High-flexural-behavior hot-formed steel used for automobiles and manufacturing method thereof

A technology for hot forming steel and a manufacturing method, which is applied in the field of steel rolling and can solve the problems of reduced strength and increased plasticity of steel plates.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

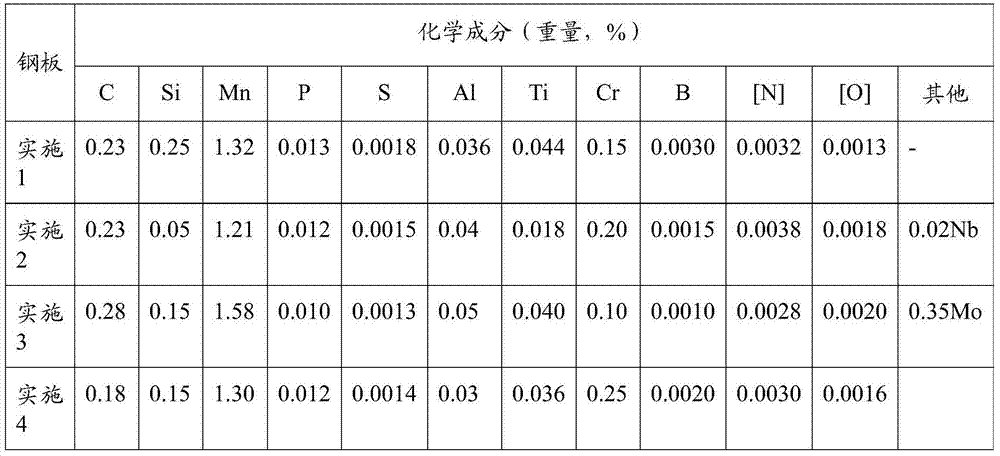

[0034] The invention provides a high-bending-resistant hot-formed steel for automobiles, comprising the following chemical components in mass percentage: C: 0.18-0.30%, Si≤0.30%, Mn: 1.00-1.60%, P≤0.015%, S≤ 0.0020%, Cr: 0.10~0.30%, Ti: 0.02~0.06%, Al: 0.020~0.060%, B: 0.0005~0.0040%, [N]≤0.004%, [O]≤0.003%, the balance is Fe and Inclusions are inevitable. In addition, the following chemical components are added in mass percentage: Nb: 0.02-0.10%, Mo: 0.15-0.40%, V≤0.10%, W≤0.40%, REM≤0.05%.

[0035] Among them, carbon (C): a solid solution strengthening element, plays a decisive role in the strength of the steel plate. In order to make the tensile strength of hot-formed steel reach more than 1300MPa, the C content must reach more than 0.18%, and with the increase of carbon content, cold working is difficult and the welding performance deteriorates. Therefore, the C content is controlled at 0.18-0.30%, which reduces the processing difficulty while ensuring the tensile streng...

Embodiment approach 2

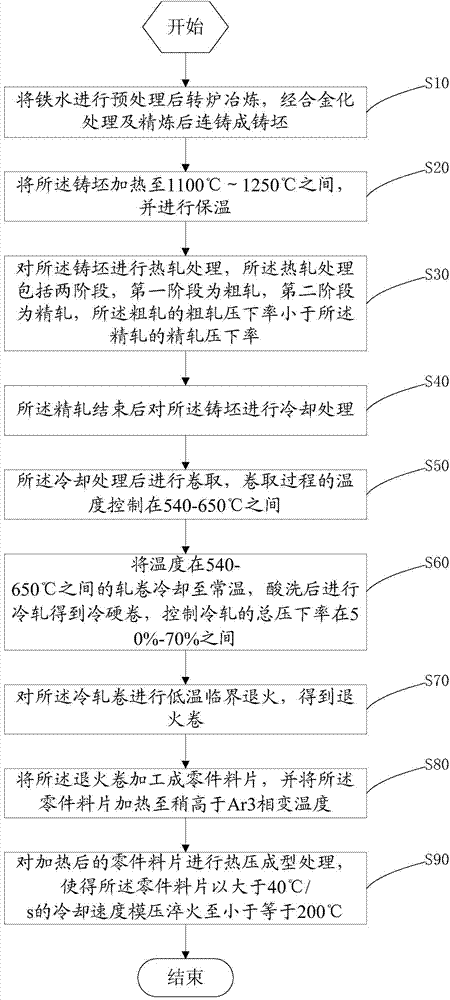

[0052] Such as figure 2 as shown, figure 2 It is a schematic flowchart of a method for manufacturing hot-formed steel with high bending resistance for automobiles provided by Embodiment 2 of the present invention.

