Lead-free epitaxial thin film with wide working temperature and preparation method thereof

A wide working temperature, epitaxial thin film technology, applied in chemical instruments and methods, metal material coating process, ion implantation plating, etc. Effect of temperature and stable breakdown field strength

- Summary

- Abstract

- Description

- Claims

- Application Information

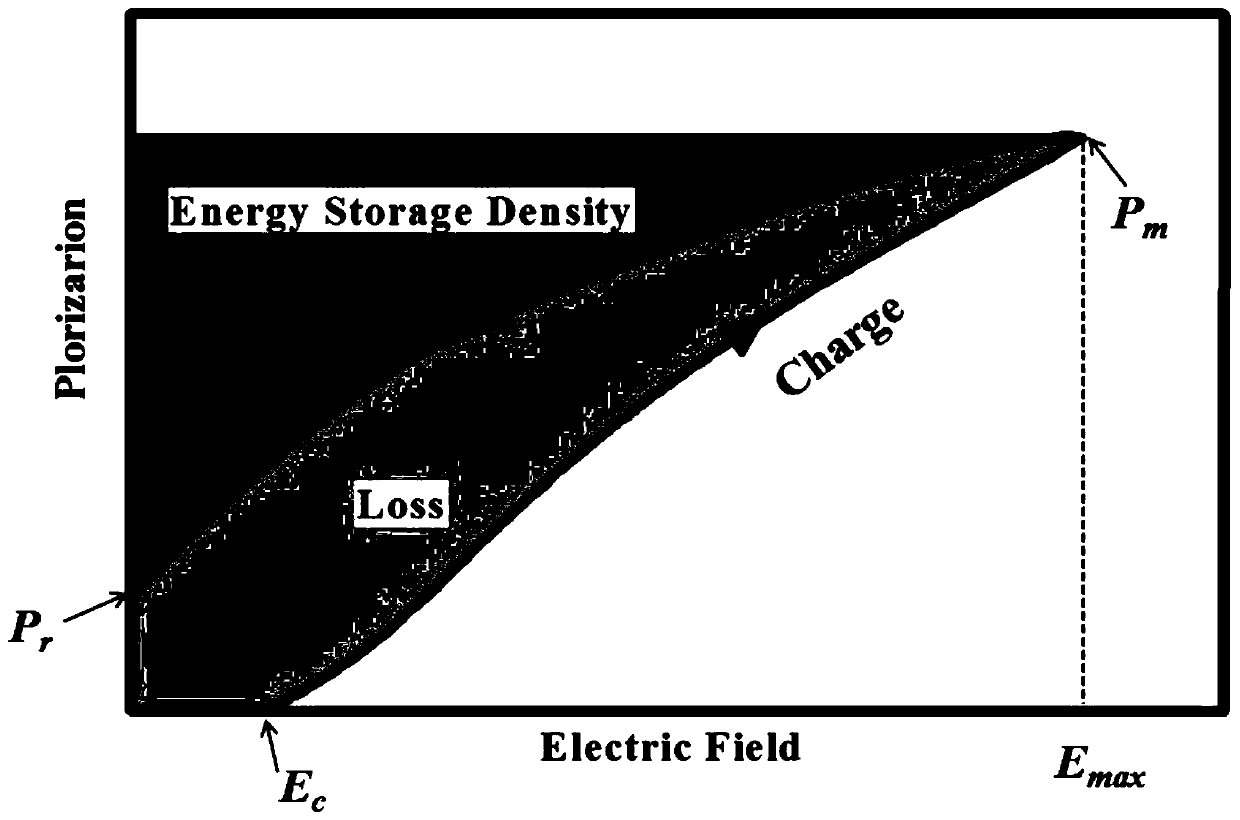

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

[0040] The wide operating temperature lead-free epitaxial film of the present invention is a lead-free epitaxial film with higher operating temperature characteristics, and is a barium titanate-based lead-free epitaxial film. The preparation method comprises the following steps:

