Method for preparing three-dimensional graphene structure through 3D printing

A 3D printing and graphene technology, which is applied in the field of 3D printing to prepare three-dimensional graphene structures, can solve problems affecting the precision of three-dimensional graphene and graphene membrane wrinkles, and achieve the effects of small deformation, fast flow, and improved precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

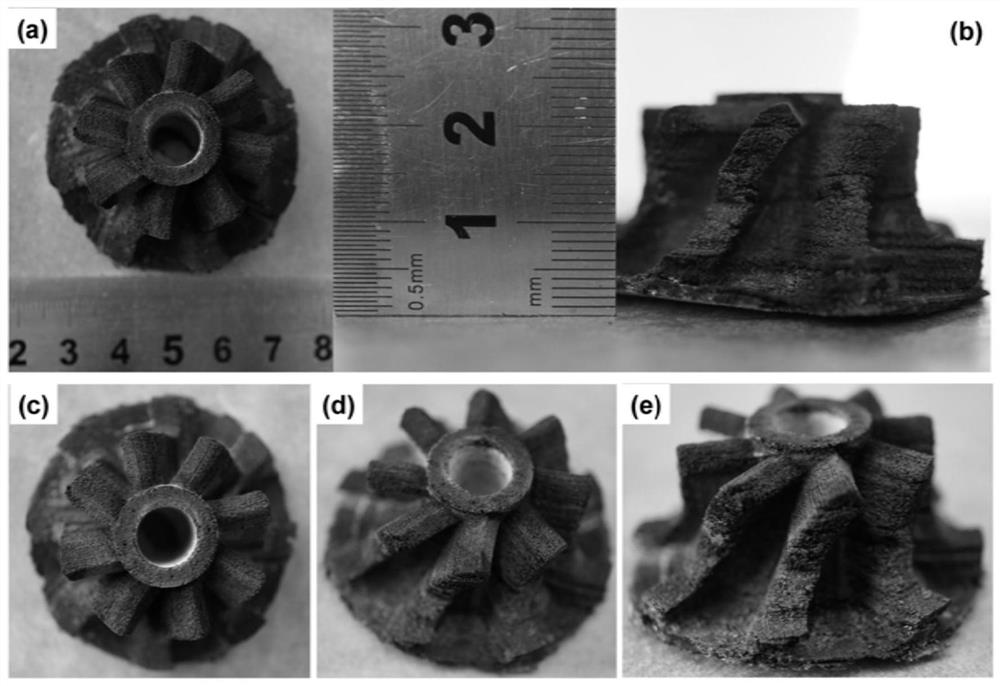

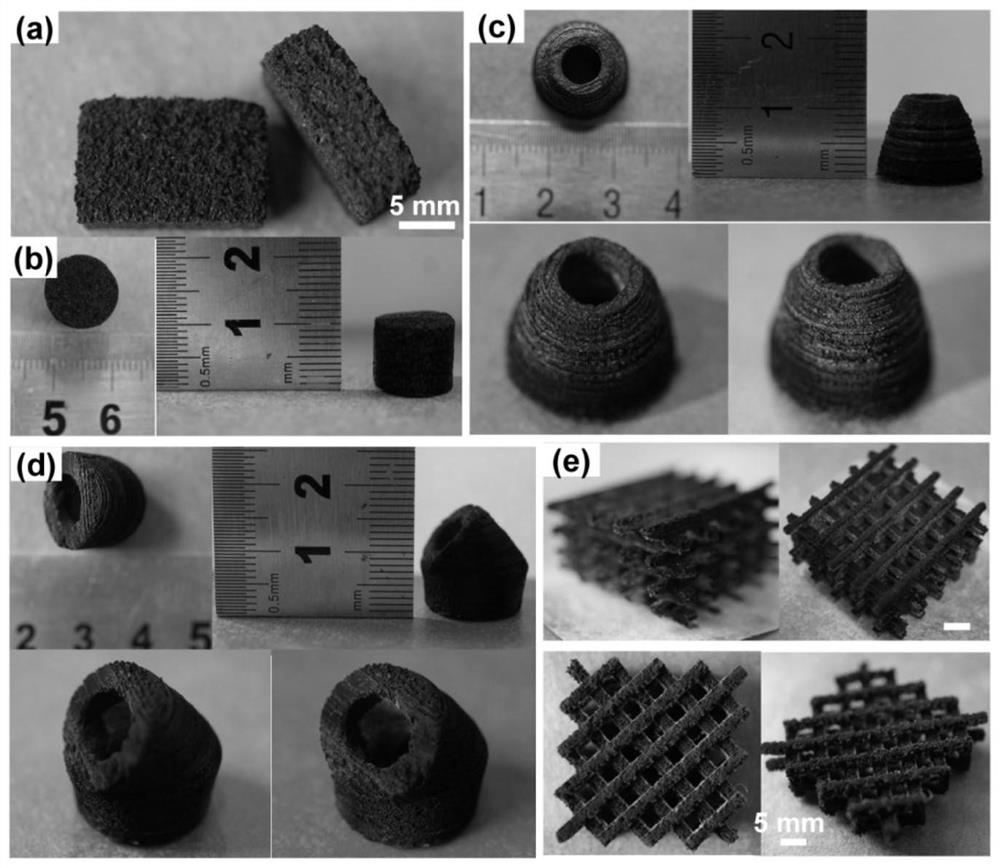

[0057] The preparation method of the present invention can realize the direct preparation of three-dimensional graphene structures of various shapes, and besides solid structures such as simple blocks 3 (a) and columns 3 (b), cavities 3 (c) can also be realized. ), the variable cross-section structure 3(d) and the hollow structure 3(e) and the preparation of three-dimensional structures with complex shapes; the diversity of such macroscopic structures is more conducive to the development and research of the wide application of three-dimensional graphene structures.

