Multifunctional circular seam type gas supply element for steel melting

A gas supply element and multi-functional technology, applied in the manufacture of converters, furnace types, furnaces, etc., can solve the problems of low life, high resistance, and easy melting loss of reblown converters, and achieve easy maintenance, reflow, and flow adjustment wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

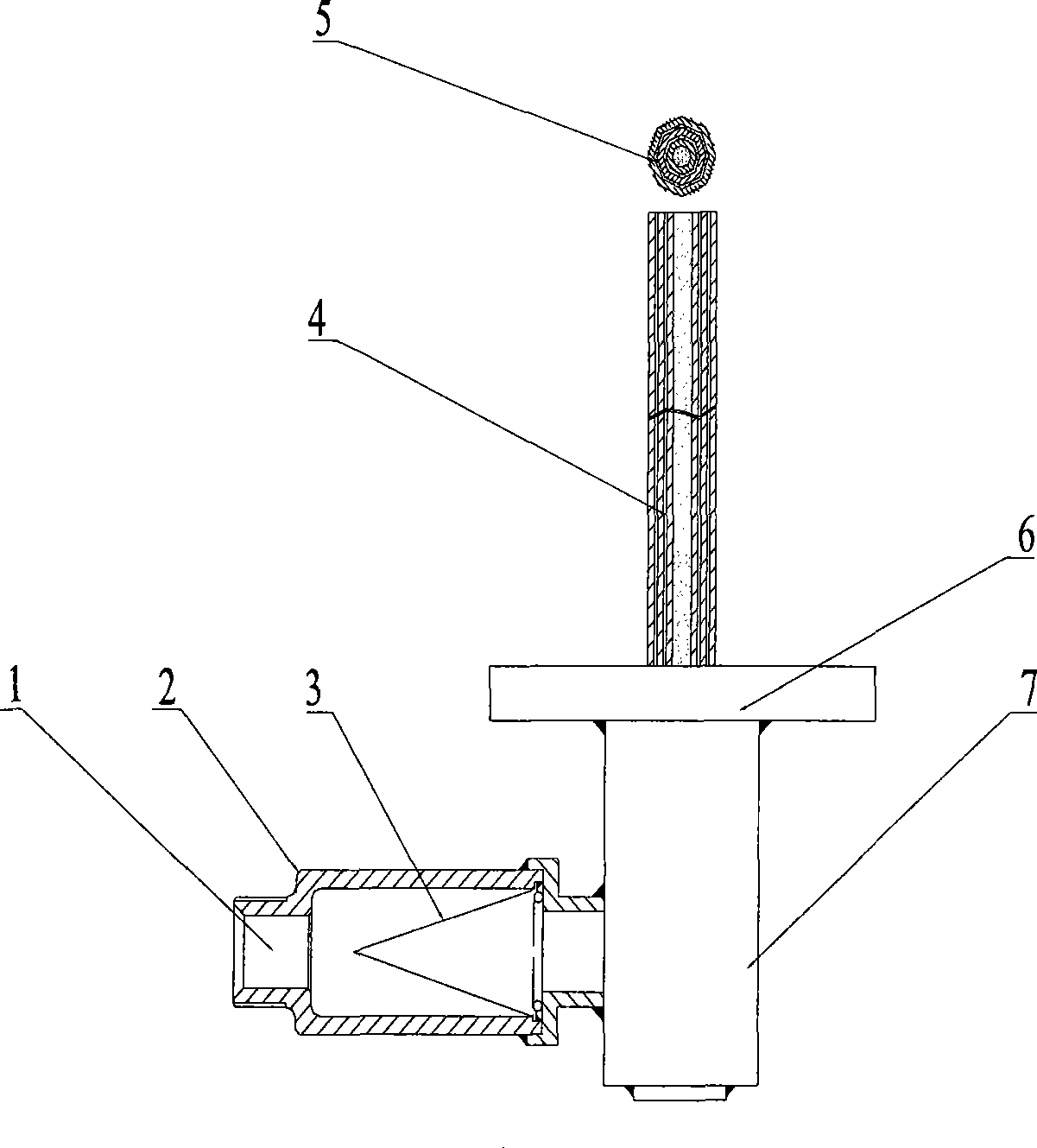

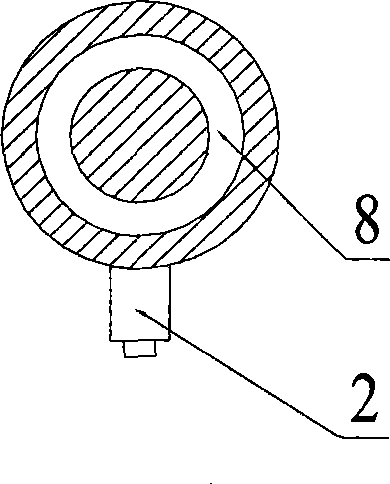

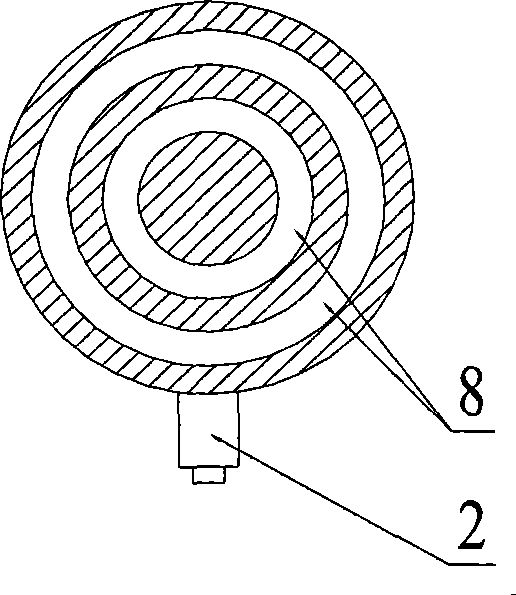

[0057] Figure 1-7 It is a specific embodiment of the present invention.

[0058] In a 300-ton re-blowing converter steelmaking plant, 16 multi-functional circular-slit gas supply elements were installed at the bottom of the spherical furnace bottom of the converter. Nitrogen and argon were injected into the furnace through the gas supply elements to stir molten steel, and good results were obtained. The metallurgical effect (see Table 2), under the basic parameters of the annular seam type gas supply element used:

[0059] (1) The outer diameter of the bottom blowing element is: 28mm;

[0060] (2) Jet pipe structure: central pipe, two-layer, three-layer pipe, double ring seam;

[0061] (3) The mounting flange is spherical;

[0062] (4) Double air inlets in the air intake chamber.

[0063] The invention has been applied to 109 converters in 43 factories, the service life is synchronized with the furnace age, and good economic benefits have been achieved. Table 2 shows s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com