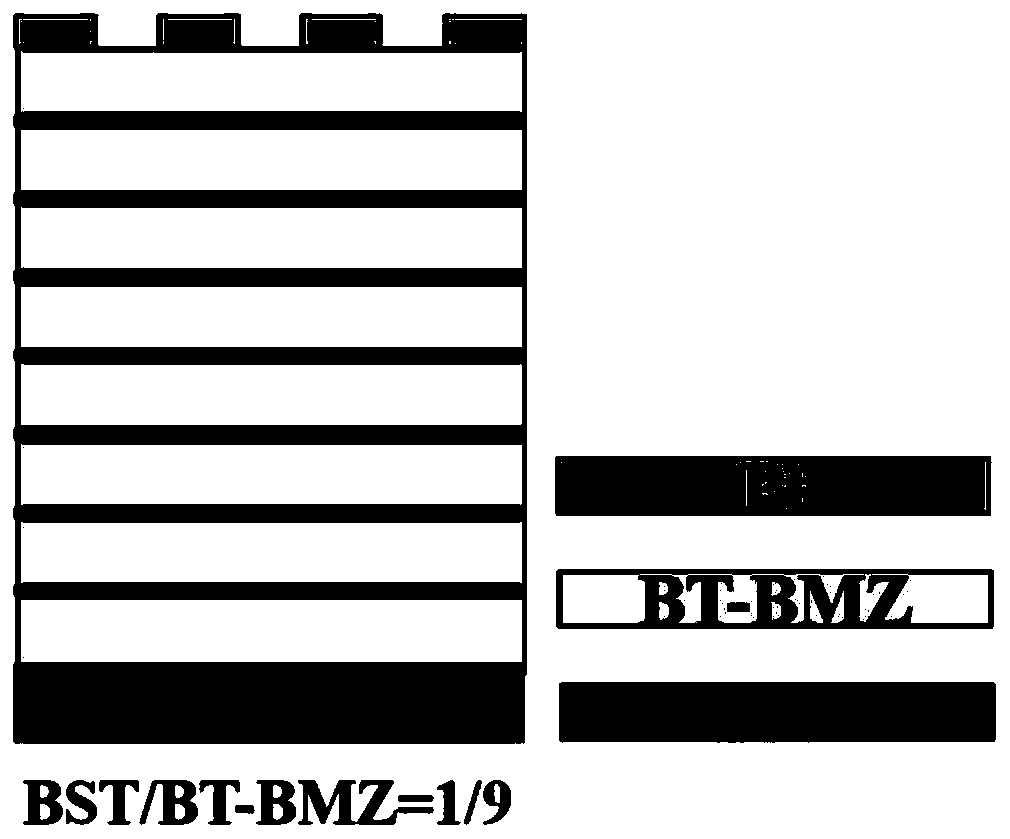

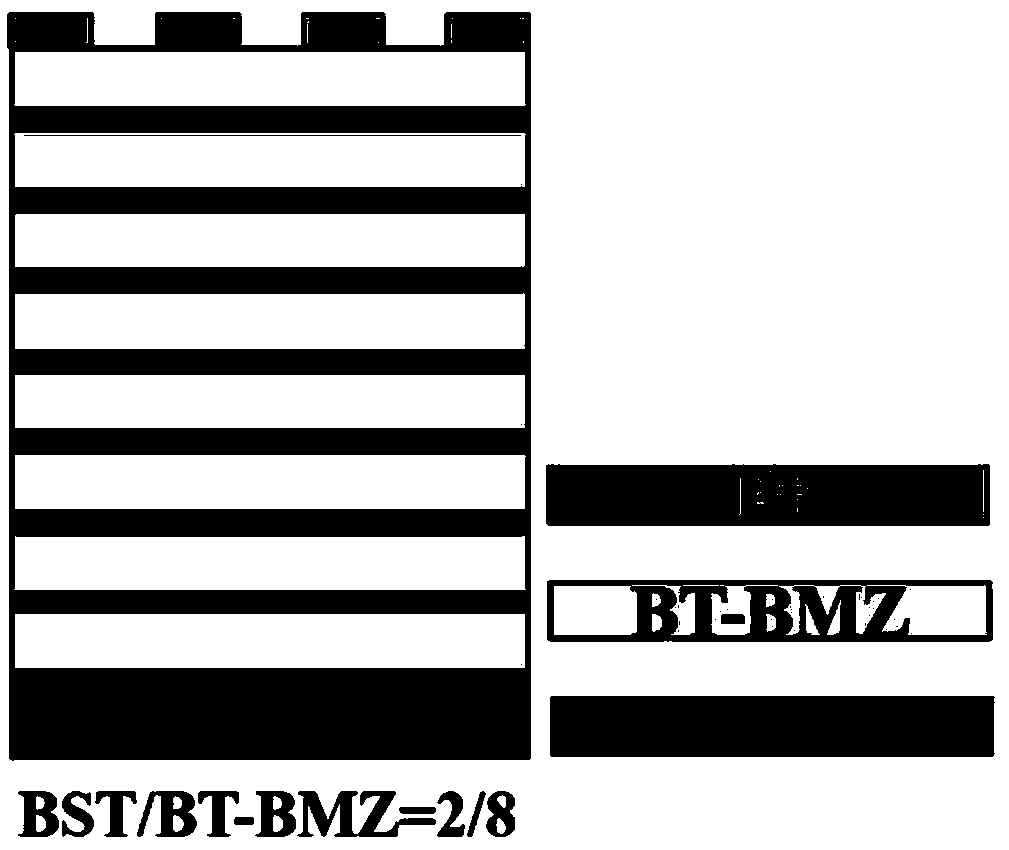

[0041] Step (1) Weigh the corresponding raw materials according to the chemical formula, wherein, the BST ceramic target (i.e. used for growing Ba 0.3 Sr 0.7 TiO 3 Thin film ceramic target) BaCO with a purity level of 4-5N 3 Powder, SrCO 3 Powder, TiO 2 Powder prepared, BT-BMZ ceramic target (that is, used to grow 0.85BaTiO 3 -0.15Bi(Mg 0.5 Zr 0.5 )O 3 Thin film ceramic target) is BaCO with a purity level of 4-5N 3 Powder, Bi 2 o 3 Powder, TiO 2 powder, MgO powder and ZrO 2 When sintering the above two ceramic targets, the sintering temperature is 100-20...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com