Method and device for improving metal solidification defects and refining solidification textures

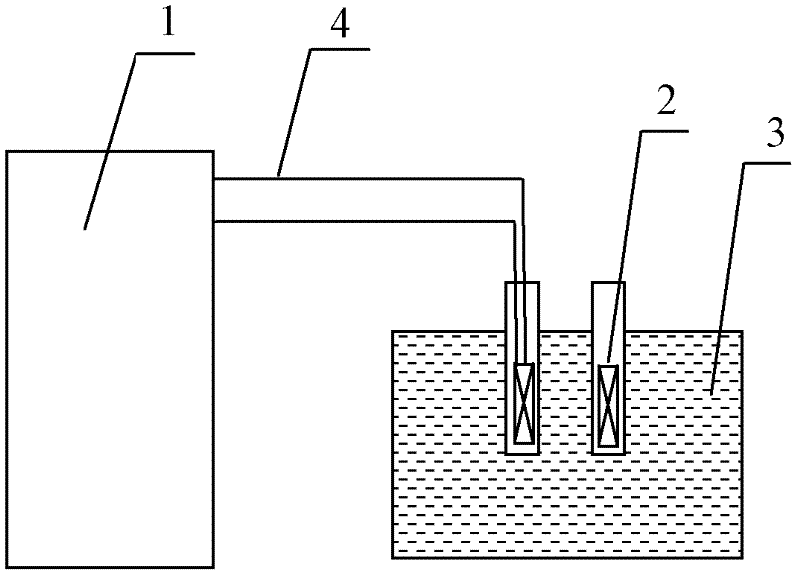

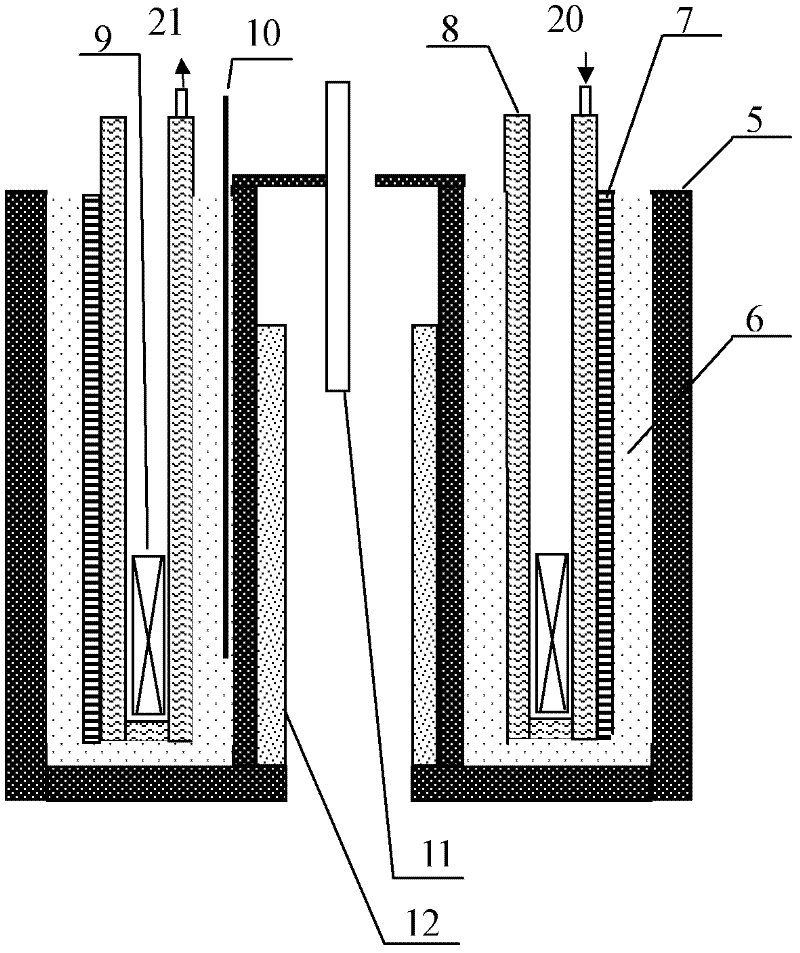

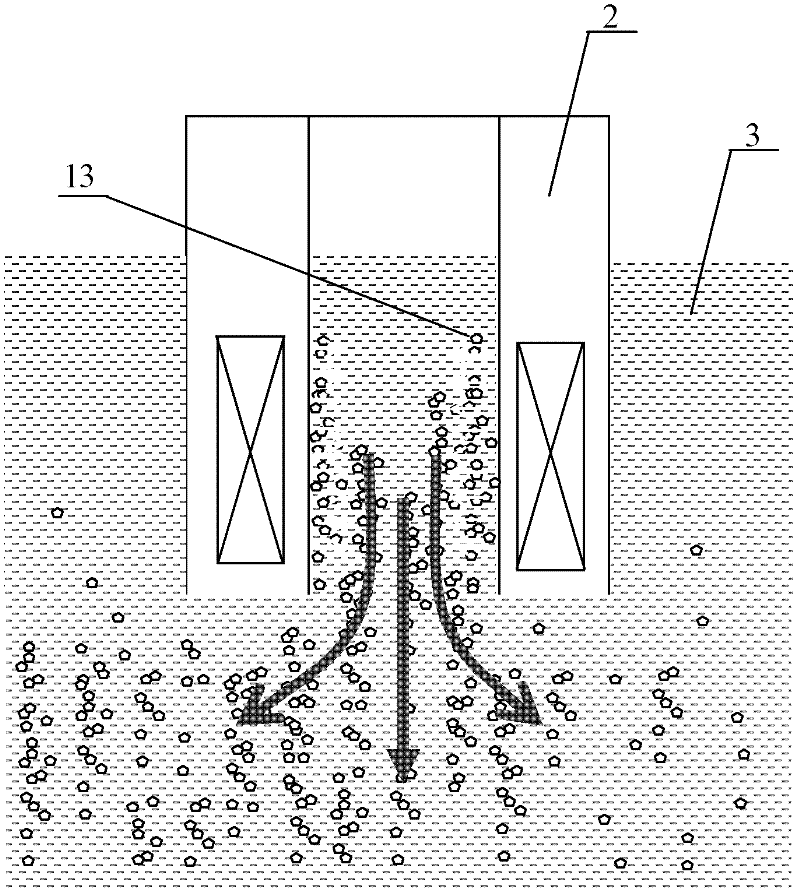

A solidification structure and metal solidification technology, applied in the field of improving metal solidification defects, refining solidification structure and devices, can solve problems such as involvement in defects and affecting applications, and achieve the effect of improving performance, improving utilization rate, and refining solidified structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] Cast 29 tons of die-cast steel ingots, the material of which is 40Cr. After the mold assembly tooling is completed, a magnetic field generating device is placed on the upper end of the riser. The frequency of the excitation current is 2.5Hz, and the excitation voltage is 200V. The magnetic field generating device bakes and heats the cladding layer and the inner surface to 850°C before immersing in the molten metal. After the steel ingot is poured, a magnetic field generating device is added in the riser of the steel ingot. During the application of the magnetic field, argon protection is carried out inside the magnetic field generating device. The argon pressure is 0.5 MPa, the flow rate is 0.2 liters / minute, and the magnetic field application time is 10 hours. The solidified structure of the prepared steel ingot is as follows: Figure 7 shown, from Figure 7 It can be seen that the steel ingot has a dense structure, no central shrinkage cavity and obvious A segregatio...

Embodiment 2

