Technique for producing anti-acid pipeline steel by RH-LF-VD refining

A technology of RH-LF-VD and pipeline steel, which is applied to the improvement of process efficiency and the manufacture of converters, etc., which can solve the problem of acid resistance (HIC and SCC resistance cannot meet the standard stably, the requirements for operation level are relatively high, and the increase of converter Solve problems such as smelting burden, achieve the effects of eliminating adverse effects, increasing furnace life, and reducing production burden

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

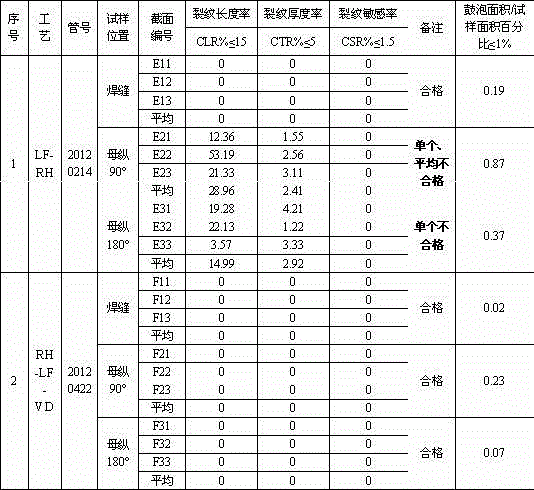

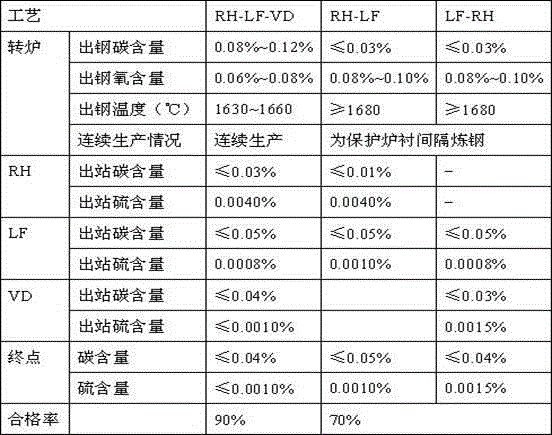

[0035] Implementation example: A steel plant in southern my country applies the process of the present invention to smelt acid-resistant (HIC and SCC) X65 pipeline steel. The specific process: hot metal pre-desulfurization-converter smelting-RH refining (decarburization and deoxidation)-LF refining (heating desulfurization) - VD refining (decarburization and degassing) - slab continuous casting - hot rolling production of 28.6mm thick acid-resistant X65 pipeline steel, the carbon content of the finished steel is controlled below 0.03%, the sulfur content is less than 0.0006%, and the steel plate is rolled into a tube Finally, it fully meets the requirements of the acid resistance test. See the table below for the quality comparison of the single vacuum (LF-RH) process and the double vacuum (RH-LF-VD) process pipeline steel pipe after sampling.

[0036] Table 1

[0037] Table 1

[0038]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com