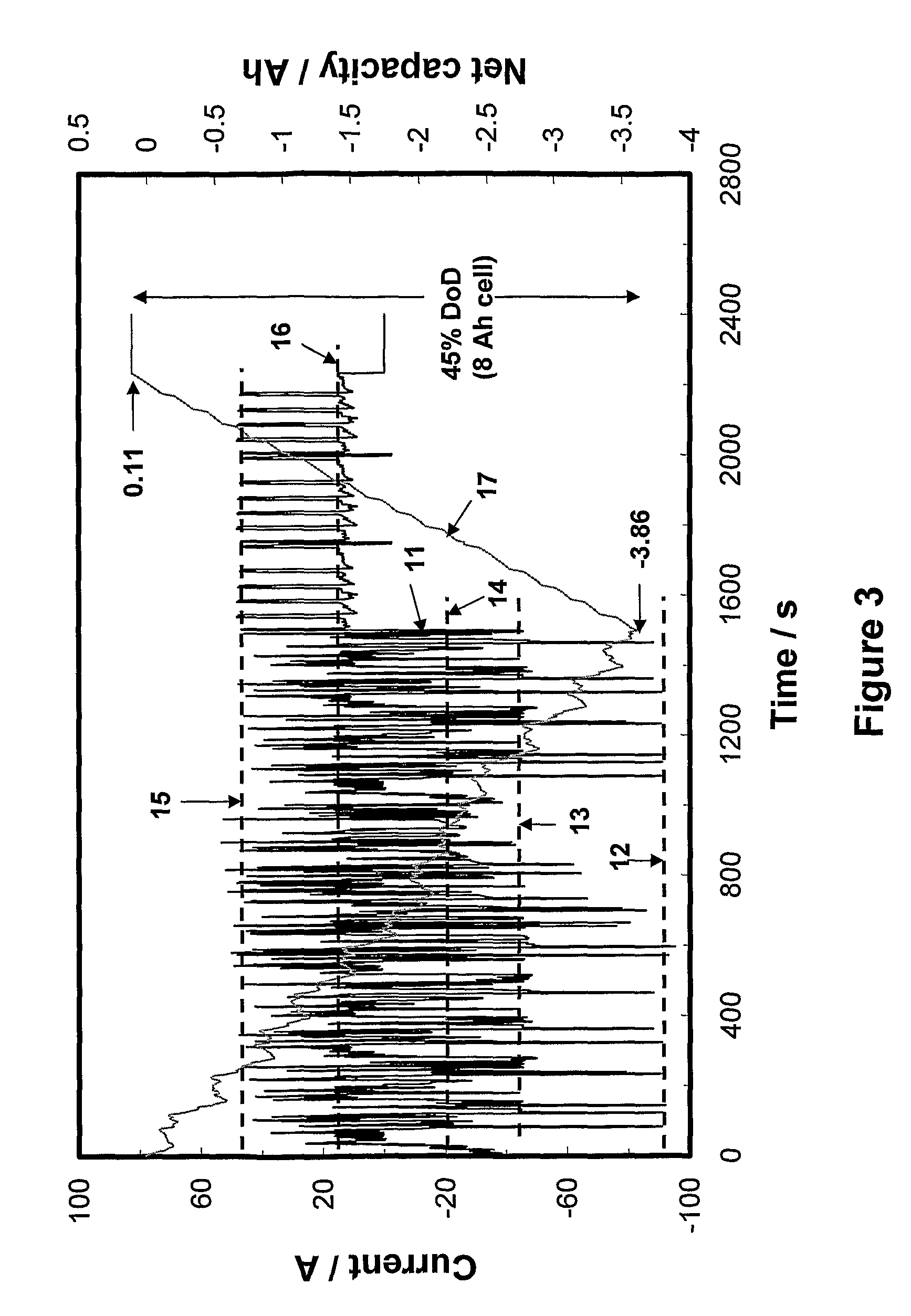

ActiveUS20100203362A1Reduce heatImprove conductivityLead-acid accumulatorsCapacitor and primary/secondary cellsTin dioxideConductive materials

An energy storage device comprising at least one negative electrode, wherein each negative electrode is individually selected from (i) an electrode comprising negative battery electrode material; (ii) an electrode comprising capacitor electrode material; (iii) a mixed electrode comprising either—a mixture of battery and capacitor electrode material or—a region of battery electrode material and a region of capacitor electrode material, or—a combination thereof, and wherein the energy storage device either comprises at least one electrode of type (iii), or comprises at least one electrode of each of types (i) and (ii),—at least one positive electrode, wherein the positive electrode comprises positive battery electrode material and a charging ability-increasing additive, such as one or a mixture of: (a) carbon nanomaterial, vapour grown carbon fibre, fullerene, or a mixture thereof, and (b) tin dioxide conductive materials.

Owner:COMMONWEALTH SCI & IND RES ORG +1

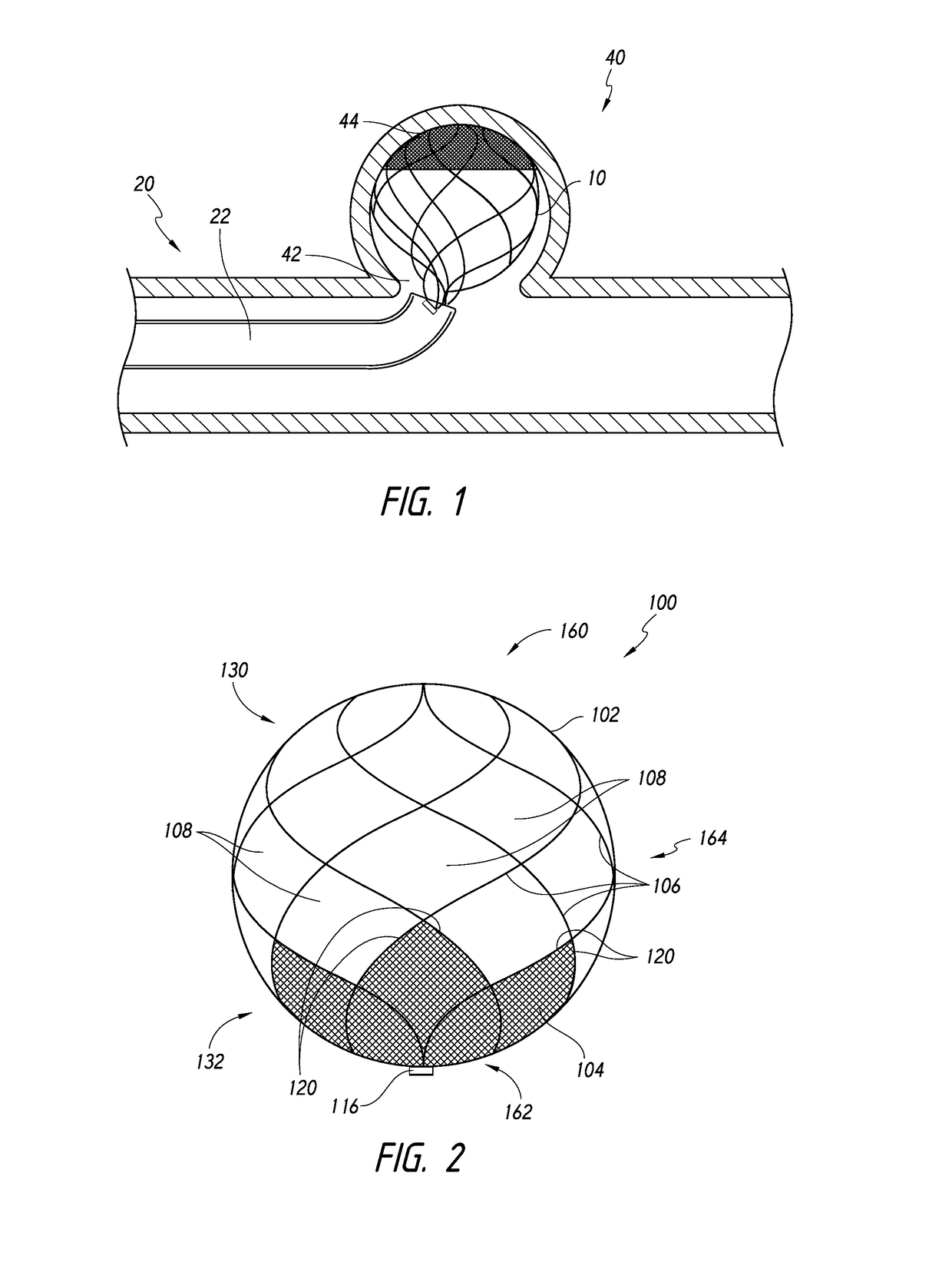

Occlusive devices

ActiveUS20170079662A1Facilitate and healing effectPromote endothelializationOcculdersPorosityComputer graphics (images)

Owner:TYCO HEALTHCARE GRP LP

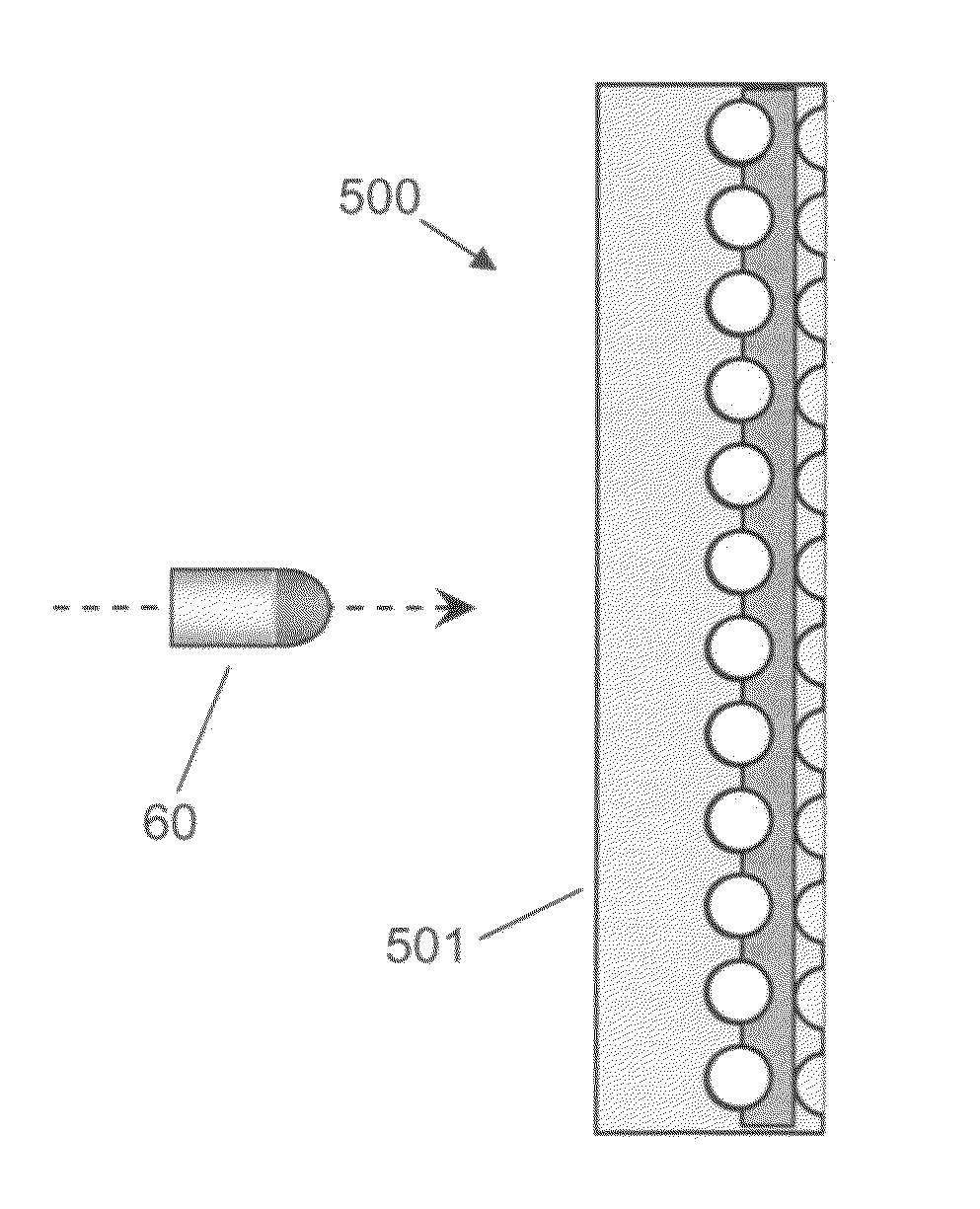

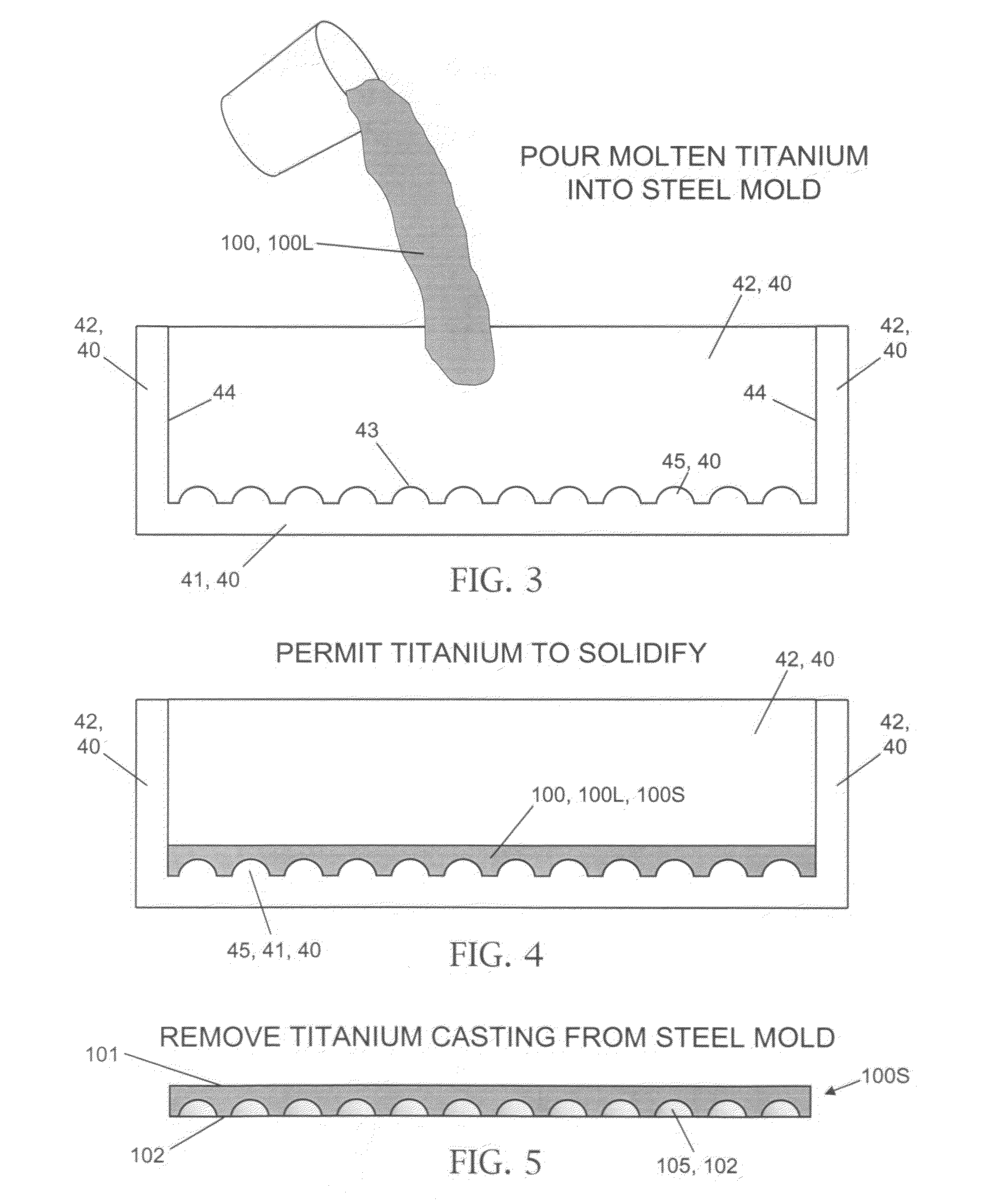

Composite armor having a layered metallic matrix and dually embedded ceramic elements

ActiveUS7833627B1Effective performance in resisting projectile impactEfficient and cost-effectiveSynthetic resin layered productsDomestic articlesMetallic materialsSpherical form

According to typical inventive practice, a first metallic material is poured into a mold including a bottom inside surface having regularly arrayed rises (truncated spherical convexities). The molten first metallic material cools and solidifies to include a surface correspondingly having regularly arrayed dents (truncated spherical concavities). The resultant “inner casting” is removed from and repositioned in the mold so that the inner casting's dent-laden surface faces upward. Ceramic spheres are placed in the dents. A second metallic material (having a higher melting point than the first metallic material) is poured into the mold with the inner casting and spheres in place. The molten second metallic material cools and solidifies as an “outer casting” surrounding the inner casting and the spheres. The resultant integral armor structure includes the inner casting, the outer casting, and the spheres, each sphere embedded partially in the inner casting and partially in the outer casting.

Owner:UNITED STATES OF AMERICA SEC OF THE NAVY CHIEF OF NAVAL RES OFFICE OF COUNSEL ATTN CODE OOCIP THE

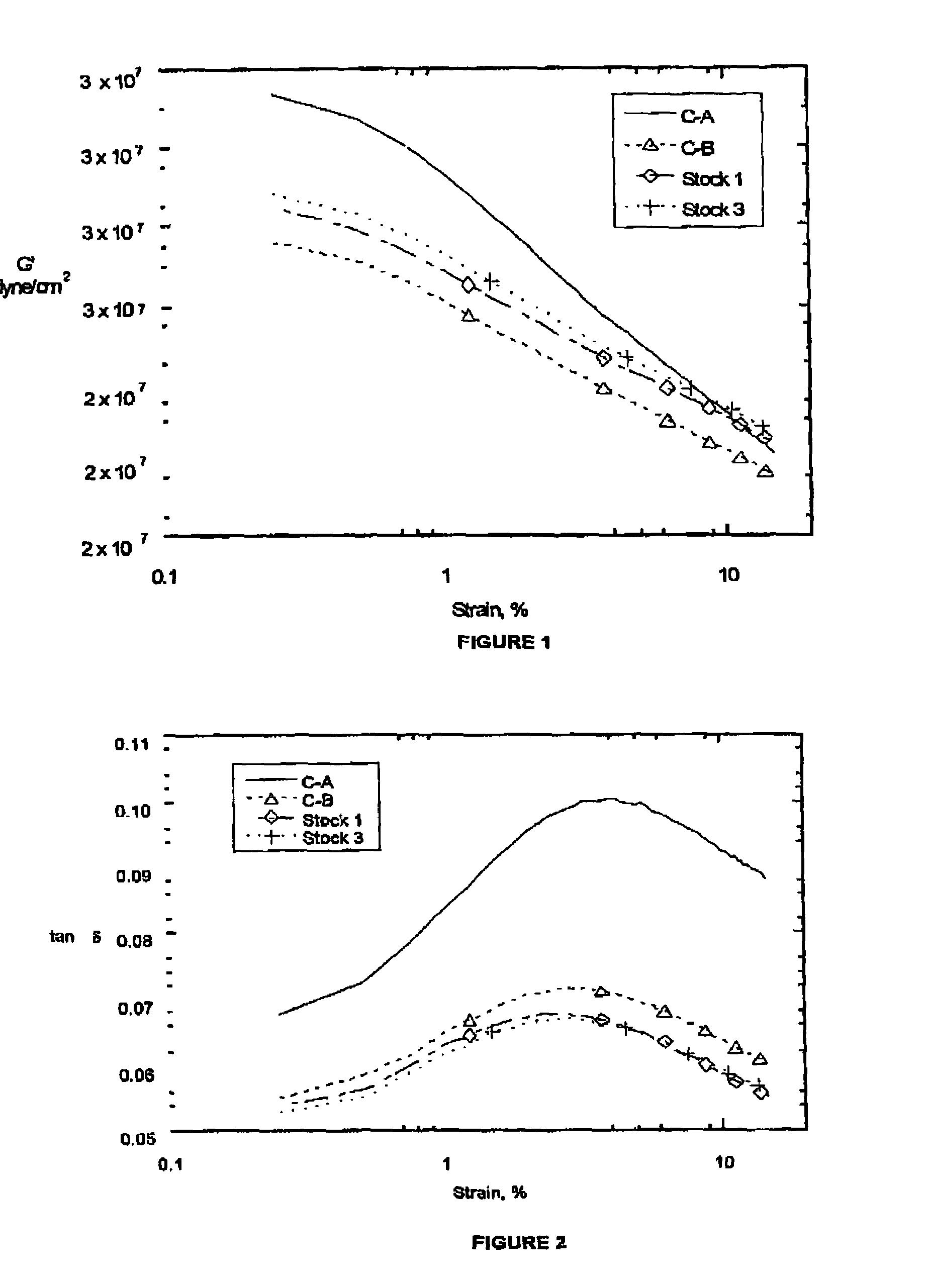

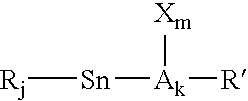

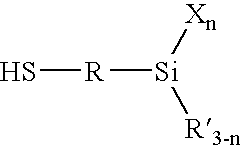

Silica-reinforced rubber compounded with an alkoxysilane and a catalytic alkyl tin compound

ActiveUS7119150B2Long scorch timeFast curingFilm/foil adhesivesSpecial tyresElastomerPolymer science

Owner:BRIDGESTONE CORP

Heat-preserving composite foam concrete and preparation method thereof

InactiveCN101805203AImprove thermal insulationLight weightSolid waste managementCeramicwareFoam concreteFoaming agent

The invention discloses a formula of heat-preserving composite foam concrete, which comprises the following components based on parts by weight: 500-1000 parts of concrete, 500-1000 parts of admixture, 5-20 parts of additive, 1-30 parts of polyurethane grains, 5-20 parts of foaming agent and 500-900 parts of water. The preparation method the foam concrete comprises the following steps of: preparing foaming agent water solution, smashing the polyurethane into grains, and adjusting the sizes of the grains as required, wherein the diameters of the grains are 1-3mm; adding the polyurethane grains into the concrete, the residual water after preparing the foaming agent water solution, the additive and the admixture, and evenly stirring to obtain slurry; mixing and stirring the slurry with the foam prepared by the foaming agent water solution; and maintaining, pouring and shaping into the cast-in-situ foam concrete. The invention solves the problems of the coordination between the intensity of the foam concrete and the heat-conducting property and the treatment of the waste polyurethane. The foam concrete can guarantee the intensity and has better heat-insulating effect.

