Method for casting large-sized steel ingot with internally arranged cold core and top arranged electromagnetic field

An electromagnetic field and cold core technology, applied in the field of steel ingot casting, can solve the problems of serious segregation and coarse structure in the center of the steel ingot, and achieve the effects of improving solidification quality, reducing production costs and reducing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

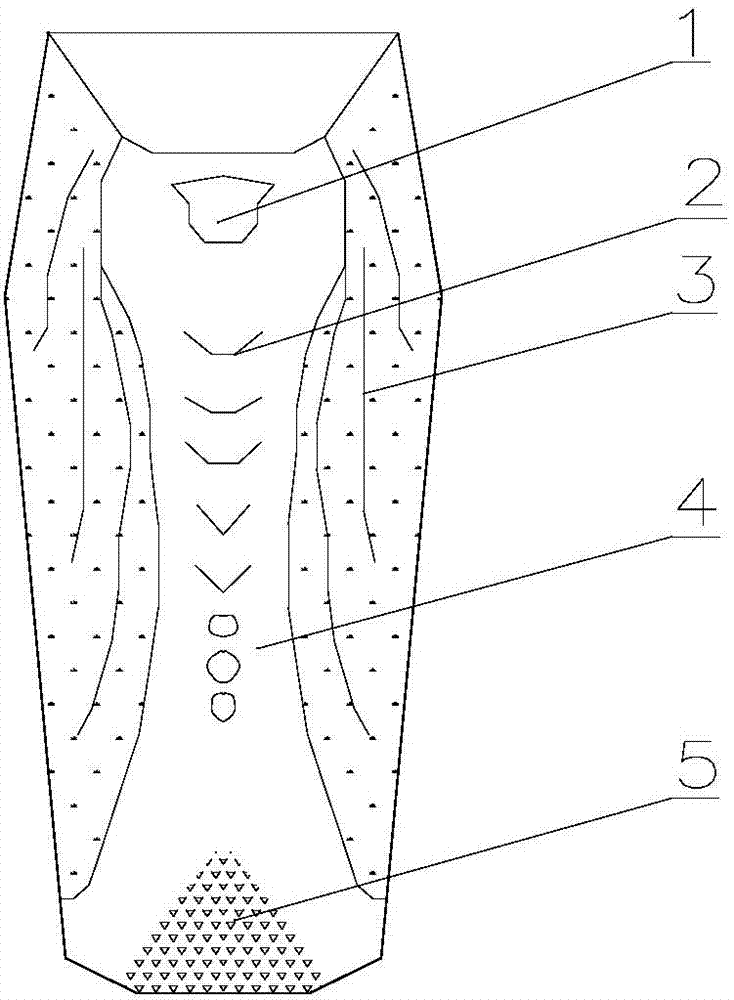

[0036] Such as figure 1 As shown, the upper cast 12 angle 39t solid 4Cr13 steel ingot, the specific steps are as follows:

