Barium strontium titanate-based ceramic material as well as preparation method and application thereof

A ceramic material, strontium-barium-based technology, applied in the field of strontium-barium titanate-based ceramic materials and its preparation, can solve the problems of energy storage performance to be improved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The present invention provides a method for preparing the strontium barium titanate-based ceramic material described in the above technical solution, comprising the following steps:

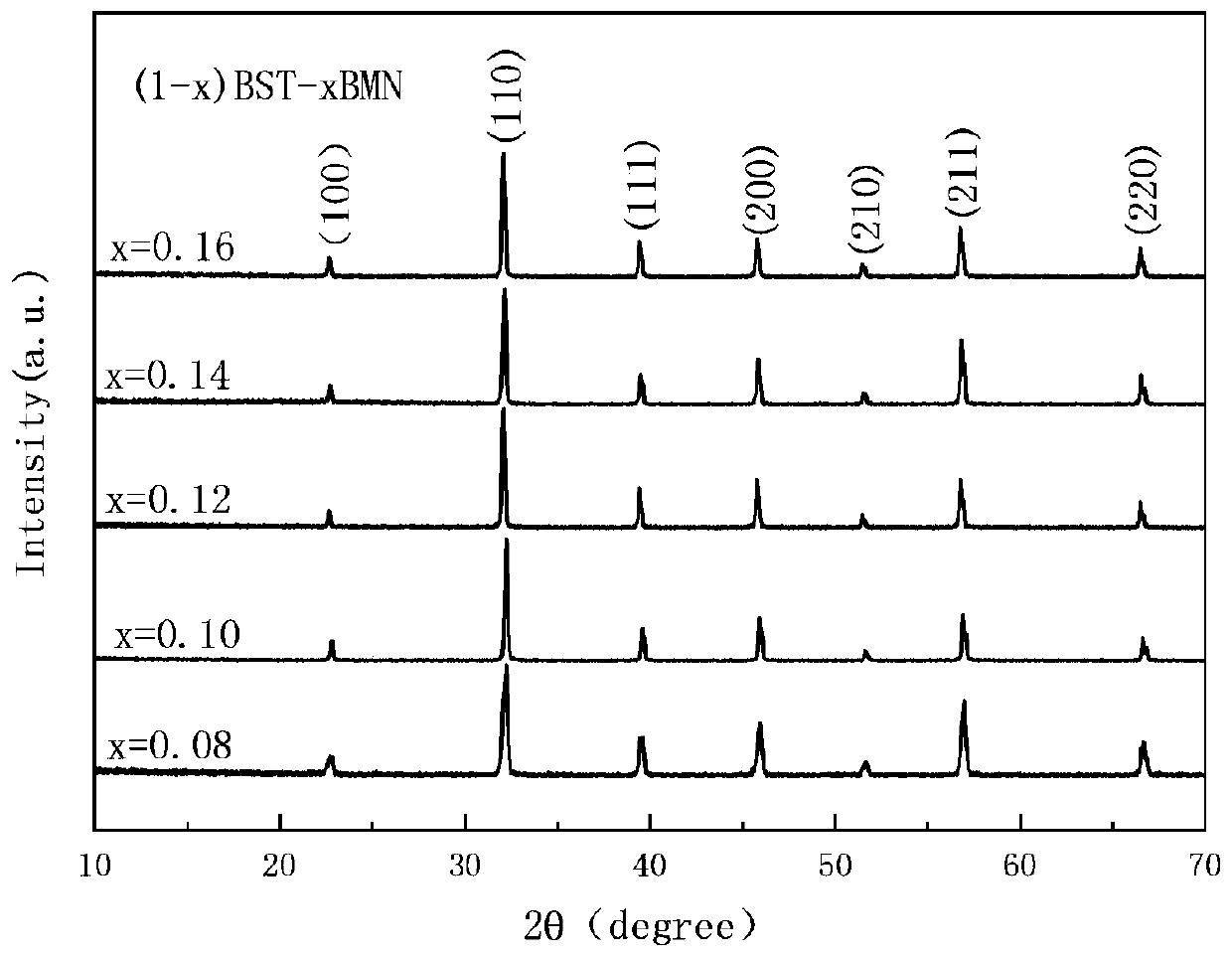

[0029] BaCO 3 、 Bi 2 o 3 , Nb 2 o 5 , MgO, SrCO 3 and TiO 2According to the chemical composition of the barium strontium titanate-based ceramic material, the first ball milling, calcining, second ball milling, granulation and tableting, debinding and sintering are carried out sequentially to obtain the barium strontium titanate-based ceramic material.

[0030] The present invention will BaCO 3 、 Bi 2 o 3 , Nb 2 o 5 , MgO, SrCO 3 and TiO 2 Mixing ingredients according to the chemical composition of the barium strontium titanate-based ceramic material to obtain a mixed raw material. In the present invention, according to the chemical composition of the barium strontium titanate-based ceramic material, the mass of each raw material is weighed by an electronic balance, and the ele...