Owner:建研建材有限公司 +1

Preparation method of low heat expansion carbon fiber reinforced resin matrix composite material mold

The invention relates to a preparation method of a low heat expansion carbon fiber reinforced resin matrix composite material mold, belonging to the technical field of composite material preparation. The method is capable of forming a molding surface with a VARI (Vacuum Assisted Resin Infusion) technique, and ensuring low heat expansion performance of the mold by controlling the carbon fiber laying direction, precuring temperature, postcuring manner and postprocessing manner of the molding surface. With the adoption of the VARI technique, when a vacuum pressure reaches to 0.1MPa, carbon fiber cloth is compressed by vacuum, so that the product is internally dense after resin is guided in the product, and the volume content of composite material fibers is ensured; and meanwhile, bubbles between carbon fiber cloth layers are removed so as to ensure that the content of internal pores of the composite material is as few as possible and ensure the strength of the composite material.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

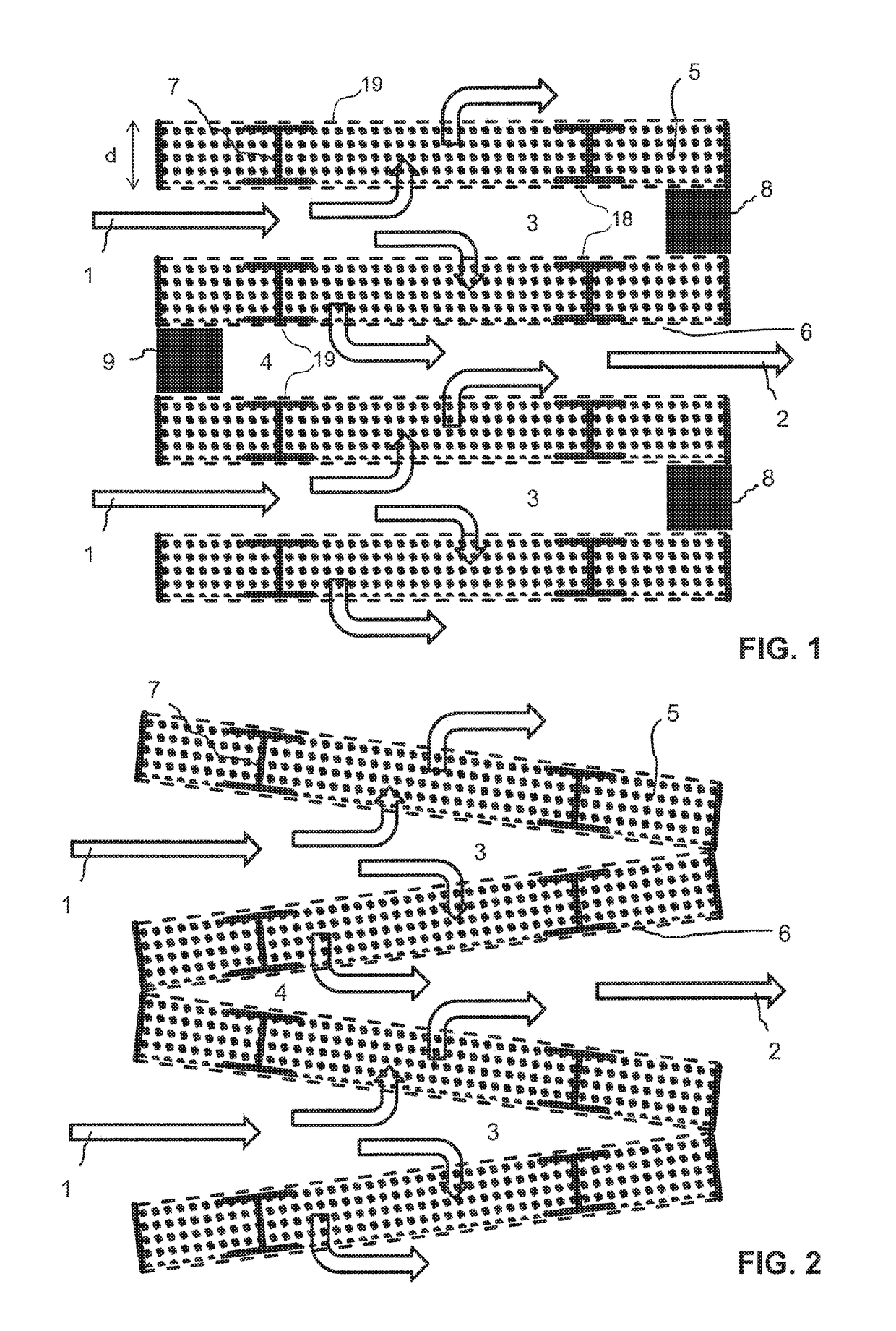

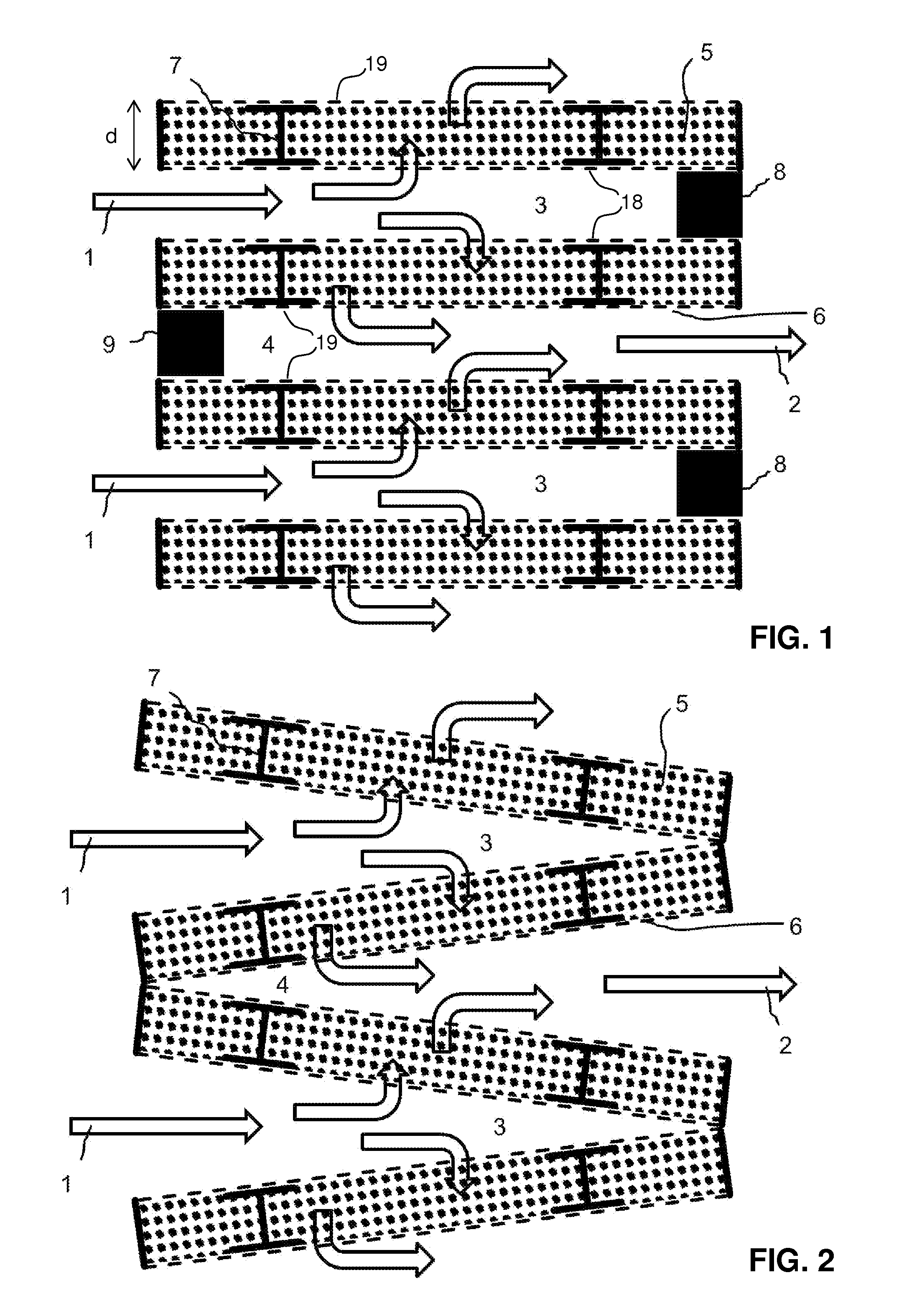

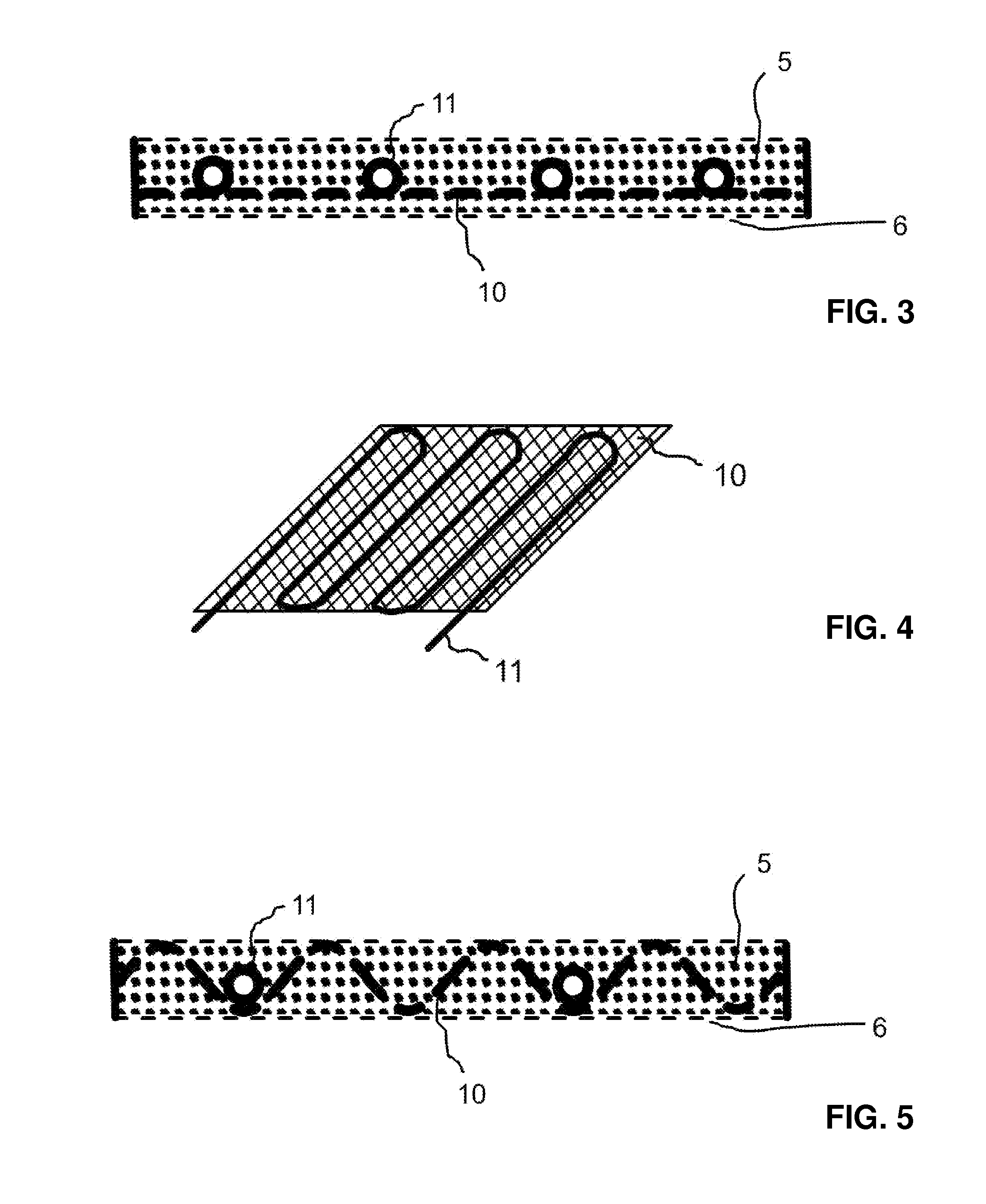

Low-pressure drop structure of particle adsorbent bed for adsorption gas separation process

ActiveUS20170326494A1Improve thermal conductivityReduce airflowGas treatmentOther chemical processesParticulatesDesorption

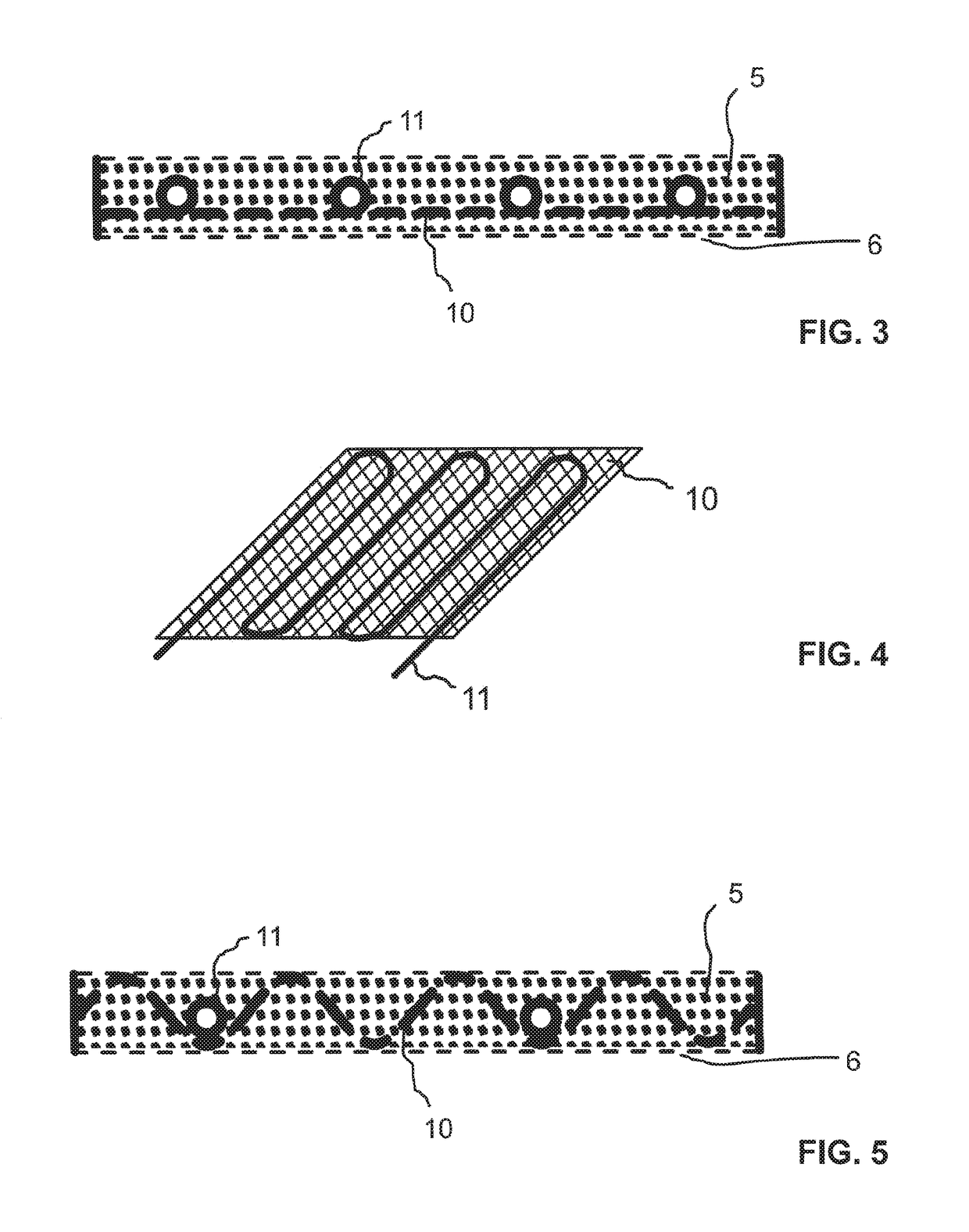

A gas separation unit for the separation of carbon dioxide from air is proposed for use in a cyclic adsorption / desorption process and using a loose particulate sorbent material. Sorbent material is arranged in at least two stacked layers, and each layer comprises two sheets of a flexible fabric material which is gas permeable but impermeable to the loose sorbent material. The sheets are arranged parallel defining an inlet face and an outlet face, are arranged with a distance in the range of 0.5-2.5 cm, and are enclosing a cavity in which the sorbent material is located. Said layers are arranged in the unit such that the inflow passes through the inlet face, subsequently through the particular sorbent material located in the cavity of the respective layer, subsequently to exit the layer through the outlet face to form the gas outflow.

Owner:CLIMEWORKS

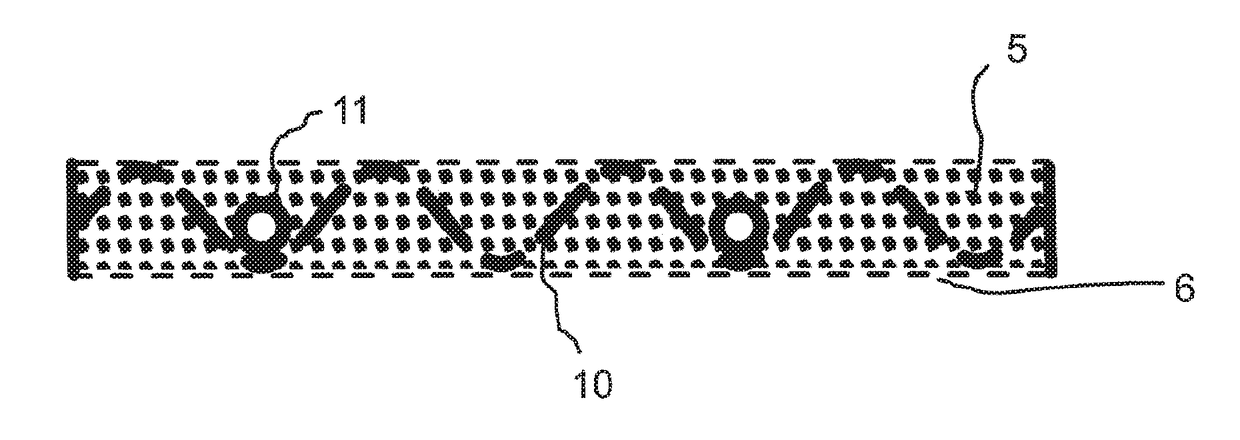

Wallboard tape

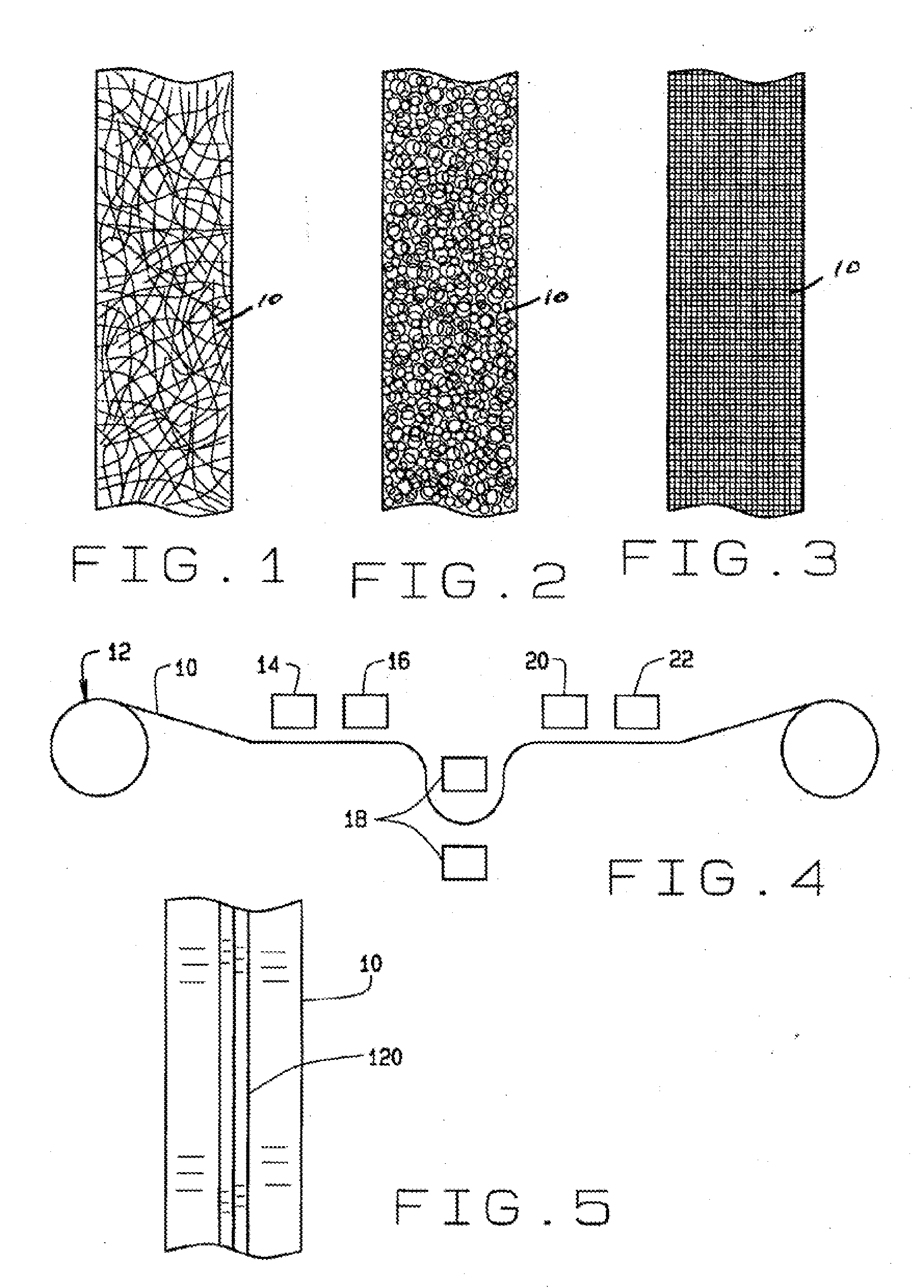

InactiveUS20100266835A1Less porosityIncrease heightAdhesive articlesSynthetic resin layered productsGlass fiberPolyester

Wallboard tapes having flexibility and elasticity are provided comprising a nonwoven mat or from at least 50% to 90% rigid fibers and no more than 50% to 10% of flexible fibers. The preferred tapes are comprised of glass fiber as the rigid fiber and polyester fiber as the flexible fiber.

Owner:CONBOY JOHN S

Low-pressure drop structure of particle adsorbent bed for adsorption gas separation process

ActiveUS20160074803A1Improve thermal conductivityReduce airflowGas treatmentIsotope separationParticulatesDesorption

A gas separation unit for the separation of carbon dioxide from air is proposed for use in a cyclic adsorption / desorption process and using a loose particulate sorbent material. Sorbent material is arranged in at least two stacked layers, and each layer comprises two sheets of a flexible fabric material which is gas permeable but impermeable to the loose sorbent material. The sheets are arranged parallel defining an inlet face and an outlet face, are arranged with a distance in the range of 0.5-2.5 cm, and are enclosing a cavity in which the sorbent material is located. Said layers are arranged in the unit such that the inflow passes through the inlet face, subsequently through the particular sorbent material located in the cavity of the respective layer, subsequently to exit the layer through the outlet face to form the gas outflow.

