PTFE (polytetrafluoroethylene)-based ceramic composite with near-zero dielectric constant temperature coefficient and preparation method of ceramic composite

A polytetrafluoroethylene based ceramic and polytetrafluoroethylene technology, which is applied in the field of polytetrafluoroethylene based ceramic composite materials and their preparation, can solve the problem of unspecified substrate dielectric constant temperature coefficient, high water absorption rate and dielectric loss and other problems, to achieve the effect of optimizing the molding process, improving performance, and simple and efficient process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

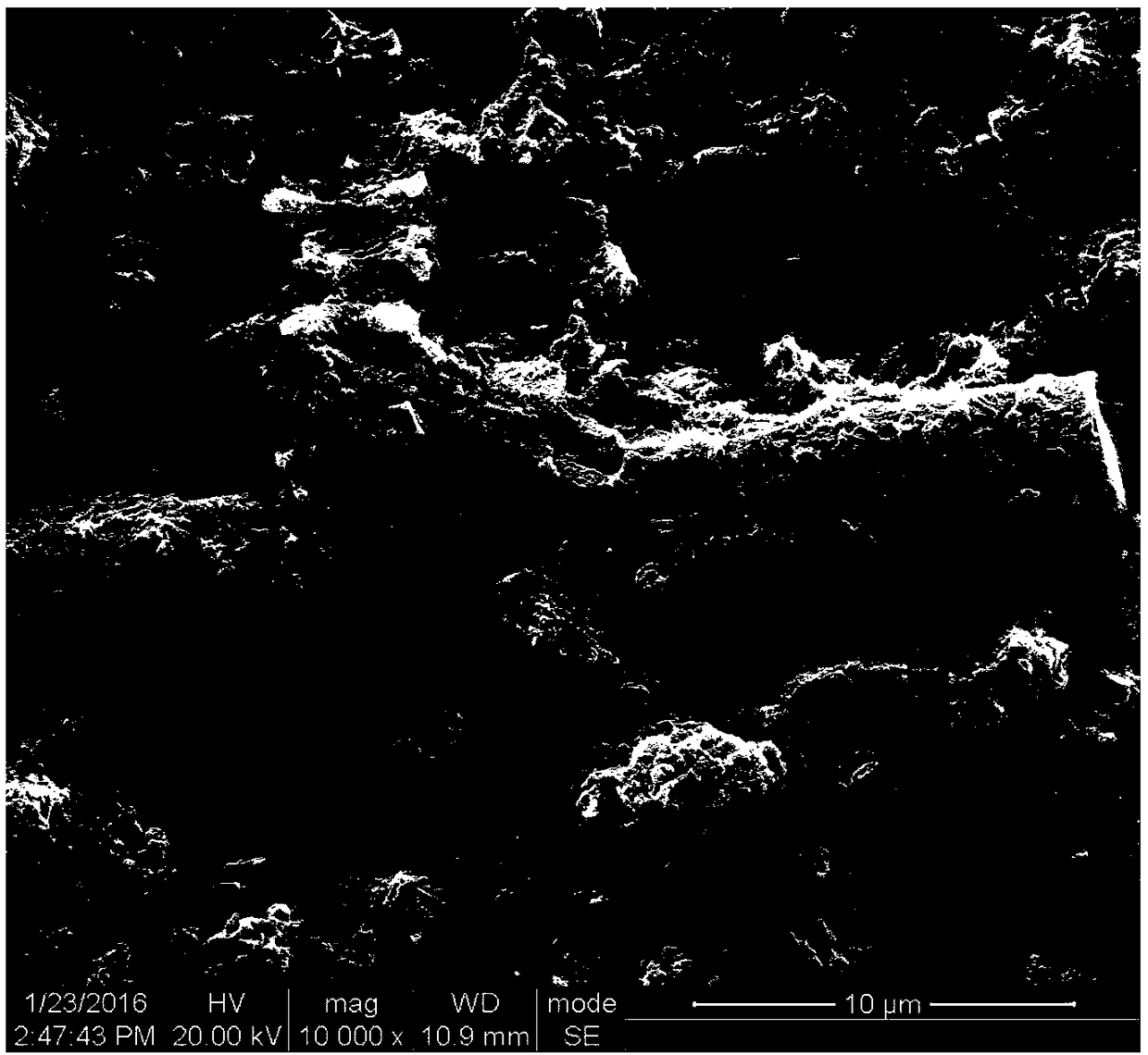

Image

Examples

Embodiment 1

[0063] This embodiment provides a method for preparing a polytetrafluoroethylene-based ceramic composite material, the specific steps of which are as follows:

[0064] (1) Weigh 100gBaZn 0.4 Ti 4 o 9.4 For ceramic powder, dry the ceramic powder in an oven at 120°C for 10 hours to remove the physically adsorbed water; then configure a mixture of hydrogen peroxide and 150ml of concentrated brine in a three-necked reflux flask, where V (hydrogen peroxide): V (concentrated brine)=30:70, then add the ceramic powder into the mixed solution and boil at 60°C, while stirring for 1.5 hours to activate and increase the effect of hydroxyl groups on the surface of the ceramic powder; finally filter the ceramic powder, And the product obtained by suction filtration was dried at 120°C for 18 hours in a vacuum environment to obtain an activated ceramic powder;

[0065] (2) Weigh 2g coupling agent, 43g deionized water and 77g dehydrated ethanol, then mix deionized water and dehydrated ethan...

Embodiment 2

[0072] This embodiment provides a method for preparing a polytetrafluoroethylene-based ceramic composite material, the specific steps of which are as follows:

[0073] (1) Weigh 200gBaZn 0.4 Ti 4 o 9.4 Ceramic powder, dry the ceramic powder in an oven at 120°C for 10 hours to remove the physically adsorbed water; then configure a mixture of hydrogen peroxide and concentrated brine 300ml in a three-necked reflux flask, where V (hydrogen peroxide): V (concentrated brine)=30:70, then add the ceramic powder into the mixed solution and boil at 60°C, while stirring for 1.5 hours to activate and increase the effect of hydroxyl groups on the surface of the ceramic powder; finally filter the ceramic powder, And the product obtained by suction filtration was dried at 120°C for 18 hours in a vacuum environment to obtain an activated ceramic powder;

[0074] (2) Weigh 4g coupling agent, 86g deionized water and 154g dehydrated ethanol, then mix deionized water and dehydrated ethanol and...

Embodiment 3

[0080] This embodiment provides a method for preparing a polytetrafluoroethylene-based ceramic composite material, the specific steps of which are as follows:

[0081] (1) Weigh 150gBaZn 0.4 Ti 4 o 9.4 For ceramic powder, dry the ceramic powder in an oven at 120°C for 10 hours to remove the physically adsorbed water; then configure a mixture of hydrogen peroxide and 250ml of concentrated brine in a three-necked reflux flask, where V (hydrogen peroxide): V (concentrated brine)=30:70, then add the ceramic powder into the mixed solution and boil at 60°C, while stirring for 1.5 hours to activate and increase the effect of hydroxyl groups on the surface of the ceramic powder; finally filter the ceramic powder, And the product obtained by suction filtration was dried at 120°C for 18 hours in a vacuum environment to obtain an activated ceramic powder;

[0082] (2) Weigh 3g coupling agent, 64g deionized water and 116g dehydrated ethanol, then mix deionized water and dehydrated etha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| dielectric loss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com