[0053] Step S10: the molten iron is pretreated, then smelted in a converter, alloyed and refined, and then continuously cast into a slab. In this example, the molten iron is subjected to KR desulfurization pretreatment and full three desulfurization converter smelting processes to control the content of harmful elements such as sulfur and phosphorus in molten steel, and is refined by LF furnace to accurately control the chemical components in molten steel content, and then use the continuous casting machine to obtain the required slab.

[0054] The cast slab obtained by the above method has the following chemical composition in mass percentage: C: 0.18-0.30%, Si≤0.30%, Mn: 1.00-1.60%, P≤0.015%, S≤0.0020%, Cr: 0.10-0.30% , Ti: 0.02~0.06%, Al: 0.020~0.060%, B: 0...

Embodiment approach 3

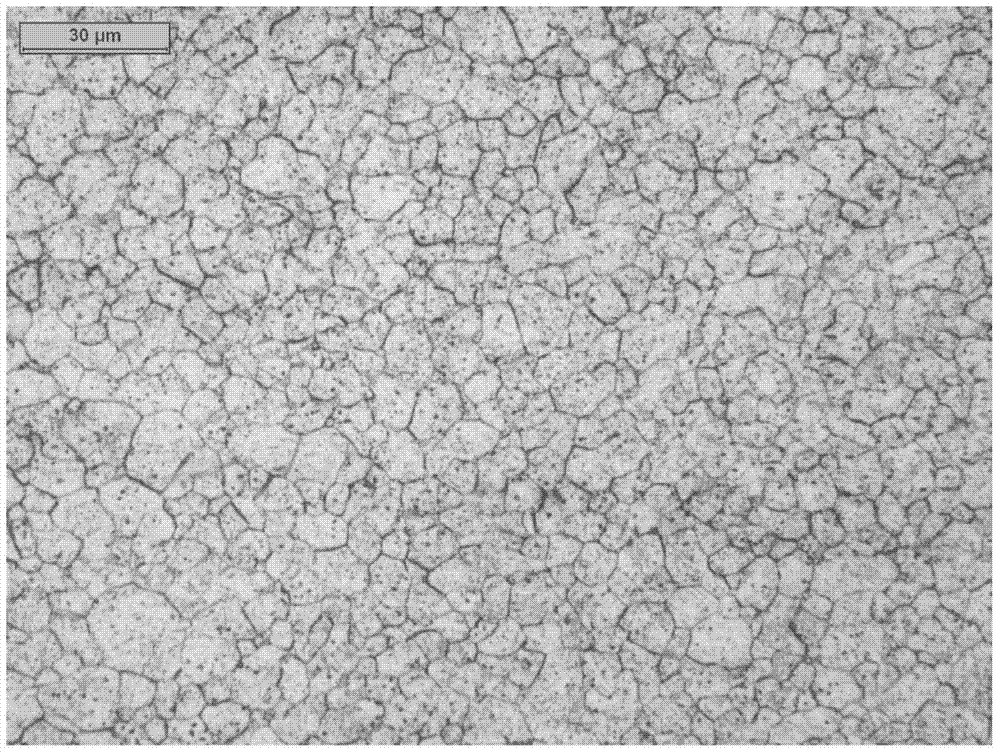

[0065] The slab with the chemical composition as described in Embodiment 1 is hot-rolled according to the manufacturing method of Embodiment 2 (see Table 1 for detailed composition), wherein the heating temperature is 1220° C., the total reduction ratio of rough rolling is 84%, and the finishing rolling The total reduction rate is 91%, the finish rolling temperature is 860°C, the time period from the end of finish rolling to the beginning of cooling is 0.5s, and the cooling rate is 20°C / s. And crimping at 600°C to obtain hot-rolled coils, the average grain size of the obtained hot-rolled coils is about 6um. The hot-rolled coils are pickled and then cold-rolled to 1.1mm, and then tempered to obtain chilled coils after annealing. The average grain size of the chilled coils is about 7.0um. After the chilled roll is cut and blanked, it is heated to 880°C, kept for 4 minutes, and then transferred to a press for hot-press forming. Finally, press quenching to 180°C at a cooling rate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com