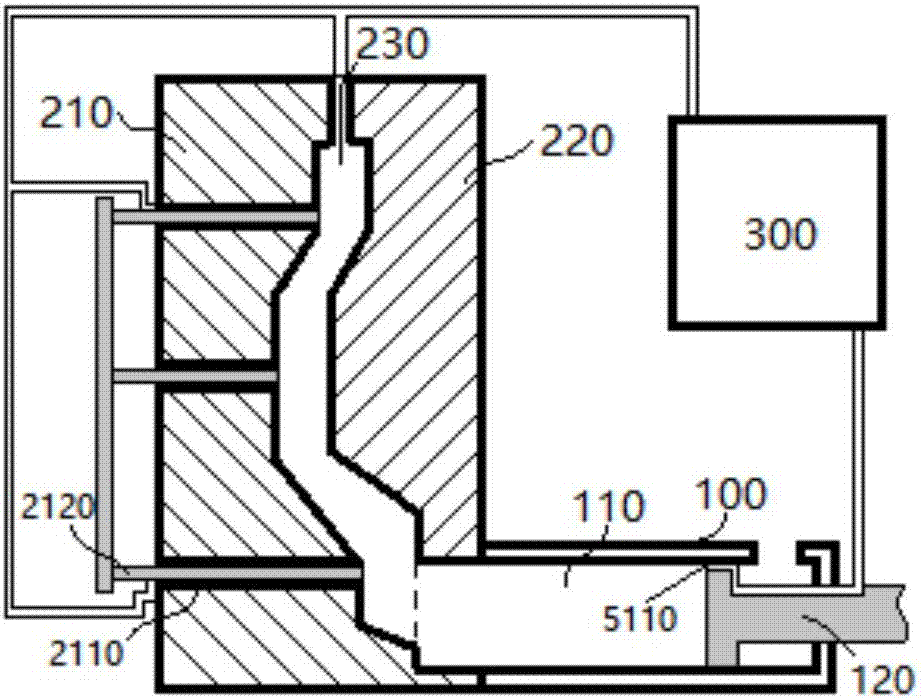

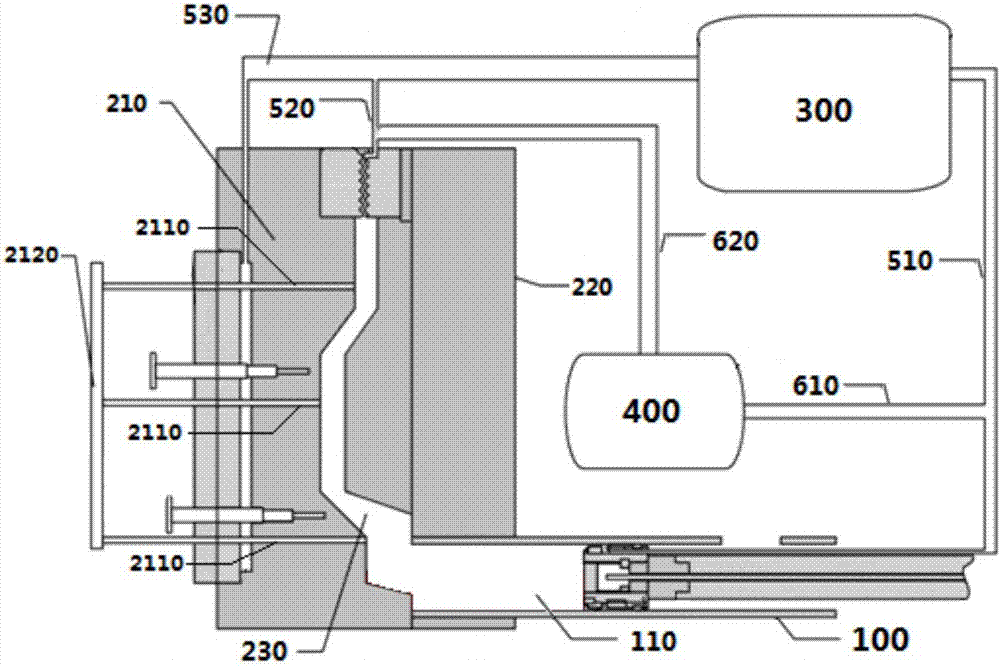

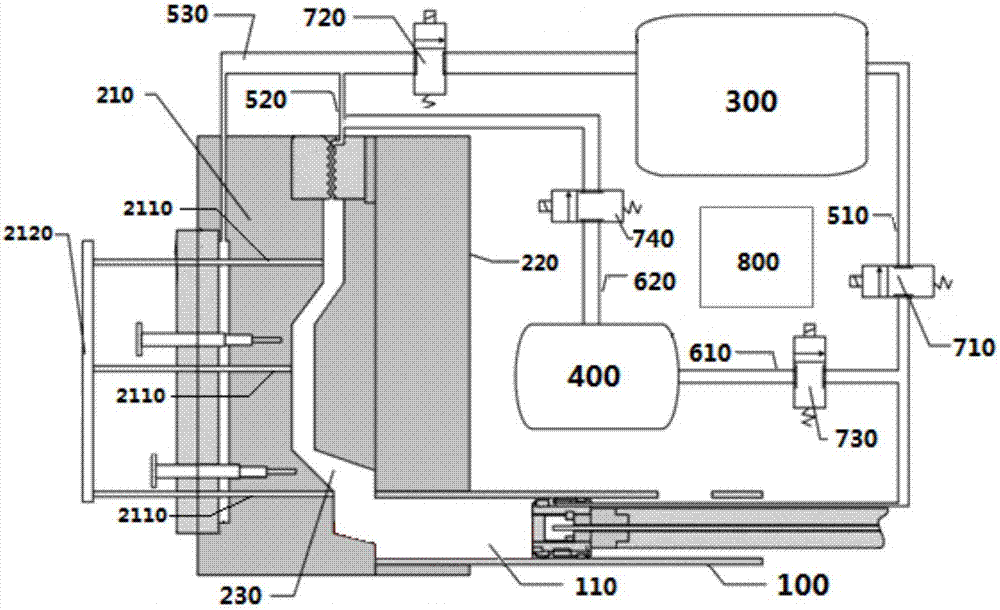

Vacuum die-casting device and high-vacuum die-casting method

A vacuum die-casting equipment and vacuum pumping technology, which are applied in the field of vacuum die-casting, can solve the problems of die-casting technology equipment and process that need to be improved, metal liquid movement, and restrictions on the application field of die-casting parts.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0102] In this embodiment, the above-mentioned high-vacuum die-casting method is used to manufacture castings. Among them, Toyo 350t cold chamber die-casting machine and its peripheral supporting equipment, including spraying machine, vacuum machine, etc., as well as punches for vacuuming, were used to carry out high-vacuum die-casting treatment on A380 alloy.

[0103] In advance, the mold of the vacuum die-casting equipment is sealed. The sealing method is based on the patent "A Vacuum Die-Casting Mold" (Patent Publication No.: 102642007A) proposed by Xiong Shoumei of Tsinghua University. The vacuum valve adopts a Z-shaped wave plate exhaust valve. The A380 alloy ingot is melted and controlled to a suitable pouring temperature of 680°C. At the same time, the mold is preheated to 180°C with a mold temperature controller, and then injection is performed at a low speed, and the pressure chamber and the mold are preheated to achieve thermal balance. High vacuum die casting method...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com