[0058] In the present invention, by fixing the laser focal length, scanning speed and printing resolution, and selecting lasers with different powers to induce powders, it is found that during the laser induction process of polymer powders, according to the gradual increase in laser processing power, the products can be divided into: 5 stages: powder particles, PI film, activated carbon film, graphene film, over-ca...

Embodiment 1

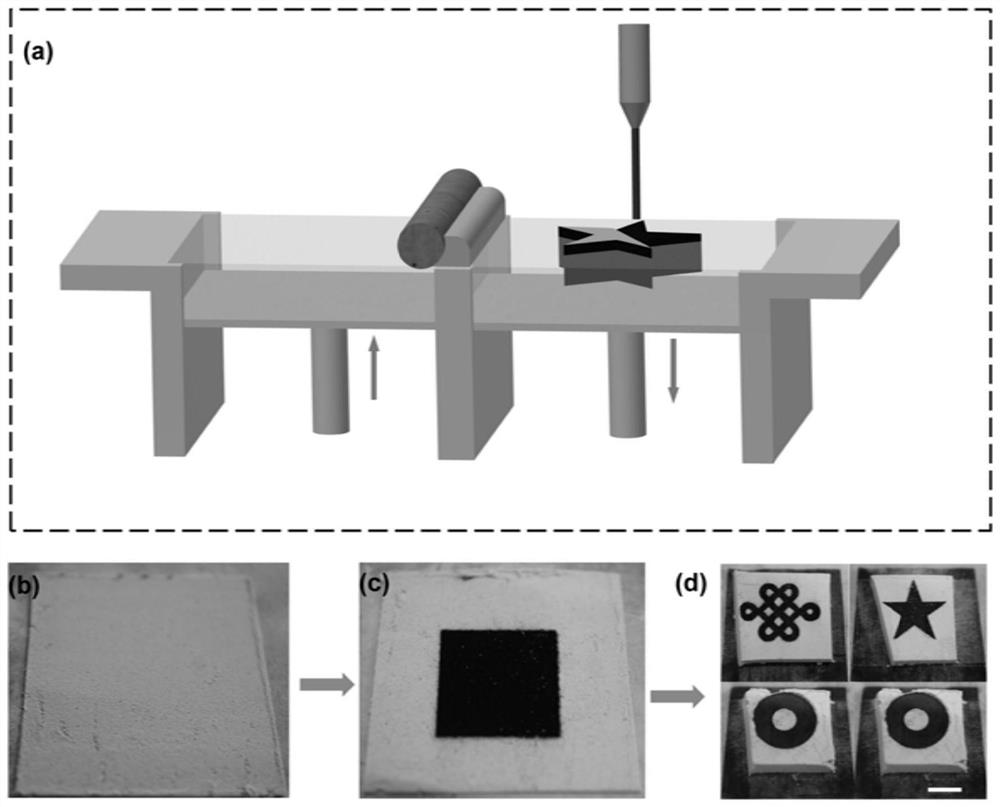

[0064] A method for preparing a three-dimensional graphene structure by 3D printing, comprising the following steps:

[0065] S1 substrate processing, fixing the polyimide (PI) paper on the aluminum plate, and laser-induced the PI paper to produce a laser-induced graphene (LIG) substrate;

[0066] S2 in the air atmosphere, spread the polyimide powder evenly on the LIG surface of S1, and use the laser to select the polyimide powder with a power of 1W, a scanning speed of 50.8mm / s and a printing resolution of 500 Sexual graphene;

[0067] S3 continues to spread the powder, on the surface of the formed graphene, carry out the second powder spreading, and the thickness of the powder spreading is 50 μm;

[0068] S4 laser induction, the laser is used to selectively graphenize the polyimide powder with a power of 1W, a scanning speed of 50.8mm / s and a printing resolution of 500 to form a pre-designed single-layer graphene film;

[0069] S5 prints layer by layer, repeatedly repeats st...

Embodiment 2

[0072] S1 substrate processing, fixing the polyimide (PI) paper on the aluminum plate, and laser-induced the PI paper to produce a laser-induced graphene (LIG) substrate;

[0073] In S2, the polyimide powder was evenly spread on the LIG surface of S1 in the air atmosphere, and the polyimide powder was processed by the laser with a power of 1.5W, a scanning speed of 50.8mm / s and a printing resolution of 500. Selective grapheneization;

[0074] S3 continues to spread the powder, on the surface of the formed graphene, carry out the second powder spreading, and the thickness of the powder spreading is 100 μm;

[0075] S4 laser induction, the laser is used to selectively graphenize the polyimide powder with a power of 1.5W, a scanning speed of 50.8mm / s and a printing resolution of 500 to form a pre-designed single-layer graphene film;

[0076] S5 prints layer by layer, repeats steps S4 and S5 repeatedly, and after the cumulative number of powder spreading reaches 70 times, the pri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com