Method for measuring Seebeck coefficient of micro/nano thermoelectric materials or devices

A Seebeck coefficient and thermoelectric material technology, applied in the direction of measuring electricity, measuring electrical variables, measuring devices, etc., can solve the problems of increasing the complexity of the preparation process, and achieve the effect of simple experimental devices and high measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

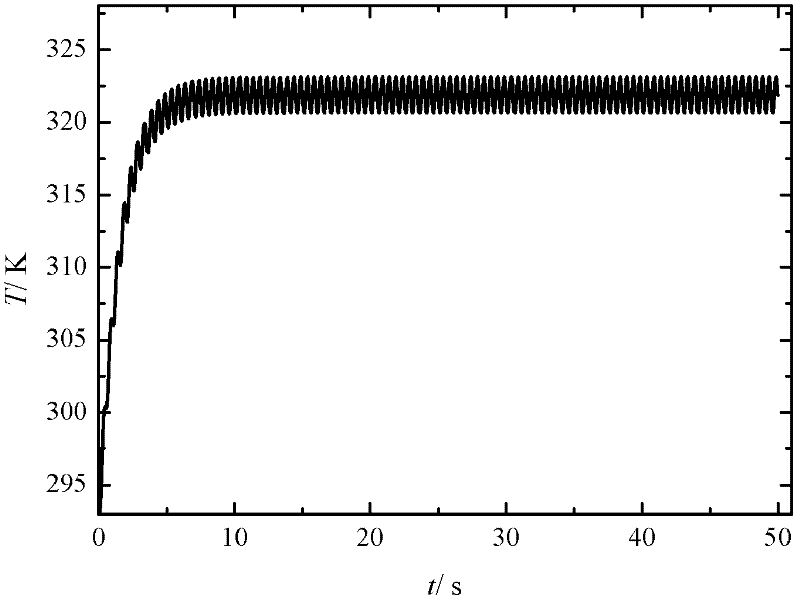

[0018] A K-type thermocouple with a diameter of 25.4 μm (Omega Engineering, positive nickel-chromium Ni:Cr=90:10, negative nickel-silicon Ni:Si=97:3) was used for experimental verification at 298K, and the physical parameters of the tested samples are shown in Table 1 shown.

[0019] Table 1 Physical property parameters of the tested samples

[0020]

[0021]

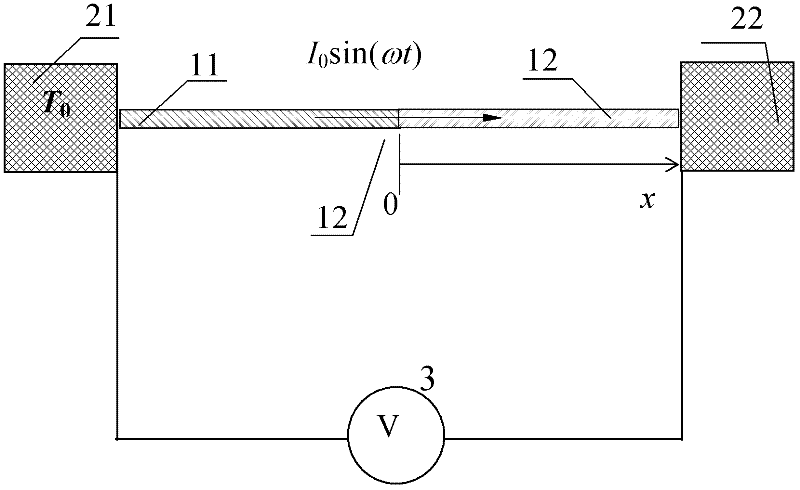

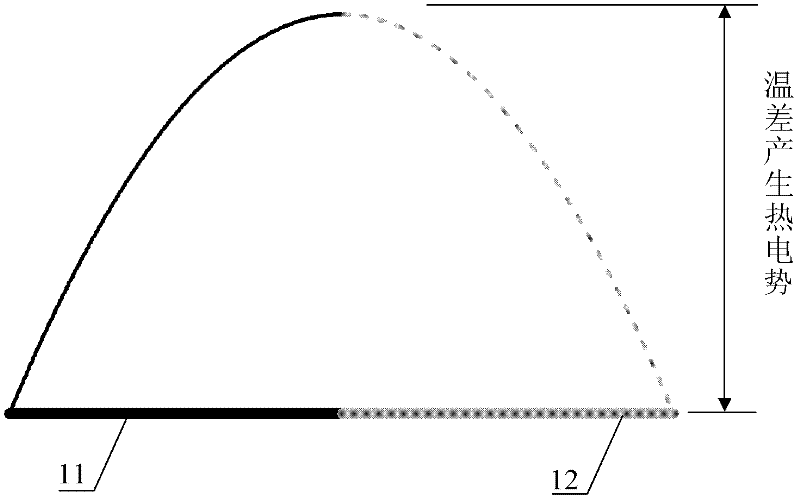

[0022] Such as figure 1 As shown, the test sample is formed by connecting the first nano-thermoelectric material 11 (the positive pole of the K-type thermocouple) and the second nano-thermoelectric material 12 (the negative pole of the K-type thermocouple), and the other end of the first nano-thermoelectric material 11 is connected to the first Heat sink 21, the other end of the second nanometer thermoelectric material 12 is connected with the second heat sink 22, passes through...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Seeback coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com