Owner:CLIMEWORKS

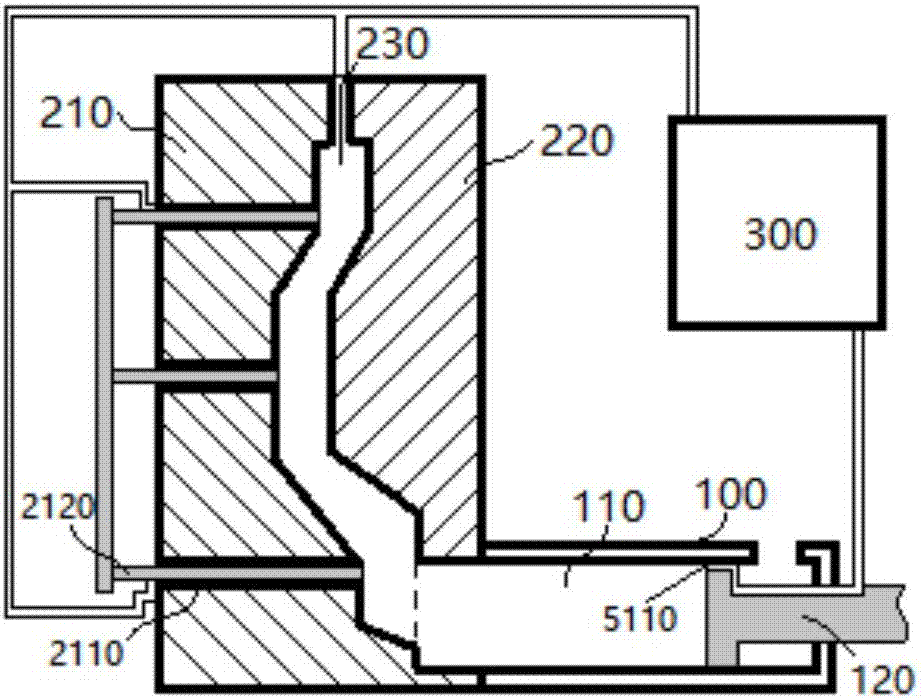

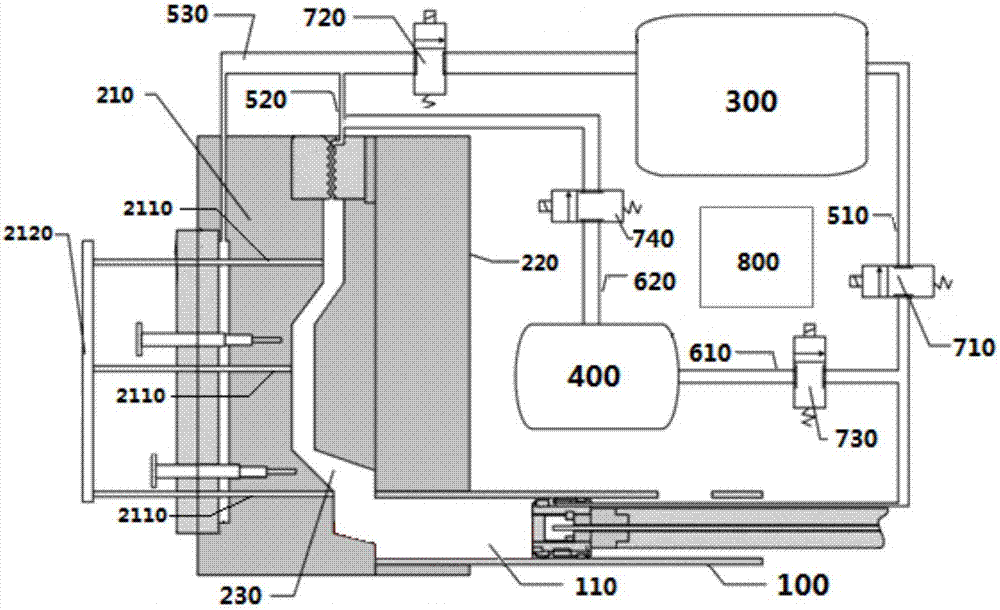

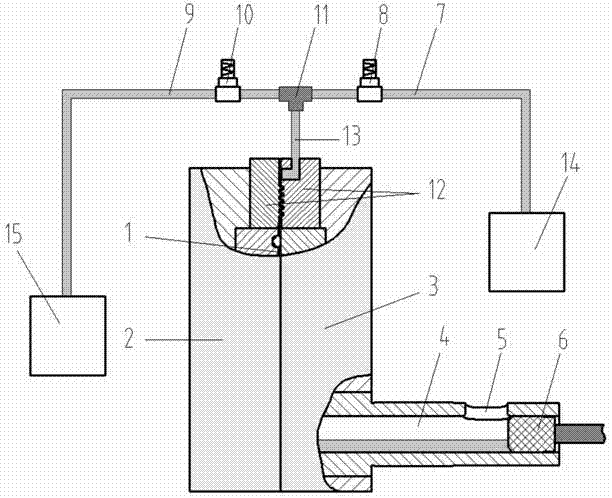

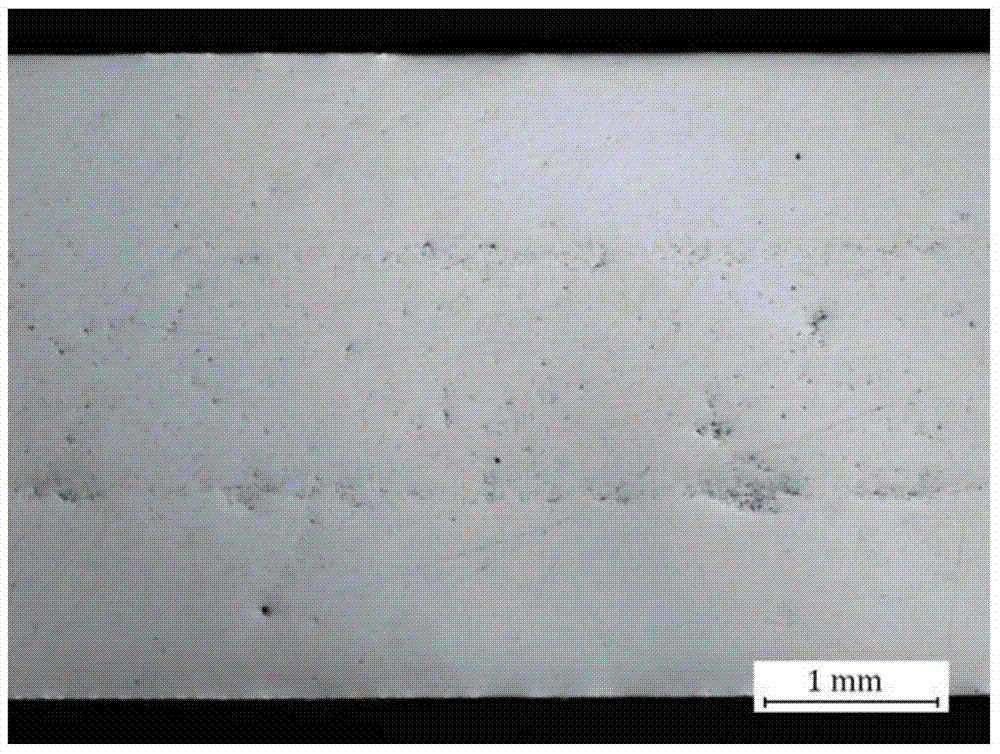

Vacuum die-casting device and high-vacuum die-casting method

The invention provides a vacuum die-casting device and a high-vacuum die-casting method. The vacuum die-casting device comprises a die chamber, a punch, dies, ejector rod through holes, an ejector rod and a vacuum generating device, wherein the die chamber defines a liquid containing space internally; the punch is arranged in the die chamber; the dies comprise a movable die and a static die which are oppositely arranged, a mold cavity is defined between the movable die and the static die, and the mold cavity is connected with the liquid containing space; the ejector rod through holes are formed in the movable die; the ejector rod is arranged in the ejector rod through holes in a sleeved mode; and the vacuum generating device is connected with the die chamber, the mold cavity and the ejector rod through holes and is used for forming vacuums in the die chamber, the mold cavity and the ejector rod through holes, and the vacuum generating device and the die chamber are connected through a first vacuum pipeline opening formed in the top end of the punch. According to the vacuum die-casting device, vacuumizing treatment on the punch in the die chamber and the ejector rod through holes in the movable die is added, and therefore the vacuum pressure of the mold cavity which is fully filled can be ensured to be below 5 kPa, the pore content of a casting which is cast by the high-vacuum die-casting can be effectively reduced, and the process requirements of subsequent heat treatment and welding treatment are met.

Owner:TSINGHUA UNIV

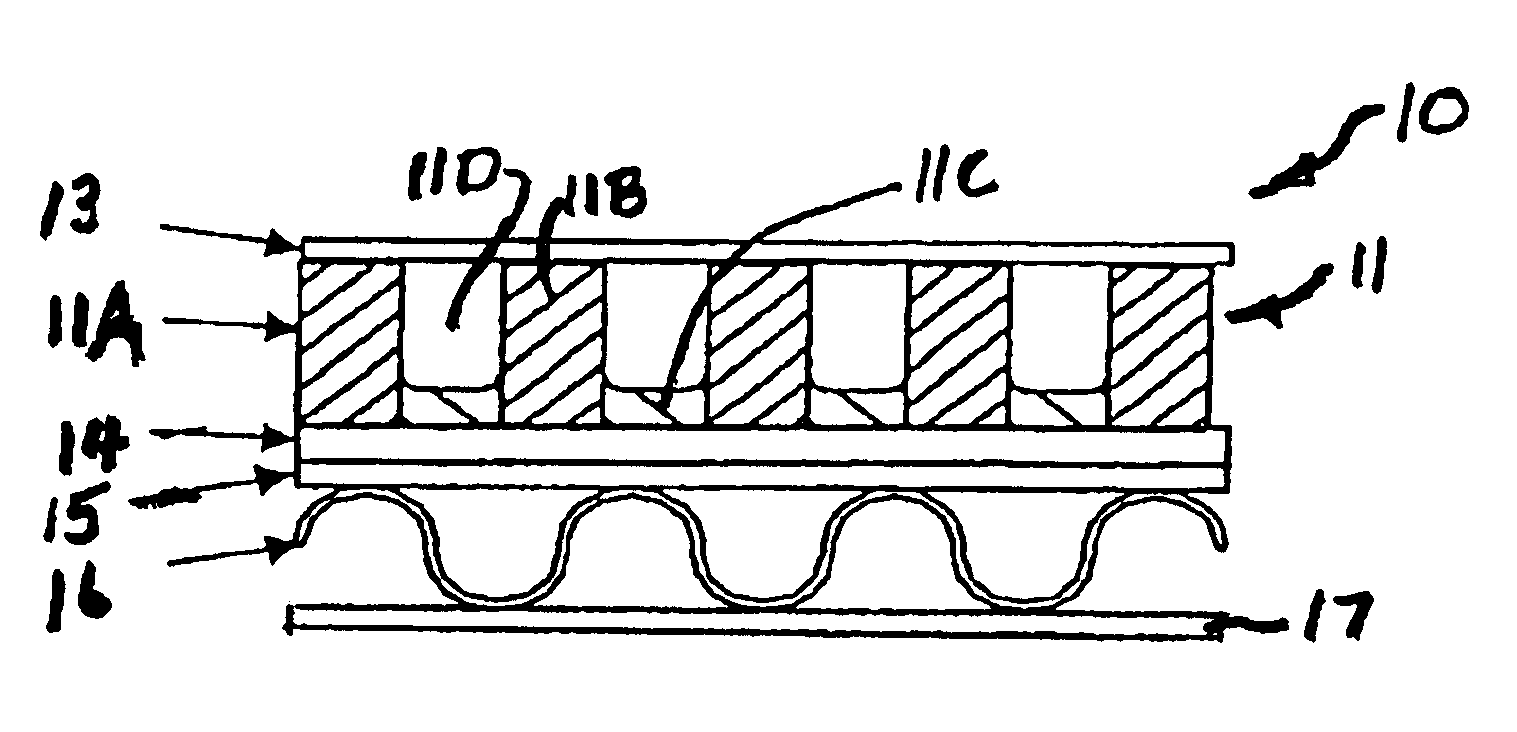

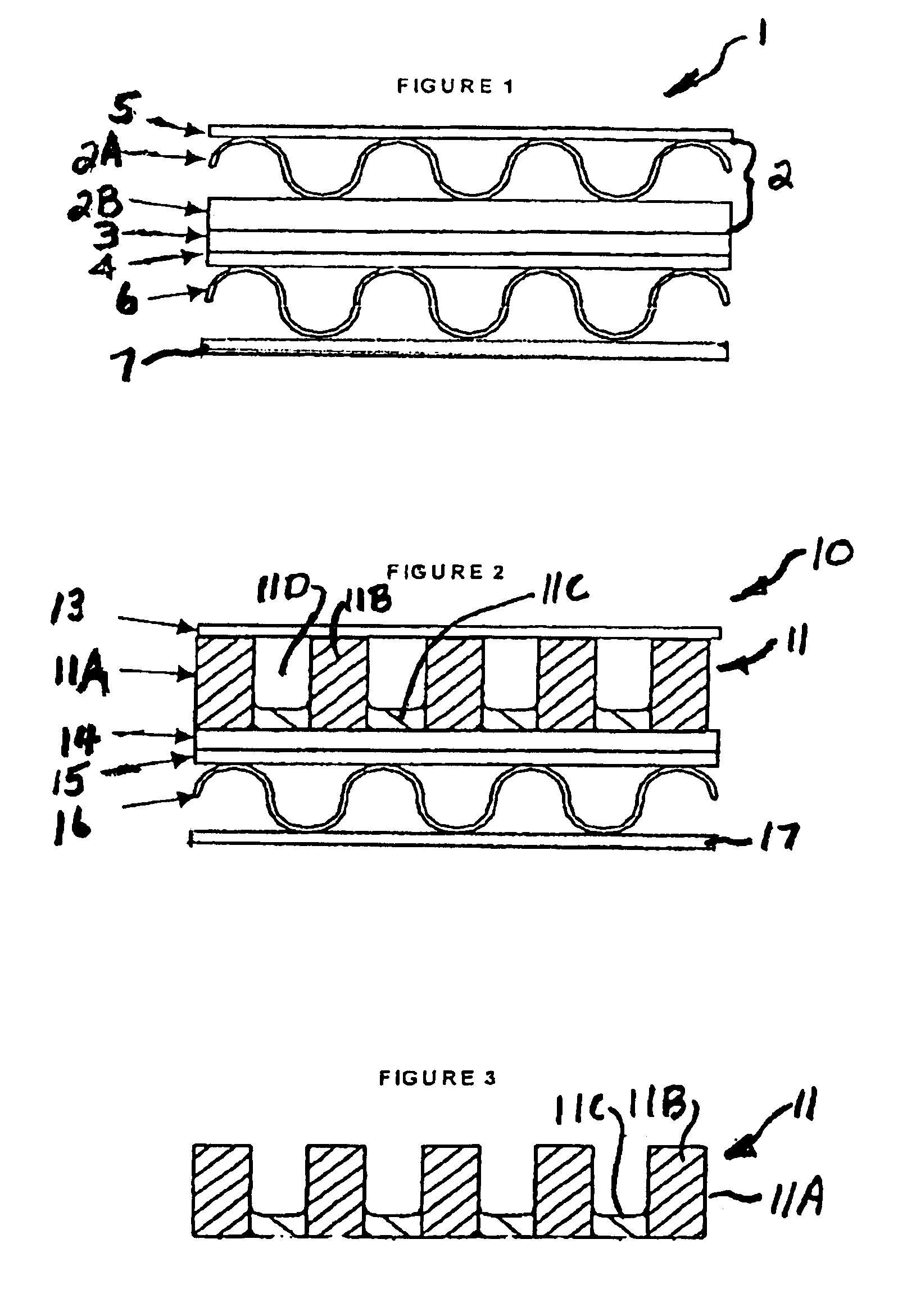

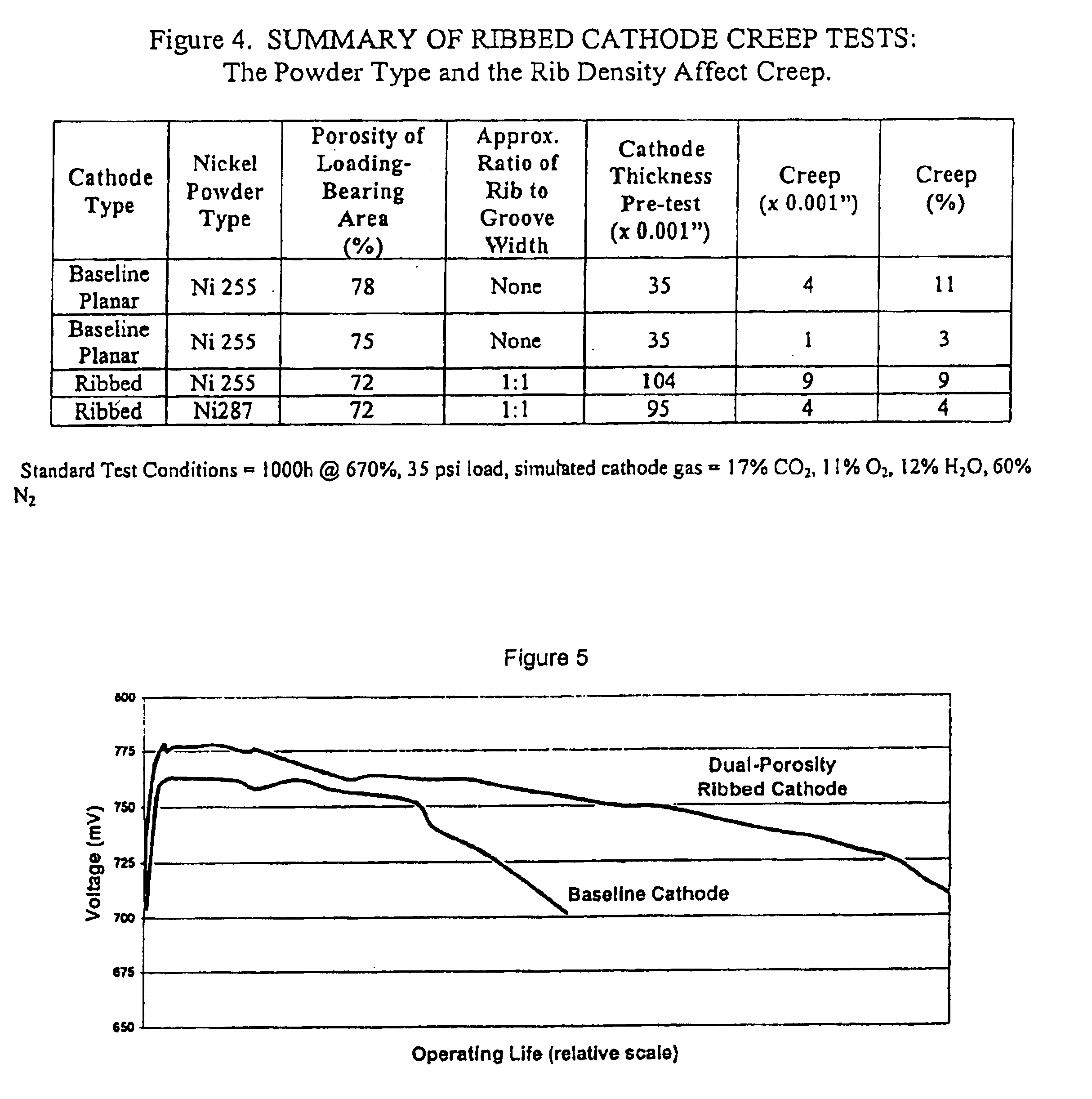

Dual-porosity ribbed fuel cell cathode

InactiveUS6890679B2Increasing the thicknessLess porosityFuel cells groupingElectrode carriers/collectorsPorosityFuel cells

