Oxygenating-vacuum die casting die device and oxygenating-vacuum die casting process

A vacuum die-casting and mold technology, applied in oxygenation-vacuum die-casting process, oxygenation-vacuum die-casting mold device field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Example 1 Oxygenation-vacuum die casting, the first predetermined speed (ie slow injection speed) is 0.1 m / s.

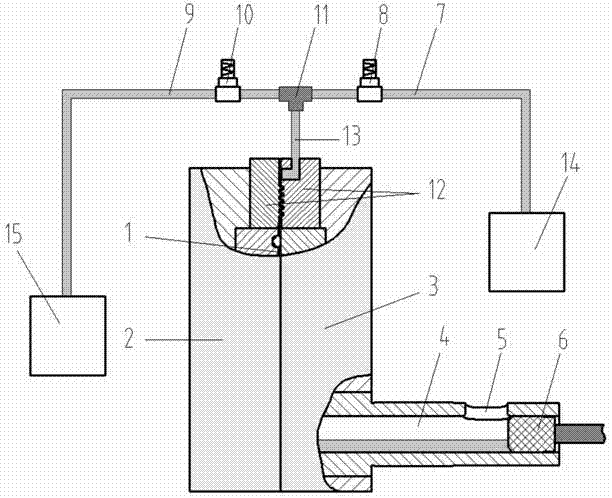

[0051] A Toyo 350-ton cold chamber die-casting machine is used, and an oxygen charging tube 7 and a vacuum tube 9 are connected to the top of the vacuum valve 12 to carry out oxygen charging and vacuuming operations respectively. Solenoid valves are respectively installed on the oxygen charging tube 7 and vacuum tube 9 to control the charging respectively. Oxygen and vacuum on and off. The sheet-shaped die-casting mold is adopted, and the die-casting material selected is AZ91D magnesium alloy.

