Method of improving insulation performance of chip resistor unit

A technology of insulation performance and resistance, applied in the direction of I-shaped/sine-shaped resistance elements, etc., can solve the problems of shortening the creepage distance, affecting the insulation performance of resistance units, and failing to meet the high-voltage requirements of the rainy environment, so as to achieve simplified isolation. way, improve the overall insulation performance, and meet the effect of high voltage resistance requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

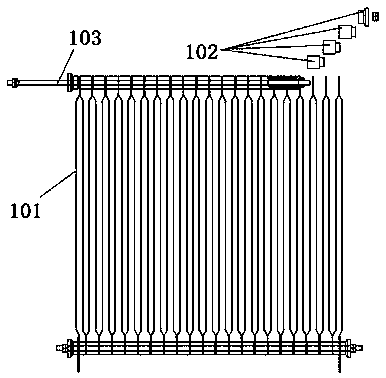

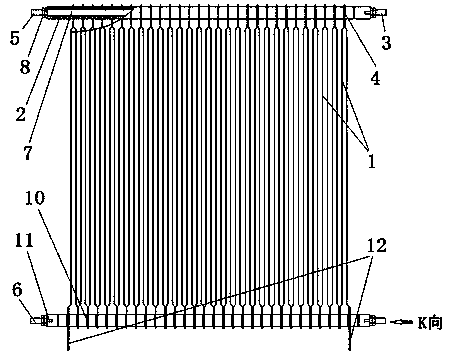

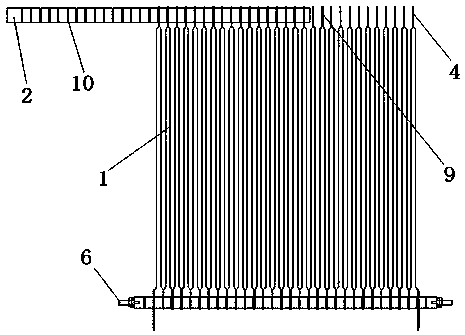

[0034] by attaching Figure 2-5 It can be seen that the present invention relates to a resistance unit with a combination structure of resistance bands, comprising a support rod 3, a resistance band 1 and a whole insulating tube 2, and the resistance unit is formed by combining the support bar 3, the resistance band 1 and the whole insulating tube 2. In the unit, the isolation and positioning of the two ends 4 of the upper and lower detours of the resistance band 1 are performed through the entire insulating tube.

[0035] The support rod 3 is a cylindrical metal rod commonly called a tie rod, and there are two support rods 3, which are respectively the first support rod 5 and the second support rod 6; the first support rod 5 and the second support rod The support rods 6 are respectively located at the upper and lower ends 4 of the resistance band 1, and pass through the central hole 7 on the entire insulating tube 2, and the two ends of the entire insulating tube 2 protrude o...

Embodiment 2

[0042] The principle of embodiment two is the same as embodiment one, but slightly different in structure, as attached Figure 6-7 As shown, the resistance unit of the combined structure of the resistance band comprises a support rod 203, a resistance band 201, a whole insulating tube 202 and a conductor 213, and the resistance unit is formed by combining the support bar 203, the resistance band 201 and the whole insulating tube 202; The isolation and positioning of the two ends of the belt 202 are carried out through the entire insulating tube 202 .

[0043] The support rod 203 is a cylindrical metal rod commonly called a tie rod, and there are two support rods 203, which are respectively the first support rod and the second support rod; the first support rod and the second support rod They are respectively located at the two ends of the resistance band 201, and pass through the center hole on the entire insulating tube 202, and the two ends protrude out of the entire insulat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com