Owner:FUELCELL ENERGY INC

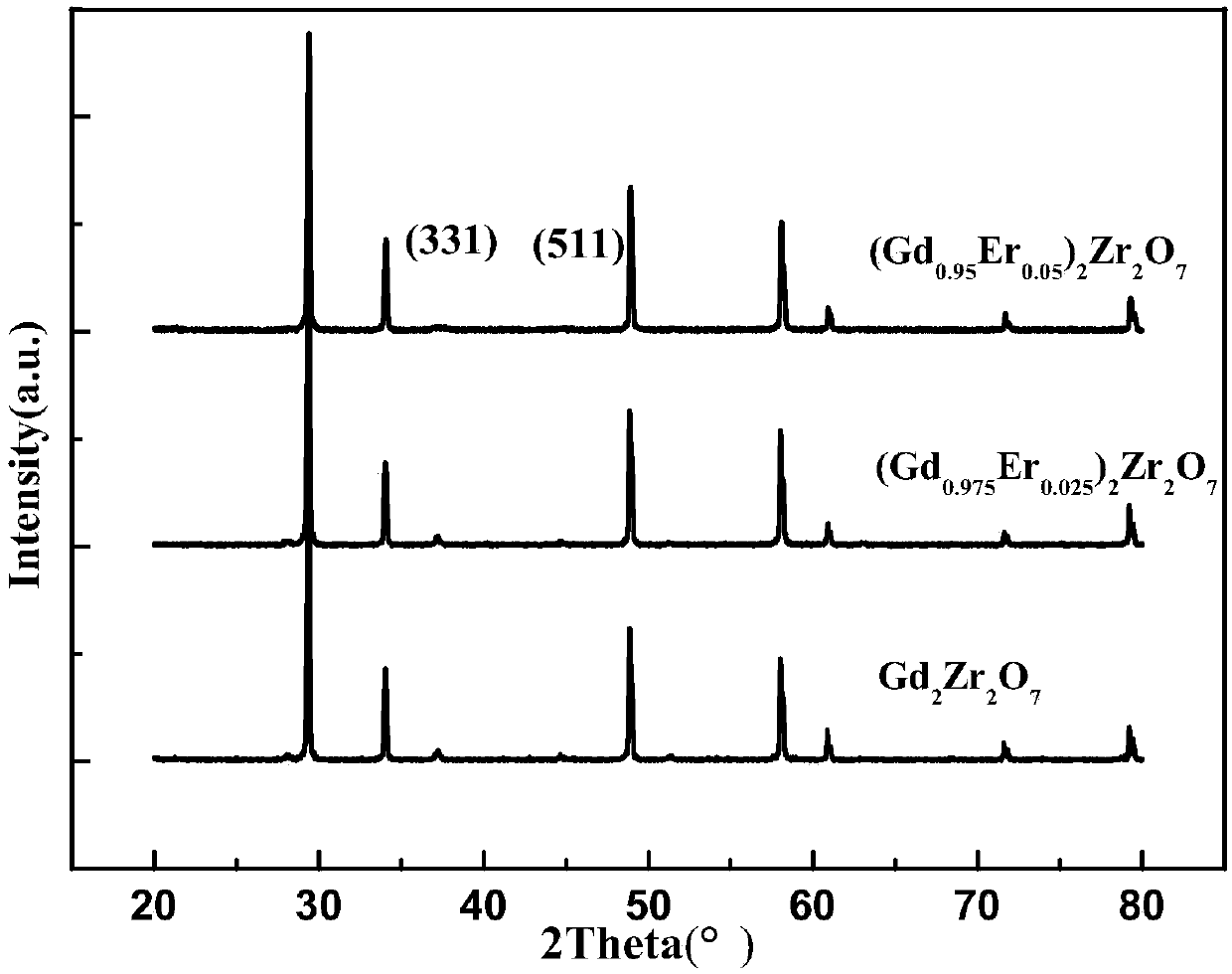

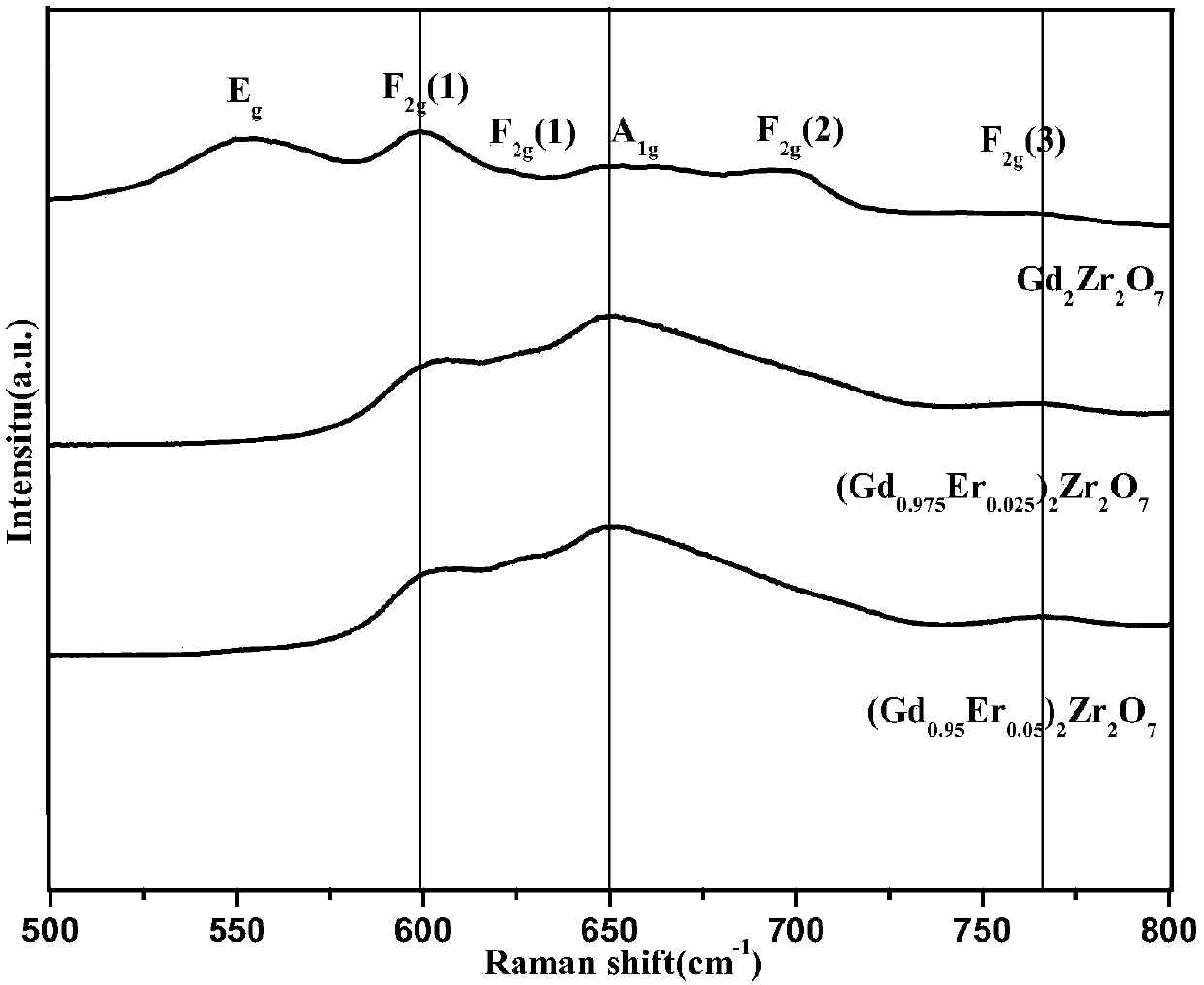

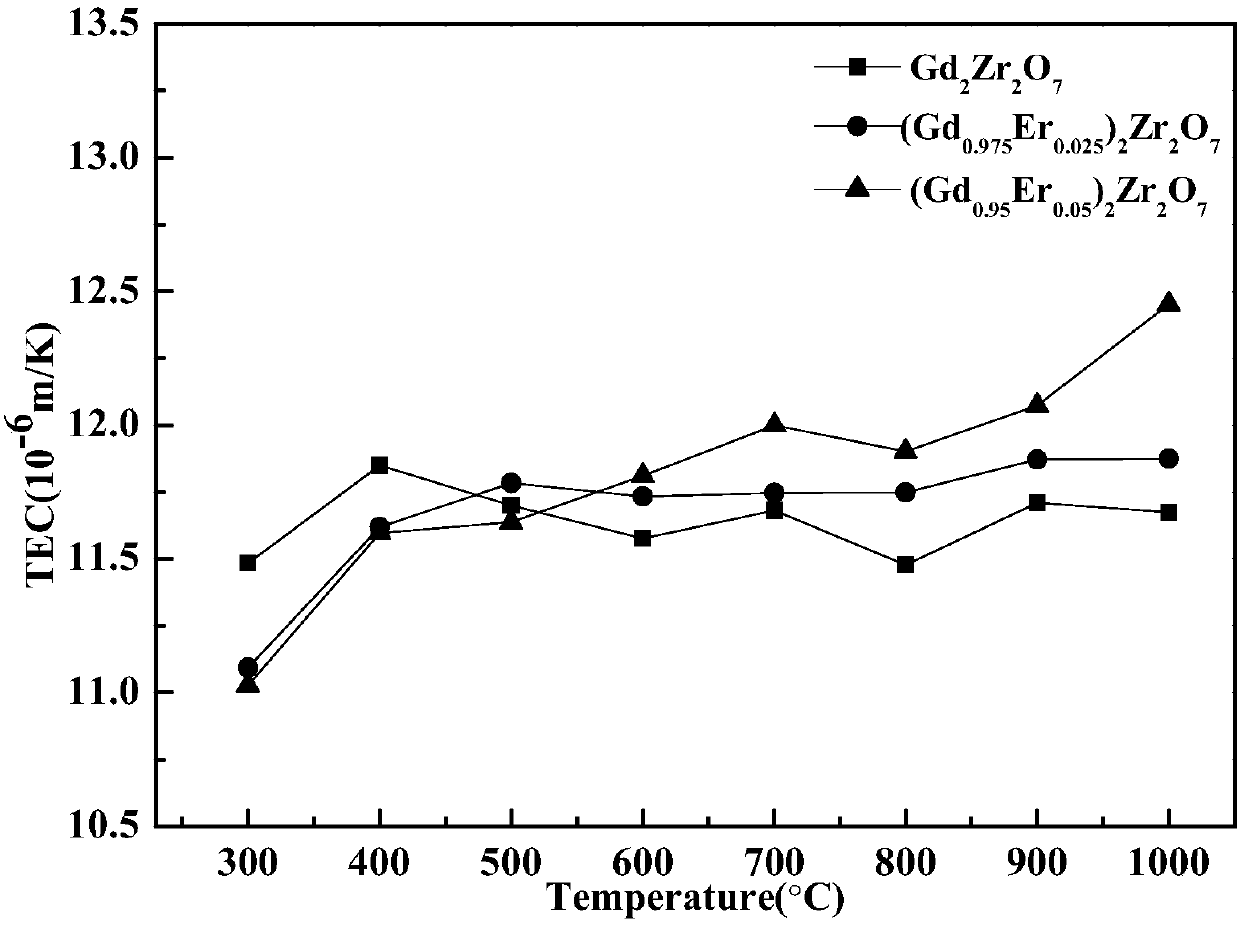

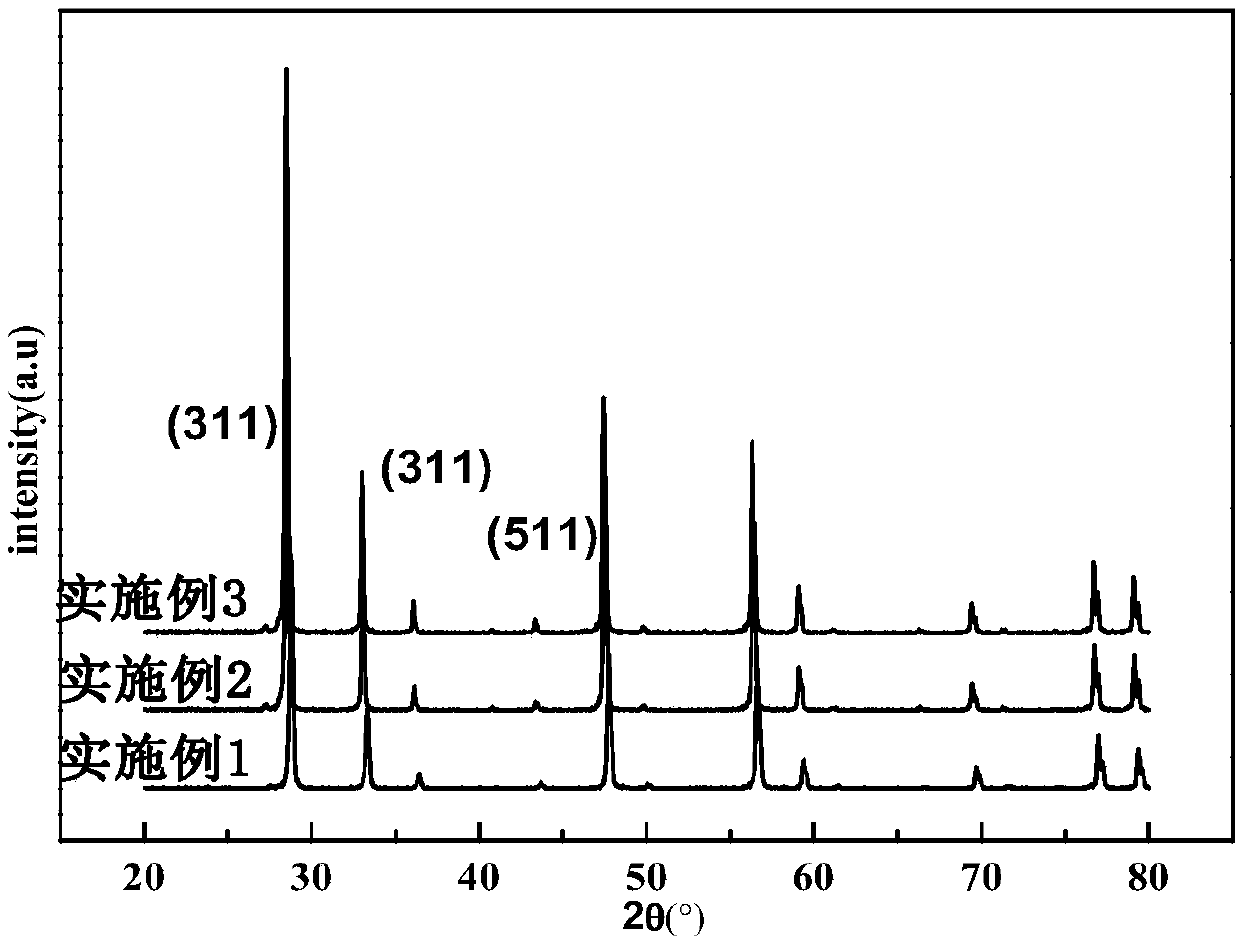

Preparation method of gadolinium zirconate-based material, gadolinium zirconate-based ceramic pelletizing powder for ionic spraying and preparation method of gadolinium zirconate-based ceramic pelletizing powder

ActiveCN108033788AParticle distance is smallLarge specific surface areaMolten spray coatingZirconateMixed materials

The invention provides a preparation method of a gadolinium zirconate-based material, gadolinium zirconate-based ceramic pelletizing powder for ionic spraying and a preparation method of the gadolinium zirconate-based ceramic pelletizing powder. According to the preparation method, oxides are mixed and grinded at a rotation speed which is increased gradually, then large micro-grade granules of rawmaterials are gradually crushed into nano-grade powder, the powder of which the particle size is relatively uniform is made, the powder has a relatively high specific surface area, solid-phase reactions in later sintering process are carried out smoothly, or the mixed material of the powder is further pressed into blocks, then distances among mass points of the powder granules are further reduced, the pore content is reduced, the density is improved, mixed oxide blocks are prepared, the solid-phase reactions in later sintering process are carried out smoothly, the solid-phase reactions can bestill ensured without high-pressure sintering, and a stable pyrochlore structure can be prepared.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

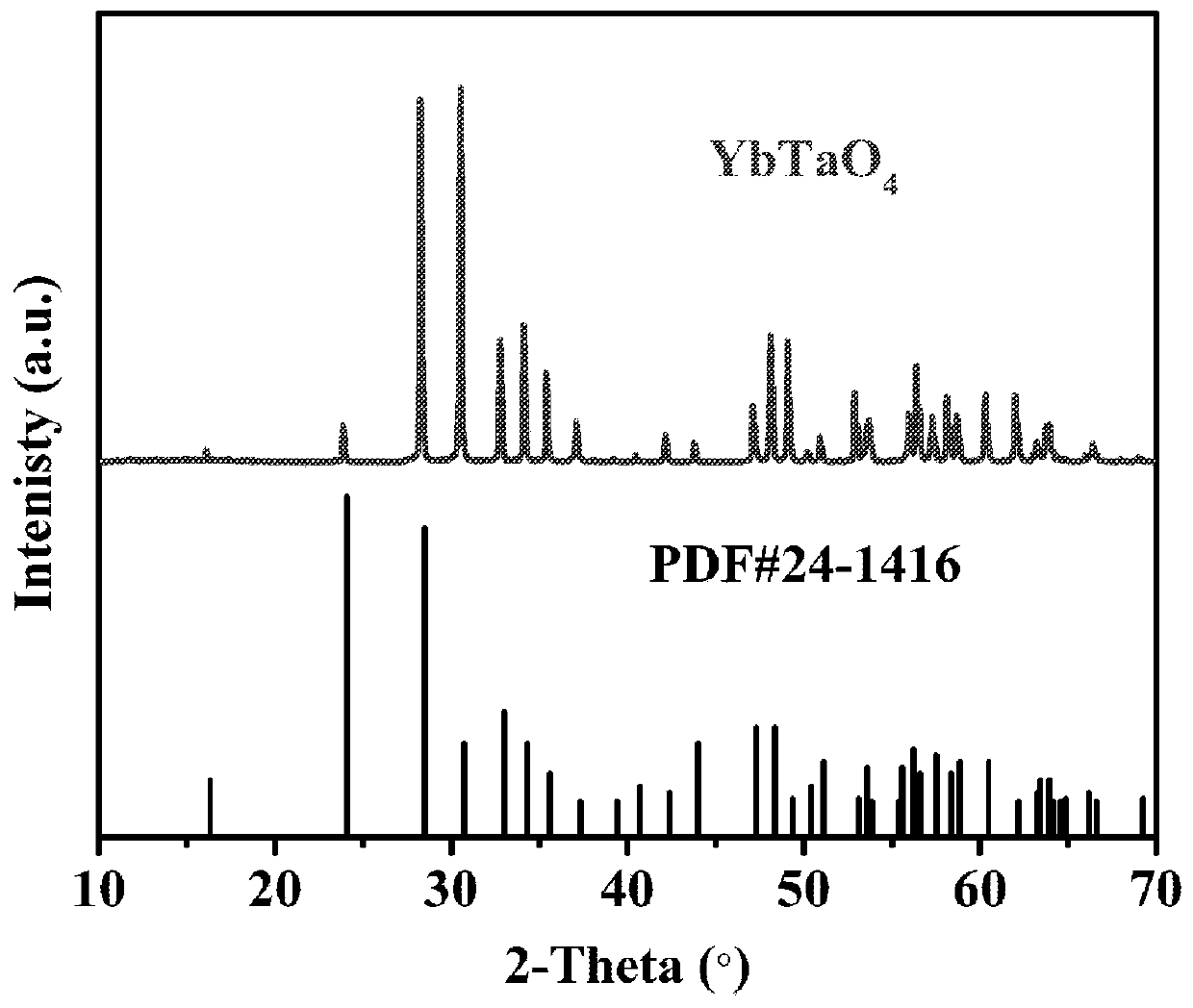

Rare earth ytterbium tantalite ceramic resisting corrosion of low-melting-point oxides and preparation method of rare earth ytterbium tantalite

InactiveCN110002872APrevent penetrationLess cracksBlade accessoriesEfficient propulsion technologiesRare earthSolvent

The invention relates to the technical field of thermal barrier coatings, and particularly discloses a rare earth ytterbium tantalite ceramic resisting corrosion of low-melting-point oxides and a preparation method of the rare earth ytterbium tantalite. The ceramic is formed by sintering of Yb2O3 powder and Ta2O5 powder, the chemical general formula of the ceramic is YbTaO4 or Yb3TaO7, and the compactness of the ceramic is greater than 97%; the preparation method of the ceramic comprises the steps that the Yb2O3 powder and the Ta2O5 powder are weighed, a solvent is added for mixing, the mixture is subjected to ball milling by a ball mill, and powder A is obtained; the powder A is dried and sieved, and powder B is obtained; the powder B is compacted and pre-sintered to form a block C, and the block C is cooled and ground by a grinding machine and is subjected to secondary sieving to obtain powder D; the powder D is sintered to obtain the rare earth ytterbium tantalite ceramic resistingthe corrosion of the low-melting-point oxides. By adopting the technical scheme, the obtained ytterbium tantalite ceramic is high in compactness and can resist high-temperature corrosion of the low-melting-point oxides.

Owner:KUNMING UNIV OF SCI & TECH

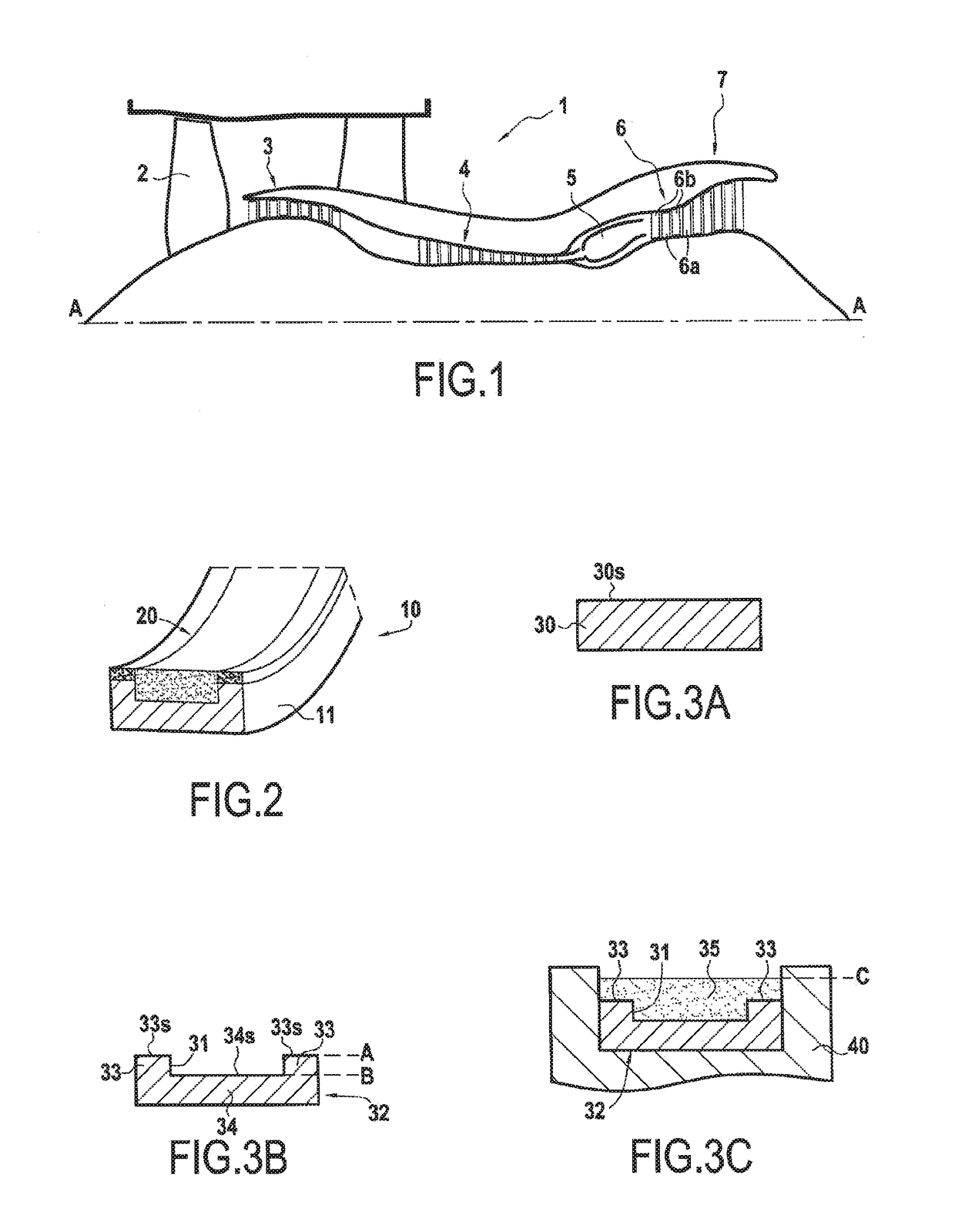

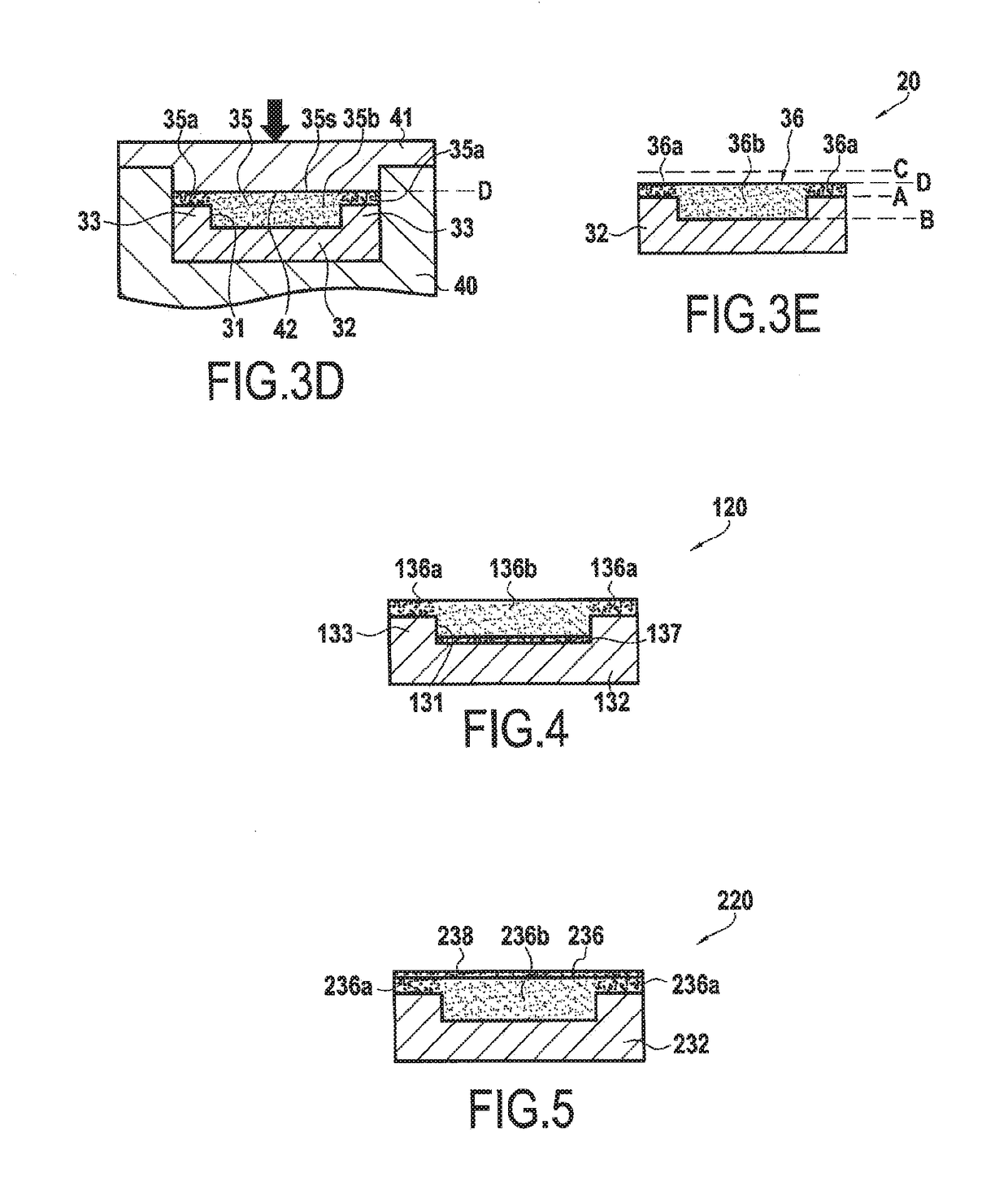

Abradable coating having variable densities

ActiveUS20180361480A1Easily abradableIncrease material densityPump componentsEfficient propulsion technologiesBearing surfaceVariable density

A method of fabricating an abradable coating of varying density, and such an abradable coating of varying density. According to the invention, the method comprises the following steps: providing a substrate (32) having a first portion with its surface situated at a first level (A), and a second portion with its surface situated at a second level (B) different from the first level; depositing a precursor material on the first and second portions of the substrate (32); compressing the precursor material between the substrate and a bearing surface; and sintering the precursor material as compressed in this way in order to obtain an abradable coating (36) having a first portion (36a) on the first portion of the substrate, and possessing a first density, and a second portion (36b) on the second portion of the substrate, and possessing a second density distinct from the first.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A +2

