Production line of polaroid release film base film and preparation method of production line

A release film and production line technology, applied in optics, flat products, optical components, etc., can solve the problems of unfavorable large-scale promotion, large investment in production equipment, and difficult control of alignment angle, etc., to achieve large-scale promotion and small production investment , good control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

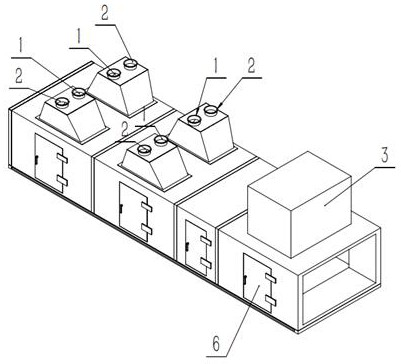

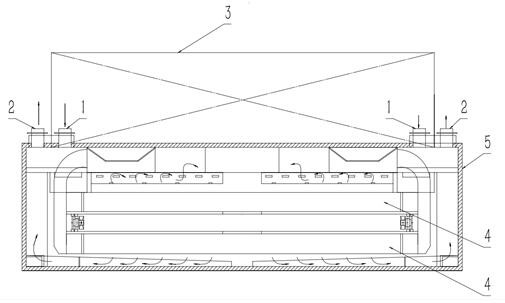

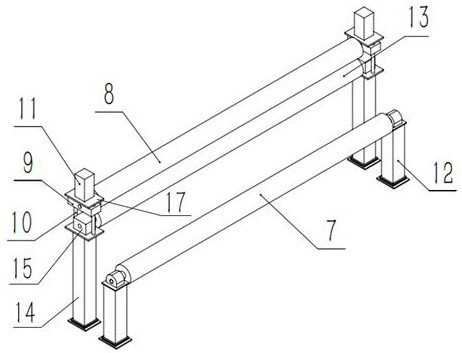

[0046] Such as Figure 1-5 The production line of a polarizer release film base film shown, the production line includes a main extruder and an auxiliary extruder arranged side by side, and filters arranged in sequence after the main extruder and the auxiliary extruder , melt pipeline, die distributor, cold drum, preheating roller, infrared heating lamp, cooling roller, horizontal stretching machine and traction winding system, horizontal stretching machine includes preheating section, transverse stretching section, high temperature setting section and The heat setting cooling section, the production line also includes a transverse stretching cooling box and an S-type pressure roller, the transverse stretching cooling box is arranged between the transverse stretching section and the high-temperature setting section, and the S-type pressing roller is arranged at the exit of the horizontal stretching machine.

[0047] The transverse stretching cooling box includes a box body, a ...

Embodiment 2

[0065] The production line of the polarizer release film base film in this embodiment is the same as that in Embodiment 1, and will not be repeated here.

[0066] The preparation method of polarizer release film base film comprises the steps:

[0067] S1. Extrusion: The raw polyester chips are respectively melted and extruded by the main extruder and the auxiliary extruder at a temperature of 275°C to obtain a melt. The melt passes through a filter at a temperature of 275°C and a melt at a temperature of 270°C. Pipeline, precisely compounded and flowed out under the die distributor at a temperature of 270°C;

[0068] S2. Cast sheet: The melt flows out through the lip of the die distributor. The temperature of the die lip is 275°C. After the melt flows down 2mm at the die lip, it is attached to the cold drum at a temperature of 25°C to form a cast sheet. The width of the cast sheet A crunch of 3%;

[0069] S3. Longitudinal stretching: the cast sheet is gradually heated by the...

Embodiment 3

[0077] The production line of the polarizer release film base film in this embodiment is the same as that in Embodiment 1, and will not be repeated here.

[0078] The preparation method of polarizer release film base film comprises the steps:

[0079] S1. Extrusion: The raw polyester chips are respectively melted and extruded by the main extruder and the auxiliary extruder at a temperature of 255°C to obtain a melt. The melt passes through a filter at a temperature of 260°C and a melt at a temperature of 260°C. The pipes are precisely compounded and flowed out under the die distributor at a temperature of 260°C;

[0080] S2. Cast sheet: The melt flows out through the lip of the die distributor. The temperature of the die lip is 255°C. After the melt flows down 1mm at the die lip, it is attached to the cold drum at a temperature of 18°C to form a cast sheet. The width of the cast sheet The amount of crunch is 1%;

[0081] S3. Longitudinal stretching: the casting sheet is gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com