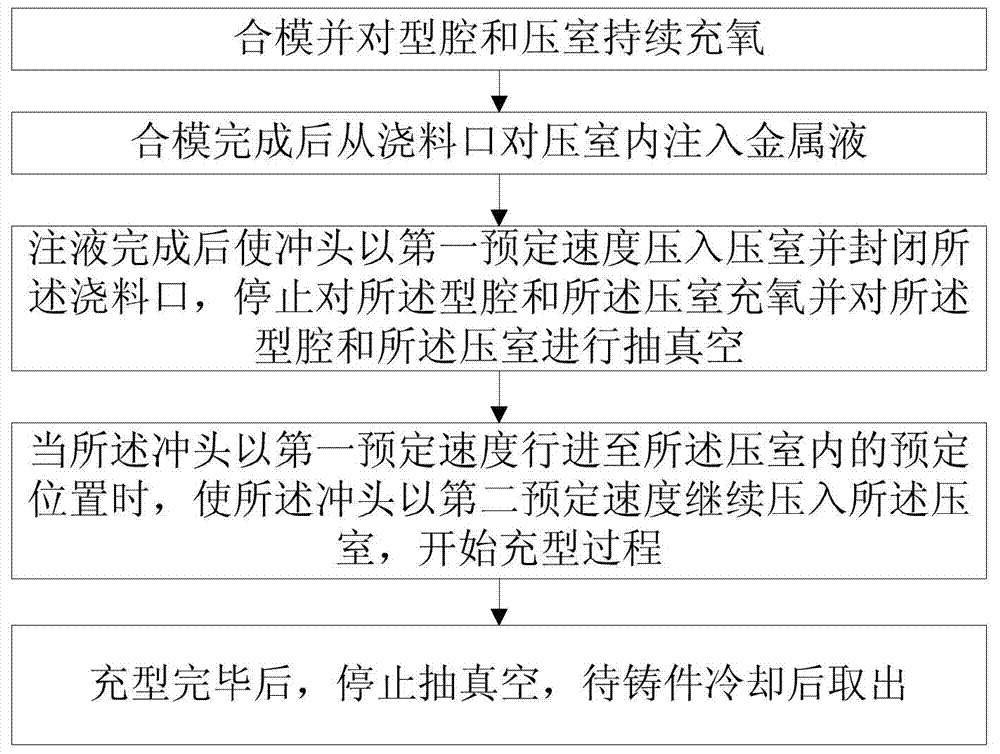

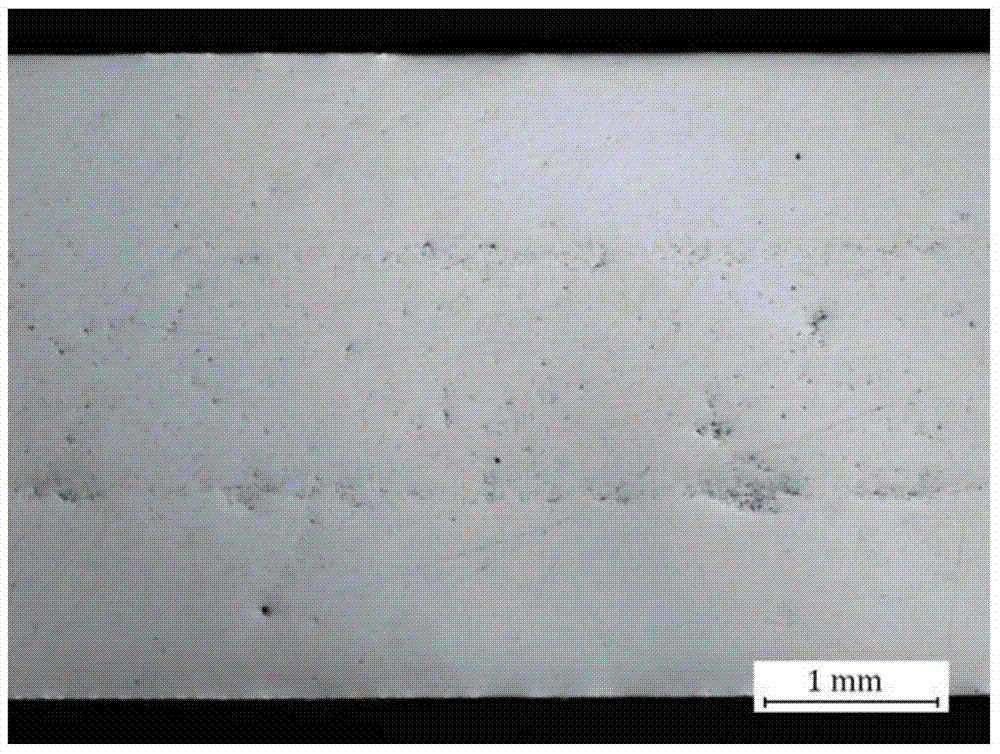

[0052] The specific steps are as follows: the mold is preheated to 180°C, and the first valve 8 on the oxygenation pipe 7 is opened to start oxygenation during the mold closing process. After the mold is closed, molten metal with a temperature of 680°C is added from the sprue 5. After the feeding is completed, the punch 6 is pressed in at a slow injection speed of 0.1...

Embodiment 2

[0054] Example 2 Oxygenation-vacuum die-casting, the first predetermined speed (ie slow injection speed) is 0.2m / s, the experimental device and experimental materials are the same as in Example 1.

[0055] The specific steps are as follows: the mold is preheated to 180°C, and the first valve 8 on the oxygenation pipe 7 is opened to start oxygenation during the mold closing process. After the mold is closed, molten metal with a temperature of 680°C is added from the sprue 5. After the feeding is completed, the punch 6 is pressed in at a slow injection speed of 0.2m / s. When the punch 6 closes the gate 5, the first valve 8 of the oxygenation tube 7 is closed and the second valve 10 of the vacuum tube 9 is opened. Oxygenation was stopped and vacuum started. The punch 6 advances to the 245mm in the pressure chamber 4, the vacuum pressure of the cavity 1 is 37.2kPa, and the punch 6 starts to be pressed in at a fast injection speed of 5m / s. After filling the mold, close the second v...

Embodiment 3

[0057] Example 3 Oxygenation-vacuum die-casting, the first predetermined speed (ie slow injection speed) is 0.3m / s, and the experimental device and experimental materials are the same as those in Example 1.

[0058] The specific steps are as follows: the mold is preheated to 180°C, and the first valve 8 on the oxygenation pipe 7 is opened to start oxygenation during the mold closing process. After the mold is closed, molten metal with a temperature of 680°C is added from the sprue 5. After the feeding is completed, the punch 6 is pressed in at a slow injection speed of 0.3m / s. When the punch 6 closes the gate 5, the first valve 8 of the oxygenation tube 7 is closed and the second valve 10 of the vacuum tube 9 is opened. Oxygenation was stopped and vacuum started. The punch 6 travels to the 245mm in the pressure chamber 4, the vacuum pressure of the cavity 1 is 57.2kPa, and the punch 6 starts to be pressed in at a fast injection speed of 5m / s. After filling the mold, close the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com