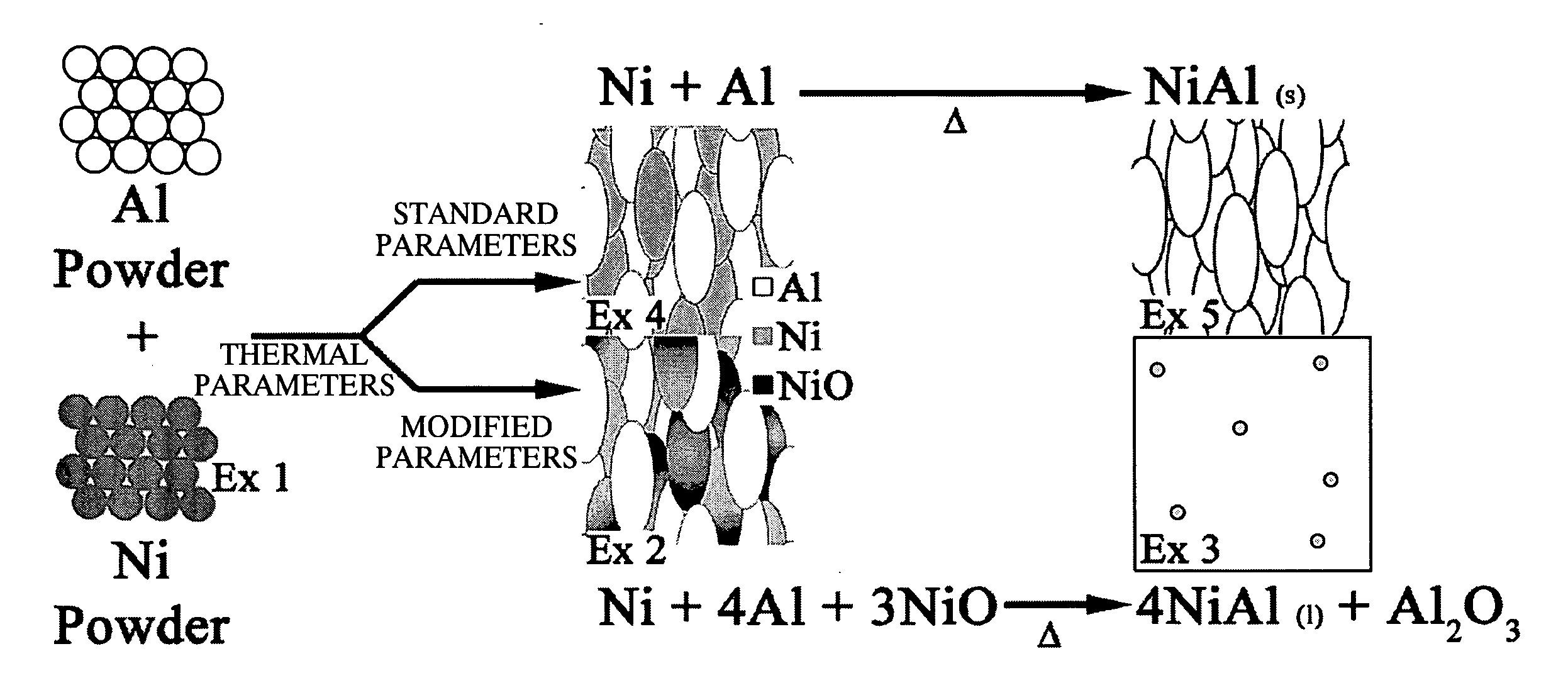

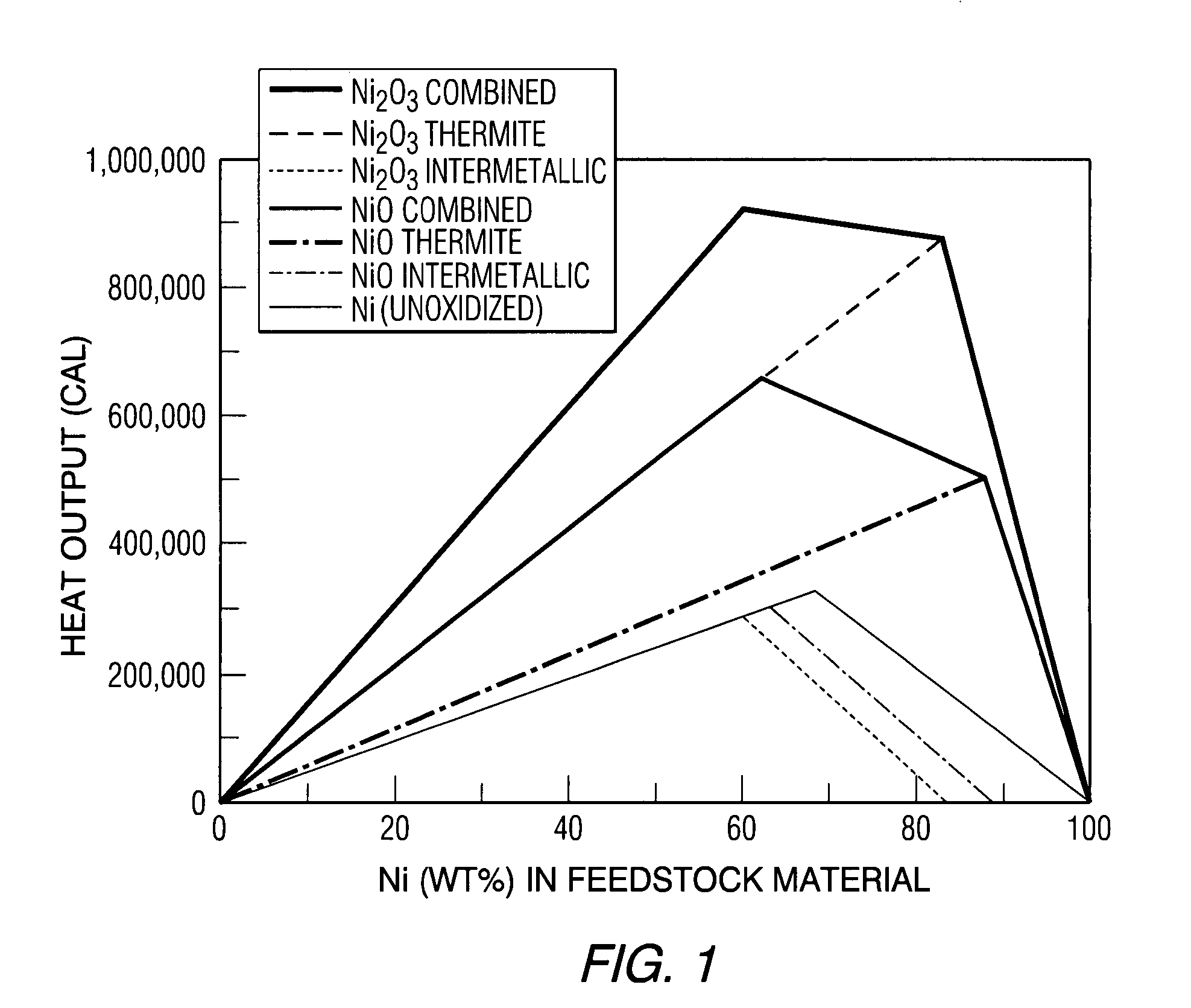

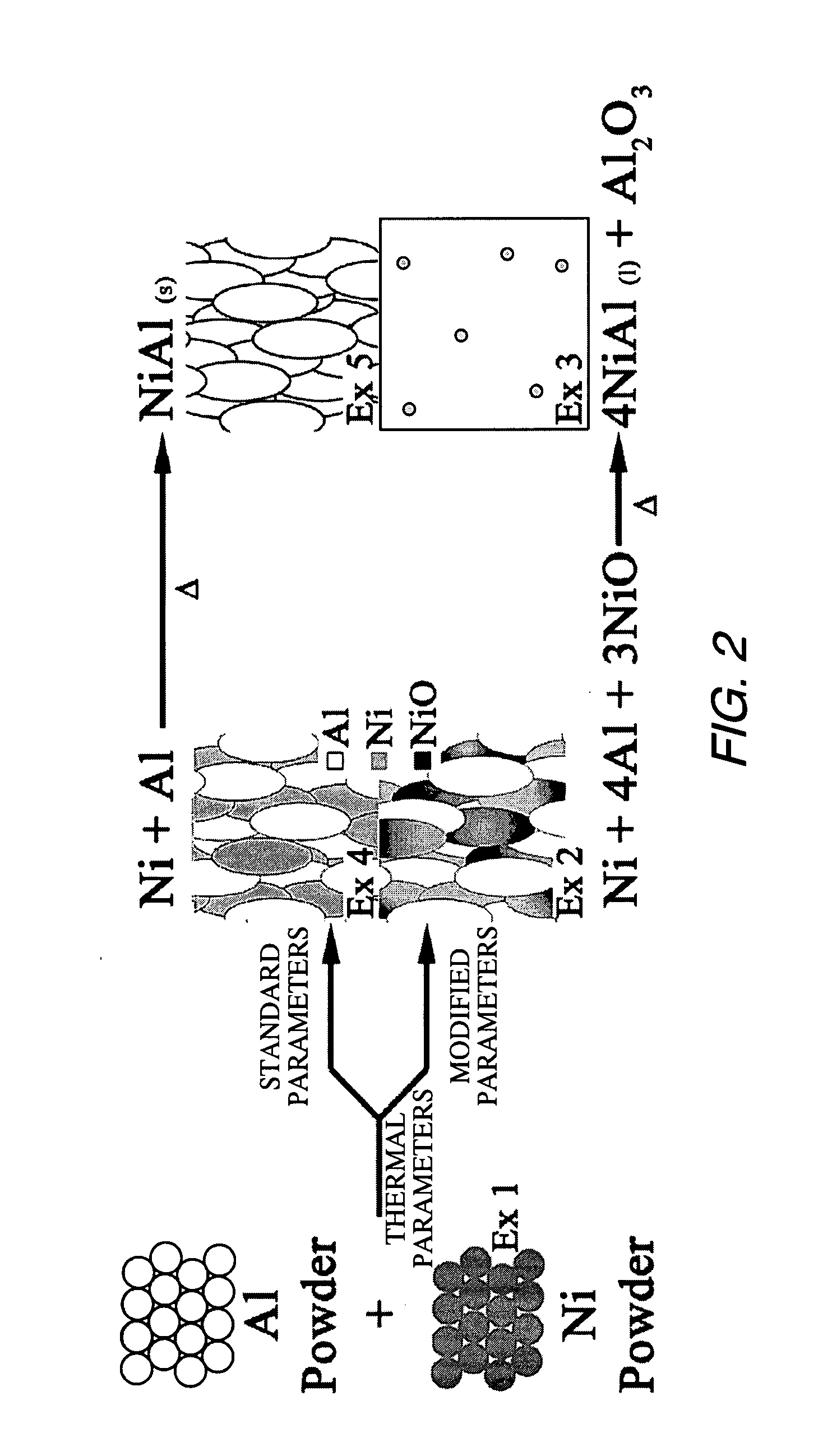

Thermal deposition of reactive metal oxide/aluminum layers and dispersion strengthened aluminides made therefrom

InactiveUS20080038149A1Less porosityGood contactMolten spray coatingSealing arrangements for enginesExothermic reactionAluminide

Metal aluminides are formed by an initial thermal deposition process which forms an intermediary material comprising elemental aluminum and another elemental metal, as well as an oxide of the other metal. The thermally formed intermediary material is subsequently heated to initiate an exothermic reaction which forms the metal aluminide material. The reaction may be initiated by localized or bulk heating of the intermediary material, and may involve reaction between the aluminum and elemental metal as well as a thermite reaction between the aluminum and the metal oxide. The resultant metal aluminide material may be substantially fully dense and may contain oxide strengthening precipitates such as aluminum oxide.

Owner:SURFACE TREATMENT TECH INC

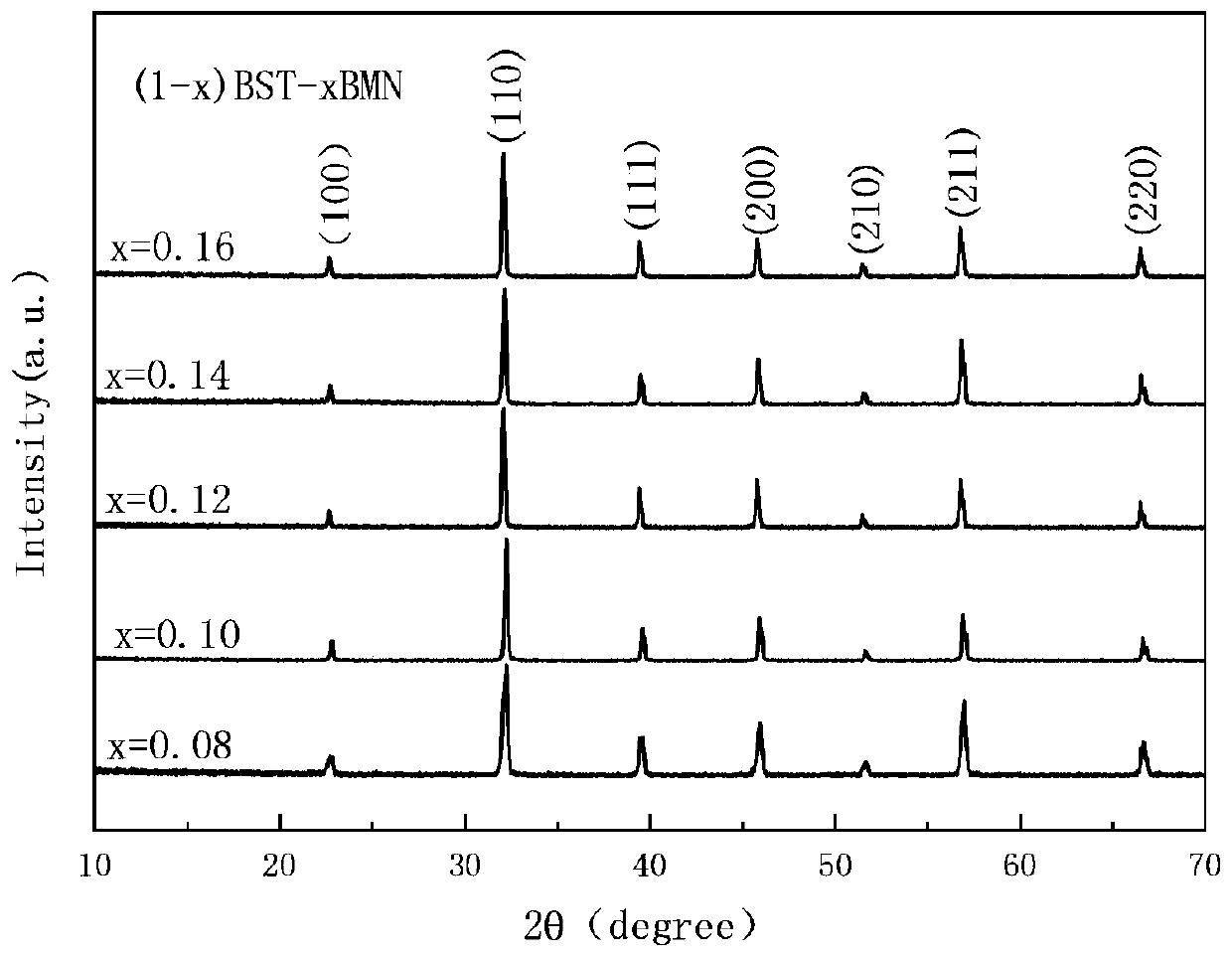

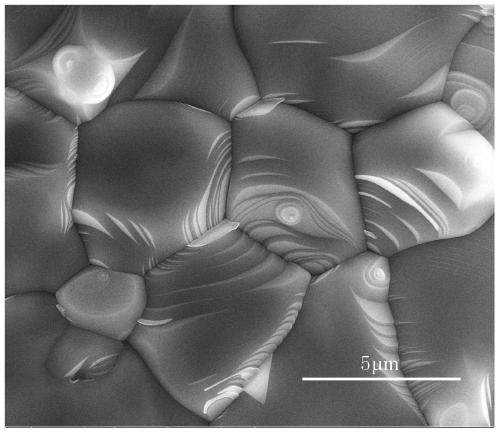

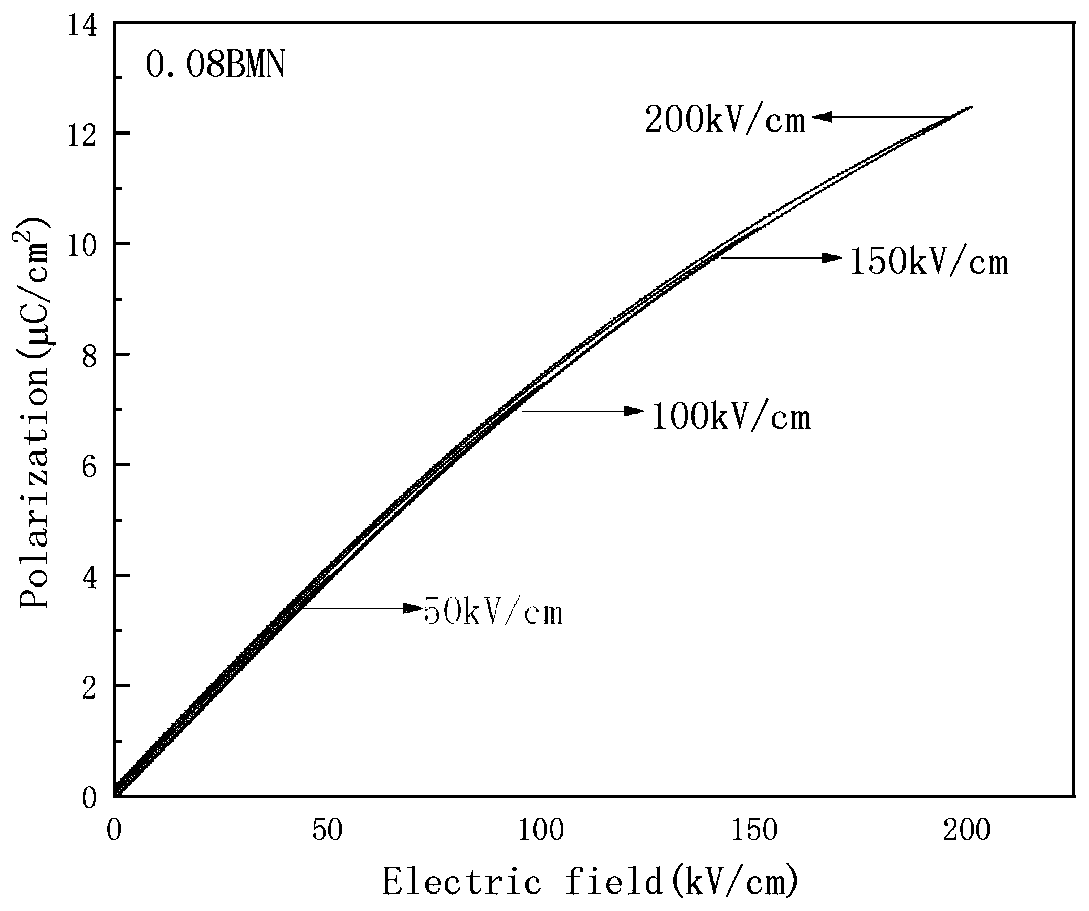

Barium strontium titanate-based ceramic material as well as preparation method and application thereof

InactiveCN111484325AImprove energy storage characteristicsHigh dielectric relaxivityStrontium titanateBarium strontium titanate

The invention provides a barium strontium titanate-based ceramic material as well as a preparation method and application thereof, and belongs to the technical field of energy storage ceramic materials. The chemical composition of the barium strontium titanate-based ceramic material provided by the invention is (1-x) Ba < 0.8 > Sr < 0.2 > TiO < 3-x > Bi (Mg < 2 > / 3Nb < 1 / 3 >) O < 3 >, and x is greater than or equal to 0.08 and less than or equal to 0.16. The barium strontium titanate-based ceramic material provided by the invention has high energy storage density and energy storage efficiency.Results show that the barium strontium titanate-based ceramic material provided by the invention has high dielectric relaxation and breakdown resistance, and can obtain a slender hysteresis loop; under an external electric field of 250 kV / cm, the effective energy storage density of the barium strontium titanate-based ceramic material is 2.028 J / cm < 3 >, and the energy storage efficiency reaches96.8%.

Owner:XIAN TECHNOLOGICAL UNIV

PTFE (polytetrafluoroethylene)-based ceramic composite with near-zero dielectric constant temperature coefficient and preparation method of ceramic composite

The invention discloses a PTFE (polytetrafluoroethylene)-based ceramic composite with near-zero dielectric constant temperature coefficient and a preparation method of the ceramic composite, and belongs to the technical field of PTFE-based ceramic composites. Ceramic powder with near-zero and positive dielectric constant temperature coefficient and glass fiber are selected as inorganic filler, andsubjected to surface modification, so that the surfaces of the ceramic powder and the glass fiber are grafted with -C-F2-chemical chain with structure similar to that of PTFE, PTFE is demulsified inthe ball milling process with a ball milling composite process, the ceramic powder and the glass fiber can be evenly distributed in PTFE by ball milling movement, and the composite with excellent performance is obtained. The process is reasonable, the filler mixing process is simple, the inorganic filler is uniformly dispersed in PTFE, and various properties of the PTFE microwave composite substrate material filled with the ceramic powder are greatly improved. The preparation process is greatly simplified while stable performance of the composite substrate material is guaranteed, and mass production can be met.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Lanthanum zirconate-based ceramic granulated powder for atmospheric plasma spraying and preparation method thereof

The invention provides lanthanum zirconate-based ceramic granulated powder for atmospheric plasma spraying and a preparation method thereof. The preparation method comprises the steps that mixed materials with the particle size of 60 nm or below are pressed into blocks, the material point distance among powder particles is reduced, the content of pores is reduced, and the densification is improved; mixed oxide blocks are obtained, and a solid phase reaction in the following sintering process is conducted smoothly and conveniently. In combination of the sintering process, the solid phase reaction of different oxides in the mixed materials is achieved, a lanthanum zirconate-based material is obtained and further crushed, low-speed sanding with low energy consumption is conducted at first, the loss of grinding bodies is reduced, the preliminary refinement of the larger sintered particles after sintering is achieved, and further refinement is facilitated; in combination with high-speed sanding at the second stage, nano-powder is obtained, the dispersion is good, the particle size is even, and the granulation requirements are met. Subsequently, in strict accordance with a defined granulation mode, the ceramic granulated powder meeting APS requirements is obtained.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

Dental zirconia all-ceramic material and preparation method thereof

InactiveCN110078500AGuaranteed antibacterial propertiesConstrained growth processCeramicwareMetallurgySolvent free

The invention relates to a preparation method of a dental zirconia all-ceramic material. The dental zirconia all-ceramic material is prepared with a preparation method comprising steps as follows: accurately weighing raw materials including ceramic powder, a pore forming material, a binder, a stabilizer and an auxiliary for preparing the dental zirconia all-ceramic material in a certain ratio; performing mixed ball milling or sanding on the ceramic powder, the stabilizer and at least part of the auxiliary in the presence of a certain quantity of a solvent or under the solvent-free condition toobtain material powder, adding the pore forming material, the binder and the remaining auxiliary to the material powder under the heating or cooling condition respectively to obtain a material suspension, and placing the material suspension in a die for cooling and drying to obtain the dental zirconia all-ceramic material.

