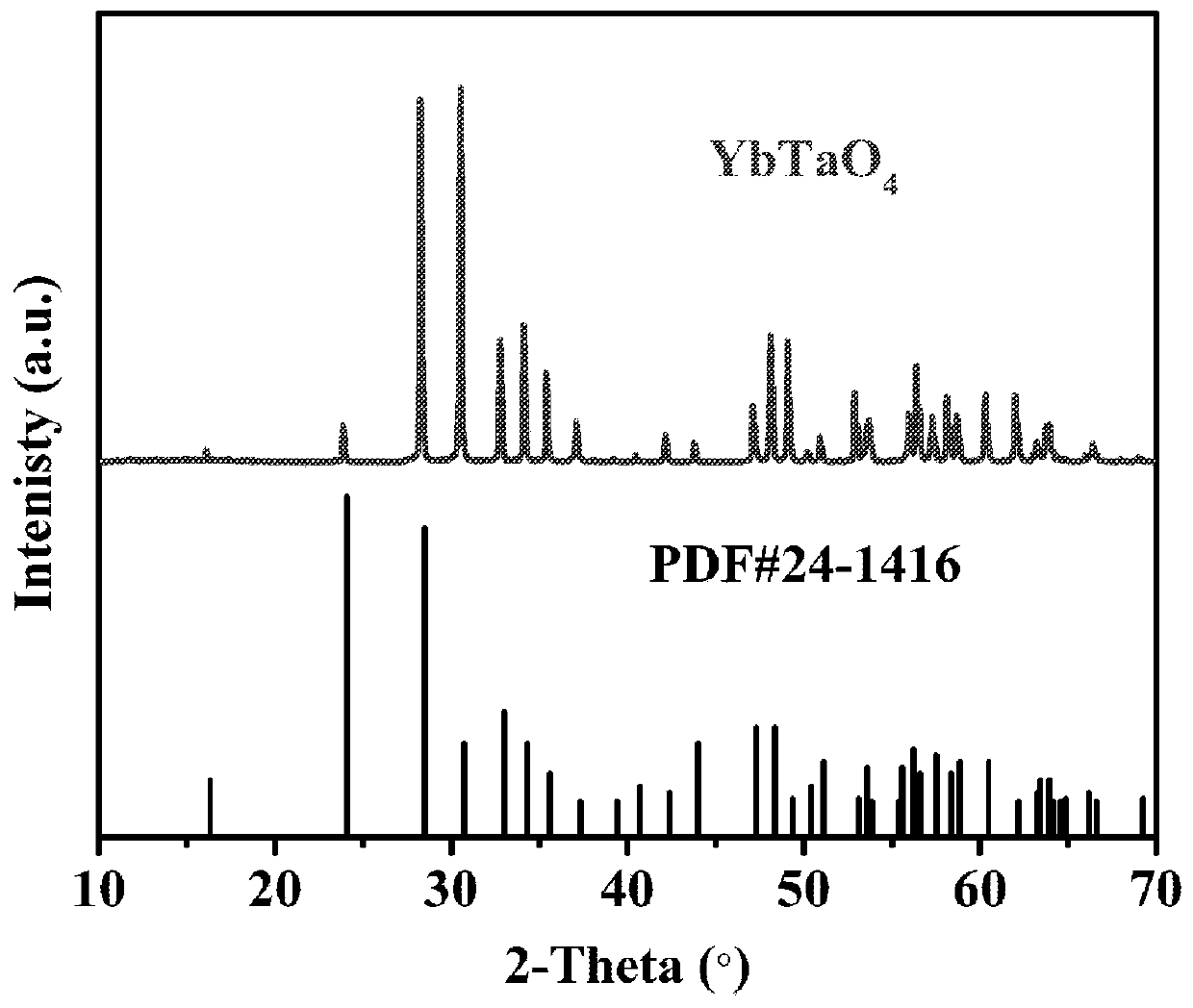

Rare earth ytterbium tantalite ceramic resisting corrosion of low-melting-point oxides and preparation method of rare earth ytterbium tantalite

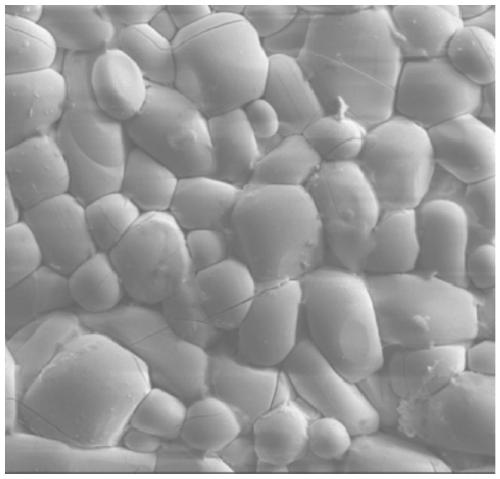

An oxide and low melting point technology, applied in the direction of mechanical equipment, blade support components, machines/engines, etc., can solve problems such as thermal barrier coating cracking, achieve the effects of reduced micro-cracks, low porosity, and improved corrosion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0047] The preparation method of the above-mentioned rare earth tantalate ceramics resistant to corrosion by low melting point oxides comprises the following steps:

[0048] Step (1): Weigh Yb with a molar ratio of Yb:Ta of 1:1 or 3:1 2 o 3 Powder and Ta 2 o 5 Powder, mixed with distilled water or ethanol solvent, where Yb 2 o 3 Powder and Ta 2 o 5 The molar ratio of the powder to the solvent is (3:1)~(5:1), and the ball mill is used for ball milling, and the powder A is obtained after drying; the ball mill adopts a frequency conversion planetary ball mill, the model is XQM, and the ball milling time is 10~24h , the speed of the ball mill is 300~500r / min, and the raw material Yb 2 o 3 Powder and Ta 2 o 5 The purity of the powder is not less than 99.9%.

[0049] Step (2): Dry the powder obtained in step (1) and sieve for the first time to obtain powder B, wherein the drying temperature is 50-200°C, the drying time is 8-24h, and the mesh size of the first sieve is 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com