Novel multi-pipe external-heating revolving activation furnace

An external heating type and activation furnace technology, applied in inorganic chemistry, carbon compounds, chemical industry, etc., can solve the problems of low output and poor activation effect, and achieve the effects of purifying air pollution, saving energy, and increasing the service life of the furnace

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

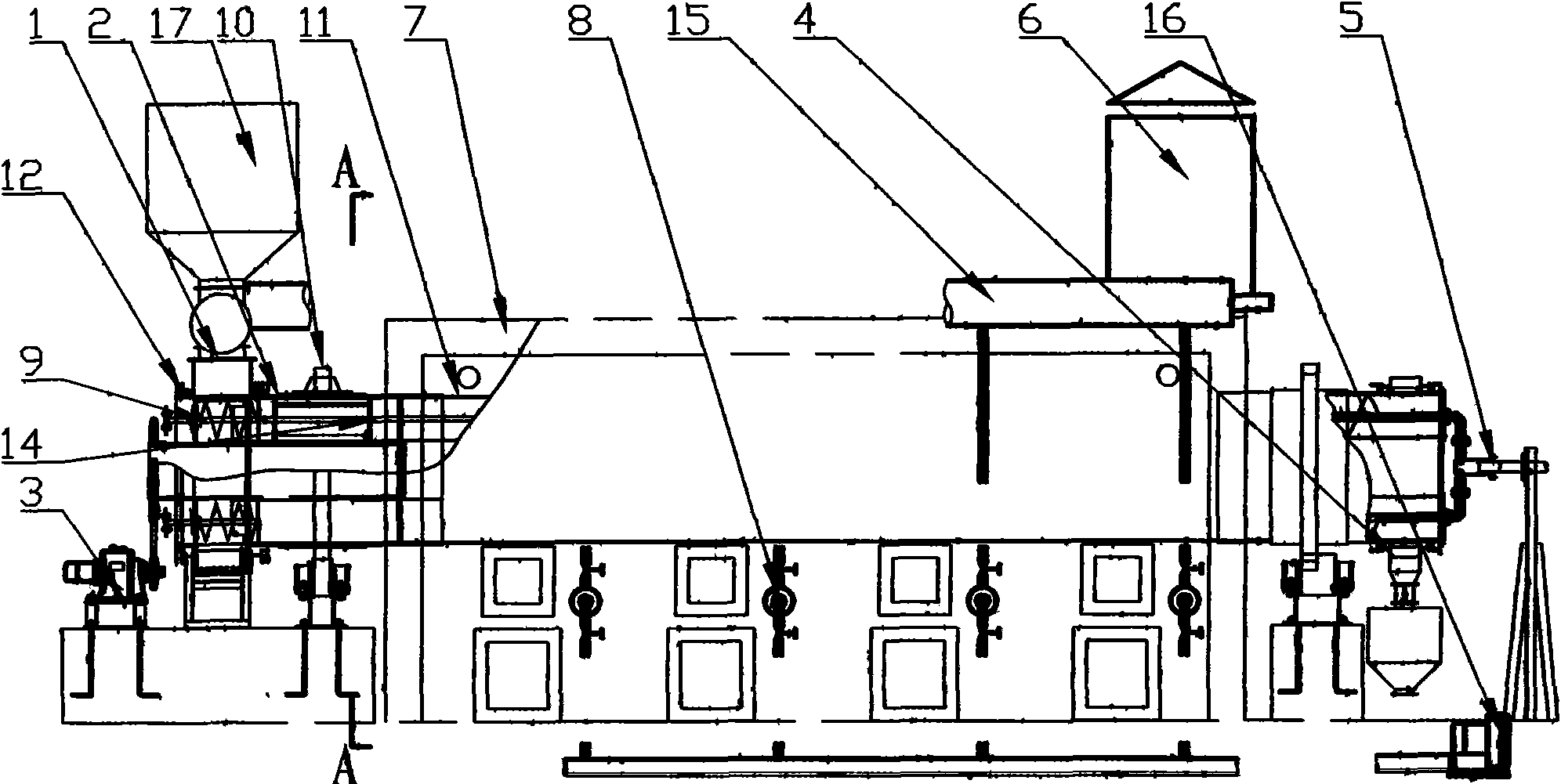

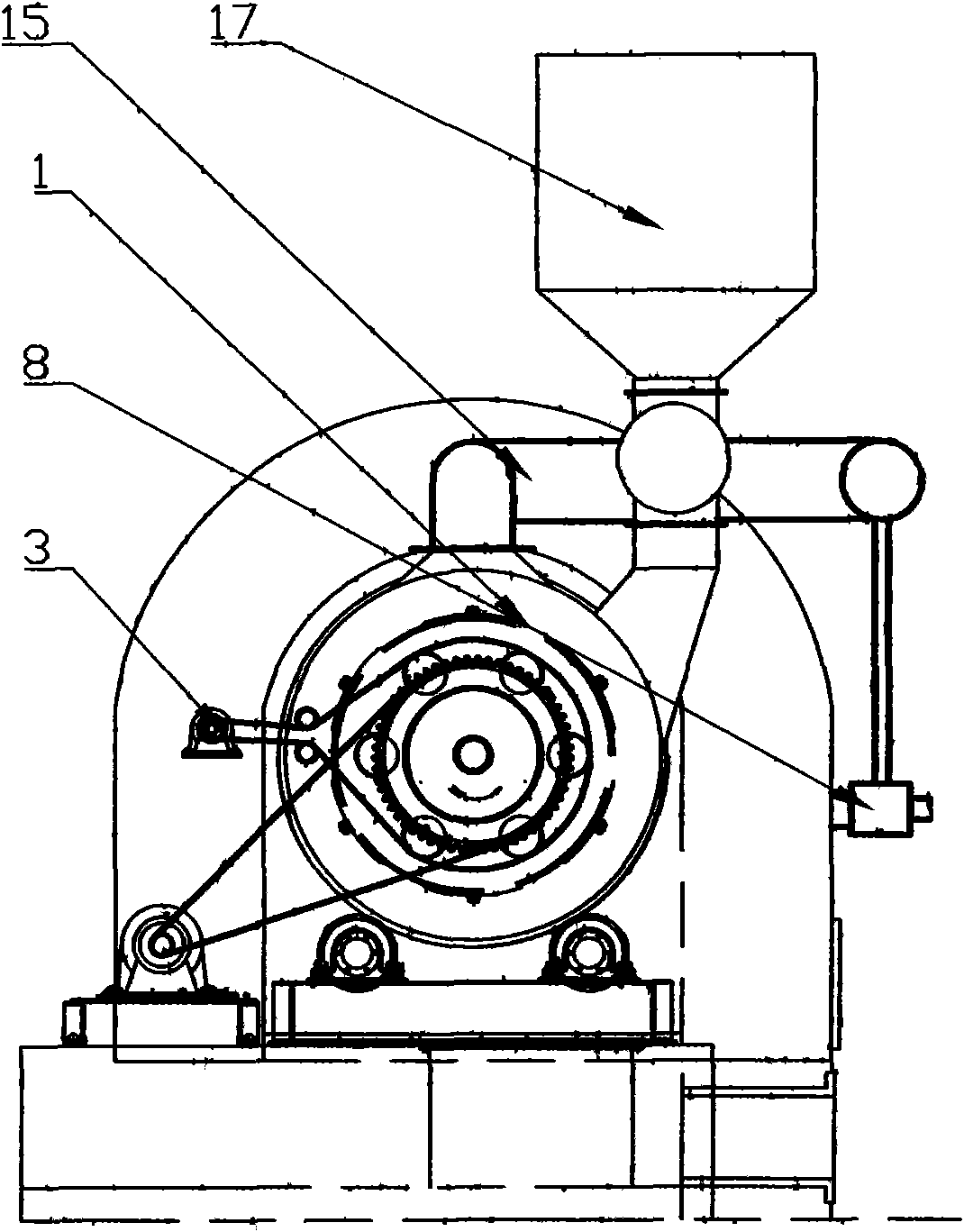