Owner:南京赛诺特斯材料科技有限公司

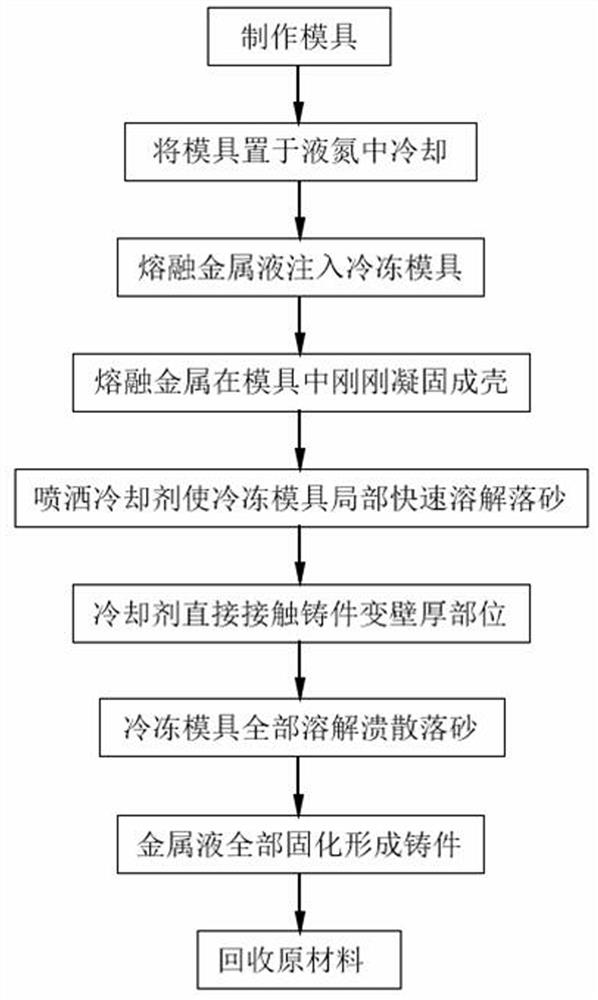

Environment-friendly freezing-dissolving casting process

ActiveCN112642994AHigh strengthSpeed up coolingFoundry mouldsFoundry coresManufactured materialMaterials science

The invention provides an environment-friendly freezing and dissolving casting process and belongs to the technical field of casting. The process comprises the steps that a mold is fabricated by using molding sand and water, the mold is frozen to obtain a frozen mold, molten metal liquid is injected into the frozen mold, molten metal is solidified into a shell in the mold, cooling water is sprayed to the wall thickness portion of the mold, the frozen mold is made to be locally and quickly dissolved and collapsed, the cooling water makes direct contact with the variable wall thickness portion of a casting for cooling, and the molten metal is completely cured to form a target casting to recycle the molding sand, a coolant and other raw materials. By means of the environment-friendly freezing and dissolving casting process, the cooling speed of the casting can be increased, the cooling speed rate of the variable wall thickness portion of the casting is balanced, and the mechanical performance of the variable wall thickness complex casting is greatly improved; and meanwhile, the sand falling cleaning link is omitted along with final freezing mold dissolution and collapse sand falling, furthermore, casting wastes are few, and the environment-friendly freezing and dissolving casting process is a novel environment-friendly casting technology and has a great development prospect.

Owner:ZHONGBEI UNIV

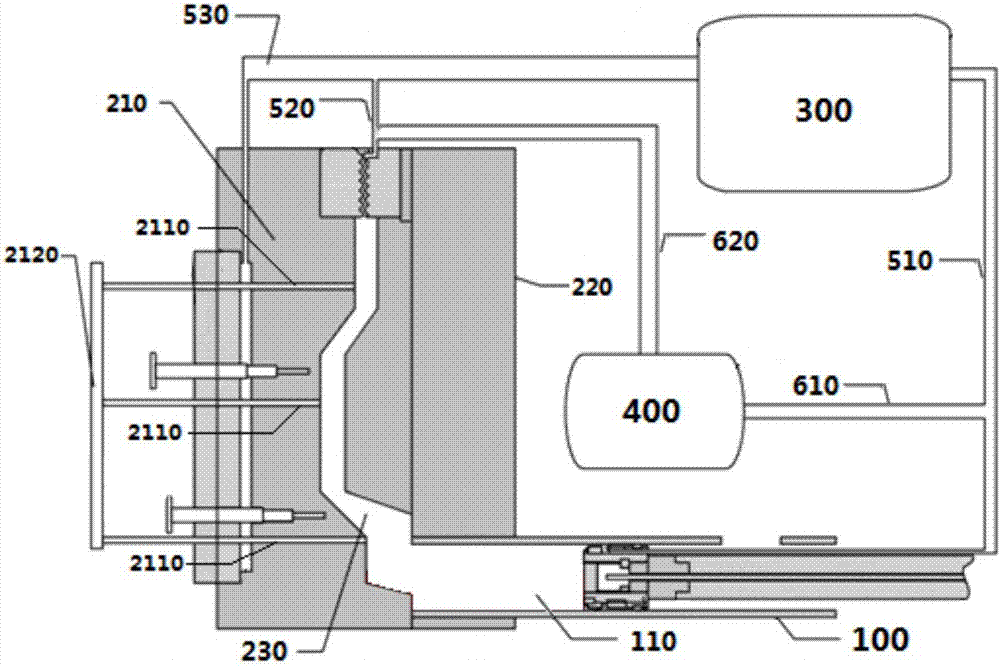

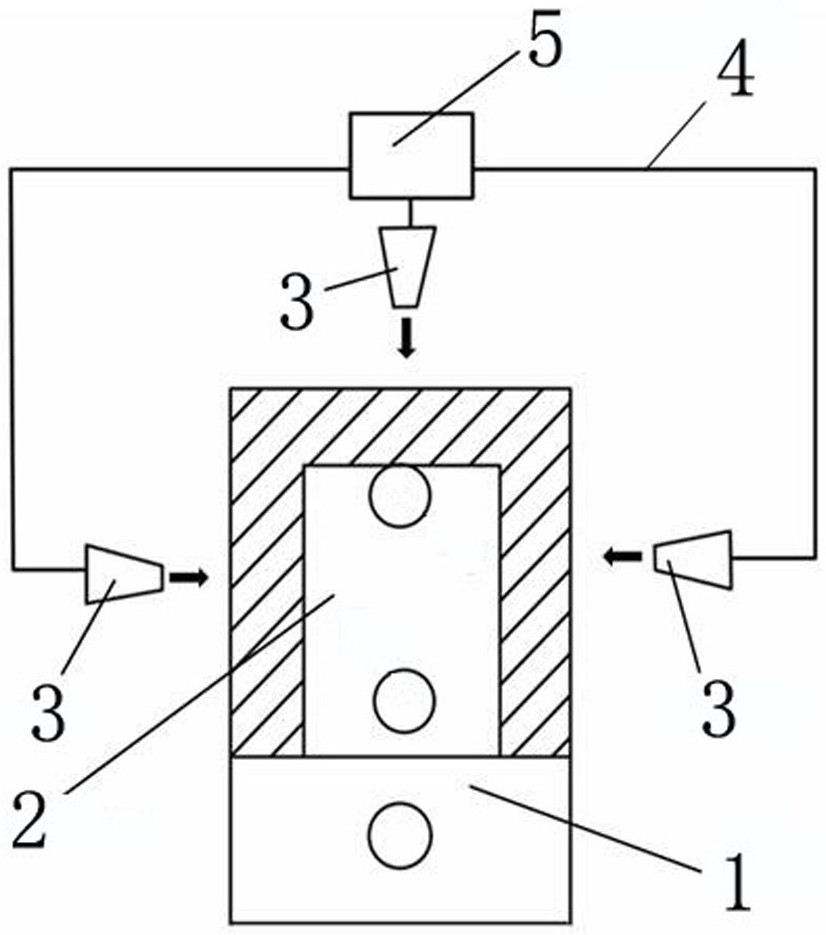

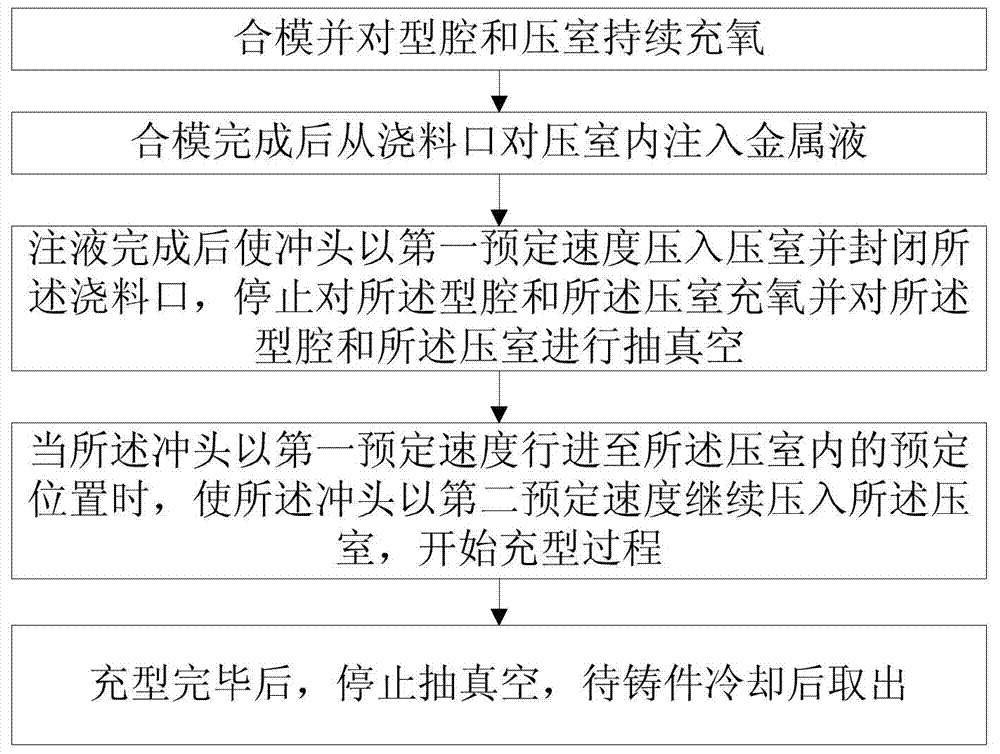

Oxygenating-vacuum die casting die device and oxygenating-vacuum die casting process

The invention provides an oxygenating-vacuum die casting die device and an oxygenating-vacuum die casting process. The oxygenating-vacuum die casting process comprises the following steps that die assembling is carried out, and a mold cavity and a pressure chamber are continuously oxygenated; after die assembling is completed, molten metal is injected into the pressure chamber from a casting material opening; after liquid injection is completed, a puncher pin is pressed into the pressure chamber at first preset speed and seals the casting material opening, the mold cavity and the pressure chamber are stopped from being oxygenated, and the mold cavity and the pressure chamber are vacuumized; when the puncher pin moves to the preset position in the pressure chamber at the first preset speed, the puncher pin continues to be pressed into the pressure chamber at second preset speed, and the mold filling process is started; after mold filling is completed, vacuumizing is stopped, and a casting is taken out after being cooled. According to the oxygenating-vacuum die casting process, the limit that a vacuum die casting process has high requirements for the vacuum degree of the mold cavity is overcome, and meanwhile the problem that a large amount of heat is released when an oxygenating die casting process is independently used is solved.

Owner:TSINGHUA UNIV

Resin ceramic wear-resistant composite material and preparation method thereof

The invention provides a resin ceramic wear-resistant composite material and a preparation method thereof. The method comprises the steps: firstly, respectively preparing a polyurethane prepolymer, an epoxy resin component and a curing agent component; then premixing silicon carbide and brown fused alumina filler, and then mixing with a polyurethane prepolymer, an epoxy resin component, a curing agent component, a silane coupling agent, a dispersing agent and a defoaming agent to obtain a castable of the composite material; and finally, injecting the castable into a mold, curing and molding, and demolding to obtain the resin ceramic wear-resistant composite material. The mass fraction of the composite material ceramic filler prepared by the method can reach 87%, the composite material is firmly combined with an embedded part, cracks caused by stress are avoided, the composite material is particularly suitable for manufacturing flow passage components of large transmission equipment, and the prepared wear-resistant composite material flow passage component has the service life in the same working condition environment up to 8 times or more of that of a traditional high-chromium alloy material flow passage component.

Owner:洛阳嘉斯诺泵业制造有限公司

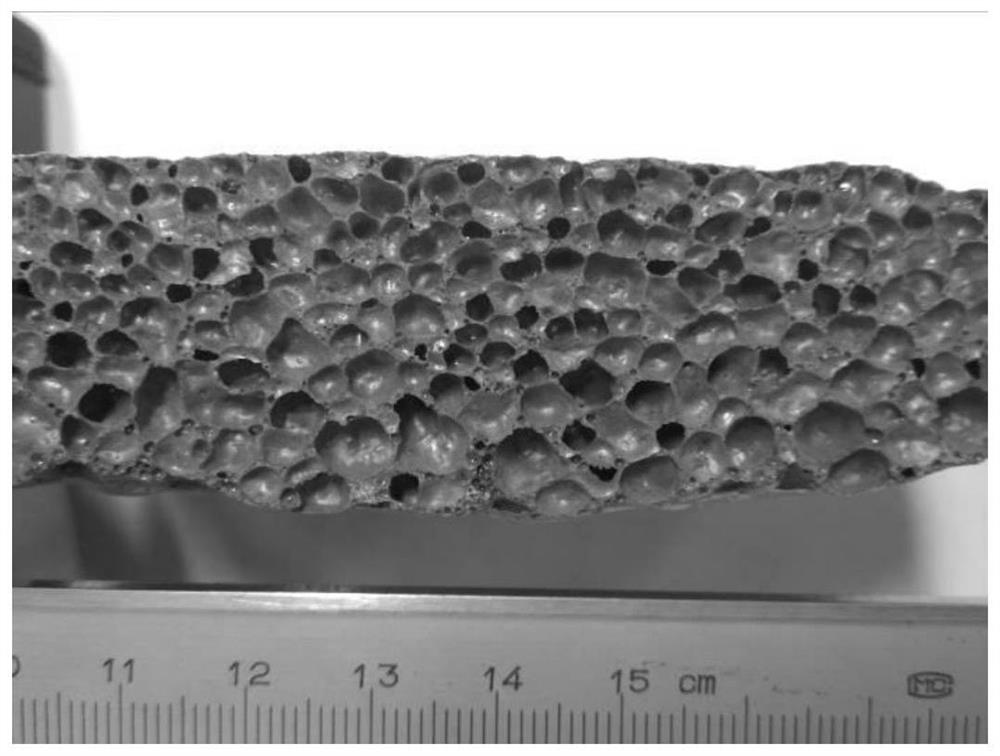

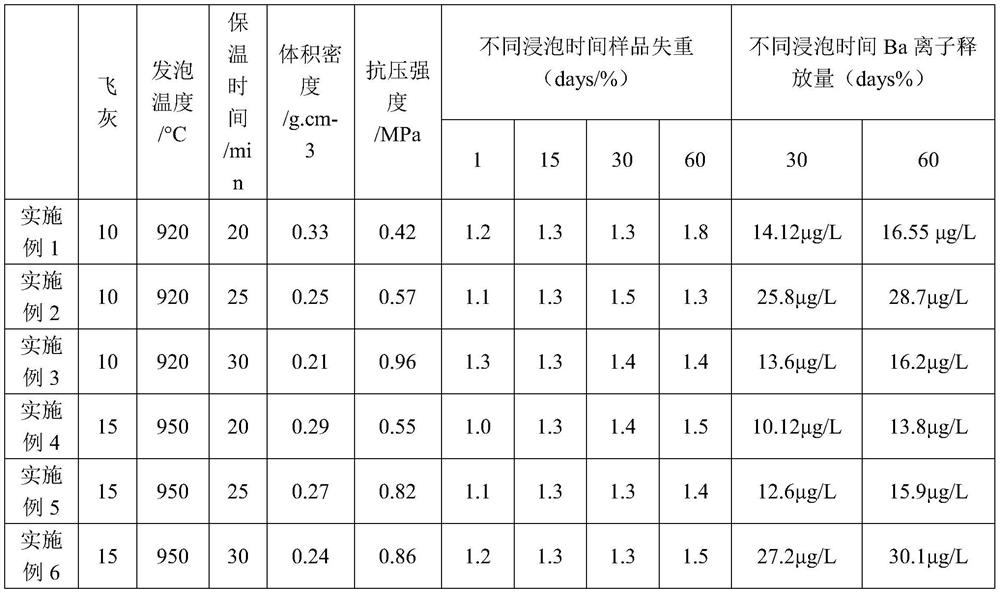

Foam glass prepared from fly ash as well as preparation method and application thereof

PendingCN112279498AEfficient decompositionAvoid harmGlass shaping apparatusFoaming agentPolluted environment

The invention discloses foam glass prepared from fly ash as well as a preparation method and application of the foam glass, and belongs to the technical field of foam glass preparation. Fly ash and glass powder are adopted as raw materials and mixed with a foaming agent, then a PVB alcoholic solution is added for granulation, and after molding, high-temperature foaming is conducted through two times of heating, so that the foam glass is obtained. Through two times of heating and heat preservation, part of dioxin can be effectively decomposed, and meanwhile, the formation amount of a high-temperature melt phase is promoted so as to effectively coat residual dioxin, high chlorine, high calcium and heavy metal components. According to the method, the high-temperature melt effectively coats the high chlorine, high calcium, heavy metal components and residual dioxin, the heavy metal elements are left to stand in water for a long time, leakage of the high calcium and high chlorine componentsis little, and harm of the components to the environment is avoided. The method is simple in process and suitable for large-scale production, the fly ash is adopted as the raw material, and the problem of environmental pollution is solved while the low-cost raw material is obtained.