[0066] Cast 1 ton of sand mold steel ingot, the steel ingot is made of 45# steel, after the mold assembly tooling is completed, place a magnetic field generating device on the upper end of the riser. The frequency of the excitation current is 2.5Hz, and the excitation voltage is 100V. The magnetic field generating device bakes and heats the cladding layer and the inner surface to 900°C before immersing in the molten metal. After the steel ingot is poured, a magnetic field generating device is added in the riser of the steel ingot. During the application of the magnetic field, argon protection is carried out inside the magnetic field generator, the pressure of the argon gas is 1 MPa, the flow rate is 0.4 liter / min, and the magnetic field application time is 1 h. Figure 8(a) is the solidification structure of a conventional 1-ton sand-cast steel ingot, and Figure 8(b) is the solidification structure of a 1-ton sand-cast steel ingot prepared in this embodiment. It can be seen fro...

Embodiment 3

[0068] Casting 24 tons of continuous casting billet size is 600mm × 1000mm × 3400mm, material is ZG15Cr2Mo1, after the mold assembly tooling is completed, a magnetic field generator is placed on the upper end of the riser. The frequency of the excitation current is 5Hz, and the excitation voltage is 200V. The magnetic field generating device bakes and heats the cladding layer and the inner surface to 960°C before immersing in the molten metal. During the pouring process of the molten metal, a magnetic field generating device is added in the crystallizer. During the application of the magnetic field, argon protection is carried out inside the magnetic field generator, the argon pressure is 1.3 MPa, the flow rate is 0.5 liters / minute, and the magnetic field application time is 8 hours. The analysis results of the steel ingot are as follows Figure 9 As shown in the figure, it can be seen that there is no obvious central shrinkage cavity, porosity and A segregation inside the ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com