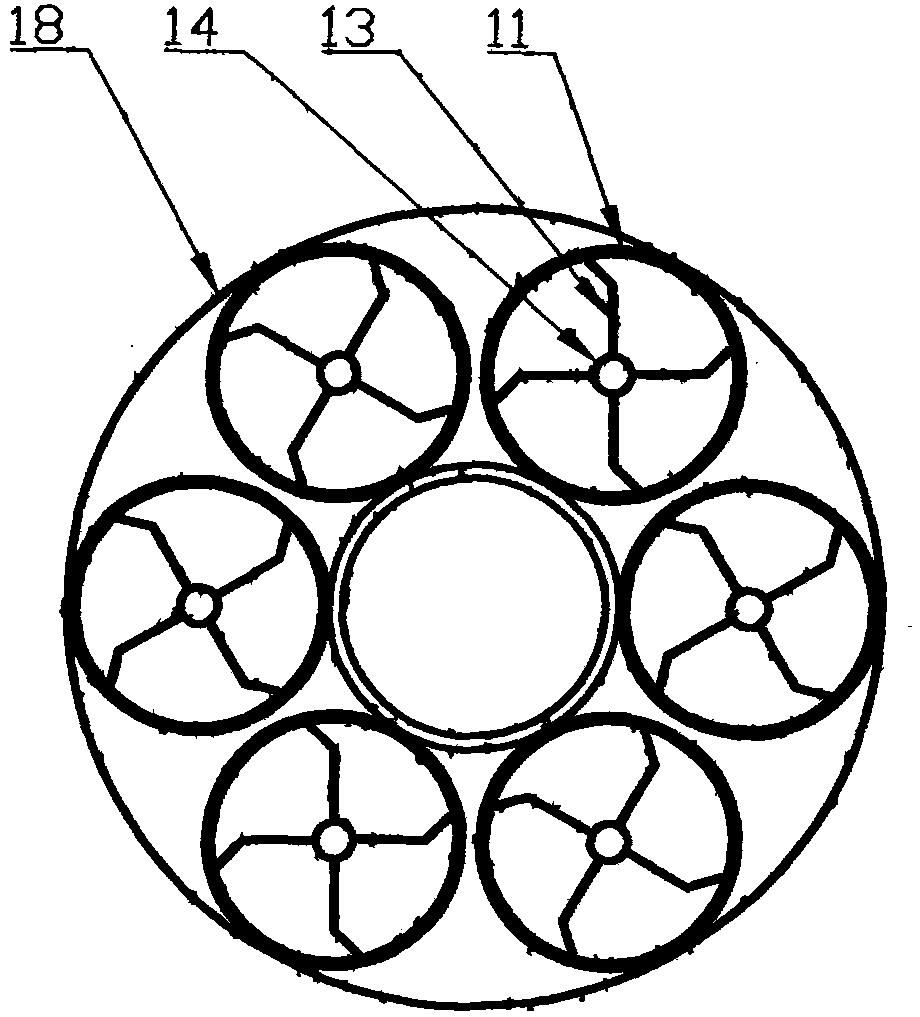

[0014] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0015] Such as figure 1 As shown, the present invention is composed of a feed / gas collection device 1, a furnace body 2, a drive device 3, a discharge device 4, a steam distribution device 5, a chimney 6, a heating furnace 7, a steam distribution device 8, and a wheel belt 10. The feeding / exhausting device 1 is a device that can feed materials into the furnace, and can also collect and discharge the activated gas generated during the activation reaction process. One side of the furnace body 2 is connected to a steam distribution device 5 , and the steam distribution device 5 is connected to a steam pipe 14 in a heat-resistant stainless seamless steel pipe 11 . Screw gas compression pump 16 leads air, provides the oxygen used for combustion. The feeding / gas collecting device 1 and the discharging device 4 are respectively connected to the furnace body 2 through the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com