Owner:SHAANXI UNIV OF SCI & TECH

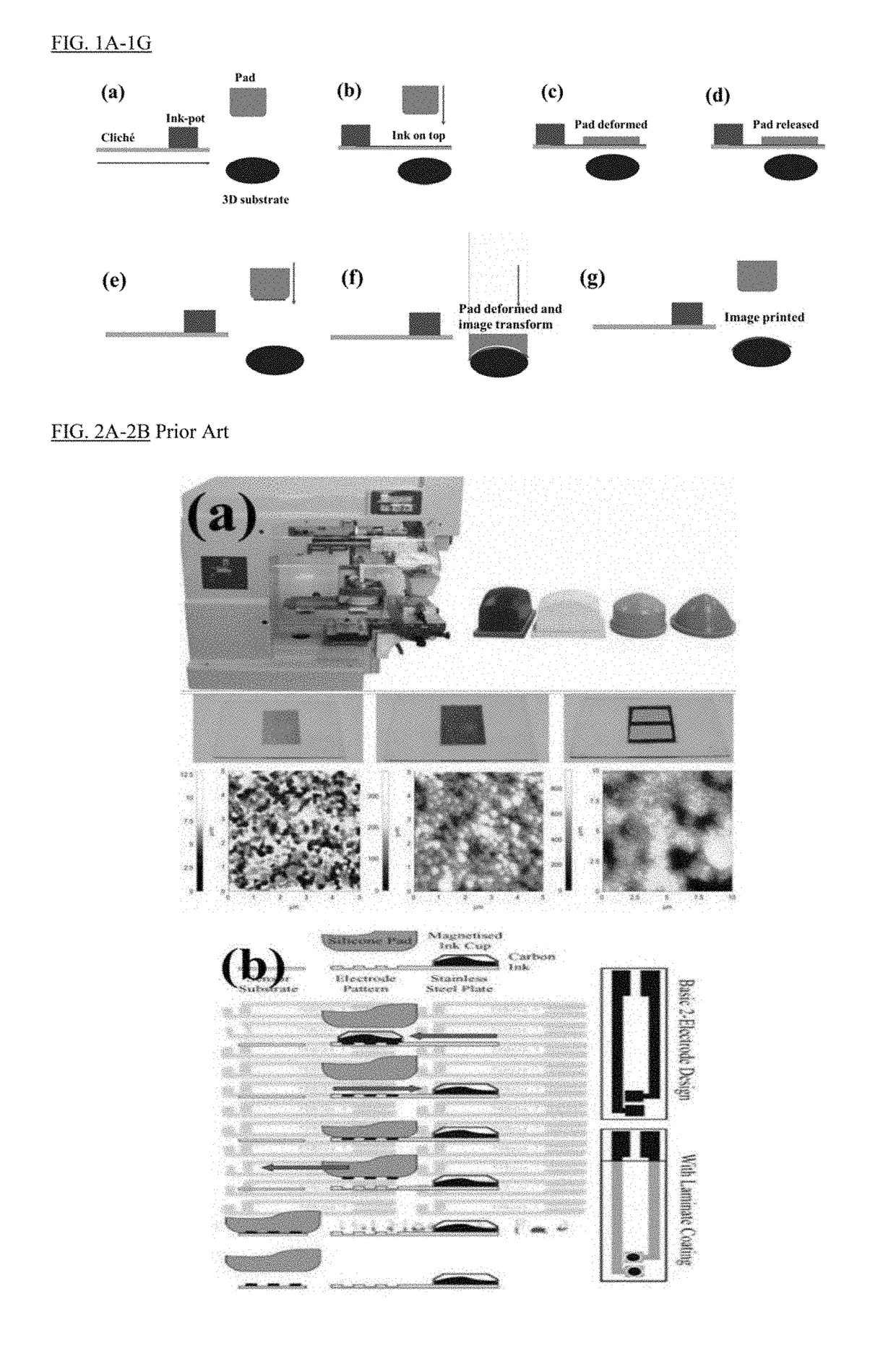

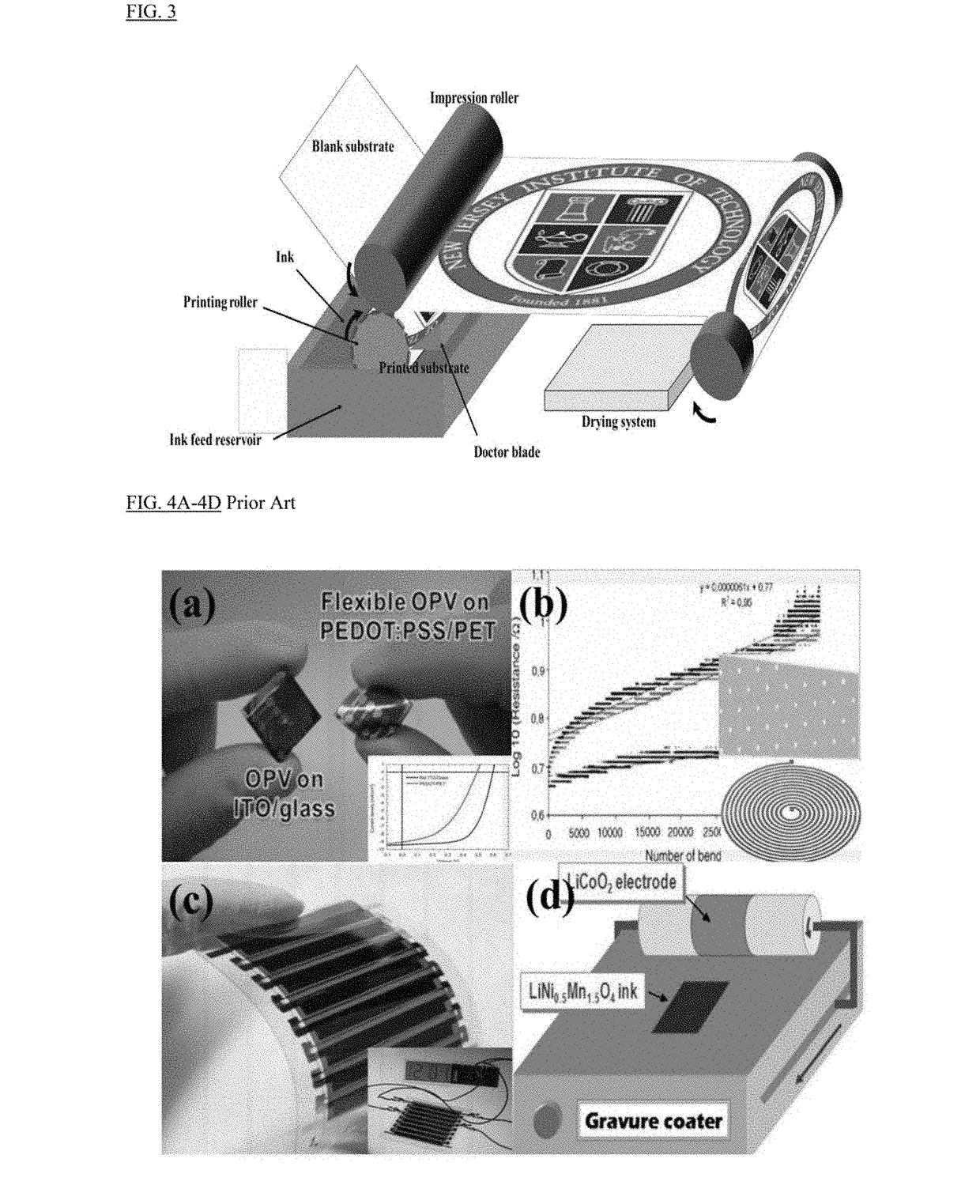

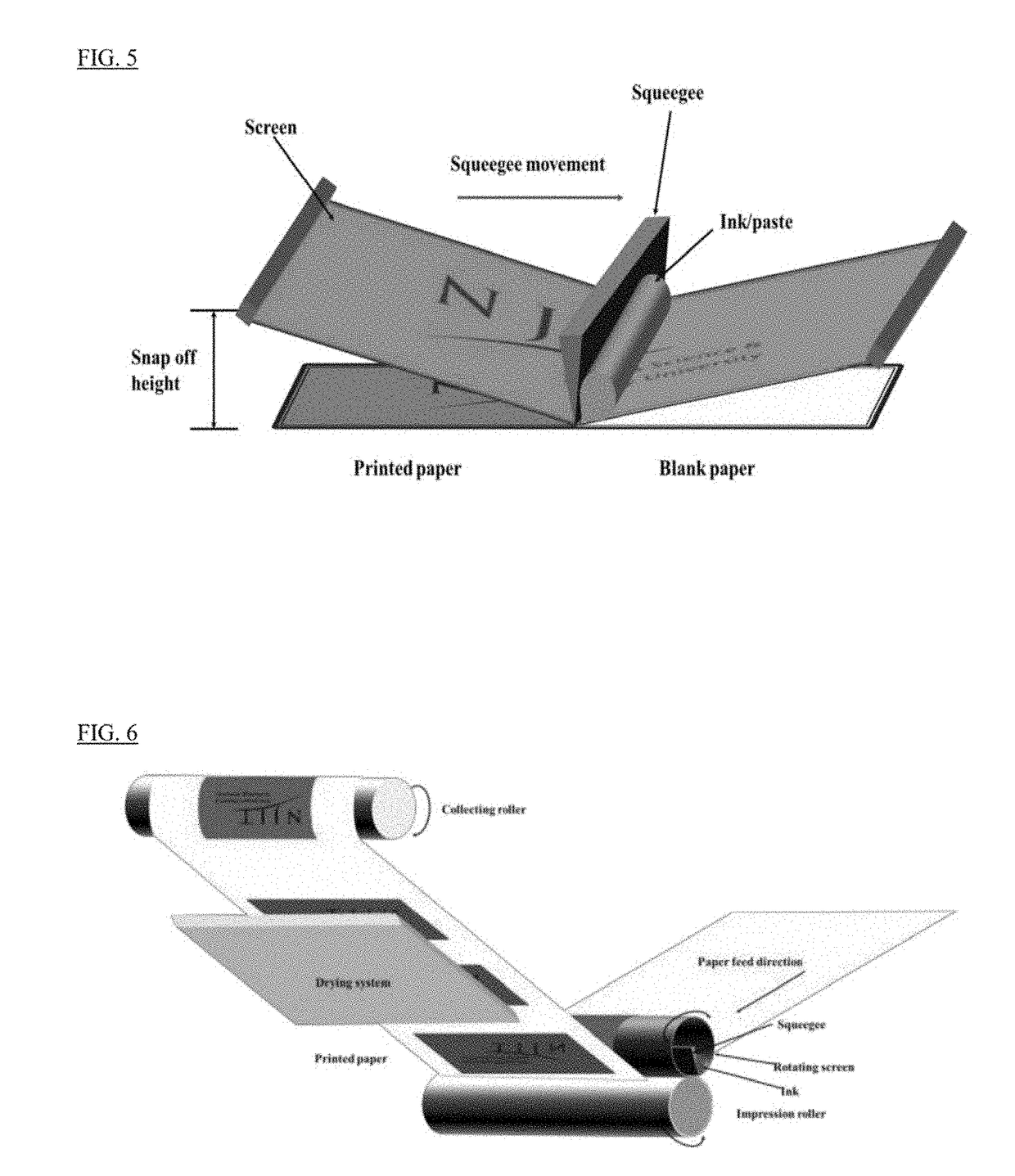

Fabrication of flexible conductive items and batteries using modified inks

InactiveUS20180342760A1Easy to sinterHigh resolutionAdditive manufacturing apparatusHybrid capacitor electrolytesSilver inkLithium-ion battery

A chemical process to formulate conductive ink with low sintering temperature for inkjet printing is described and shown. The application of fabricated flexible conductive film on lithium ion batteries is also described. This chemical method and composition can remove the oxidation on metallic nanoparticle surface during ink fabrication and sintering processes. Etched metallic ions in the conductive ink are reduced and particles bridged while annealing printed patterns to achieve low temperature sintering at about 350° C. The chemical process can be applied on nickel materials that are excellent current collectors for lithium ion batteries due to high chemical stability especially at high charging-discharging potential of less than 3 Volts. Thermal decomposition and chemical reduction of silver salts are two methods disclosed for particle-free silver ink. Surfactant additive further make silver film more uniform and easier to be sintered.