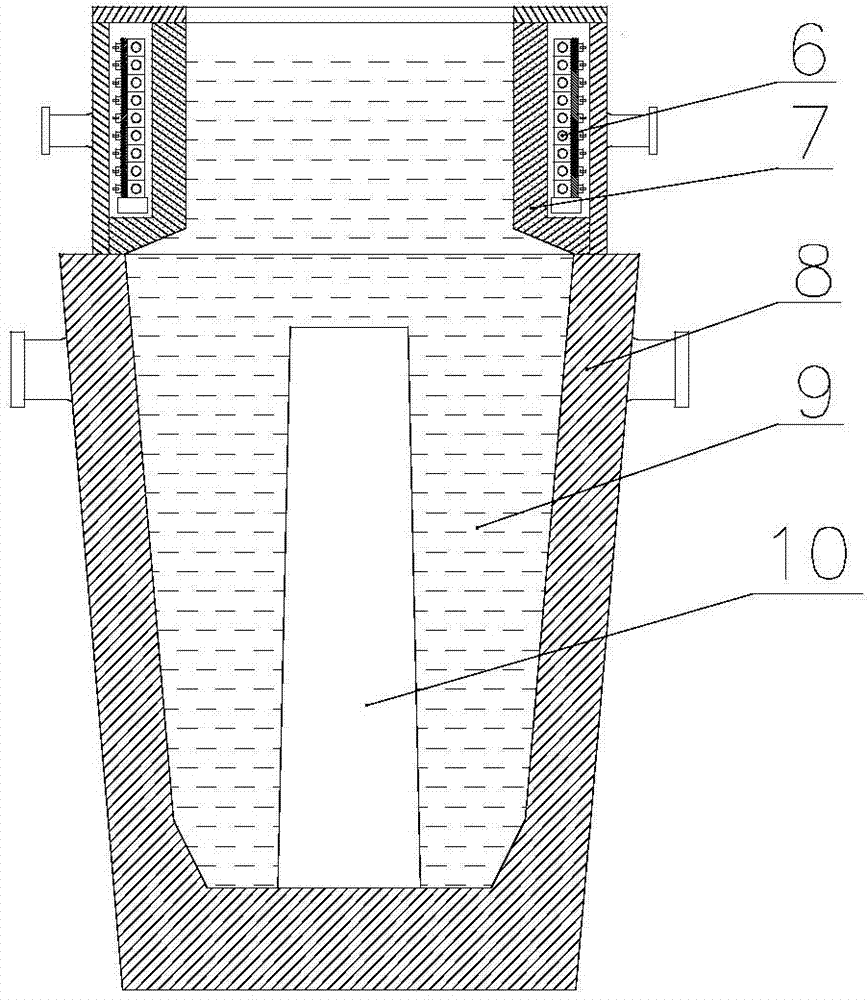

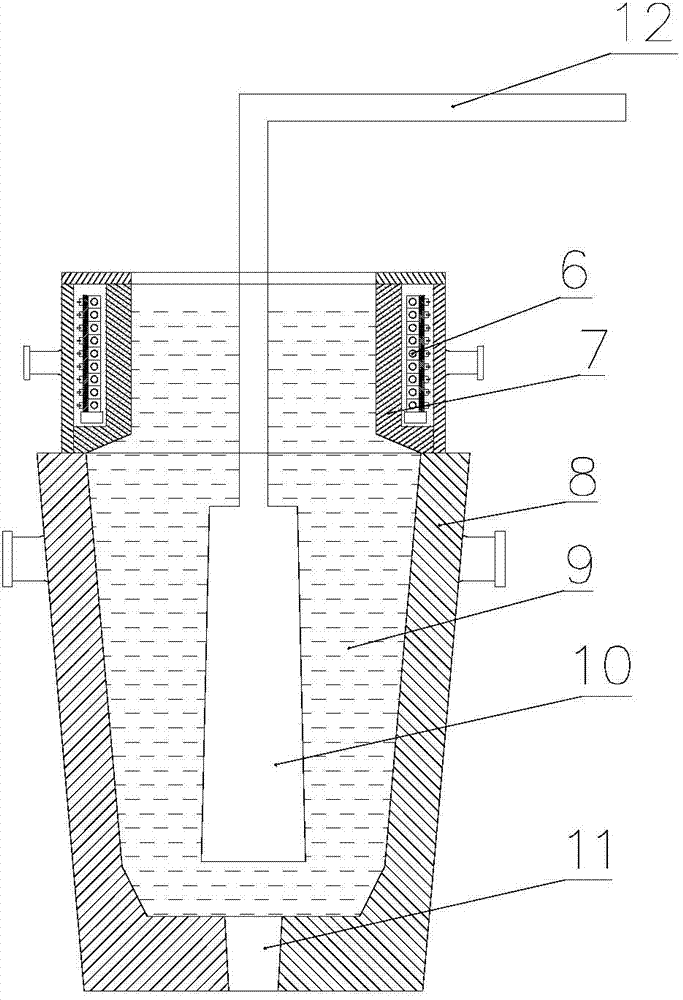

[0037] Preparation of cold core: firstly, cold core 10 is prepared in the whole mold process. The raw material selection standard of cold core 10 is: the composition is similar to that of 4Cr13, and the content of C, Si, Mn, P, and S elements is slightly lower than that of molten steel. There are no defects such as porosity, shrinkage cavity, inclusion and gas inside the cold core. The cold core 10 is polished to remove oxide layers and dirt. The cross-sectional shape of the cold core 10 is circular. The diameter of the lower opening of the steel ingot 9 is 1340mm. The core 10 is uniformly preheated to 250° C., and the temperature of the cold core 10 is not lower than 150° C. during pouring and filling, and it is firmly seated on the bottom of the steel ingot mold 8 . Also can cold core 10 be fixed on steel ingot 9 center by fixing bar 12, the distance ...

Embodiment 2

[0043] Such as figure 2 As shown, the 12-angle 28t solid composite steel ingot is cast down, and the specific steps are as follows:

[0044] Preparing the cold core: Firstly, the cold core 10 is prepared during the whole molding process. The raw material selection method of the cold core 10 is as follows: the stainless steel cold core 10 is selected, and there are no defects such as porosity, shrinkage cavity, inclusion and gas inside. The cold core 10 is polished to remove the oxide layer and dirt. The cross-sectional shape of the cold core 10 is circular. The diameter of the lower opening of the steel ingot 9 is 1150mm. The core 10 is evenly preheated to 250°C, and the temperature of the cold core 10 is not lower than 150°C during pouring and filling, and the cold core 10 is fixed to the center of the steel ingot 9 through the fixing rod 12, and the bottom of the cold core 10 can be connected with the steel ingot 9 ingot body The plane distance of the lower mouth is 400 mm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com