Film structure for satellite flexible heat radiator and manufacturing method of film structure

A thin-film structure and thermal radiator technology, applied in the field of spacecraft thermal control, can solve problems such as the limited volume of satellites

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The film structure of the flexible heat radiator for stars of the present invention will be further described below in conjunction with the accompanying drawings. The description is only exemplary and is not intended to limit the protection scope of the present invention.

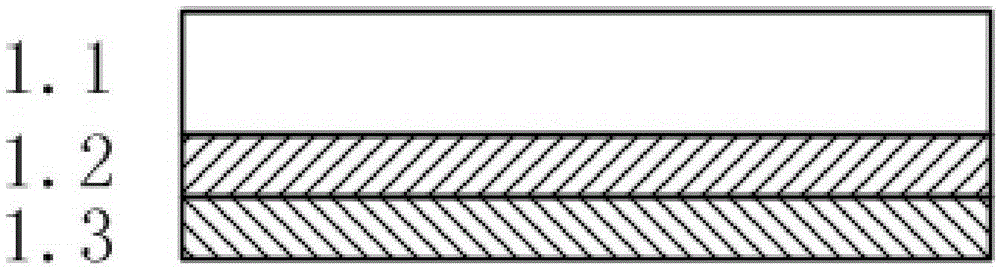

[0024] See figure 1 , figure 1 It is a thin film structure of a star heat radiator with a structure of the invention. Among them, the structure includes three layers, namely a carbon nanotube paper layer 1.1, a graphene layer 1.2 and a metal aluminum layer or a copper layer 1.3.

[0025] First, a single graphene layer 1.2 is set on the carbon nanotube paper layer 1.1, and a metal copper or aluminum layer 1.3 is plated on the graphene layer 1.2, wherein the thickness of the graphene layer 1.2 is less than 1 nm, and the metal copper or aluminum layer The thickness of layer 1.3 is 10 nm.

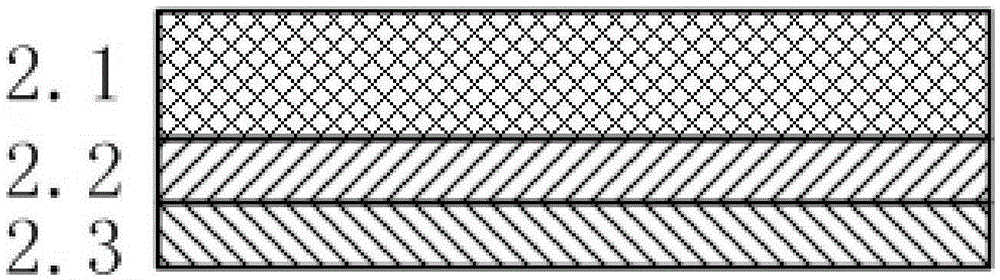

[0026] See figure 2 , figure 2 It is the thin film structure of the star heat radiator of another structure of the pres...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com