Owner:NEW JERSEY INSTITUTE OF TECHNOLOGY

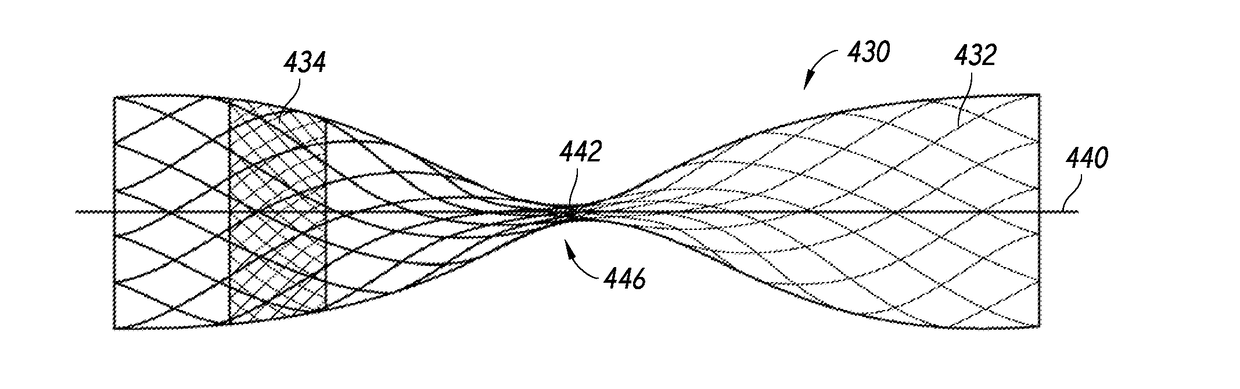

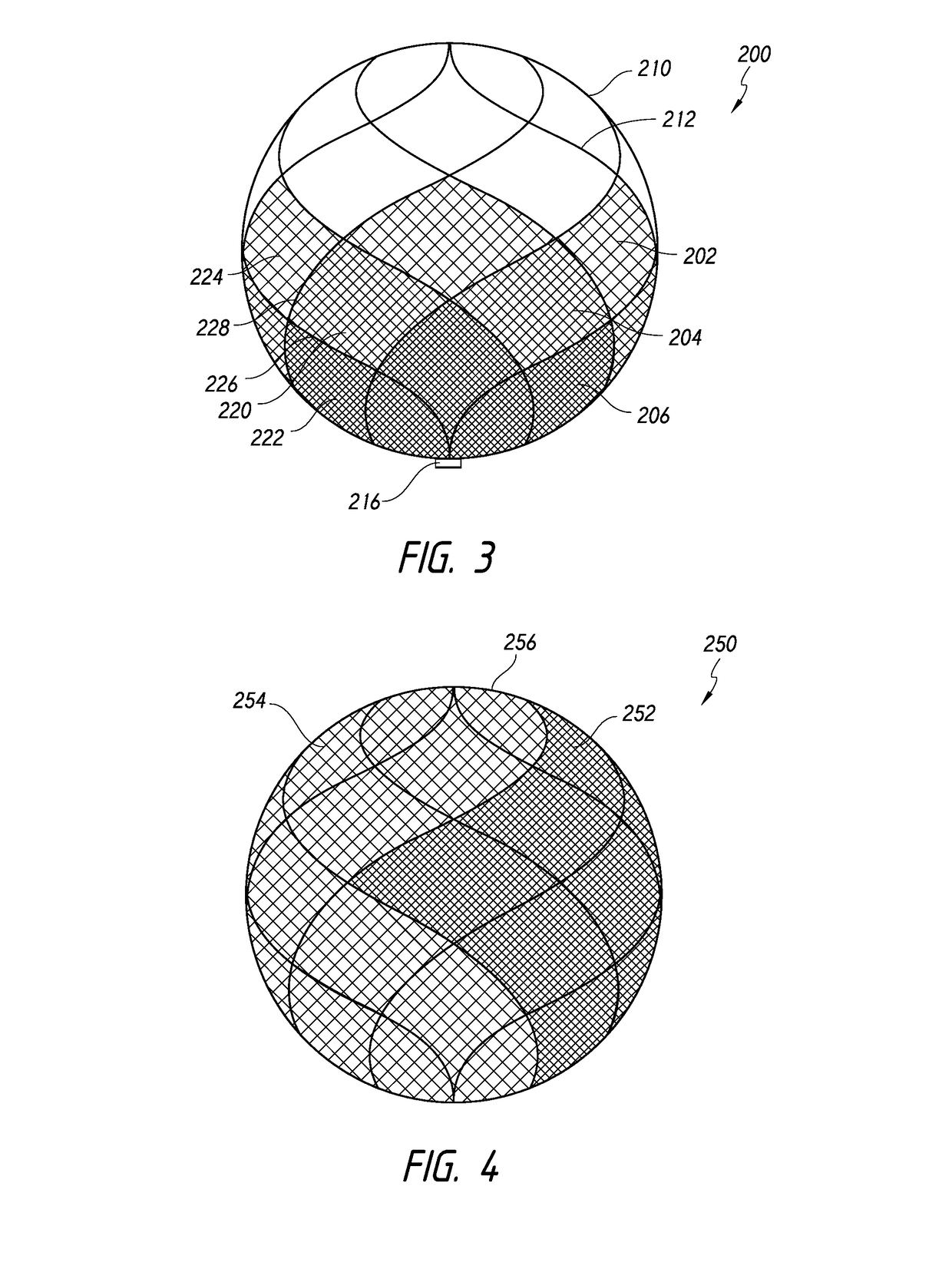

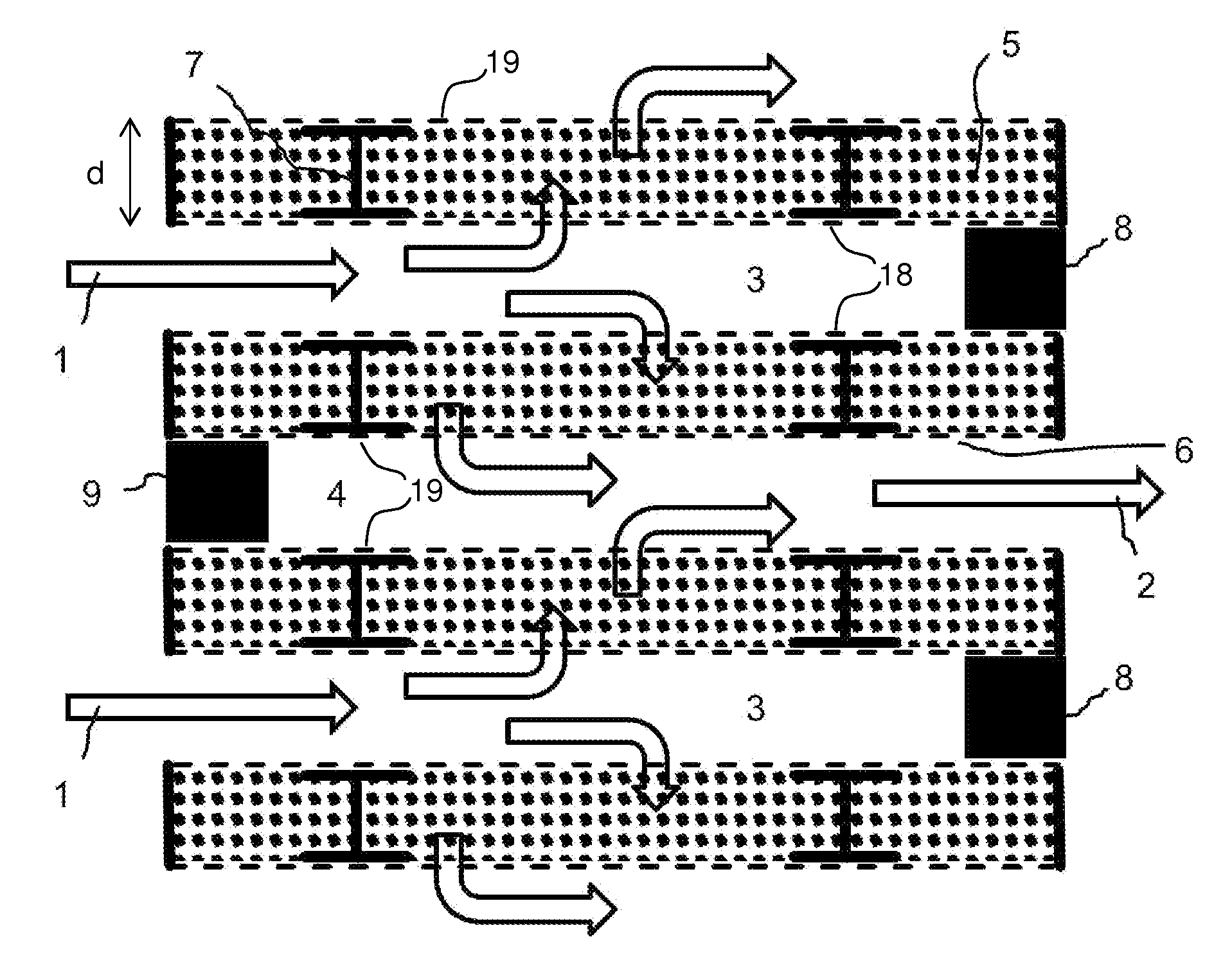

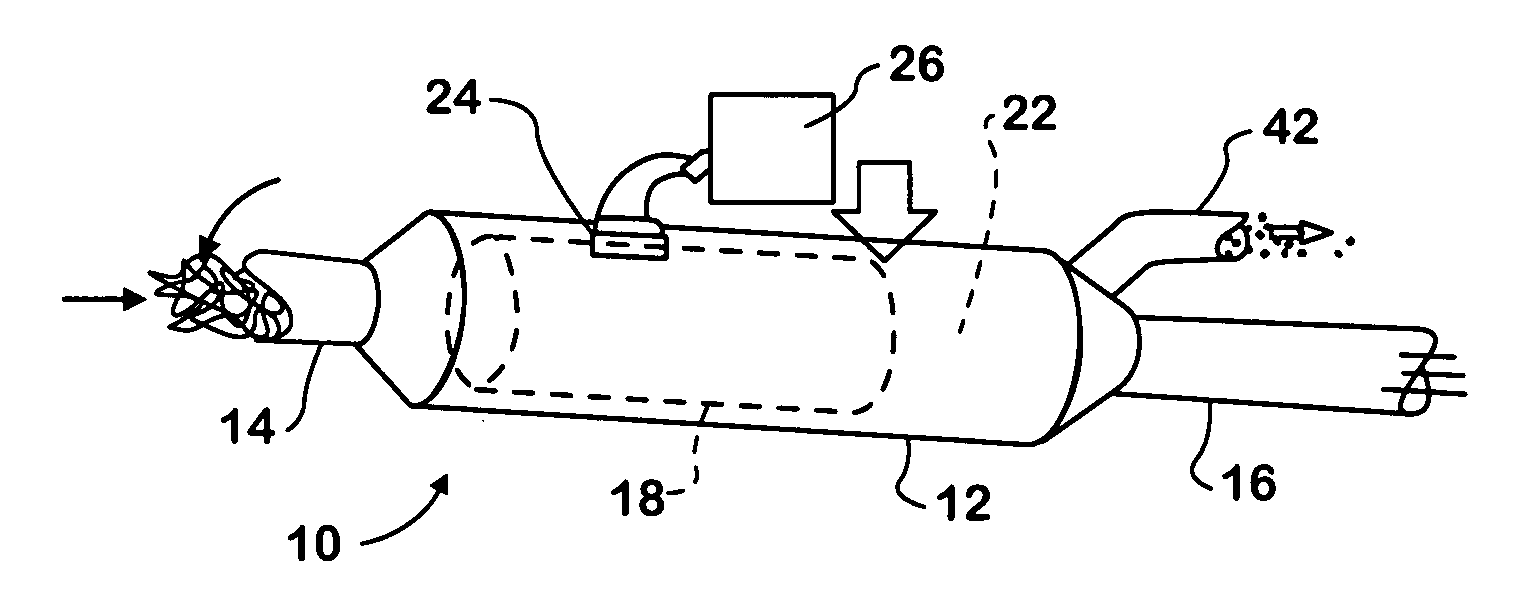

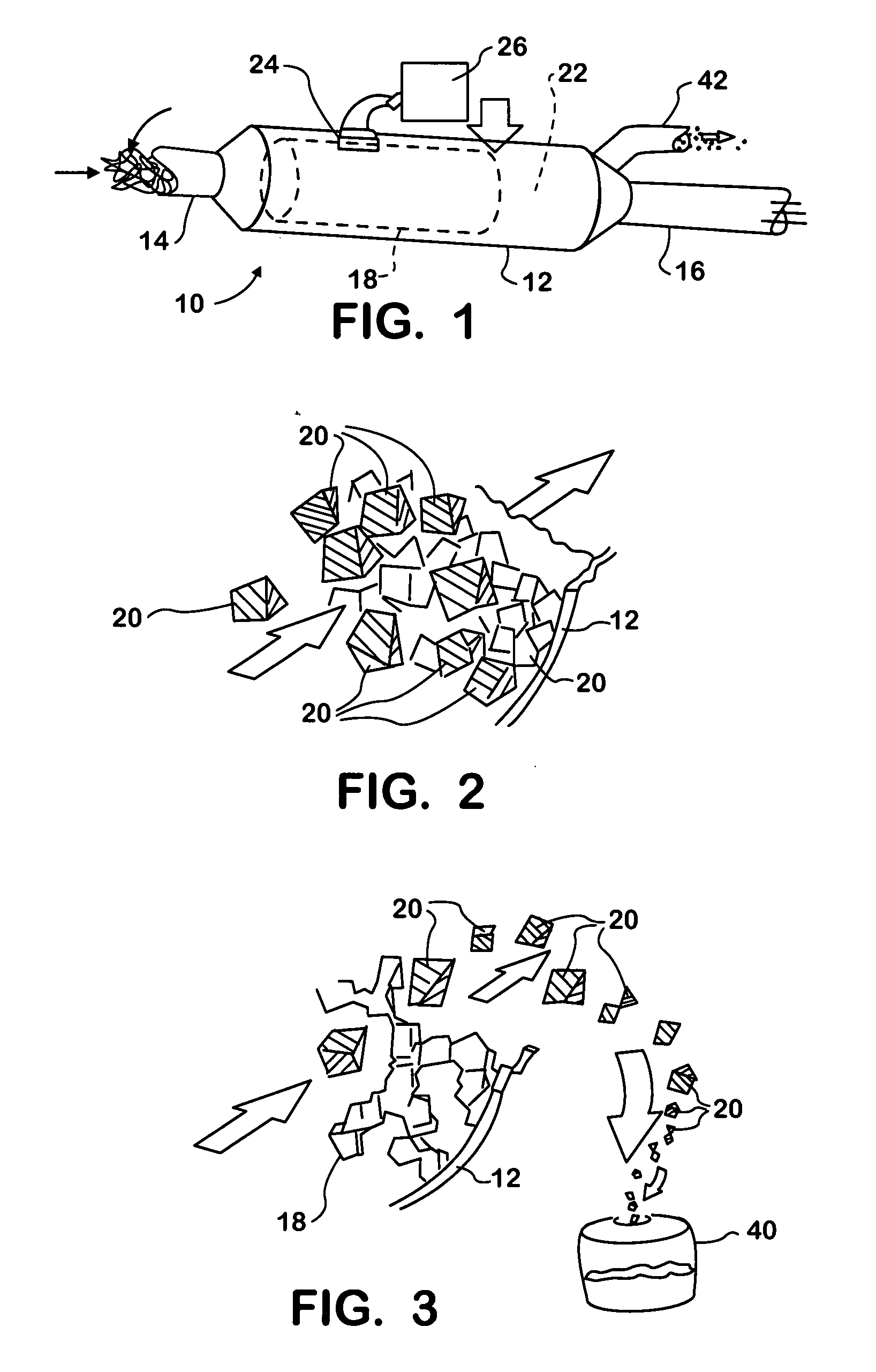

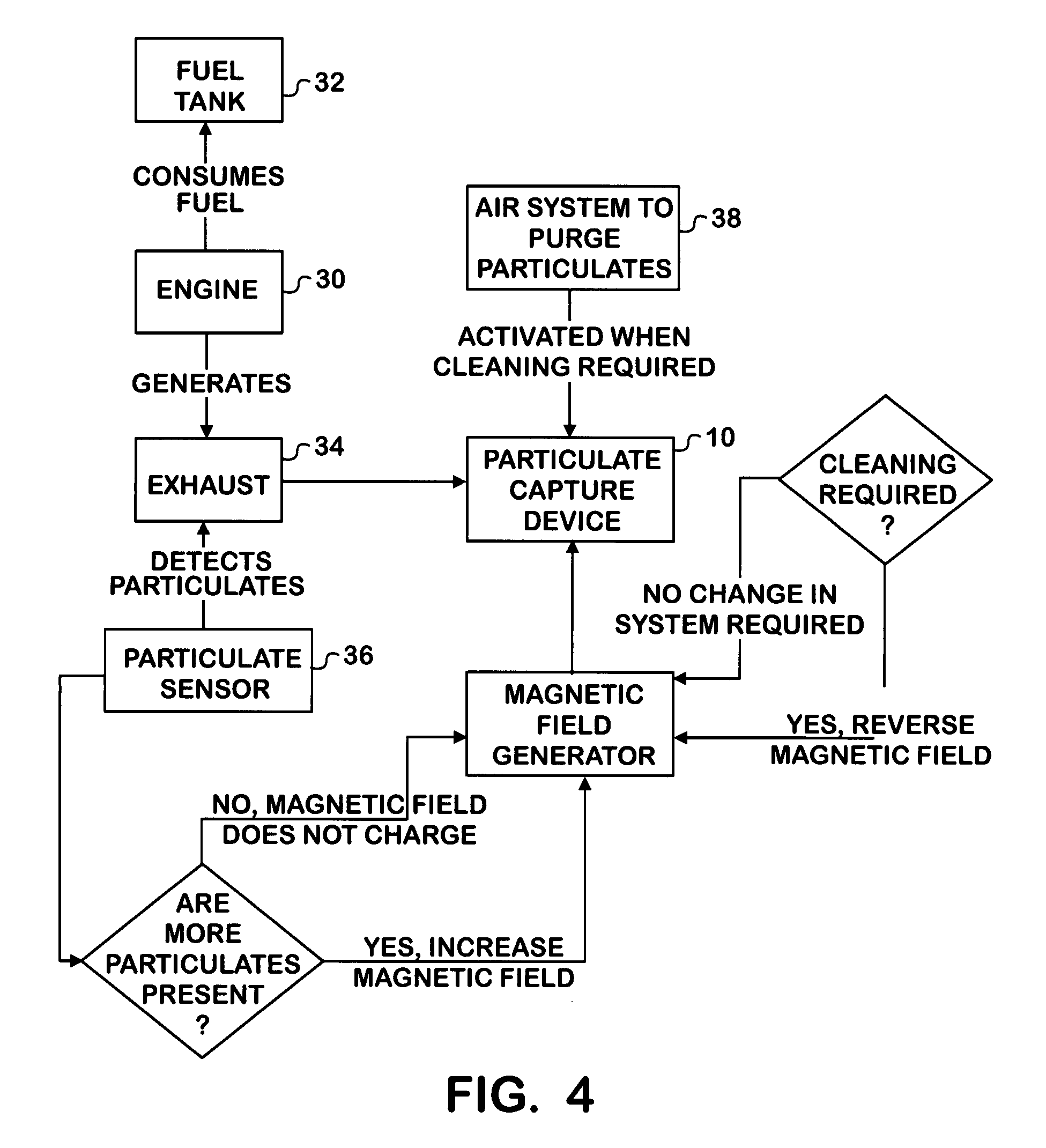

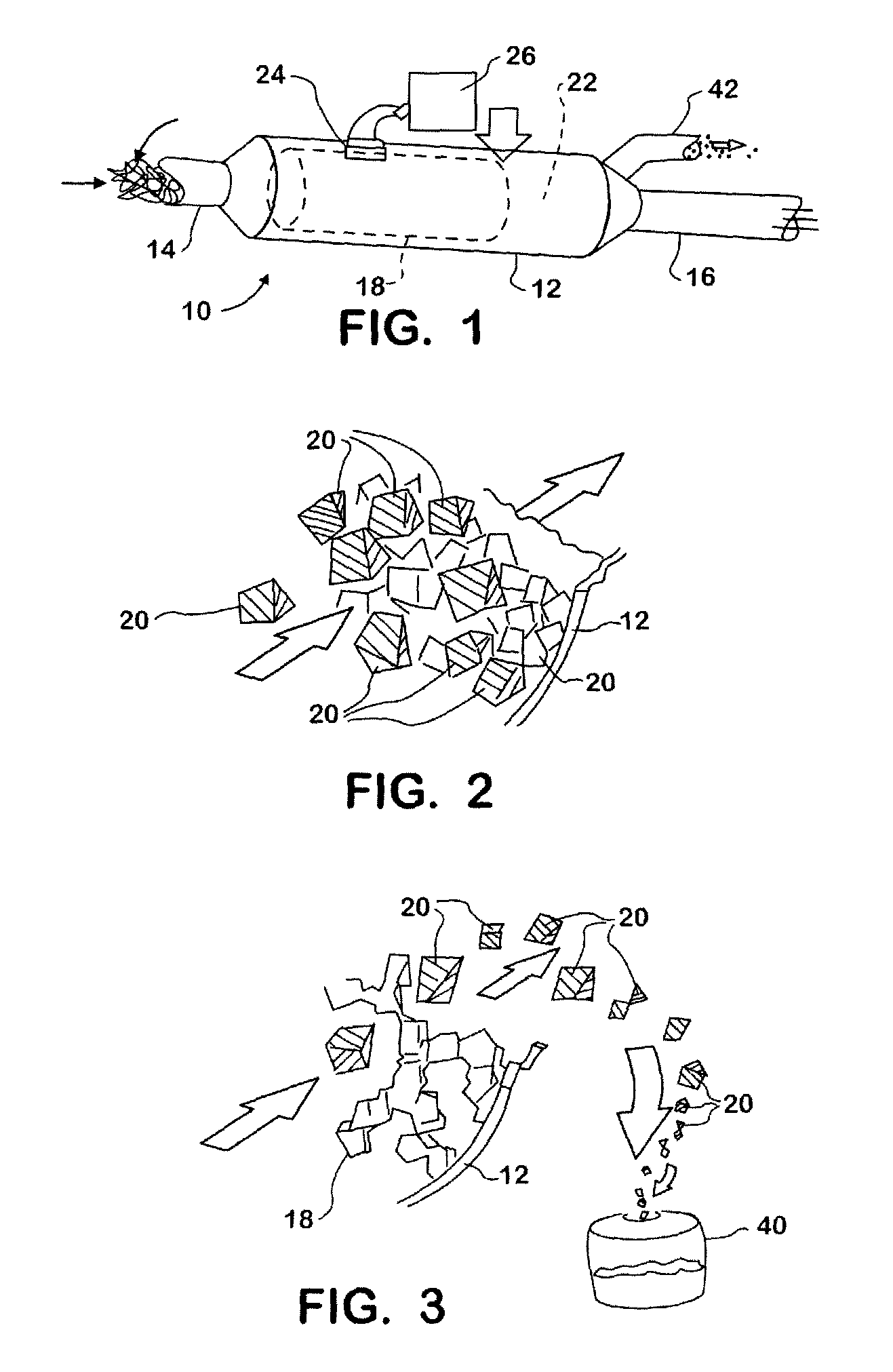

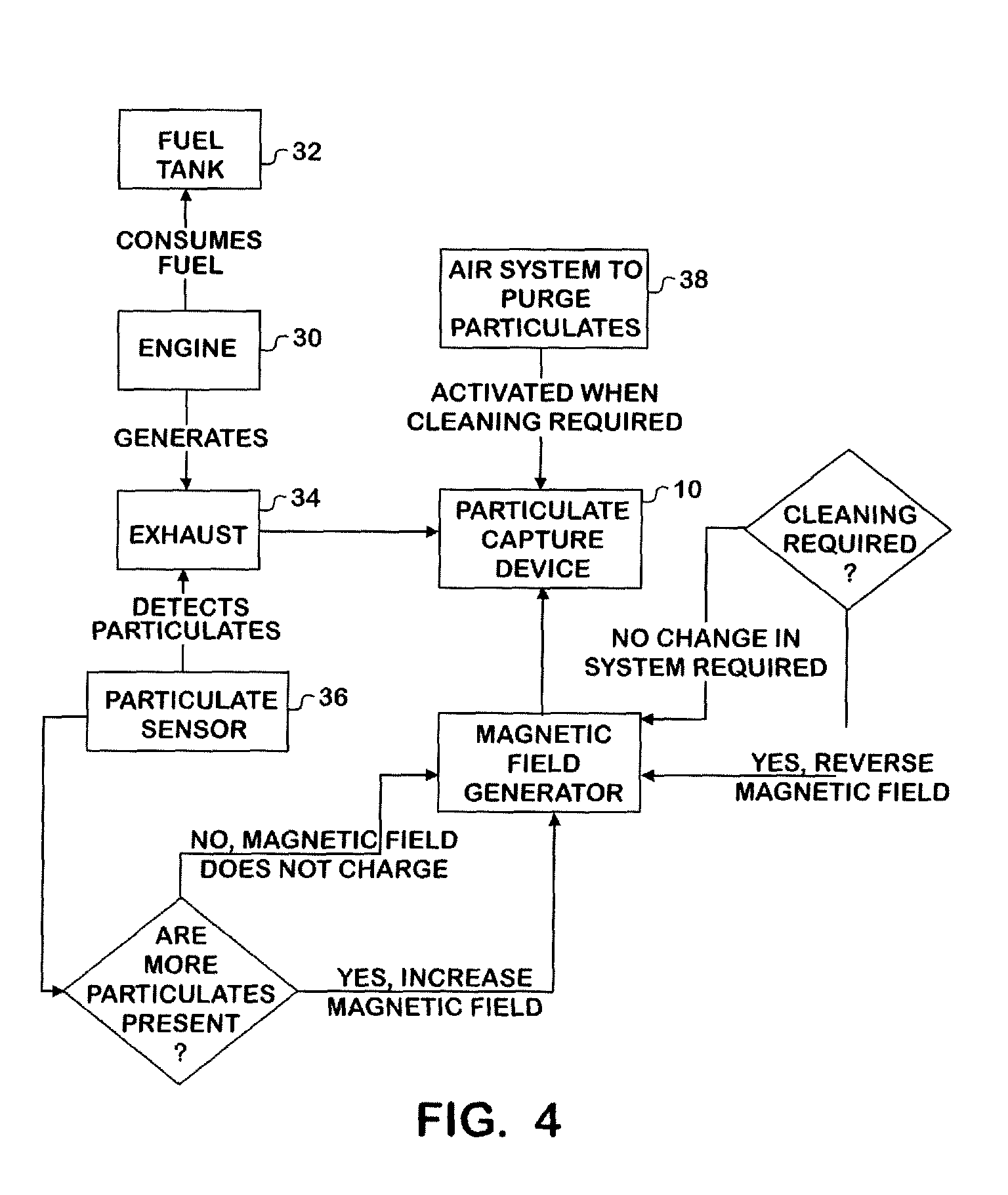

Particulate filter having expansible capture structure for particulate removal

InactiveUS20080282669A1Less porosityHigh porosityCombination devicesAuxillary pretreatmentPorosityCombustion

A combustion engine comprising an exhaust system containing a particulate filter (10, 52) for trapping particulate matter in engine exhaust passing through the exhaust system. A particulate trapping medium (18) inside a casing is selectively operable to a relatively lesser porosity for trapping particulate matter in the exhaust and to a relatively greater porosity for facilitating removal of trapped particulate matter during cleaning.

Owner:INT TRUCK INTPROP LLC

High-strength die-casting alloy material for mobile phone middle plate and preparation method and application of high-strength die-casting alloy material

The invention relates to a high-strength die-casting alloy material for a mobile phone middle plate and a preparation method and application of the alloy material. The alloy material comprises, by weight, 4.0%-8.0% of Si, 4. %-8.0% of Mg, 0.4%-1.0% of Mn, 4.0% of Cu, 1.5% of Zn, 0.5% of Fe, 0.25% of Ti, 1.0% of Sc, 0.5% of Zr, and the balance of Al, wherein the sum of the weight percentages of other impurities is controlled to be less than 1.0 %. Compared with the prior art, the high-strength die-casting alloy material and the preparation method thereof have the advantages that the tensile strength of the obtained mobile phone middle plate can reach 350-400 MPa, the yield strength can reach 250-300 MPa, and the elongation is 2.0%-4.0%.

Owner:苏州慧金新材料科技有限公司

Ceramic glaze with stable performance and preparation method thereof

The invention relates to the technical field of ceramic glaze production, and provides a ceramic glaze with stable performance and a preparation method thereof. The ceramic glaze is prepared from 10-18 parts of quartz, 10-18 parts of Zuoyun soil, 5-15 parts of frit, 3-10 parts of modified nano silicon dioxide compounded graphene oxide, 3-10 parts of boric acid, 3-10 parts of zirconium silicate, 2-6 parts of calcite, 2-6 parts of strontium titanate, 2-6 parts of barium carbonate, 0.5-3 parts of ammonium dihydrogen phosphate, 0.5-3 parts of zinc oxide and 0.5-3 parts of fluorine-containing auxiliaries. The preparation method comprises the following steps: S1, preparing modified nano silicon dioxide compounded graphene oxide; S2, crushing and sieving; and S3, preparing slurry. The hardness and wear resistance of the glaze can be greatly improved, the glaze layer is compact in structure and can fill pores in the surface of a ceramic matrix, the stain resistance and cold resistance of a ceramic product are improved, and the obtained glaze is high in quality, stable in performance and long in service life.

Owner:江西亚航科技有限公司

Particulate filter having expansible capture structure for particulate removal

InactiveUS7721536B2Less porosityHigh porosityCombination devicesAuxillary pretreatmentPorosityCombustion

A combustion engine comprising an exhaust system containing a particulate filter (10, 52) for trapping particulate matter in engine exhaust passing through the exhaust system. A particulate trapping medium (18) inside a casing is selectively operable to a relatively lesser porosity for trapping particulate matter in the exhaust and to a relatively greater porosity for facilitating removal of trapped particulate matter during cleaning.

Owner:INT TRUCK INTPROP LLC

Denitrification biological stuffing

InactiveCN106986450AImprove adsorption capacityLess porosityWater contaminantsTreatment with anaerobic digestion processesPorosityHazardous substance

The invention discloses a denitrification biological stuffing which comprises a spherical casing and a stuffing. The stuffing is starch grafted polycaprolactone capable of providing a carbon source for nitrifying bacteria, and a plurality of meshes are formed in the surface of the casing and serve as biological carriers. The casing is treated with aluminum dihydrogen phosphate, so that the adsorption performance of the surface of the casing can be improved. The denitrification biological stuffing is large in specific surface area, high in porosity, film forming rate, film forming speed, load resistance, denitrification efficiency, degradability and biostability, strong in biological adhesion force, low in biological sludge yield, free of secondary pollution and convenient to mount, and can be directly released without fixation, and no harmful substances are dissolved.

Owner:浙江川宁环保科技有限公司

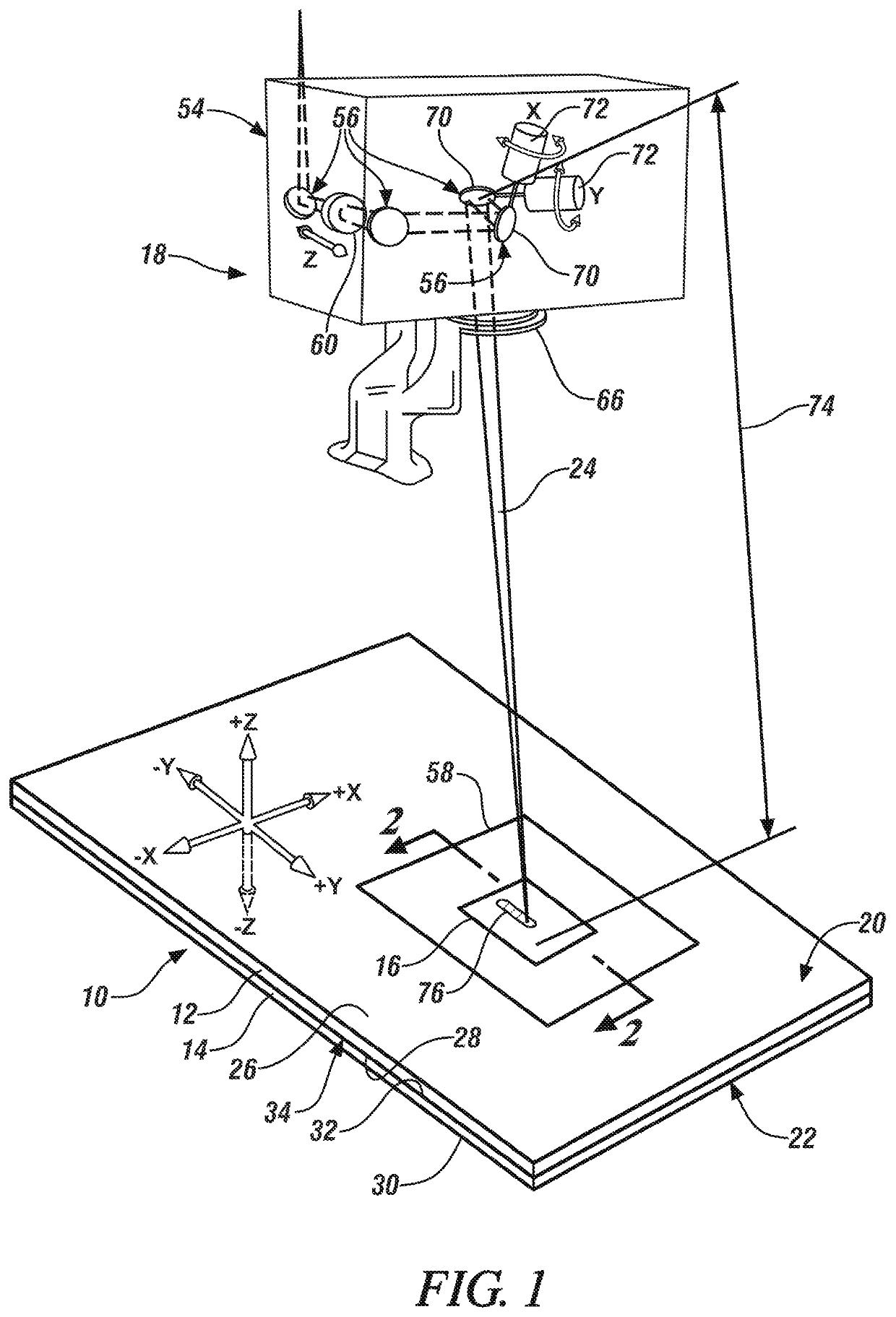

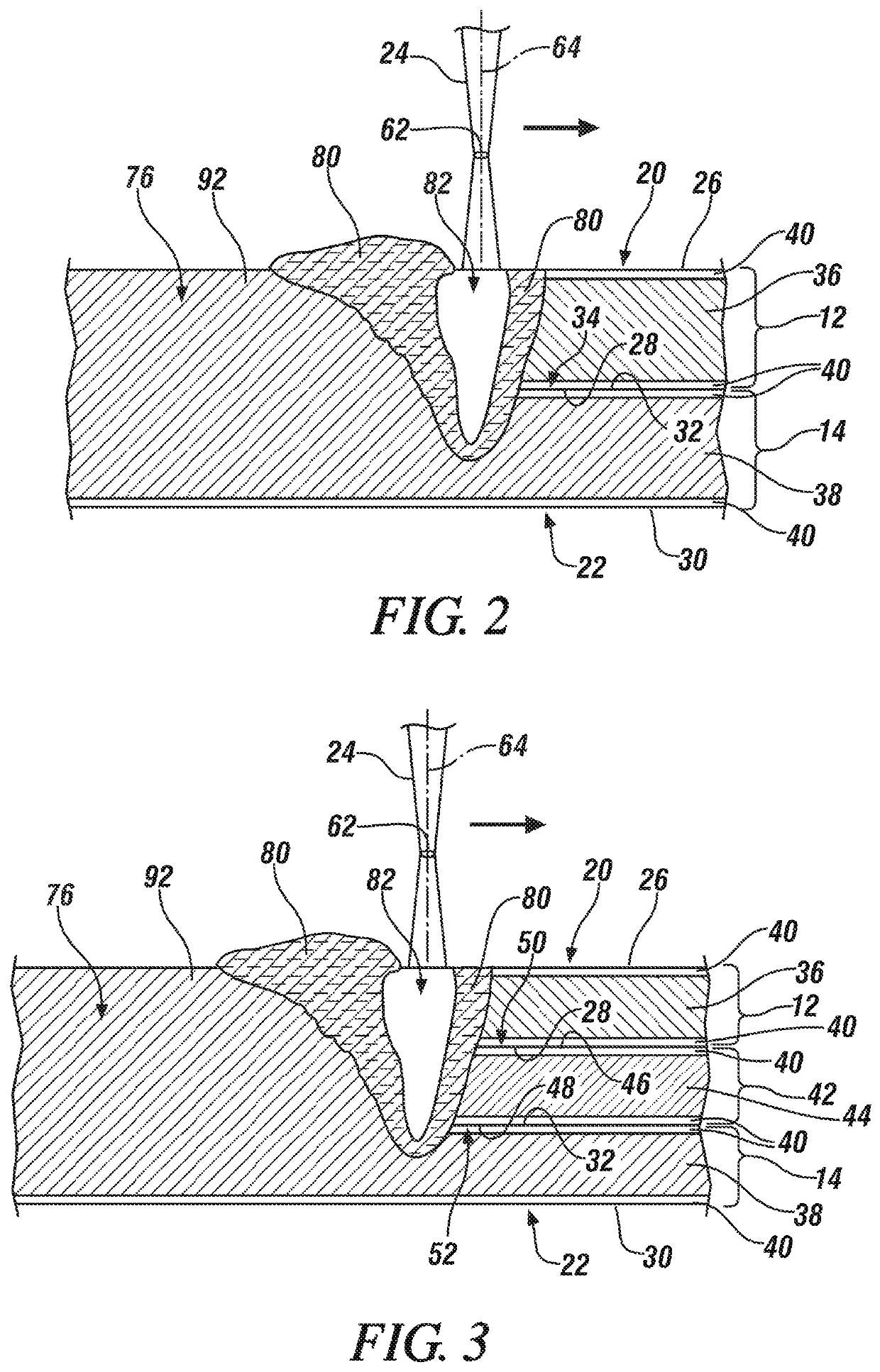

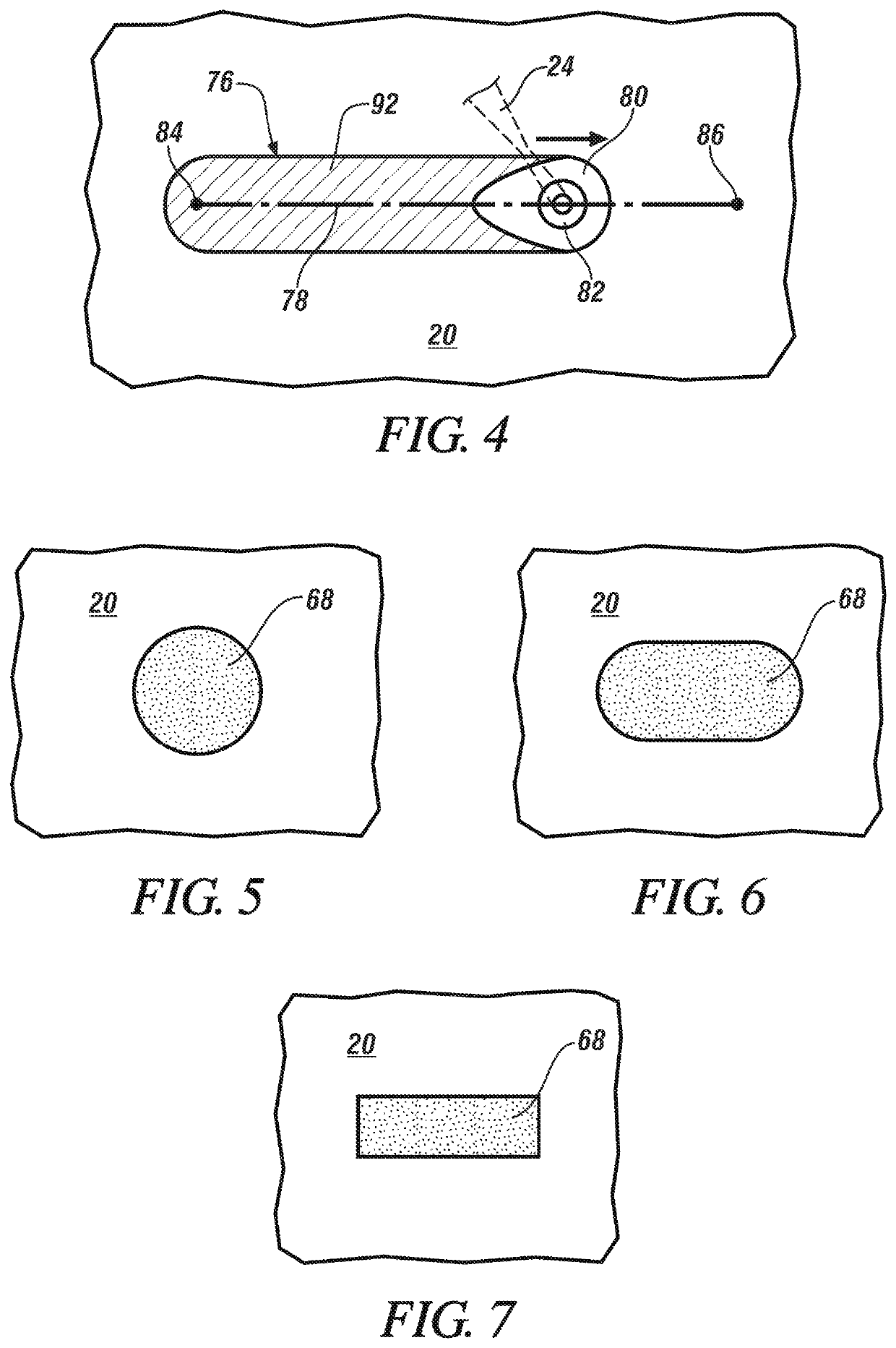

Remote laser welding of overlapping metal workpieces at fast speeds

ActiveUS10953494B2Quick indexHigh strengthVehicle componentsWelding/soldering/cutting articlesEngineeringFusion welding

A method of laser welding a workpiece stack-up (10) that includes at least two overlapping metal workpieces (12, 14) comprises advancing a laser beam (24) relative to a plane of a top surface (20) of the workpiece stack-up (10) from a start point (84) to an end point (86) along a beam travel pattern (78) at a high laser beam travel speed of greater than 8 meters per minute. The two or more overlapping metal workpieces (12, 14) may be steel workpieces or they may be aluminum workpieces, and at least one of the metal workpieces (12, 14) includes a surface coating (40). Advancing the laser beam (24) along the beam travel pattern (78) forms a weld joint (76), which includes resolidified composite workpiece material derived from each of the metal workpieces (12, 14) penetrated by a molten weld pool (80), that fusion welds the metal workpieces (12, 14) together. The relatively high laser beam travel speed contributes to improve strength properties of the weld joint (76).

Owner:GM GLOBAL TECH OPERATIONS LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com