Embodiment 1

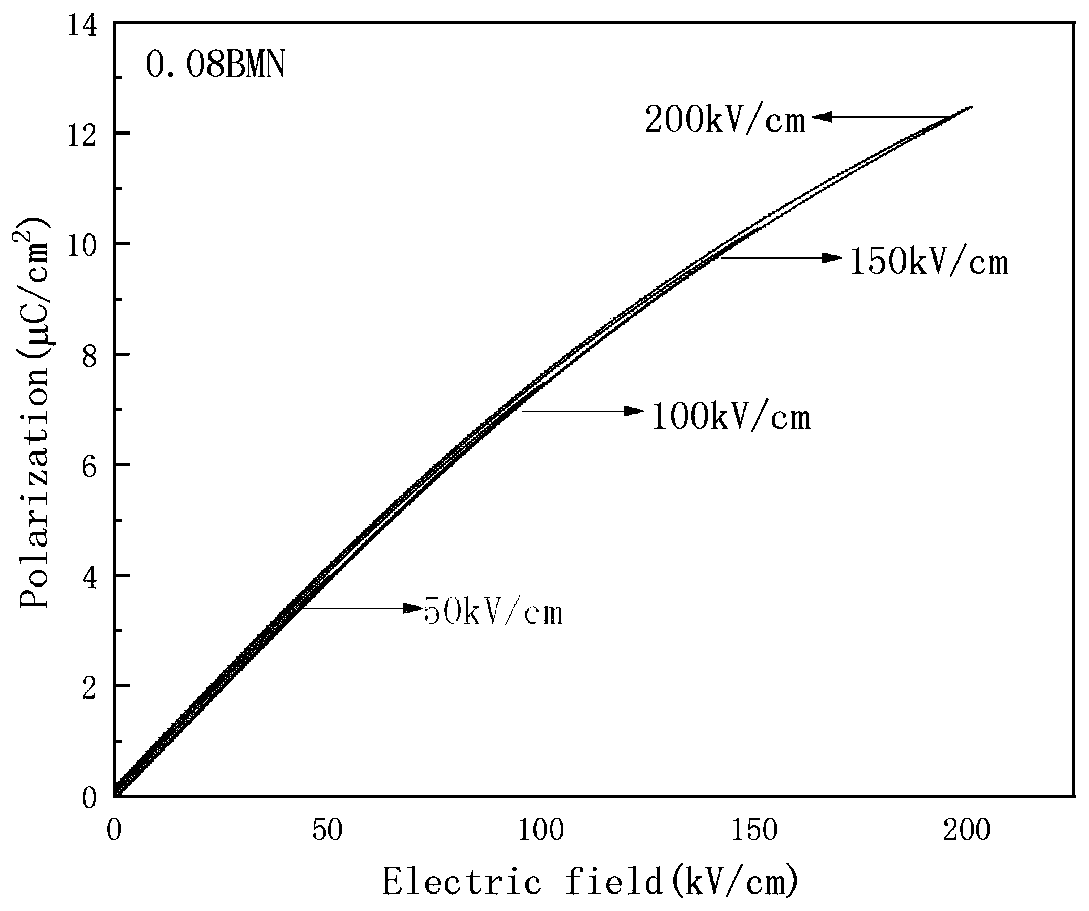

[0043] The composition of barium strontium titanate based ceramic material is 0.92Ba 0.8 Sr 0.2 TiO 3 -0.08Bi(Mg 2 / 3 Nb 1 / 3 )O 3 , the preparation method comprises the following steps:

[0044] (1) Ingredients: BaCO is calculated according to the formula ratio 3 、 Bi 2 o 3 , Nb 2 o 5 , MgO, SrCO 3 and TiO 2 The required quality of each raw material is weighed with a precision electronic balance, and the electronic balance is calibrated and cleared before the use of the electronic balance, and the reading error is 5 / 1000;

[0045] (2) Primary ball milling: according to the mass ratio of zirconium balls, ethanol and medicine (i.e. the mixture of each raw material) is 2:1:1, put them into the grinding tank, set the speed of the ball mill to 400rpm, and mill for 4 hours. Zirconium balls are separated, and the obtained slurry is dried at 80°C to obtain a ball mill mixture;

[0046] (3) Pre-burning: add the ball mill mixture into the crucible, after compaction, place it...

Embodiment 2

[0052] Prepare strontium barium titanate based ceramic material according to the method of Example 1, the difference is that the chemical composition of strontium barium titanate based ceramic material is 0.9Ba 0.8 Sr 0.2 TiO 3 -0.1Bi(Mg 2 / 3 Nb 1 / 3 )O 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com